Method for increasing fine powder rate of gas atomization powder of titanium or titanium alloys

A pre-alloyed powder and titanium alloy technology, which is applied in the field of titanium or titanium alloy powder preparation, can solve the problems that affect the life of the equipment, the stability of the production process, the difficulty, and the increase in the oxygen content of the powder, so as to achieve good promotion and application prospects and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Preparation of Ti powder with high fine powder rate by vacuum self-consumption melting casting-rolling

[0074] Sponge titanium is mixed with Y which accounts for 0.05% of the total mass of the mixed powder, and pressed into a block electrode, and the block is welded by vacuum plasma to form a consumable electrode. After 2 times of vacuum consumable smelting, the billet is opened at 1000-1250°C, rolled at 850°C, and turned into an atomized electrode rod, which is then atomized with the electrode induction melting gas atomization equipment produced by ALD Company. The atomized gas Ar gas pressure is 3MPa, melting power is 28kW. The particle size of the atomized powder is shown in Table 1. Its D50 is 56 μm, the volume ratio of fine powder in the range of 15-53 μm is 43%, and the fine powder rate is 45% higher than that of Ti powder without Y added.

Embodiment 2

[0075] Example 2: Preparation of TC4 powder with high fine powder rate by vacuum self-consumption melting casting-forging

[0076] Sponge titanium, Al-V master alloy, Al bean and 0.25% Y compound in the total weight of the mixed powder are used to press into a block electrode, and the block is welded by vacuum plasma to form a consumable electrode. After three times of vacuum self-consumption smelting, the billet is opened at 1000-1250°C, forged at 950°C, turned into an atomized electrode rod, and then atomized by the electrode induction melting gas atomization equipment produced by ALD company. The atomized gas Ar The pressure is 3MPa, and the melting power is 28kW. The particle size of the atomized powder is shown in Table 1. Its D50 is 57 μm, the volume ratio of fine powder in the range of 15-53 μm is 40%, and the fine powder rate is 73% higher than that of TC4 powder without Y added.

Embodiment 3

[0077] Embodiment 3: Cold isostatic pressing-vacuum sintering prepares Ti powder with high fine powder rate

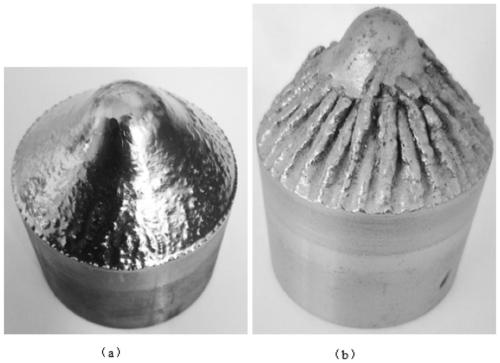

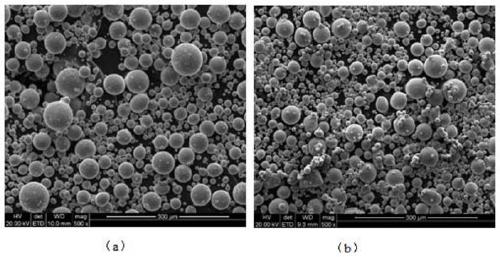

[0078] Put hydrogenated dehydrogenated titanium powder (-3 Pa, the sintering temperature is 1250°C, the sintering time is 2h, and the temperature is lowered to room temperature with the furnace after sintering. The sintered billet is processed into an atomized electrode rod, and then the electrode induction melting gas atomization equipment produced by ALD Company is used for atomization and powder production. The atomization gas Ar gas pressure is 3MPa, and the melting power is 28kW. figure 1 (b) is the material head after the titanium electrode rod is atomized, and the material head presents a large taper, indicating that the melt has good fluidity. figure 2 (b) is the morphology of the unscreened powder after atomization, the powder surface is smooth and the sphericity is good. The particle size of the atomized powder is shown in Table 1. Its D50 is 42 μm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com