Patents

Literature

46results about How to "Rapid pre-cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

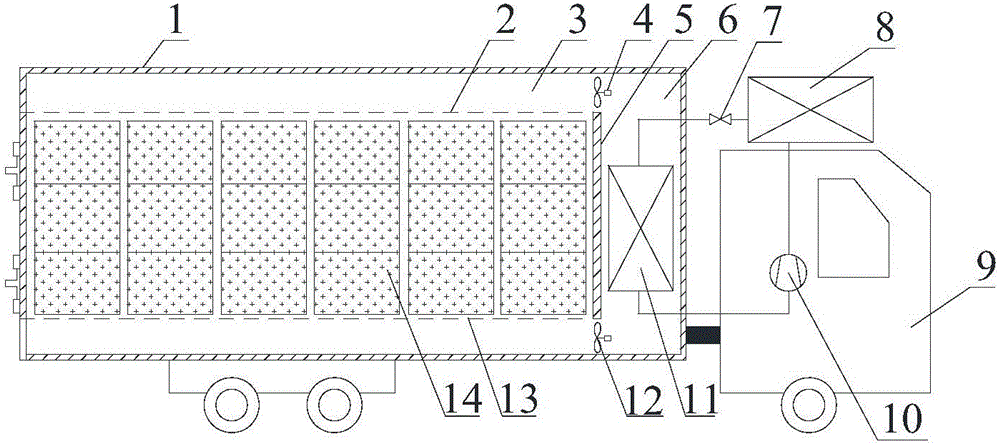

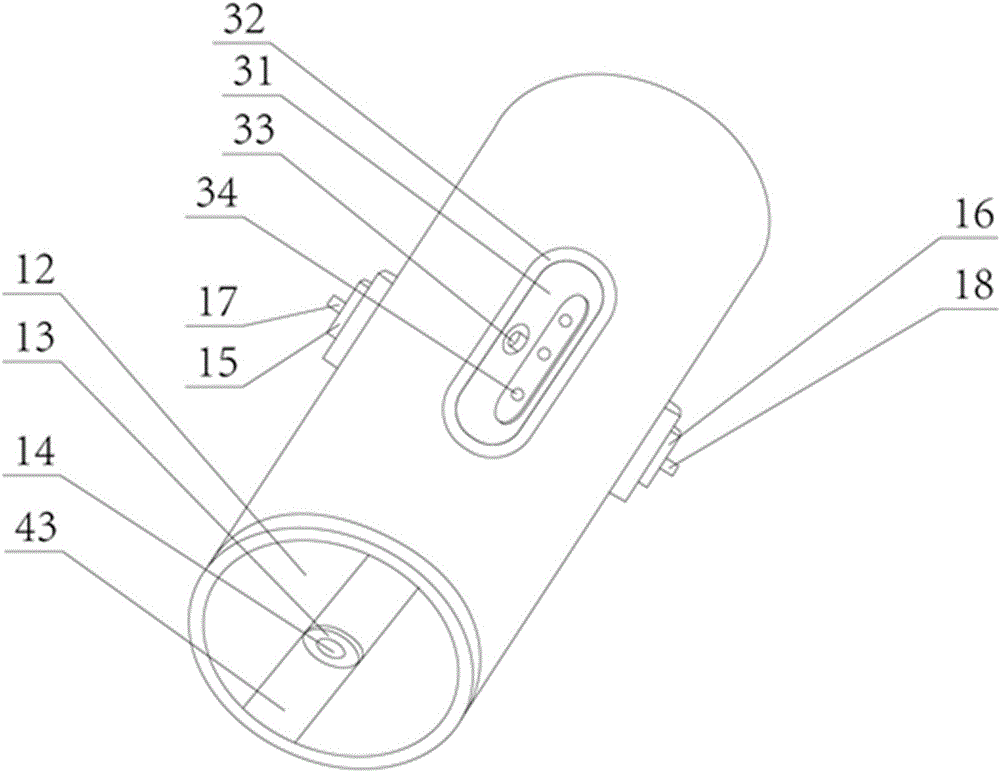

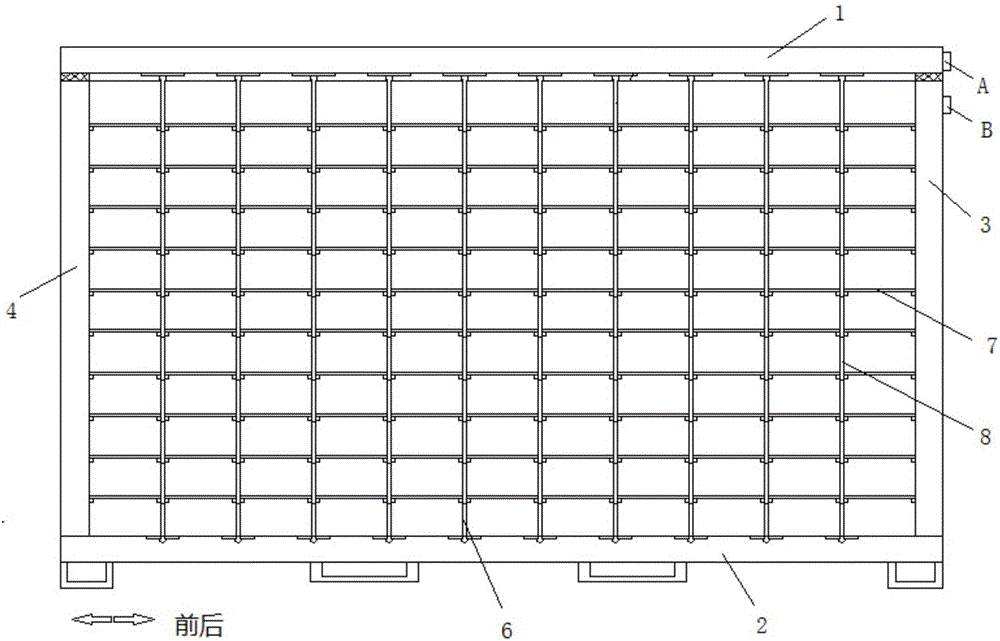

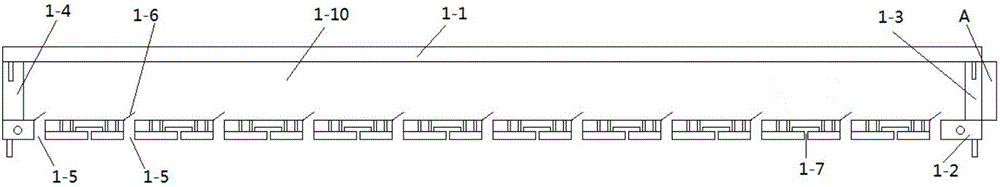

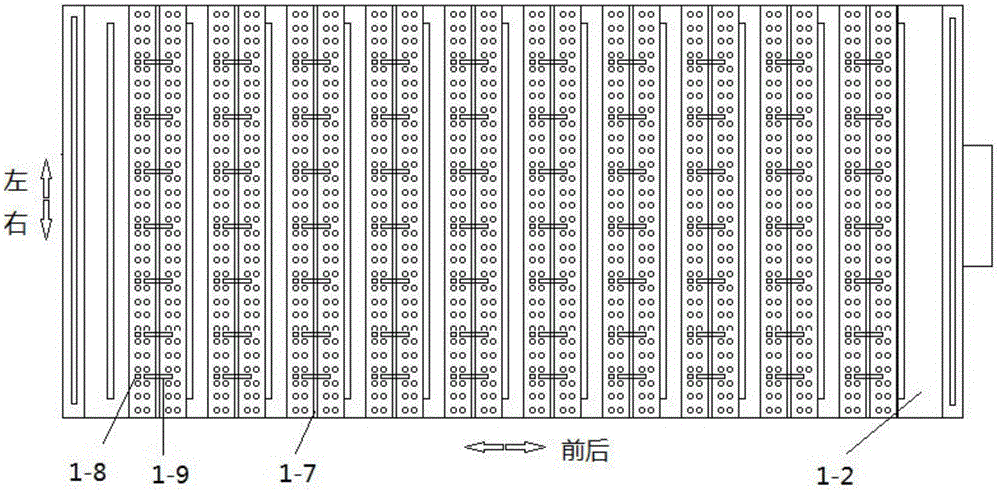

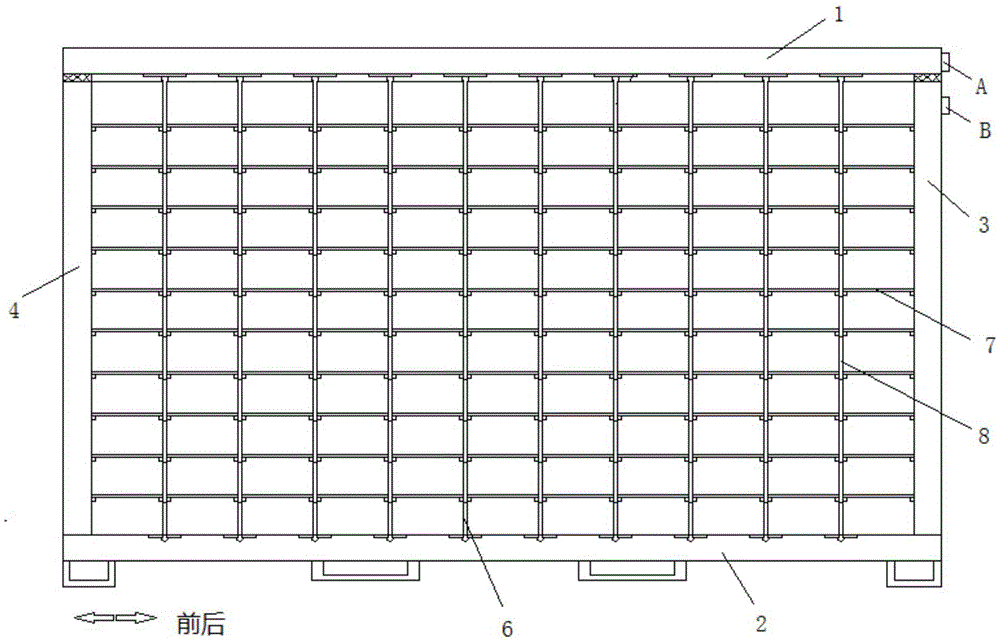

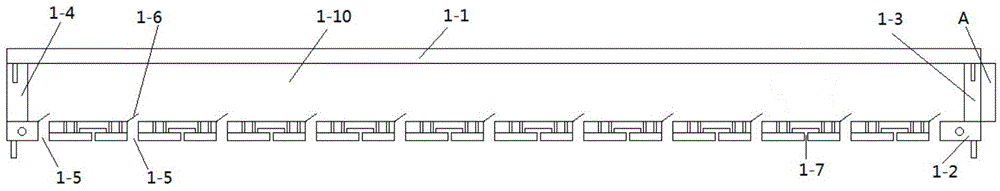

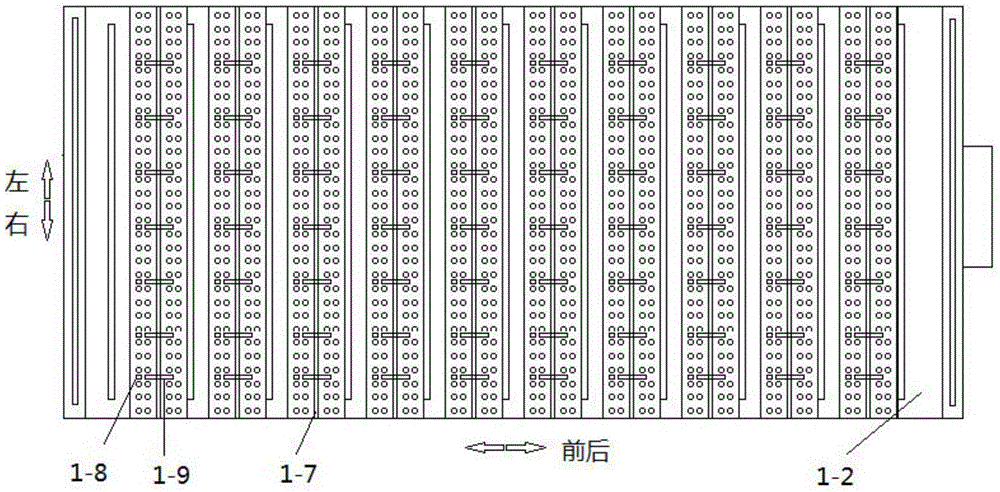

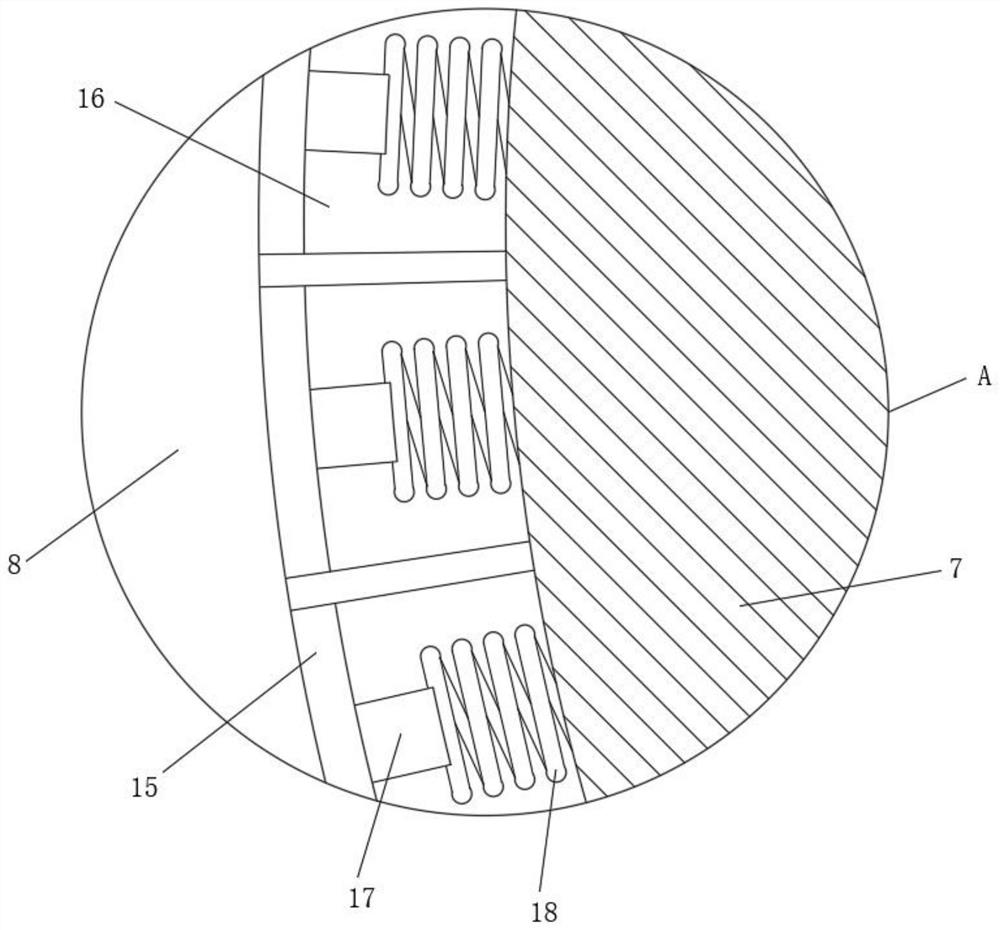

Fruit and vegetable producing area precooling vehicle

InactiveCN105034755AStrong mobilityRapid pre-coolingAir-treating devicesRefrigerated goods vehicleEvaporatorReturn channel

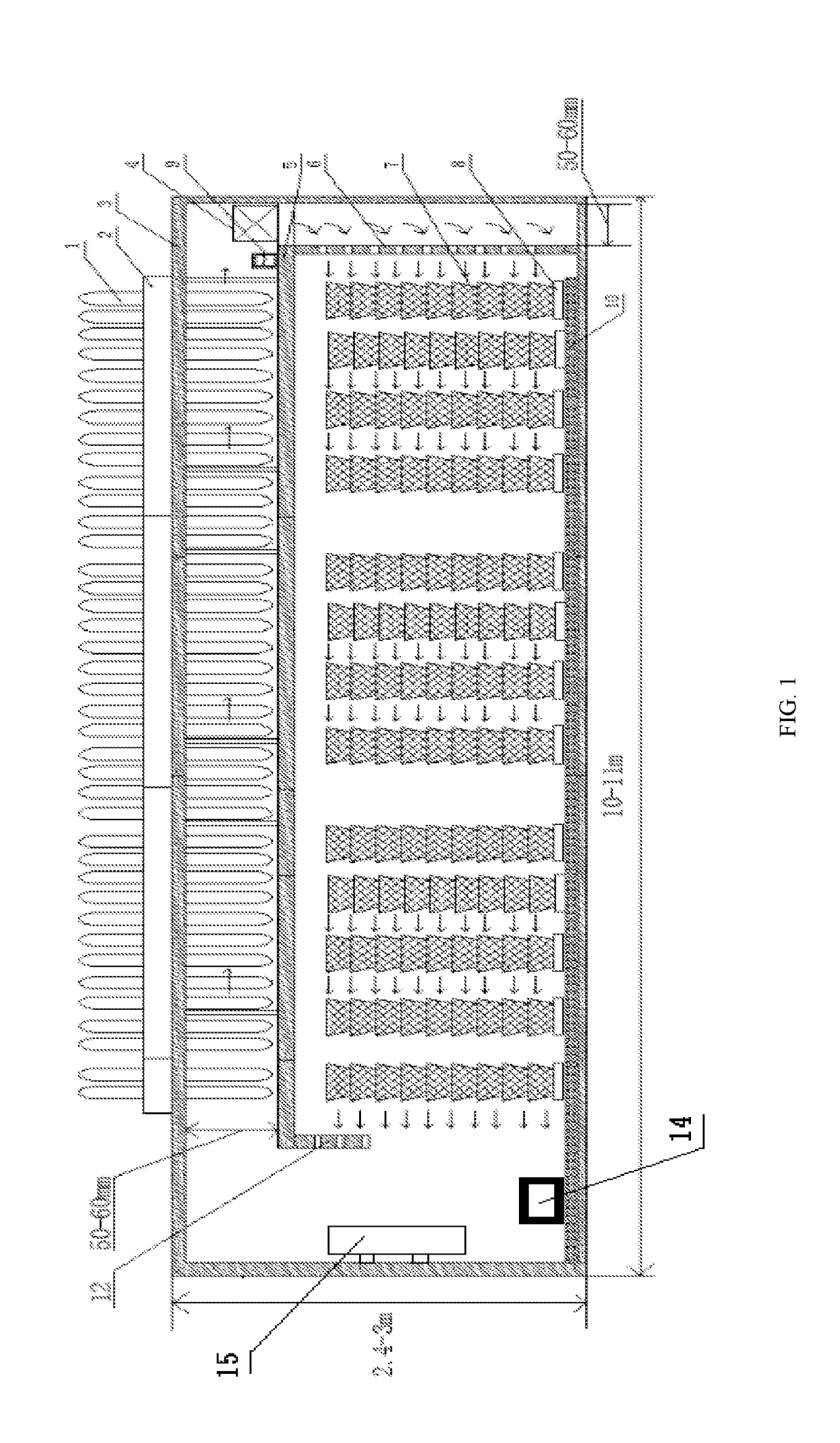

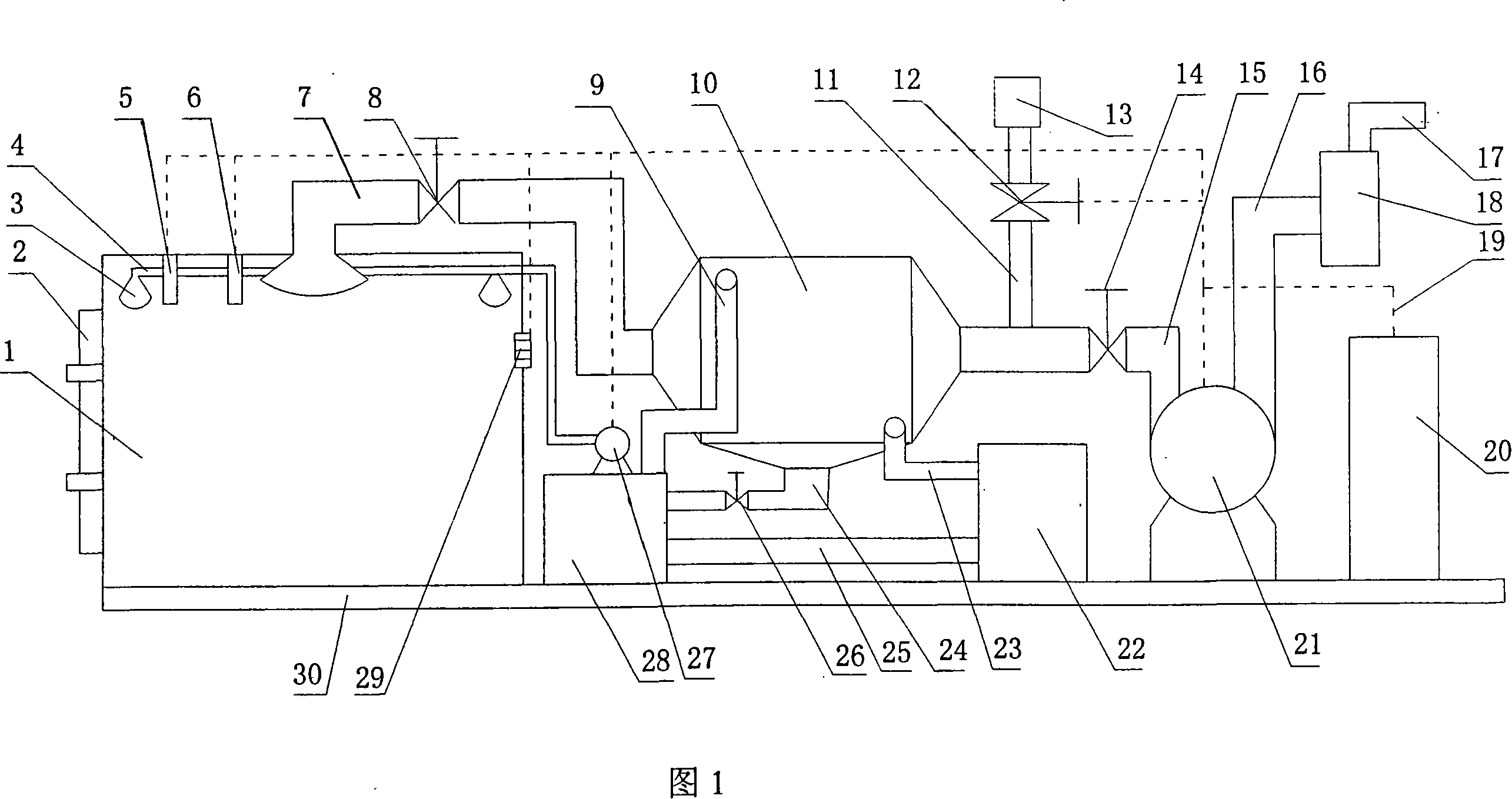

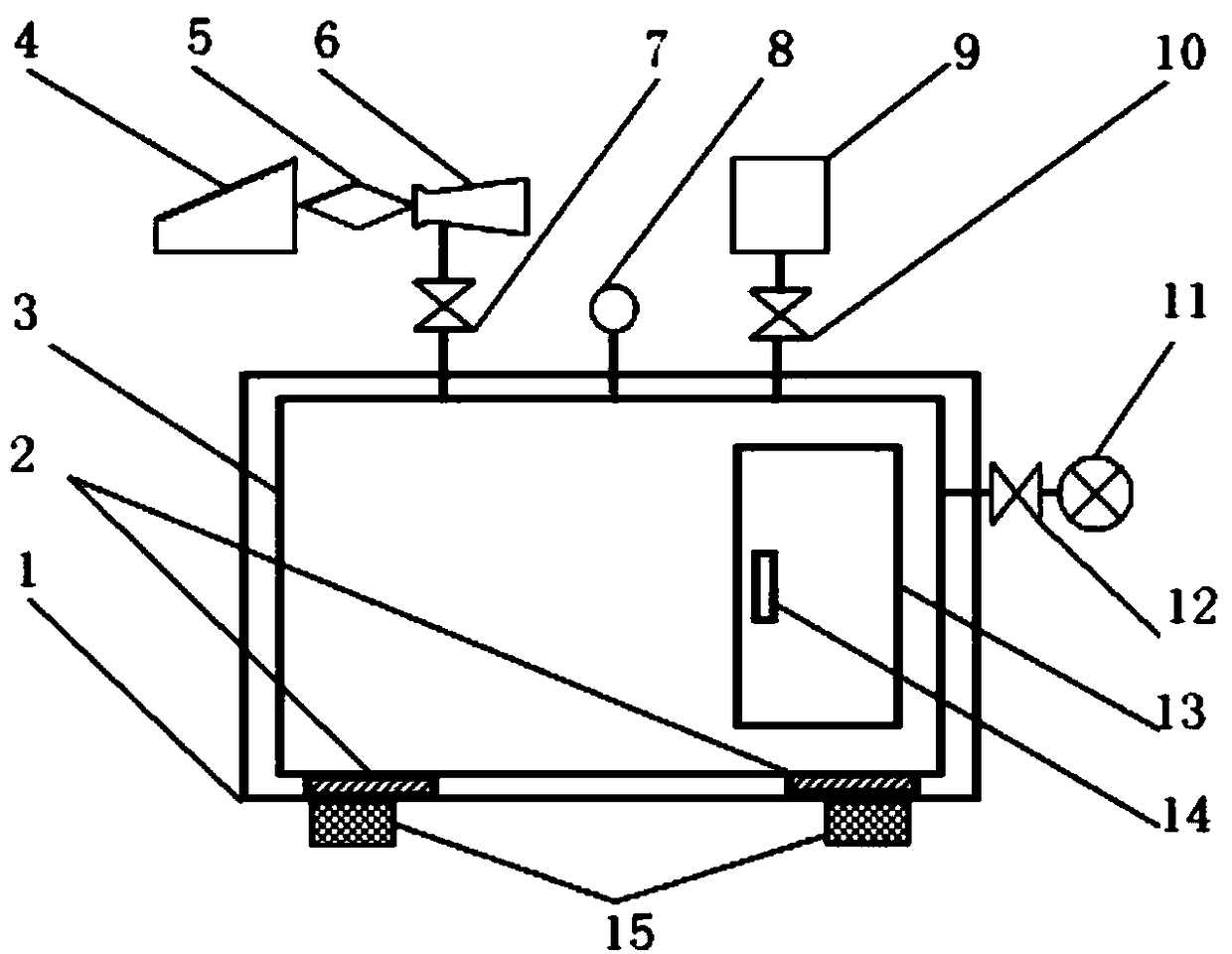

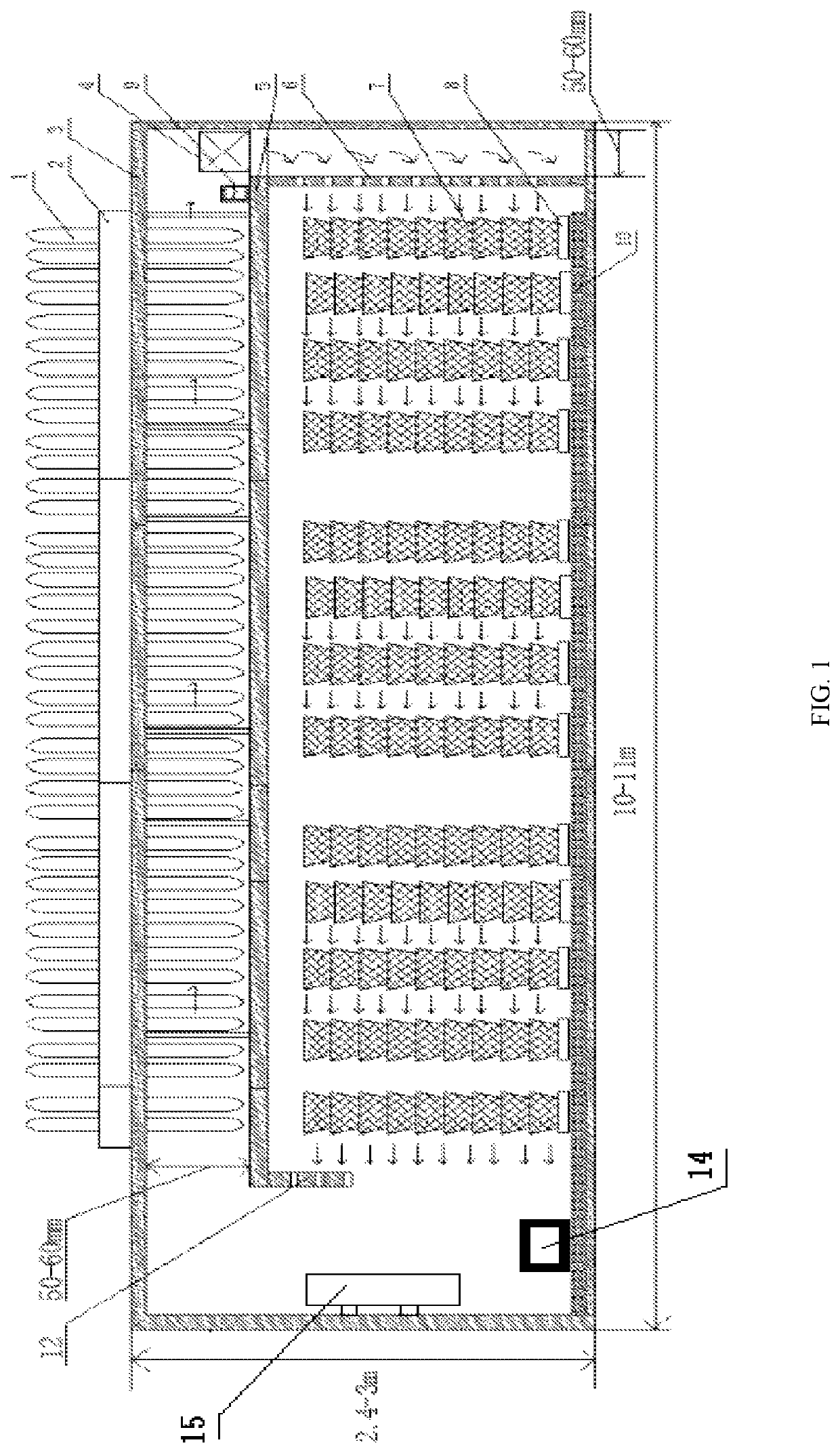

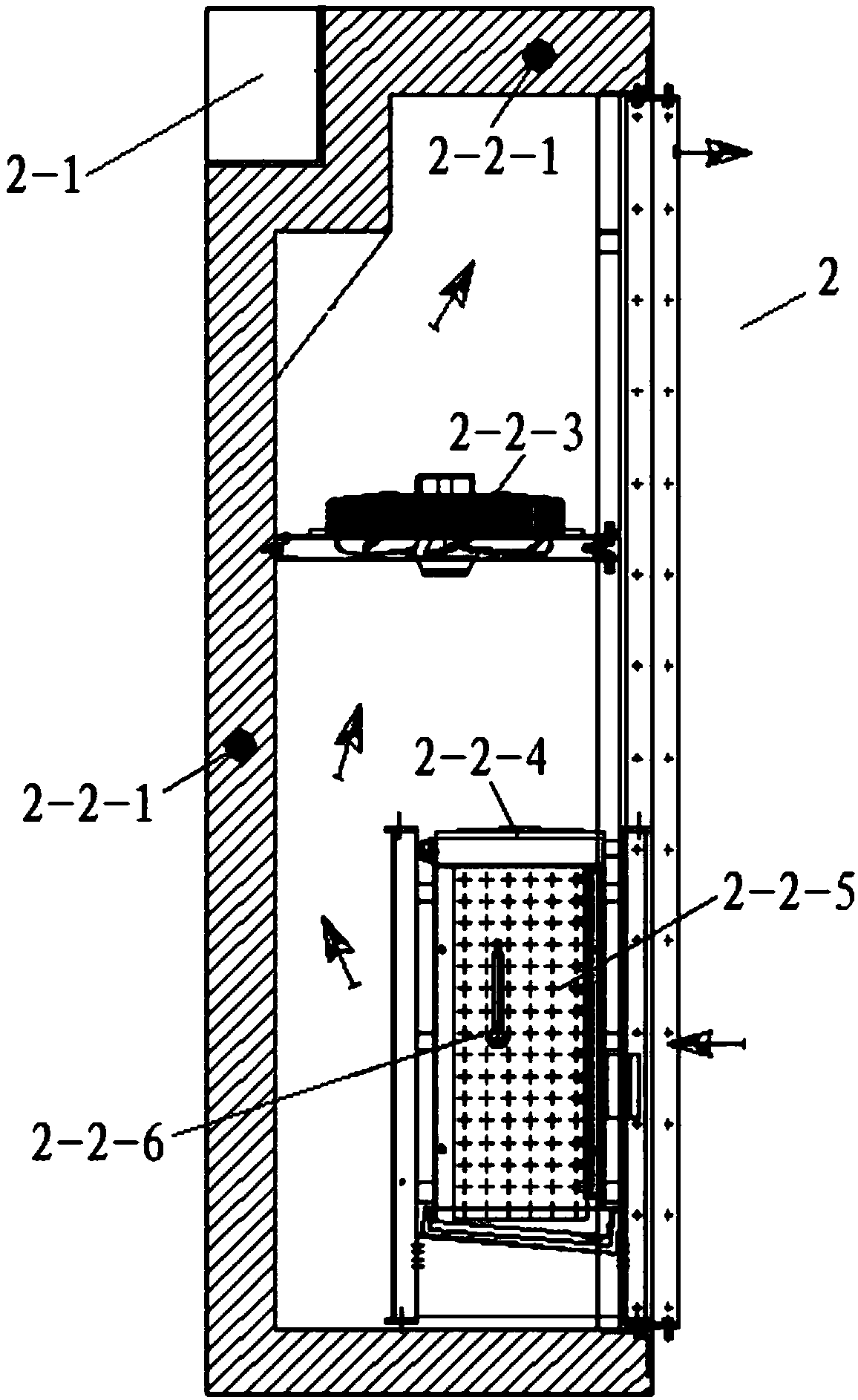

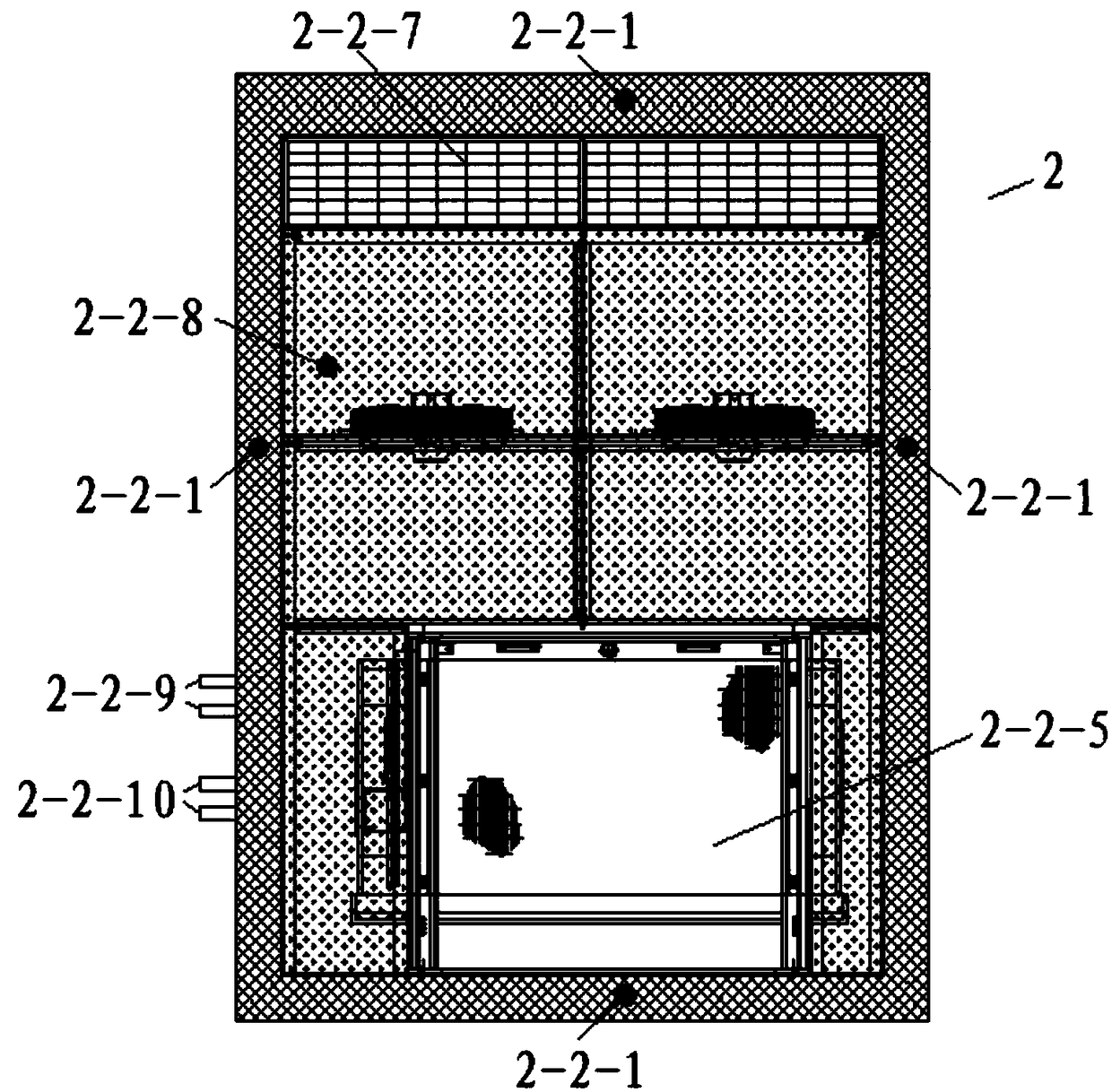

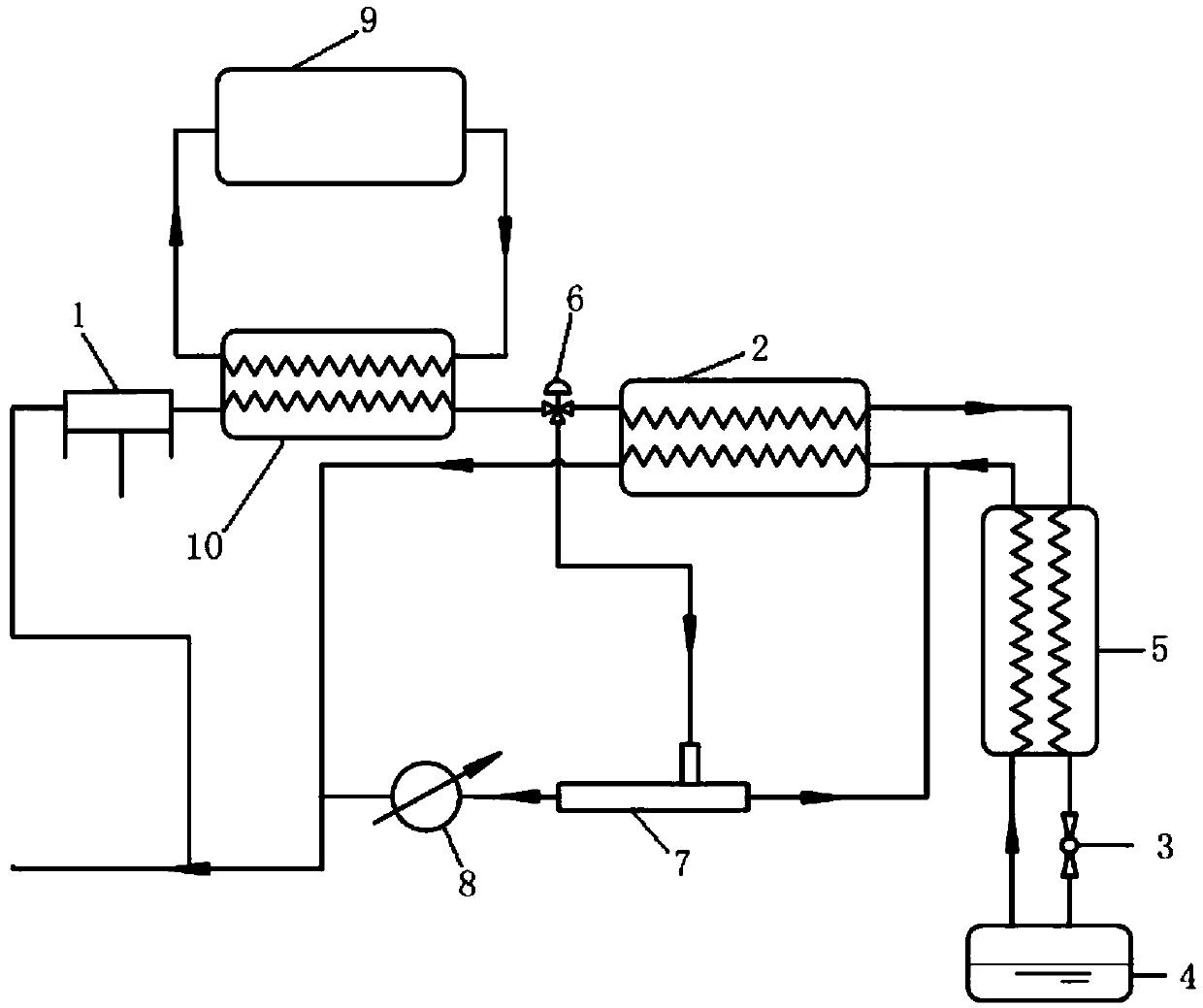

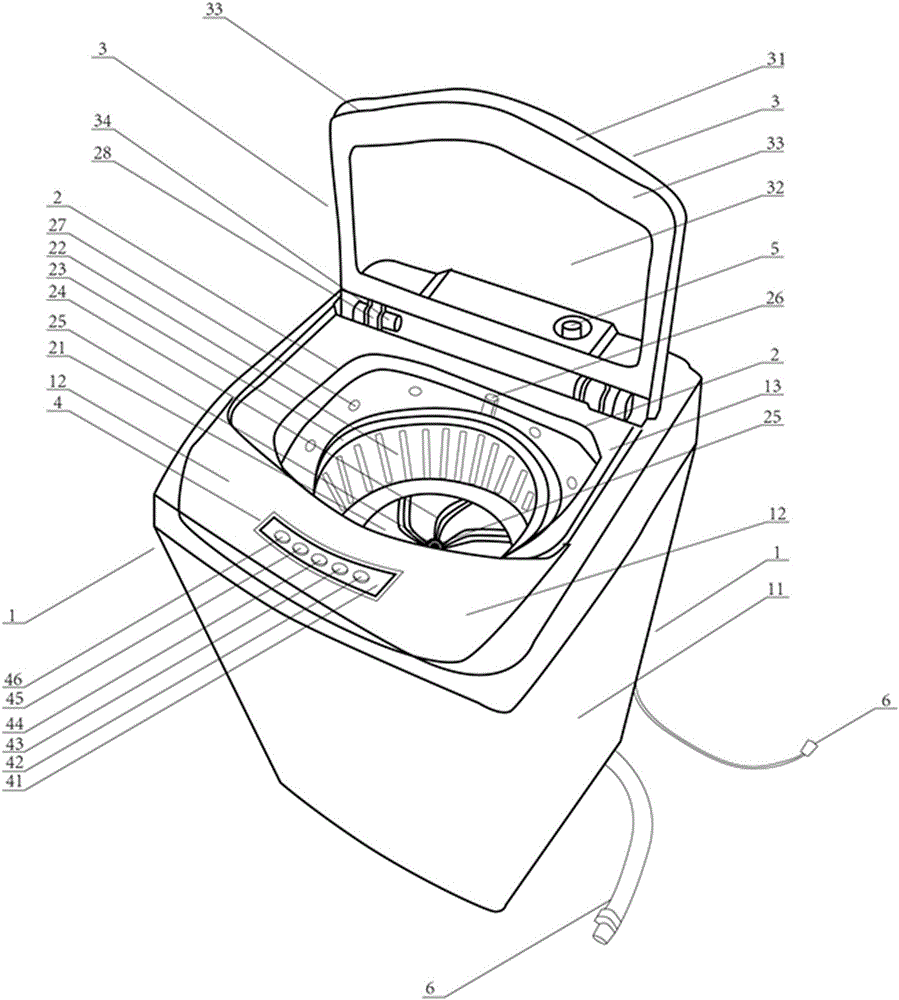

The invention discloses a fruit and vegetable producing area precooling vehicle which comprises a precooling boxcar, a precooling vehicle body, an air returning top plate, a return fan, a boxcar inner partition plate, a throttle valve, a condenser, a compressor, an evaporator, a supply fan, an air supplying floor and fruit and vegetable precooling boxes. The precooling boxcar is divided into an air treatment chamber and a fruit and vegetable precooling chamber by the boxcar inner partition plate, the air returning top plate is installed on the upper portion of the fruit and vegetable precooling chamber, the air supplying floor is installed on the lower portion of the fruit and vegetable precooling chamber, and vent holes are formed in the air returning top plate and the air supplying floor respectively; the compressor, the condenser, the throttle valve and the evaporator are connected end to end to form a circulation loop; the supply fan is installed at an inlet of an air supplying channel, and the return fan is installed at an outlet of an air returning channel; the outer surfaces of the fruit and vegetable precooling boxes are provided with vent holes, and the fruit and vegetable precooling boxes are stacked on the air supplying floor in the fruit and vegetable precooling chamber in rows; the compressor is driven by an engine of the precooling vehicle body, and an electric power system of the precooling vehicle body supplies power to the supply fan and the return fan for operation. The fruit and vegetable producing area precooling vehicle has the advantages of being flexible, convenient to operate, rapid in precooling and the like.

Owner:TIANJIN AOJING AGRI SCI & TECH DEV CO LTD

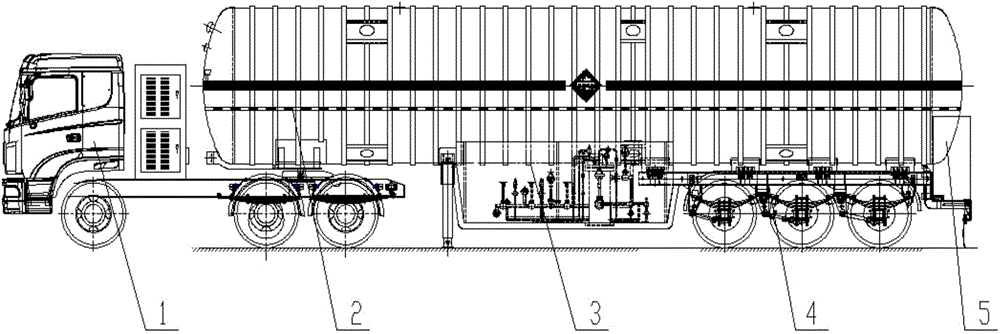

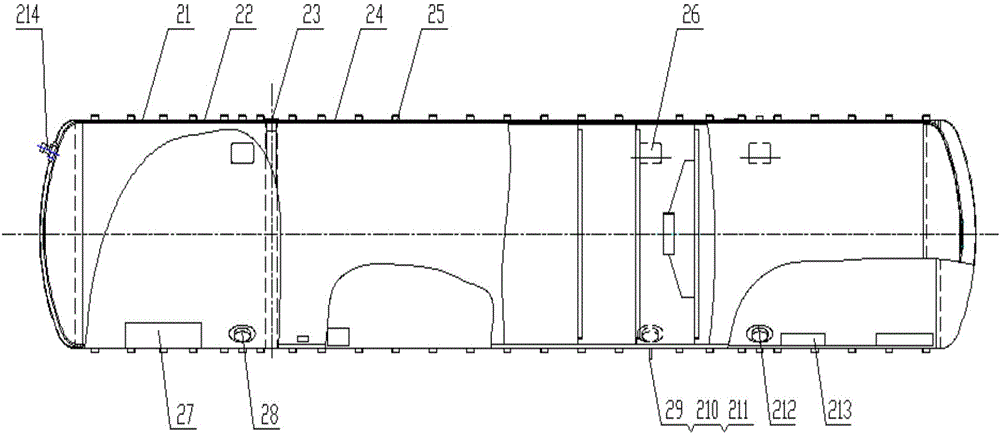

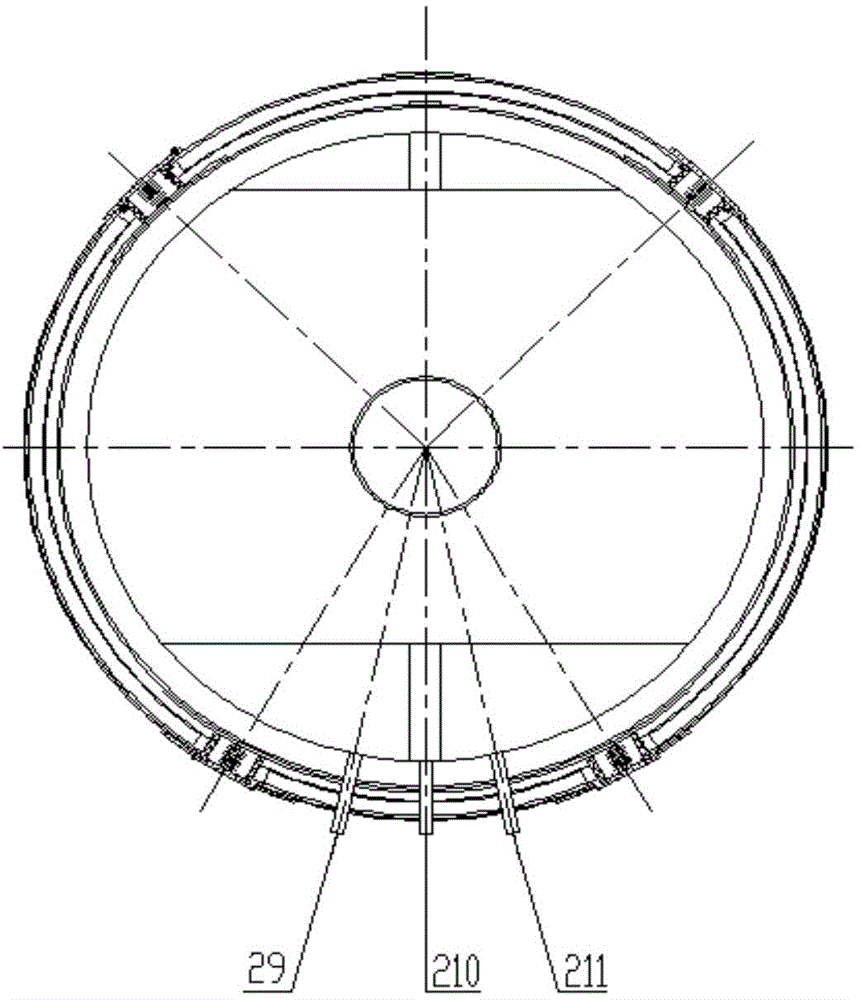

LNG (Liquefied Natural Gas) mobile filling vehicle with filling structure

ActiveCN104154415ASave vertical spaceIncrease volumeContainer filling under pressureSemi-trailerTractor

The invention discloses a LNG (Liquefied Natural Gas) mobile filling vehicle with a filling structure and belongs to the technical field of low-temperature liquid mobile filling, storing and transporting vehicles. The LNG mobile filling vehicle with the filling structure comprises a tractor vehicle, a LNG low-temperature storage tank, a tank bottom type filling mechanism, a special semi-trailer chassis walking mechanism, a rear operation pipeline and a bin body, wherein the LNG low-temperature storage tank, the tank bottom type filling mechanism, the rear operation pipeline and the bin body are mounted on the special semi-trailer chassis walking mechanism so as to form a low-temperature liquid semi-trailer; the low-temperature liquid semi-trailer is suspended on a traction seat of a traction 1 by means of a traction pin so as to form a whole vehicle. The LNG mobile filling vehicle with the filling structure not only has the function of stopping in any place at any time for independently filling LNG for LNG vehicles and dual-fuel vehicles, but also has the transportation function of transporting LNG by the road; meanwhile, the LNG mobile filling vehicle with the filling structure not only has the function of stopping in a fixed place at any time for independently filling LNG for LNG vehicles and dual-fuel vehicles, but also has the transportation function of transporting LNG by the road. Due to the lightweight design of the whole vehicle, the whole vehicle is relatively light in weight and relatively large in maximum filling weight or filling quantity.

Owner:XINXING ENERGY EQUIP

Method for keeping fruit fresh

InactiveCN110432317AInhibit synthesisPassivation activityFruits/vegetable preservation by freezing/coolingSalicylic acidNitrogen

The invention belongs to the technical field of storage and fresh-keeping of agricultural products, in particular relates to a fresh-keeping method of fresh fruits, and specifically relates to a fresh-keeping method of combining a compound solution containing melatonin, gibberellin and salicylic acid with liquid nitrogen fumigation. The steps are as follows: spraying fruits with the compound solution containing melatonin, gibberellin and salicylic acid one day before harvest, transferring the fruits to a closed space for short-time fumigation with liquid nitrogen after harvest, and then immediately transferring the fruits to a spontaneous controlled atmosphere packaging for low temperature storage. The compound solution containing melatonin, gibberellin and salicylic acid is combined withliquid nitrogen fumigation, thus the fresh-keeping method can not only realize sterilization and inhibit the synthesis of ethylene, but also inactivate fruit enzymes, and at the same time, and can achieve fast precooling so as to maintain the storage quality of fruits, achieves the purpose of prolonging the storage period and improving the fresh-keeping effect of fruits; and at the same time, theoperation is convenient, the efficiency is improved, the practicability is high and the application is convenient.

Owner:GUIYANG UNIV +2

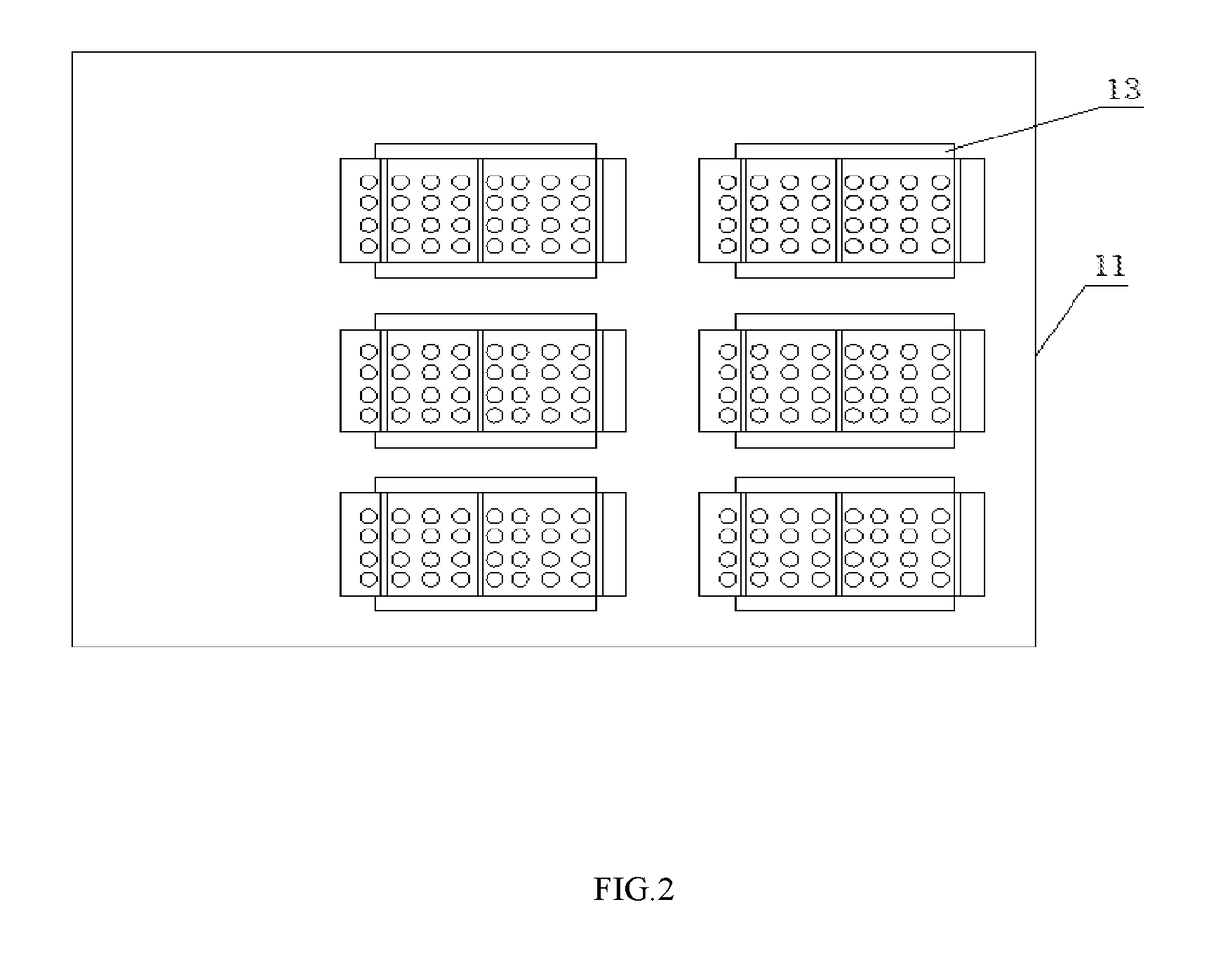

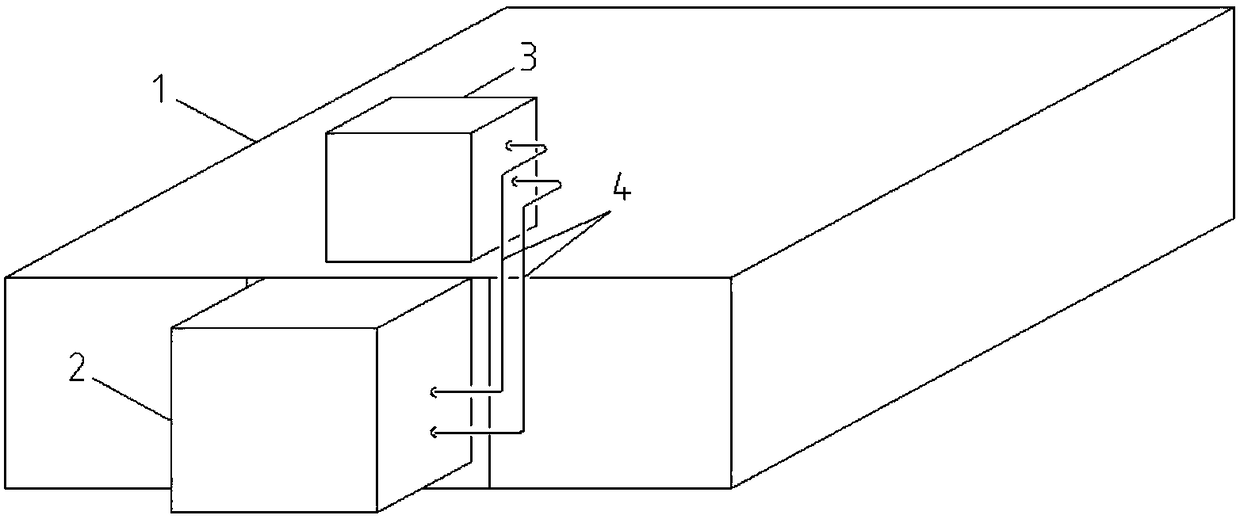

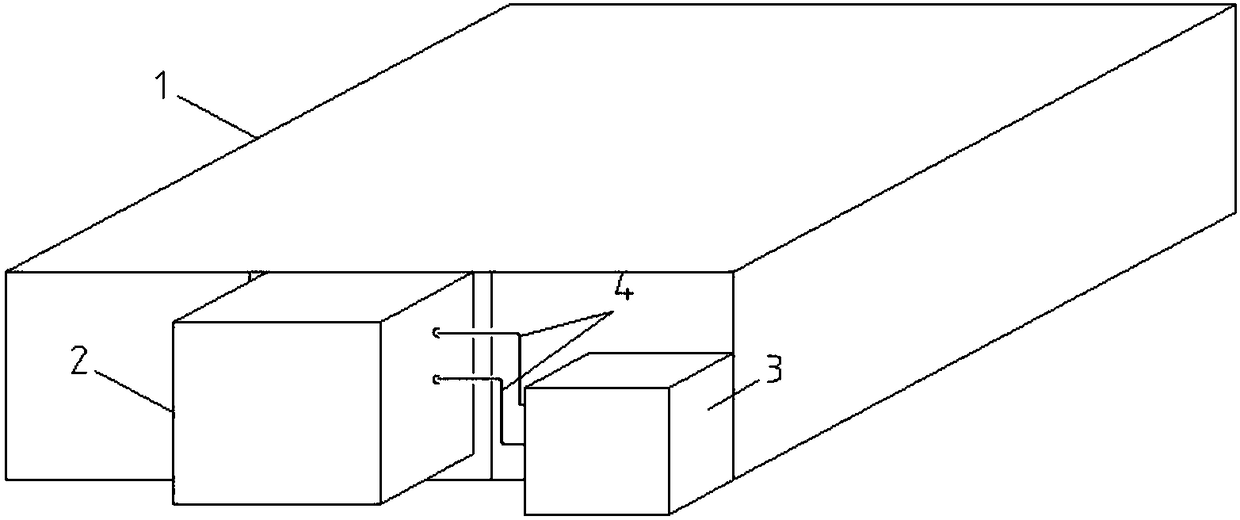

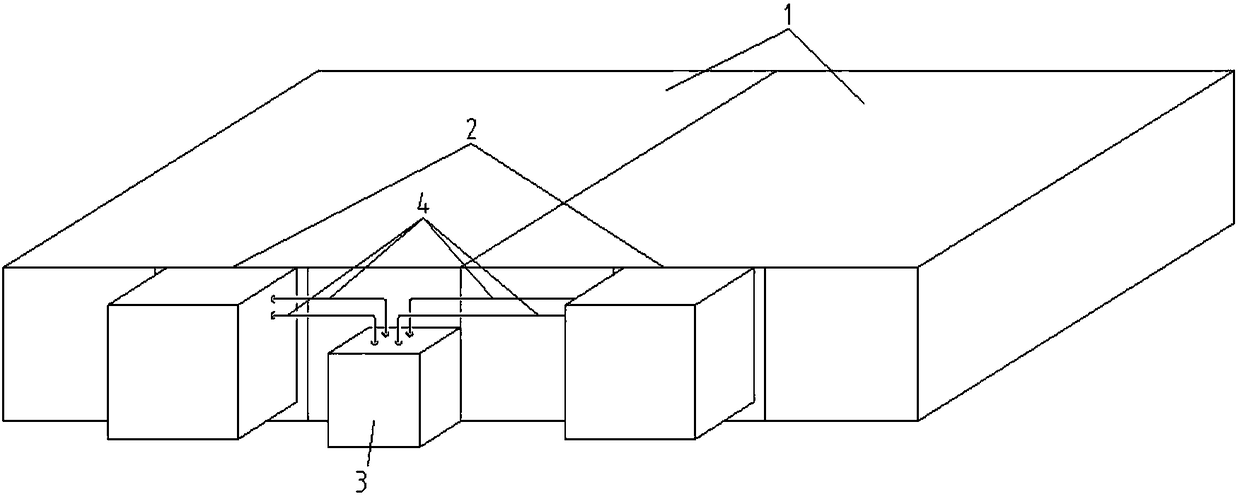

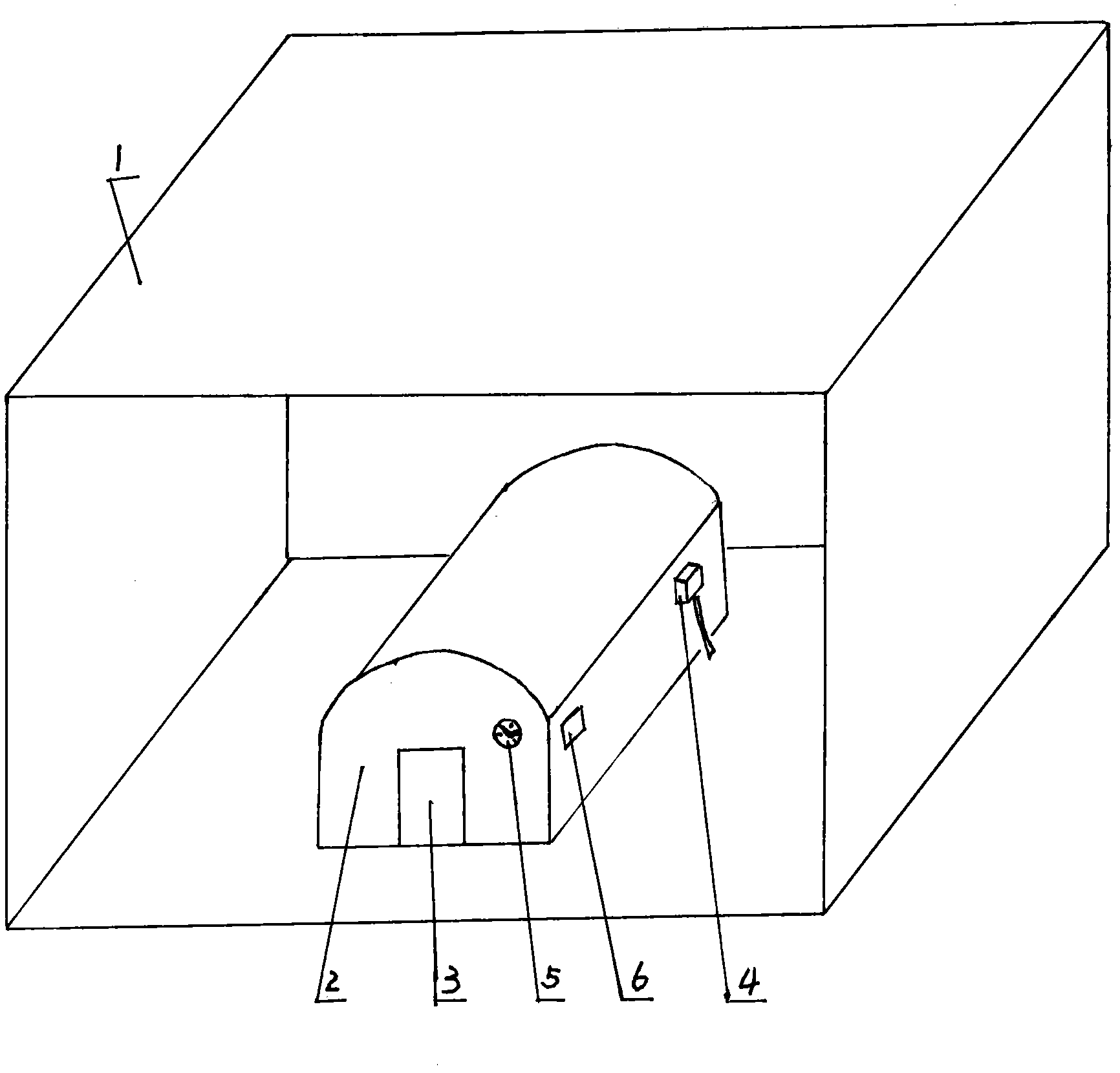

Technology and device for fruit and vegetable phase-temperature precooling compatible multi-coupling Anti-aging treatment

ActiveUS20190053507A1Easy to solveRapid pre-coolingFruits/vegetable preservation by freezing/coolingDifferential pressureHermetic seal

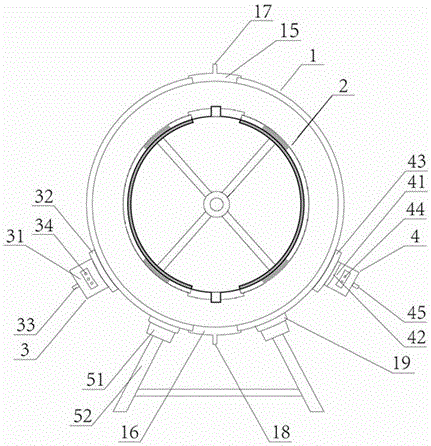

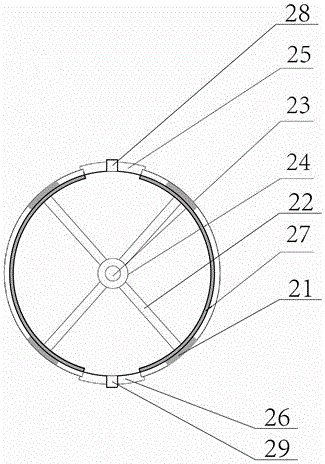

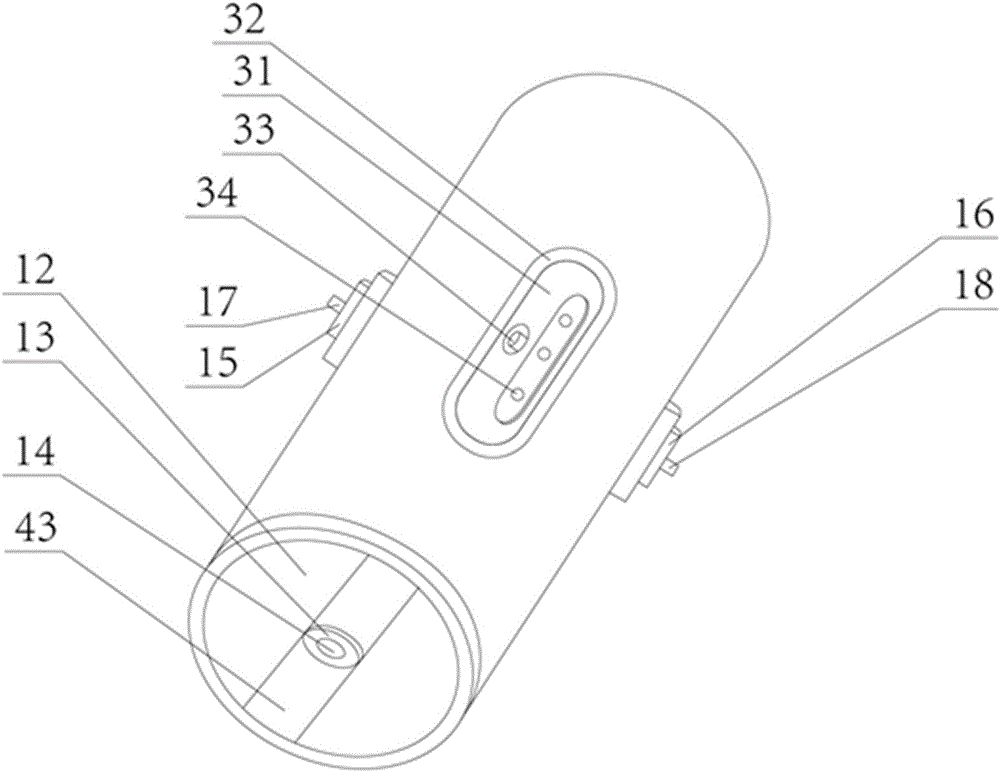

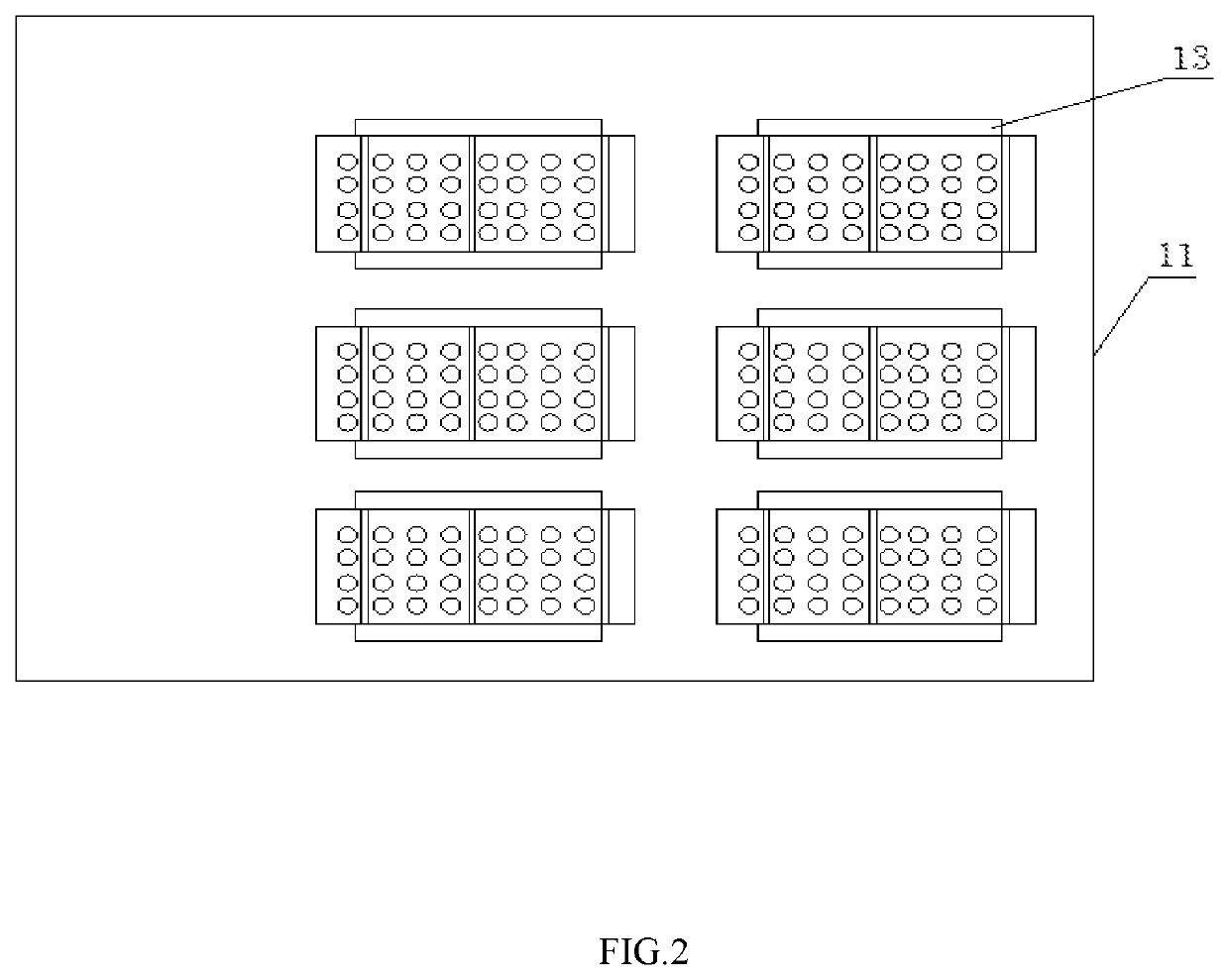

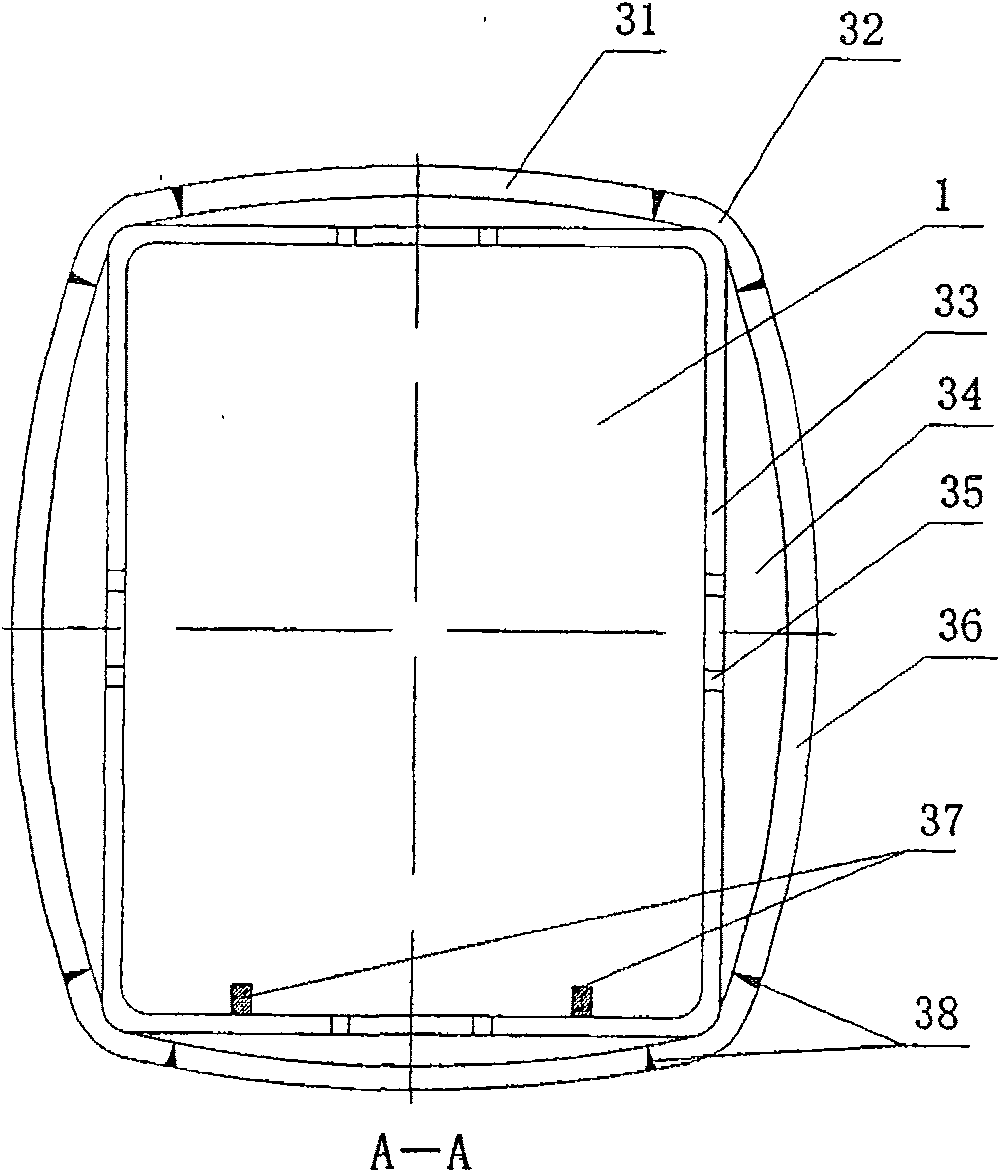

A device for fruit and vegetable phase-temperature precooling compatible multi-coupling anti-aging treatment comprises a refrigeration house with a plurality of differential pressure precooling devices placed therein. The differential pressure precooling device comprises a hermetic seal tunnel precooling box, a separator plate is fixedly mounted at an upper part inside the tunnel precooling box and in parallel to a top wall of the tunnel precooling box with a space formed therebetween; the separator plate extends to the bottom of the tunnel precooling box; a venting plate is fixedly mounted to one side of the separator plate and in parallel to a side wall of the tunnel precooling box with a space formed therebetween; a section of wind shield is vertically and downwardly mounted to an end of the other side of the separator plate; an axial flow fan is mounted at a corner of the tunnel precooling box between the separator plate and the venting plate.

Owner:TIANJIN LVXIN CRYOGENIC SCI & TECH CO LTD

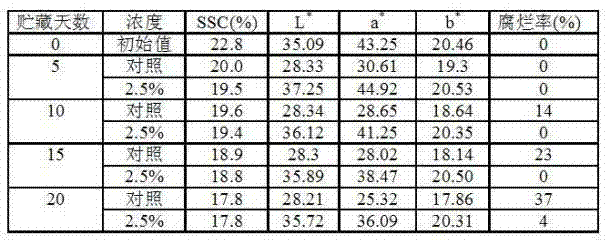

A kind of fresh-keeping method of litchi fresh fruit

ActiveCN102293244AHigh activityIncrease resistanceFruits/vegetable preservation by freezing/coolingLychee fruitNutrition

The invention belongs to the field of fresh keeping of fruit and vegetables, and particularly discloses a fresh keeping method of fresh litchi fruit, which comprises the following steps that: 80 to 90 percent ripeness litchi fruit sequentially carries out pre-cooling, acidified calcium sulfate solution soaking, drying and package treatment and is then stored at 0 to 5 DEG C, wherein the pre-cooling treatment is the treatment for 20 to 30 min at 0 to 5 DEG C under the vacuum condition, the time of the acidified calcium sulfate solution soaking treatment is 2 to 3min, the drying treatment refers to the drying under the room temperature condition until no water drips drop from the surface of the litchi, and polyurethane (PE) perforated film bags are adopted for package. The fresh keeping method solves the safety problem caused by the sulphuration fresh keeping and antiseptic agents combined with the sulfur treatment technology, belongs to a safe and effective litchi fresh keeping method and is suitable for being popularized and applied by wide fruit farmers, sales persons and production enterprises, the fresh litchi fruit can be stored for 20 days at 5 DEG C, the rot rate is lower than 5 percent, and the nutrition quality index sulfide stress cracking (SSC) and the color indexes (L*, a* and the like) of the litchi are perfectly maintained, so the litchi quality and the browning are perfectly controlled.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Multi-functional modular combined cold box

PendingCN108438566ASimple structureReasonable designLarge containersTank wagonsModular compositionManufacturing technology

The invention relates to the technical field of manufacturing of refrigeration equipment and particularly relates to a multi-functional modular combined cold box. The multi-functional modular combinedcold box provided by the invention comprises a box body module, tail end modules and a cold source module; the box body module is connected with at least one tail end module; each tail end module isconnected with the cold source module; the box body module is used for providing a low-temperature storage space or a low-temperature operation space; each tail end module comprises a plurality of secondary functional modules and is used for providing heat exchange conditions for a low-temperature environment; the cold source module is used for providing cold source supply for each tail end module; and a control module is used for harmonizing the secondary functional modules of all tail end modules so as to provide one or a plurality of functions including temperature regulation, humidity regulation and air regulation. The cold box formed by adopting the three modules realizes standard production, is low in manufacturing cost and short in installation period, can guarantee the quality, andis also beneficial for realizing flexible switching between different functions such as quick freezing, quick precooling, cooling, cold storage of cooled materials, cold storage of frozen materials,air-regulated cold storage and low-temperature production environment.

Owner:青岛中集冷方科技有限公司

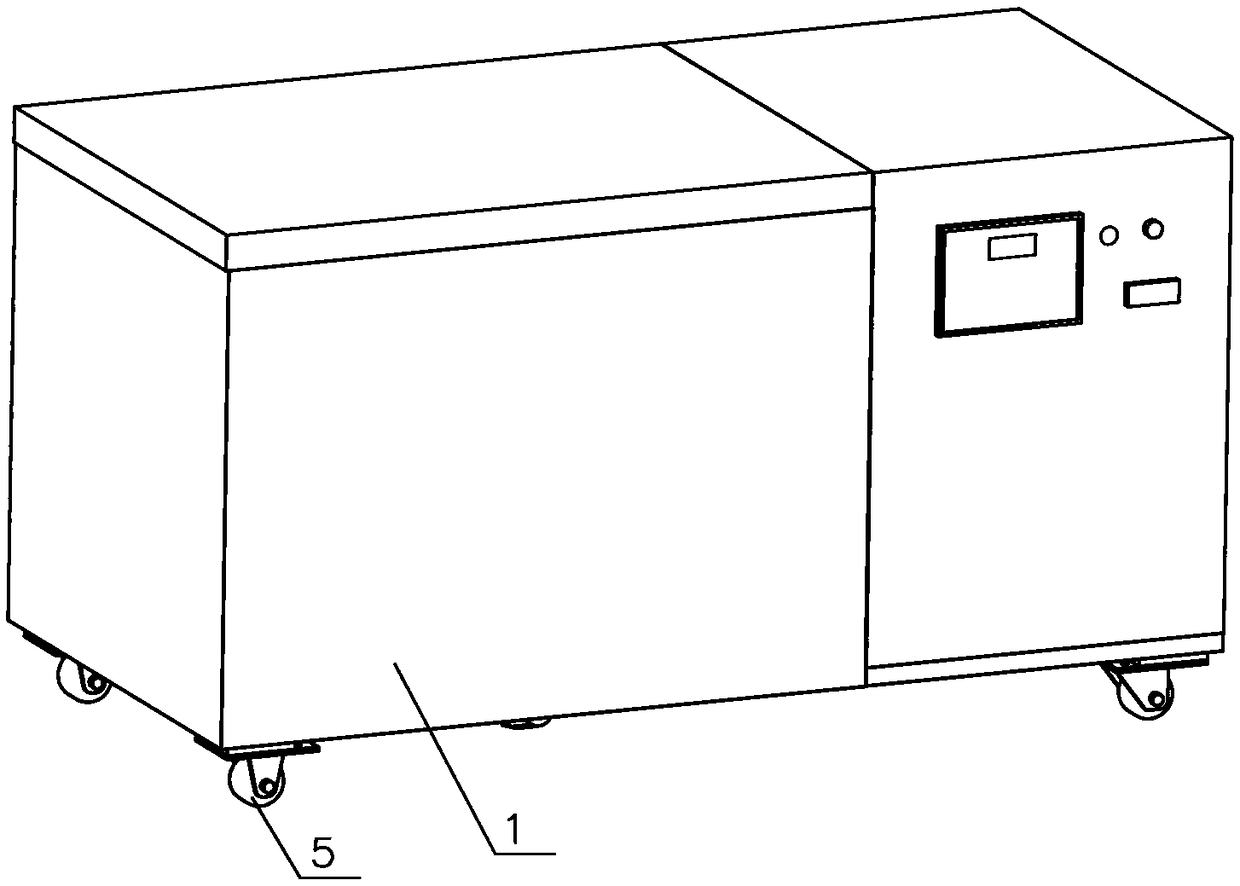

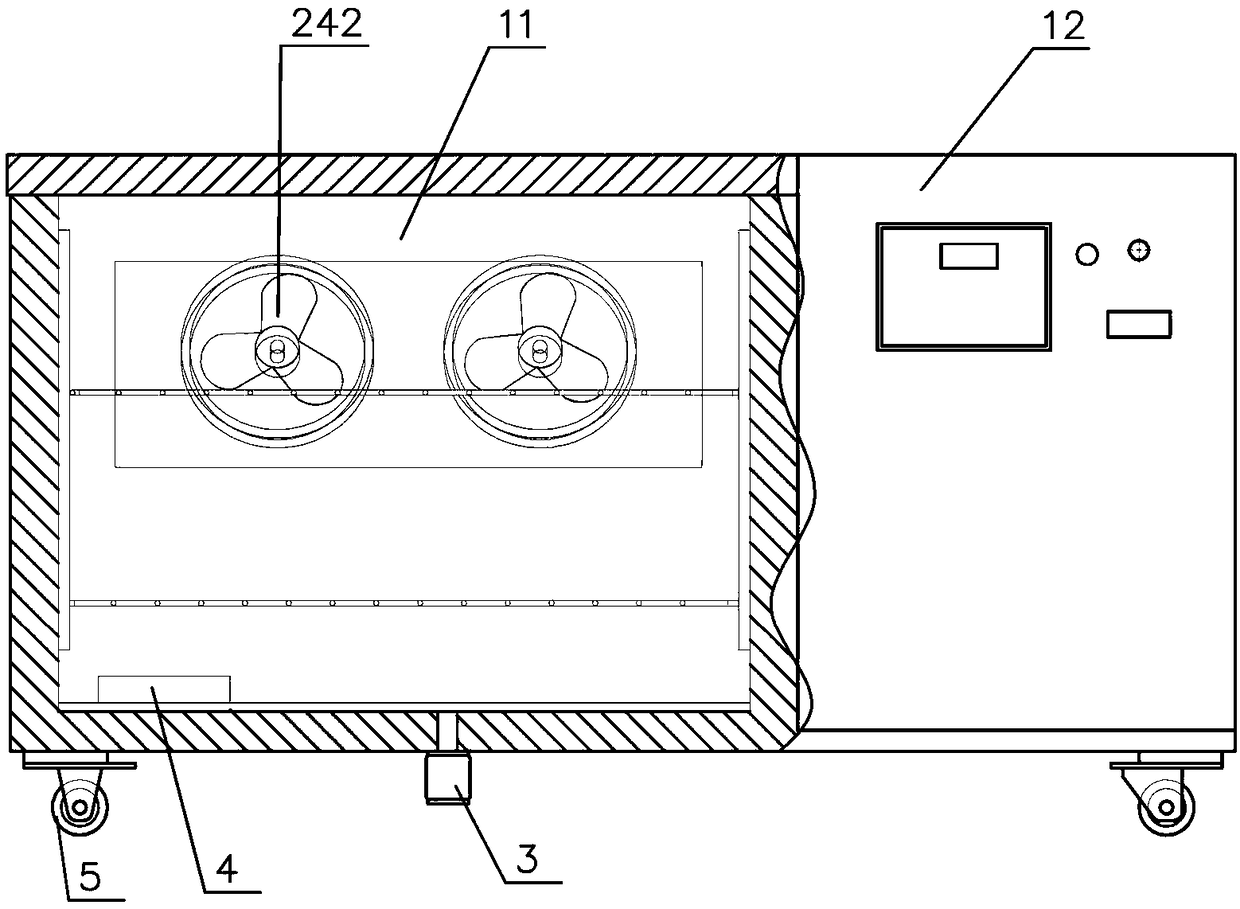

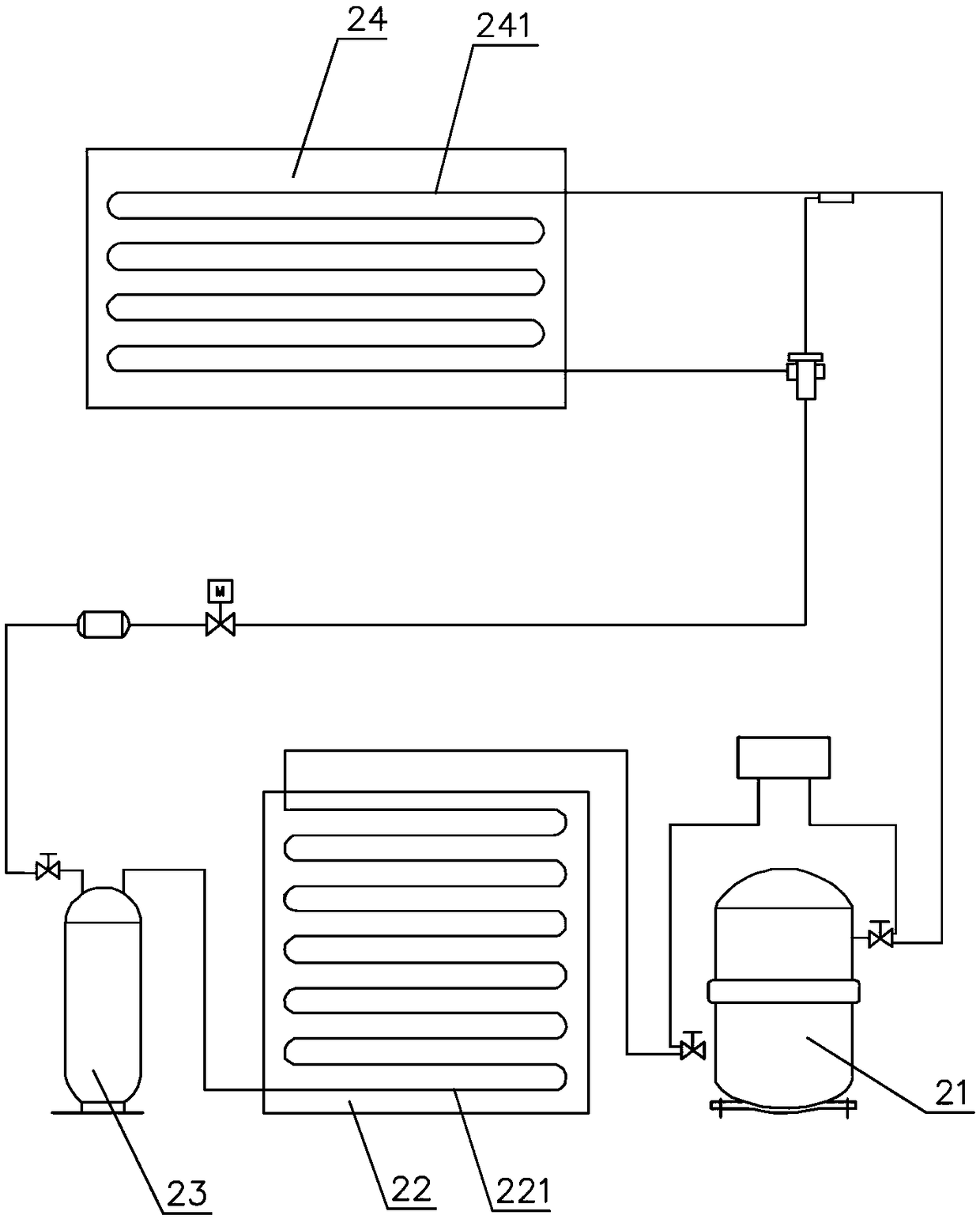

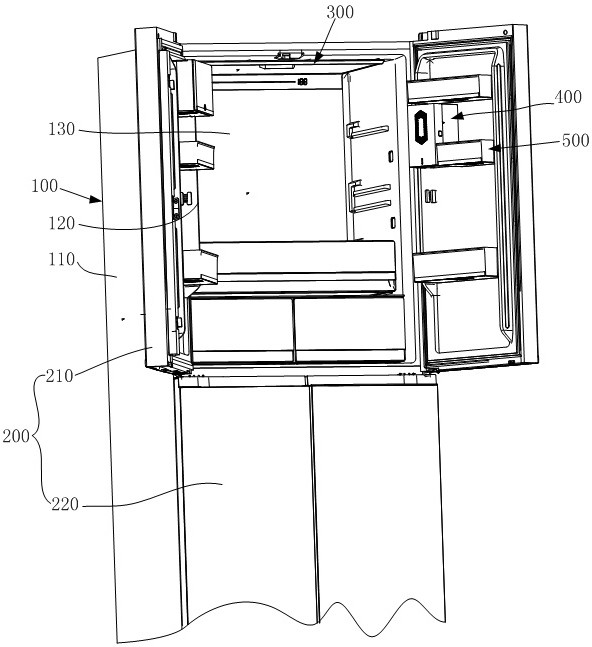

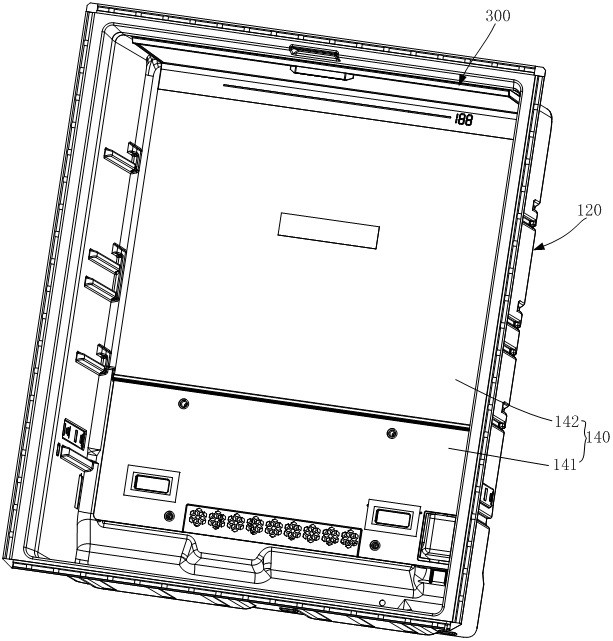

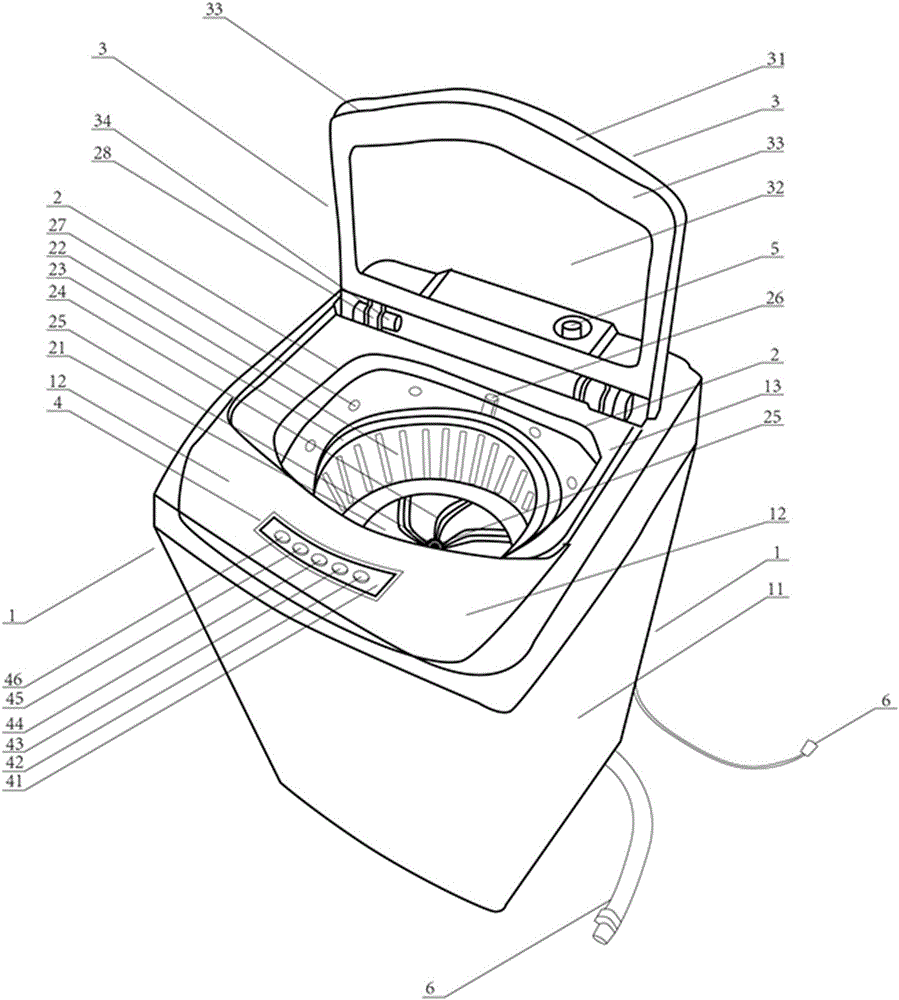

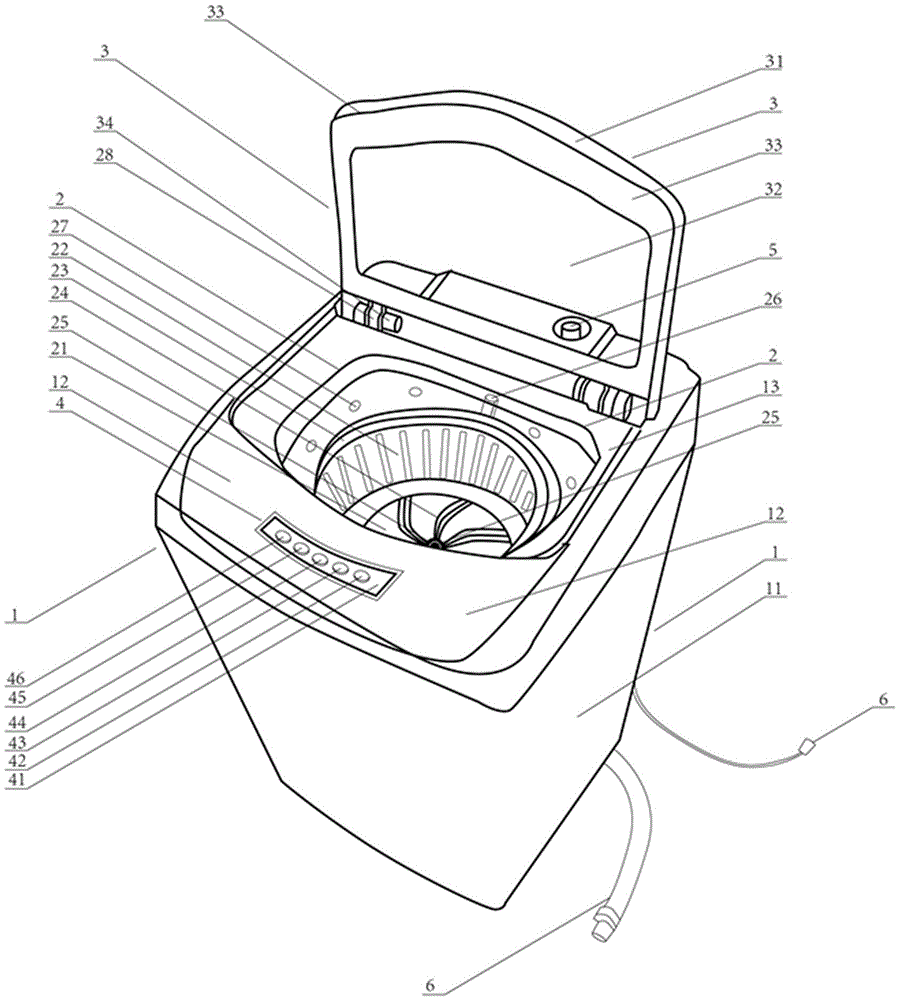

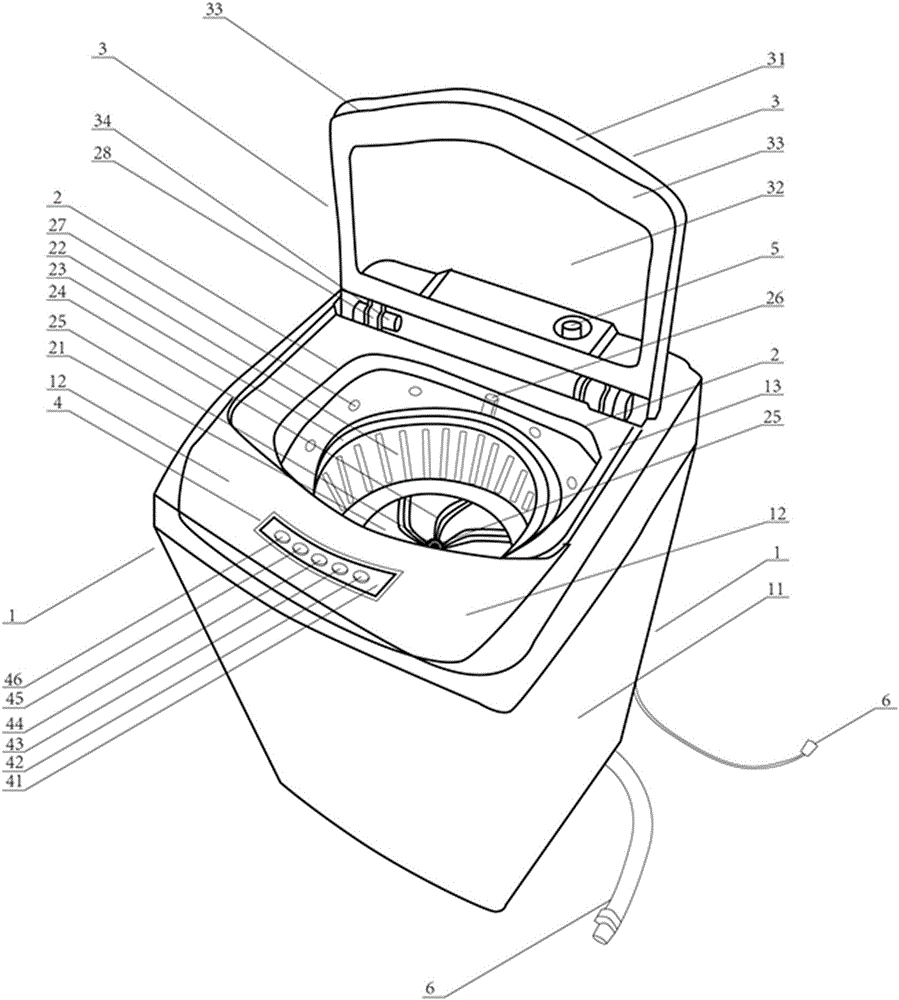

In-situ quick precooling machine for fruits

PendingCN108684812AMaintain postharvest qualityEasy to carryFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingEvaporatorEngineering

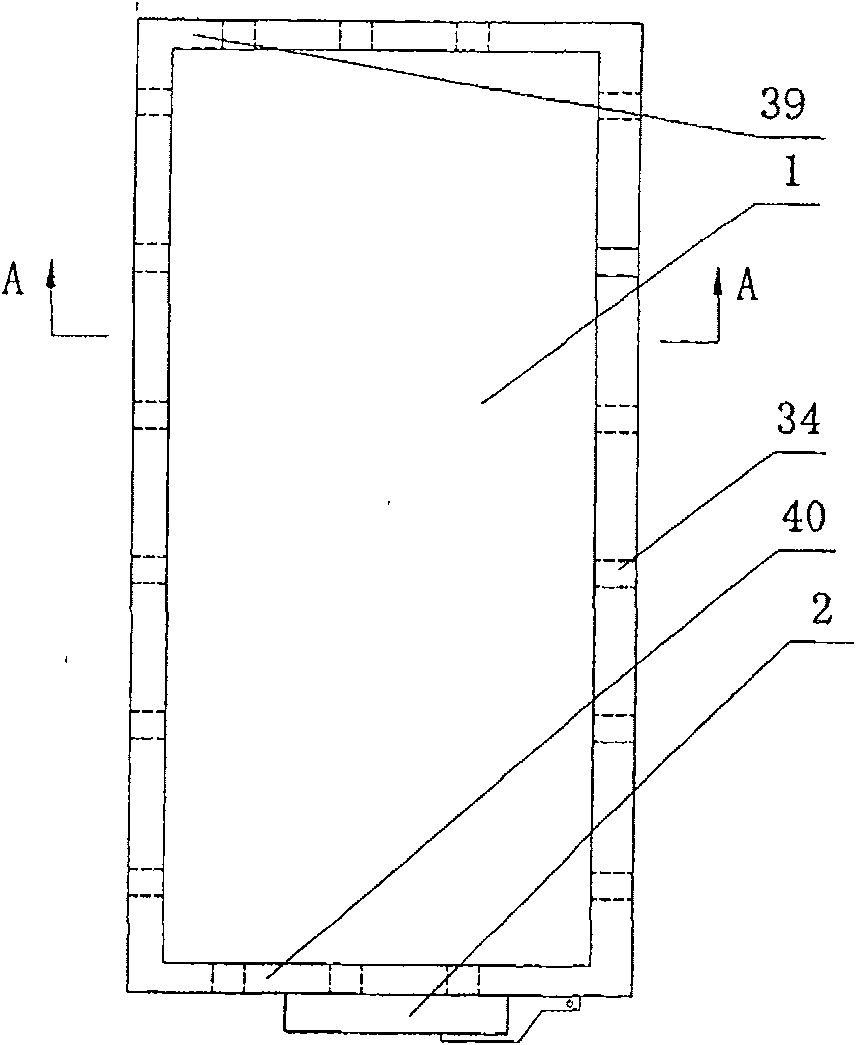

The invention relates to an in-situ quick precooling machine for fruits. The in-situ quick precooling machine for fruits comprises a box body, a refrigerating device, a dehumidifying device, a controldevice and a sterilizing device, wherein a precooling chamber and a refrigerating chamber are arranged in the box body; the refrigerating device comprises a compressor, a condenser, a liquid storingdrum and an evaporator sequentially connected by pipelines; the compressor, the condenser and the liquid storing drum are arranged in the refrigerating chamber; the evaporator is arranged in the precooling chamber; the evaporator comprises evaporating finned tubes and fans; the dehumidifying device comprises an electric heater and a water discharge valve; the electric heater is arranged on one side of the evaporating finned tubes; the water discharge valve is arranged at the bottom of the precooling chamber; and the sterilizing device is arranged in the precooling chamber. The in-situ quick precooling machine for fruits has high refrigerating speed, has dehumidifying and sterilizing functions, can effectively maintain the after-harvest quality of berries, and is light in weight of completemachine and convenient to carry and move in the field.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES +1

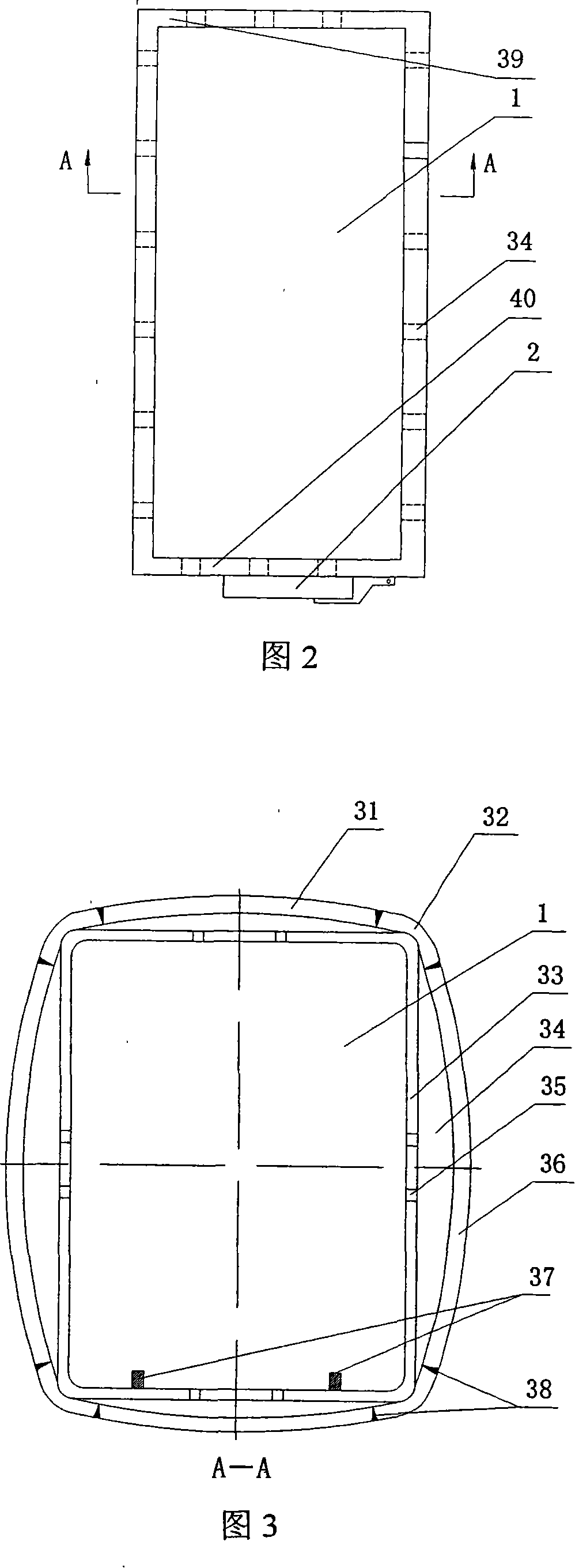

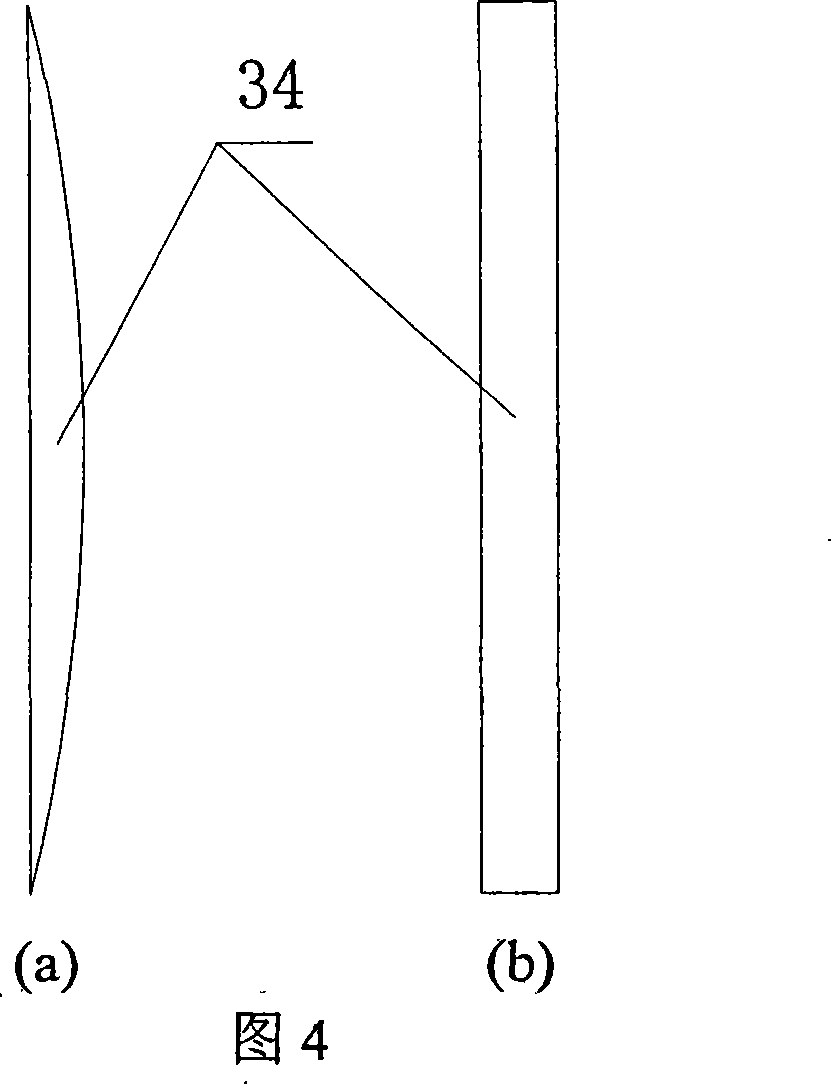

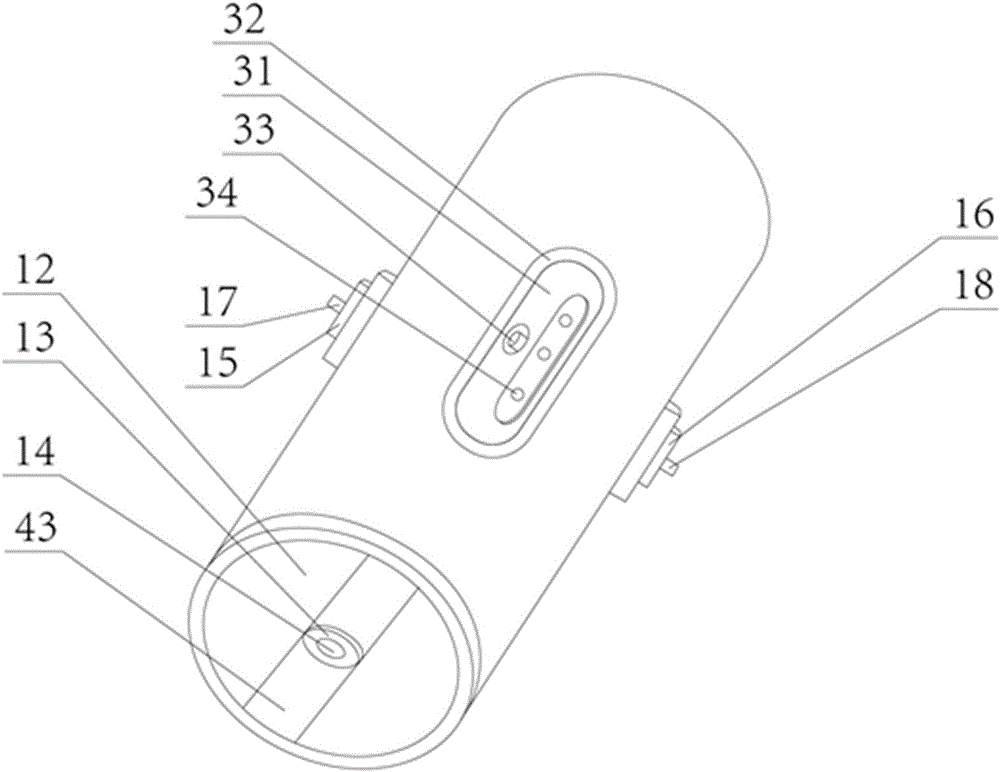

Mobile vacuum precooling device

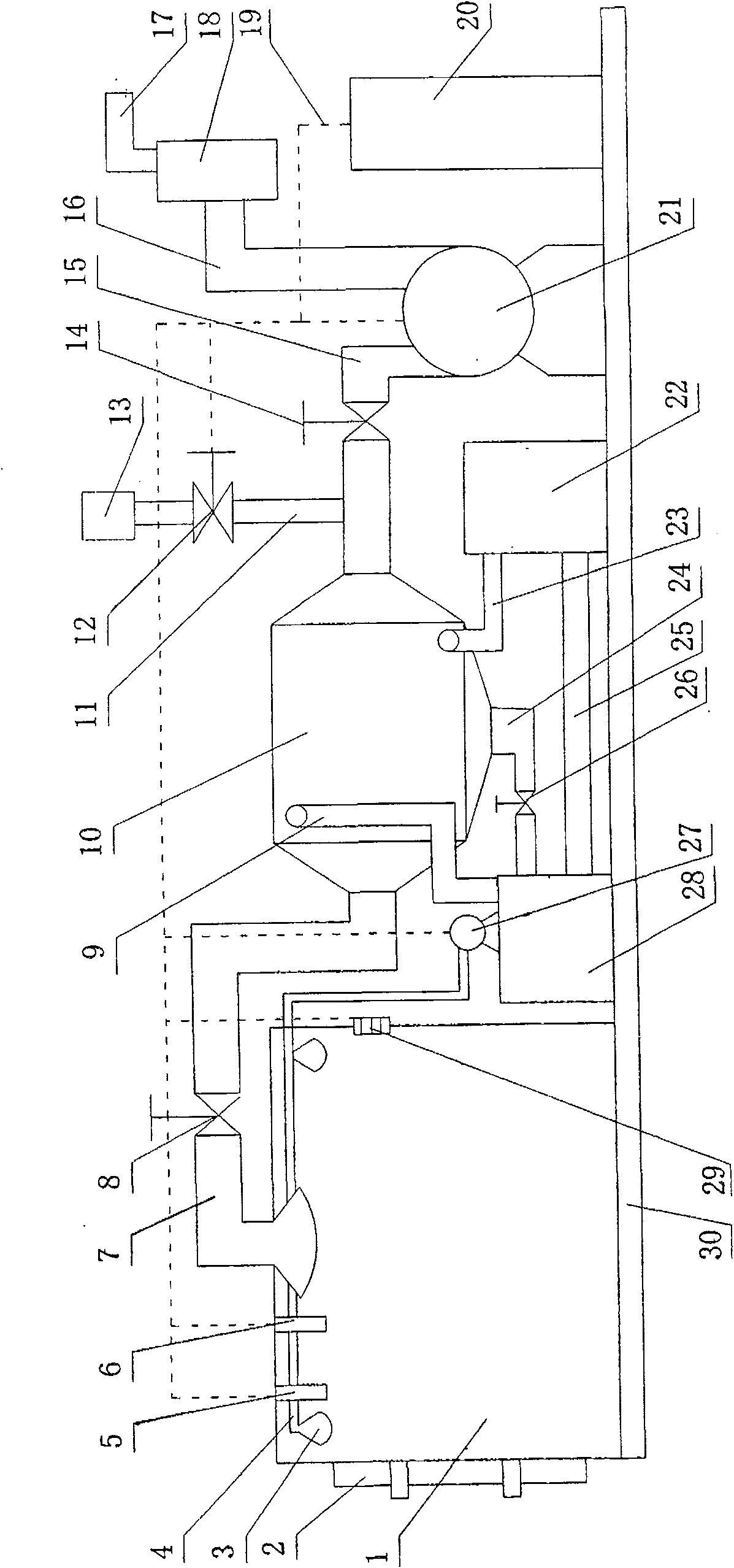

InactiveCN101138365AReduce field lossesEasy to moveLighting and heating apparatusStationary refrigeration devicesAutomatic controlEngineering

The present invention discloses a movable vacuum pre-cooling device; the device consists of a vacuum groove, a vapor collecting system, a refrigeration system, a vacuum system and an automatic control system. The vacuum groove is a combined structure which is a little bent and equipped with stiffener and with a stainless steel thin plate as the lining; the structure is characterized by high external pressure resistance and light weight and the structure is convenient for movement. The vapor collecting system consists of the refrigeration system and a vapor collector and the vapor collecting system is used for removing vapor and ensuring the normal operation of the vacuum system. The automatic control system can set different vacuum degrees and operational times according to the different natures of processed agricultural product and different pre-cooling temperatures and times; the automatic control system can also control a vacuum pump and a water charging system according to different temperatures and humidity in the vacuum groove to make the temperature and humidity in the vacuum groove meet the required value. The device is equipped on a movable support, which can be moved. The vacuum pre-cooling device is characterized by great handling capacity, fast per-cooling speed, high automation level and good economic benefit.

Owner:ZHEJIANG UNIV

Refrigerator

InactiveCN111623582AReduce generationPromote generationFruits/vegetable preservation by irradiation/electric treatmentLighting and heating apparatusLight guideIcebox

The invention provides a refrigerator. The refrigerator comprises a refrigeration liner, and a light fresh keeping device, wherein the light fresh keeping device comprises a fresh increasing module; the fresh increasing module comprises a light guiding plate and a plurality of light sources; the light guiding plate is located on light paths of the light sources; the wavelengths of lights emitted by the light sources are different; the light sources comprise a first light source which can emit red light, a second light source which can emit orange light and a third light source which can emit blue light; the light fresh keeping device has a fresh increasing pattern; the fresh increasing pattern comprises a fruit fresh increasing pattern and a vegetable fresh increasing pattern; under the fruit fresh increasing pattern, in the same period, at least the first light source of the first light source, the second light source and the third light source operates; and under the vegetable freshincreasing pattern, in the same period, at least the third light source of the first light source, the second light source and the third light source operates. Through setting corresponding fresh increasing patterns, a user can select different fresh keeping patterns according to the stored food kinds, and the light fresh keeping effect is further increased.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

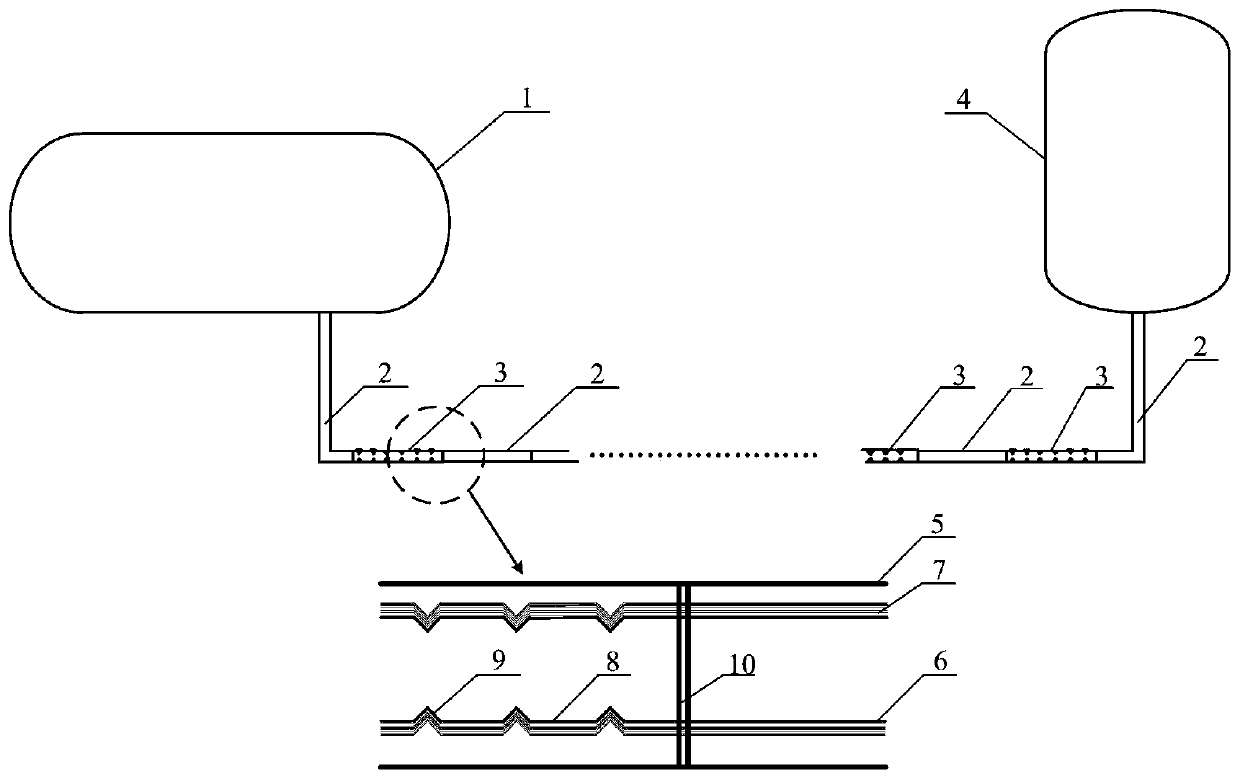

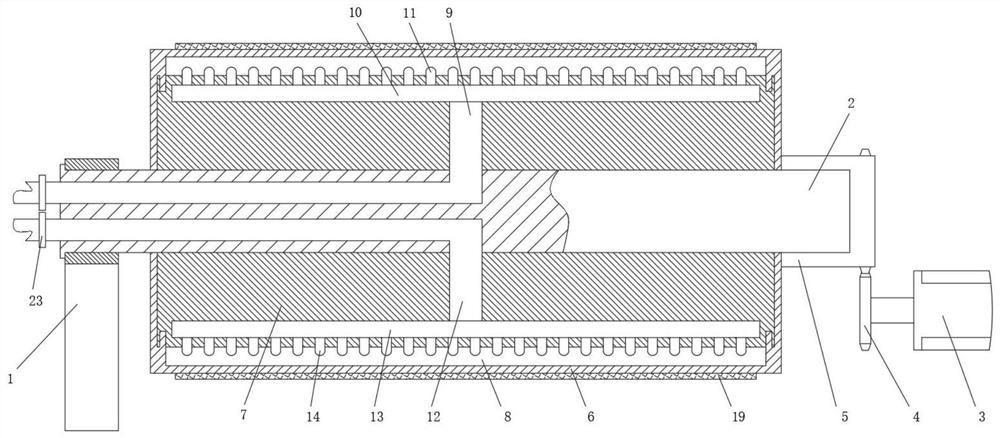

Low-temperature propellant rapid pre-cooling transmission pipeline structure

The invention relates to a low-temperature propellant rapid pre-cooling transmission pipeline structure. The low-temperature propellant rapid pre-cooling transmission pipeline structure includes a ground storage tank, a low-temperature liquid outlet of the ground storage tank is connected with an inlet of a low-temperature transmission pipeline, an outlet of the low-temperature transmission pipeline is connected with a propellant filling opening of an on-rocket storage tank, and the low-temperature transmission pipeline includes an inner micro-ribbed vacuum tube and a vacuum straight tube; thevacuum straight tube forms an annular cavity through an inner straight tube and an outer tube, the annular cavity is vacuumized, and the outer side of the inner straight tube is wrapped with a plurality of heat insulation layers; and the inner micro-ribbed vacuum tube forms an annular cavity through a micro-ribbed inner tube and an outer tube, the annular cavity is vacuumized, the outer side of the micro-ribbed inner tube is wrapped with a plurality of heat insulation layers, and micro-ribbed protrusions of the micro-ribbed inner tube are formed by machining. The low-temperature propellant rapid pre-cooling transmission pipeline structure adopts the layout form combining the inner micro-ribbed vacuum tube and the vacuum straight tube, the advantage of conversion from strengthened membranestate boiling to transition boiling of the inner micro-ribbed vacuum tube are used for achieving rapid pre-cooling, the advantage of the small resistance of the vacuum straight tube is used, the flowresistance of the overall low temperature transmission pipeline is reduced, and the pre-cooling process is accelerated.

Owner:XI AN JIAOTONG UNIV

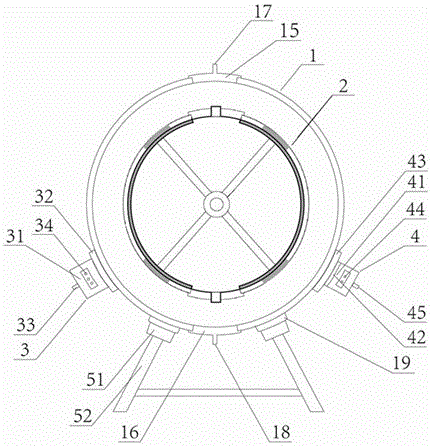

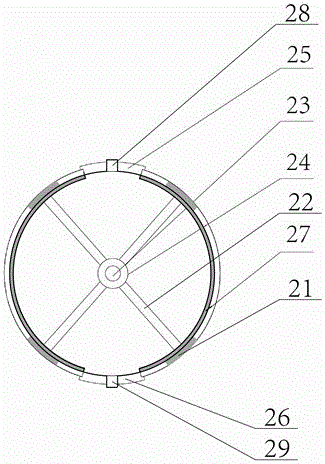

Green purifying and residue removing system for fruits and application of system

InactiveCN105707223ARapid pre-coolingDehydration fastFruits/vegetable preservation by freezing/coolingMicroorganismPesticide residue

The invention discloses a green purifying and residue removing system for fruits and application of the system.The system comprises an ozone sterilization device, a purifying and residue removing device, an ozone supply device, an automatic control device and a support frame device; the purifying and residue removing device is arranged in the ozone sterilization device, the ozone supply device and the automatic control device are arranged on the outer side of the ozone sterilization device, and the support frame device is arranged at the lower end of an ozone sterilization cabin body.The system is designed for the defects that the fruits contain microorganisms, mildew, worm egg impurities, hormones and pesticide residues; quick precooling, bacterium killing, sterilizing, purifying and residue removing operation is achieved through the technical principle that a low temperature-controlled closed or non-closed device environment can inhibit ozone decomposition and volatilization and the fact that a low-temperature aqueous ozone solution has the effects of quick precooling, bacterium killing, sterilizing, purifying and residue removing.The system has the advantages that the harmful substances such as the microorganisms, the mildew, worm eggs, the hormones and the pesticide residues in the fruits are effectively removed and decomposed, original nutrient substances are retained, the rot and deterioration losses are reduced, the structure is simple and safe, and operation is easy.

Owner:王宏峰

Saltwater spraying and quick-freezing device

PendingCN107647245ARapid pre-coolingGrowth inhibitionFood processingFood preservationQuick FreezeSaline water

The invention discloses a saltwater spraying and quick-freezing device. The saltwater spraying and quick-freezing device comprises combined freezing of a saltwater spraying and pre-freezing device anda wind cooing and freezing device. Compared with the prior art, the saltwater spraying and quick-freezing device can quick freeze boxed shrimps, and has the advantages of being high in productivity,energy-saving, good in quality of frozen products, free from running off of moisture of the frozen products and the like.

Owner:山东冰联制冷科技有限公司

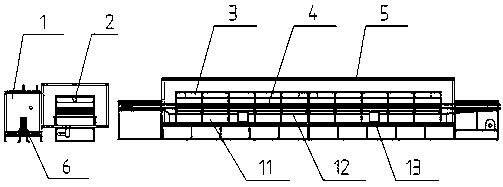

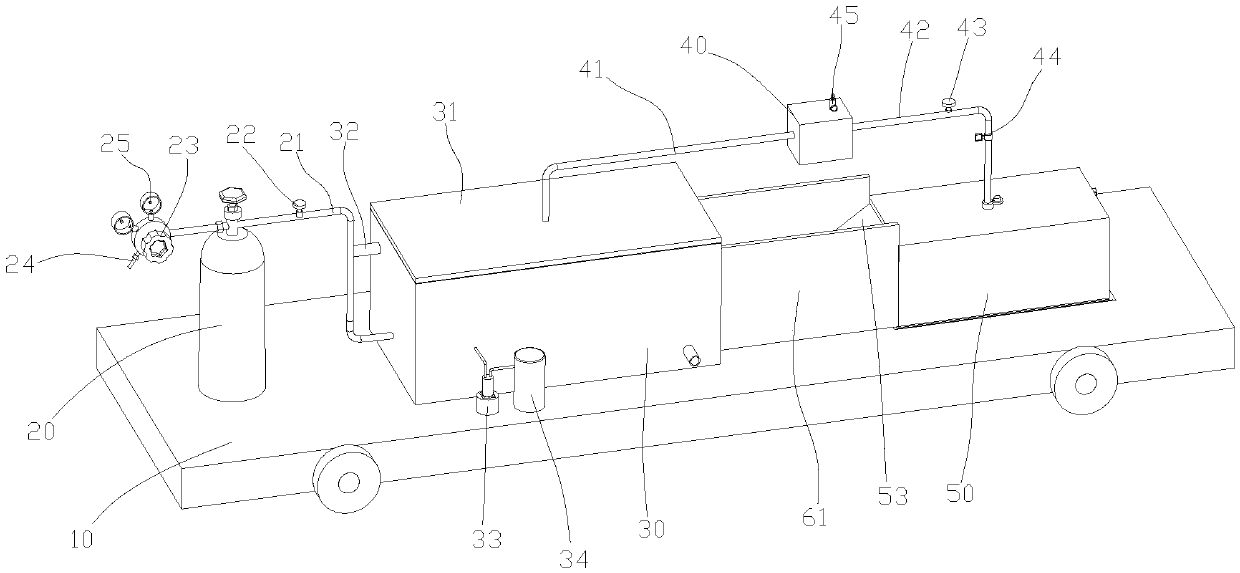

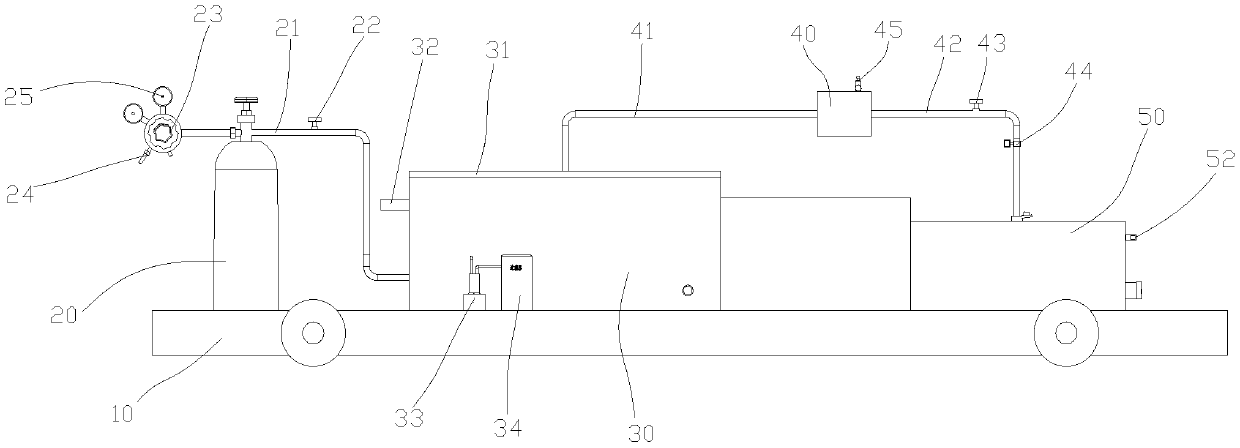

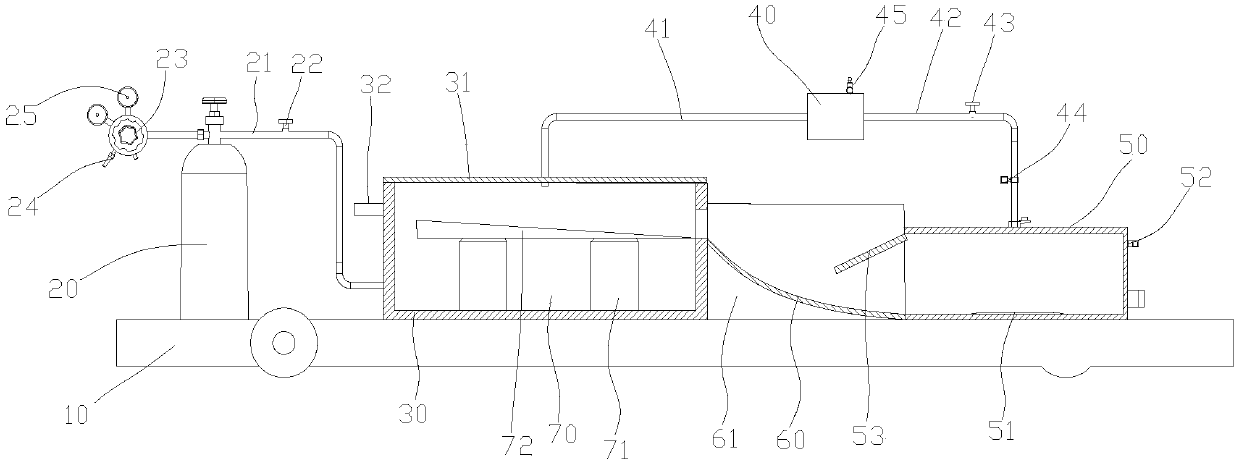

Vehicle-mounted energy-saving and environment-friendly vacuum rapid precooling equipment for fruit and vegetable

InactiveCN108870824AAchieve freshnessPracticalLighting and heating apparatusDomestic refrigeratorsCold chainInsulation layer

The invention belongs to the technical field of vacuum application, and relates to vehicle-mounted energy-saving and environment-friendly vacuum rapid precooling equipment for fruit and vegetable. Thevacuum rapid precooling equipment comprises a vacuum heat insulation outer box and a honeycomb expansion plate heat sink inner box, and vacuum heat insulation layers are arranged between the vacuum heat insulation outer box and the honeycomb expansion plate heat sink inner box; the honeycomb expansion plate heat sink inner box is formed by supercharging and bulging double-layer metal plates, and / or the inside surface of the honeycomb expansion plate heat sink inner box is blackened; and thus, the rapid cooling of the stored fruit and vegetable is benefited. Vacuum pressure is provided for thehoneycomb expansion plate heat sink inner box by a vehicle exhaust gas utilization device through a working medium generator, an injection pump and the like; the vacuum pressure is supplemented and provided for the honeycomb expansion plate heat sink inner box through a holding pump and a differential pressure valve II; and the honeycomb expansion plate heat sink inner box is maintained in the low temperature state through a refrigerator and a low temperature valve. The equipment stated in the application is rational in structural design, and the effects of energy saving and emission reduction are achieved; the equipment is high in practicability, and especially suitable for cold chain logistics transportation of fruit and vegetable product origins; the effective preservation and long-time storage of the fruit and vegetable are ensured, and the application range is wide, and the economic benefits are very obvious.

Owner:李志胜

Bottom connecting plate of multi-temperature-zone moveable warehouse

InactiveCN106347883AImprove qualityImprove distribution efficiencyRefrigerated goods vehicleLarge containersTemperature controlQuality assurance

The invention discloses a bottom connecting plate of a multi-temperature-zone moveable warehouse. The bottom connecting plate comprises a bottom connecting plate body, wherein the upper portion of the bottom connecting plate body is matched with a vertical connecting plate positioning groove of a vertical connecting plate, a bottom connecting balance part is formed at the bottom of the bottom connecting plate body and is matched with a bottom connecting plate positioning groove formed in a compartment base plate, and a transverse ventilation opening is formed in the bottom connecting plate body and extends in the width direction of the bottom connecting plate body. The temperature control zones formed by the bottom connecting plates serve as small warehouse positions and respectively store different categories of products, classified storage can be performed according to the attributes of commodities, internal detachable structures can store different volumes and sizes of products, and accordingly the quality assurance and the delivery efficiency in e-commerce industry are improved.

Owner:董康辉

Vertical connection plate of movable warehouse with multiple temperature zones

InactiveCN105644986AImprove qualityImprove distribution efficiencyLarge containersTank wagonsTemperature controlQuality assurance

The invention discloses a vertical connection plate of a movable warehouse with multiple temperature zones. The vertical connection plate comprises a vertical connection plate body, wherein the upper part of the vertical connection plate body is matched with vertical connection plate positioning grooves of a compartment top plate and a vertical connection plate; horizontal connection plate support parts are fixedly arranged on two sides of the bottom of the vertical connection plate respectively; vertical connection plate positioning grooves are formed in the lower part of the vertical connection plate body and matched with the upper parts of the vertical connection plate and a bottom connection plate; horizontal ventilation openings are formed in the vertical connection plate body and extend in the width direction of the vertical connection plate body. According to the vertical connection plate of the movable warehouse with multiple temperature zones, all formed temperature control zones are taken as small storage positions which are used for storing different kinds of products respectively, goods can be stored in classification according to the goods properties, the products with different sizes can be stored by the aid of an internal detachable structure, and accordingly, the quality assurance and the delivery efficiency of the e-commerce industry are improved.

Owner:董康辉

Environment-friendly purification and residue-removal system for fresh wild vegetable products and application thereof

The invention discloses an environment-friendly purification and residue-removal system for fresh wild vegetable products and application thereof. The environment-friendly purification residual-removal system comprises an ozone sterilization device, a purification and residue-removal device, an ozone supplying device, an automatic control device and a support frame device. The purification and residue-removal device is arranged in the ozone sterilization device; the ozone supplying device and the automatic control device are arranged outside the ozone sterilization device; the support frame device is arranged at the lower end of an ozone sterilization cabin body. The environment-friendly purification and residue-removal system is designed against the deficiency that wild vegetables contain microorganisms, ova, impurities and chemical residues, the technical principle that a closed or non-closed device environment controlled at the low temperature can inhibit ozone decomposition and volatilization is utilized, and a low temperature ozone aqueous solution has the effects of quick precooling, sterilization, purification and residue removal, so that operation of quick precooling, sterilization, purification and residue removal conducted on the wild vegetables is achieved; the system has the advantages that harmful substances such as microorganisms, ova, impurities and chemical residues can be effectively removed and decomposed, original fresh nutritional quality is maintained, losses caused by decomposition are reduced, dehydration is achieved quickly, the structure is simple, and operation is easy.

Owner:王宏峰

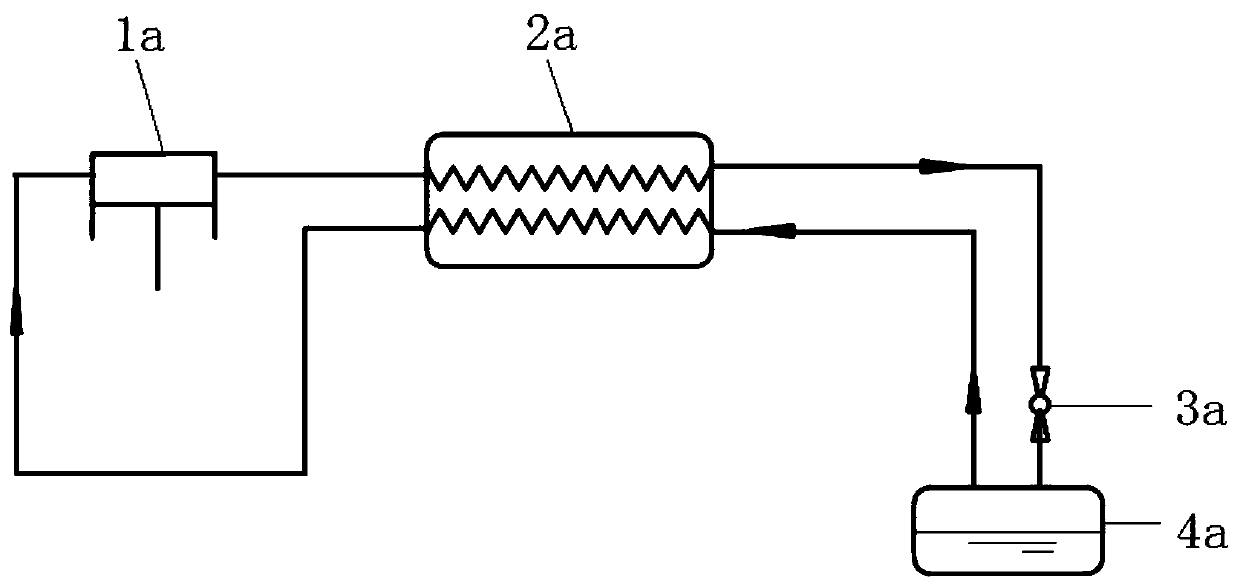

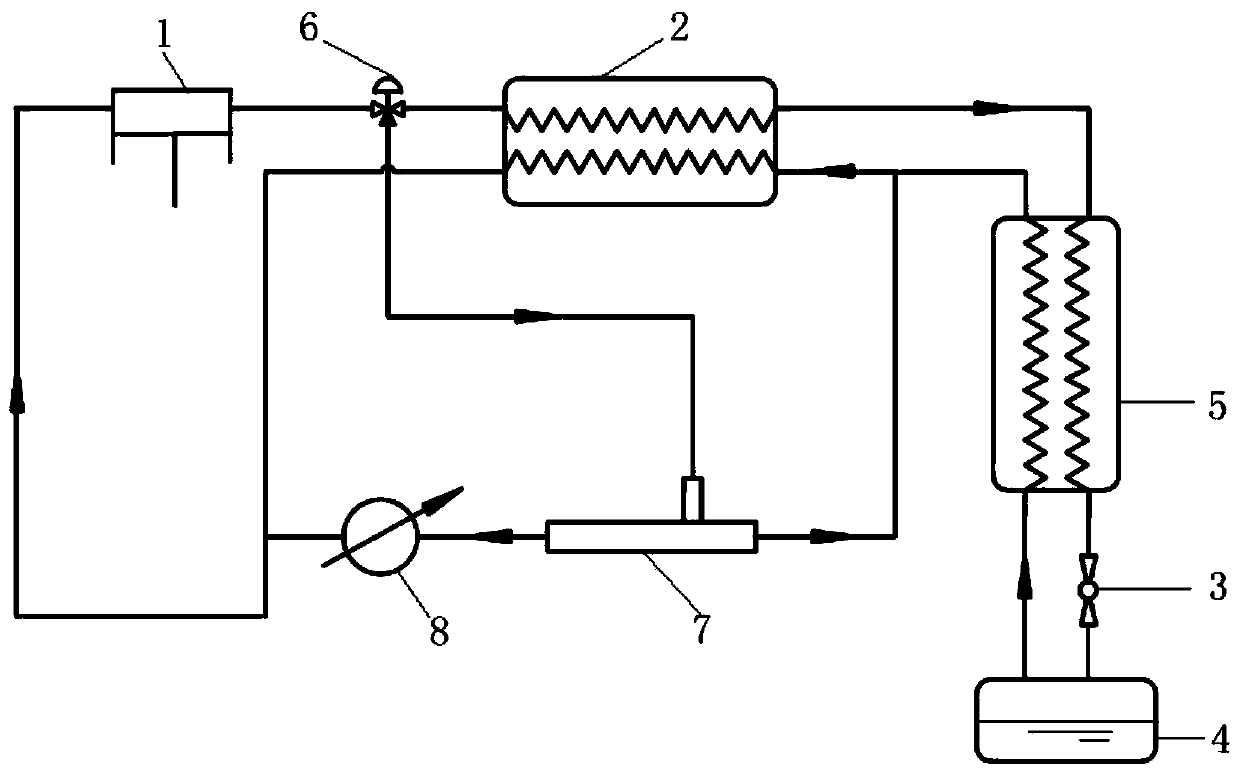

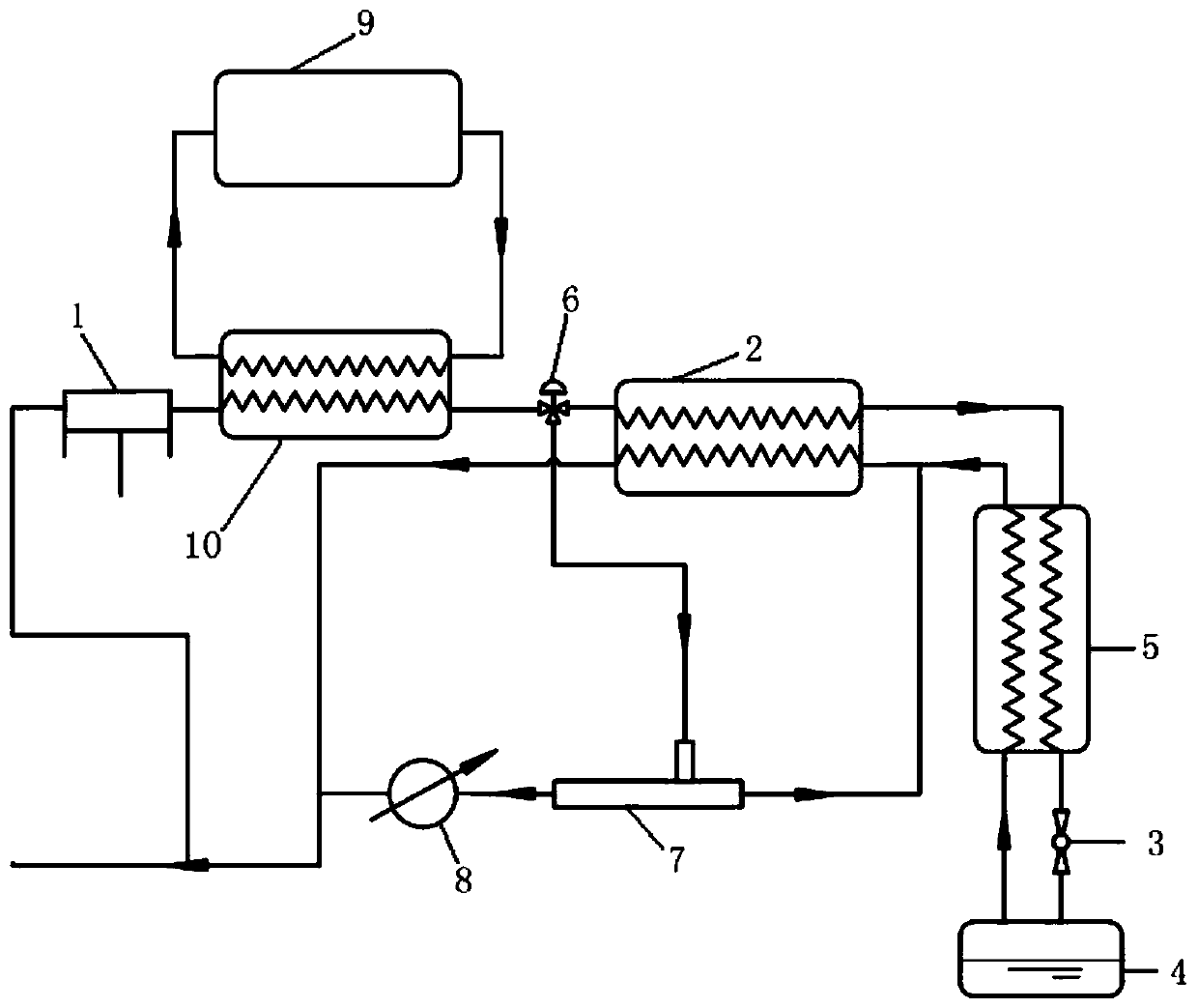

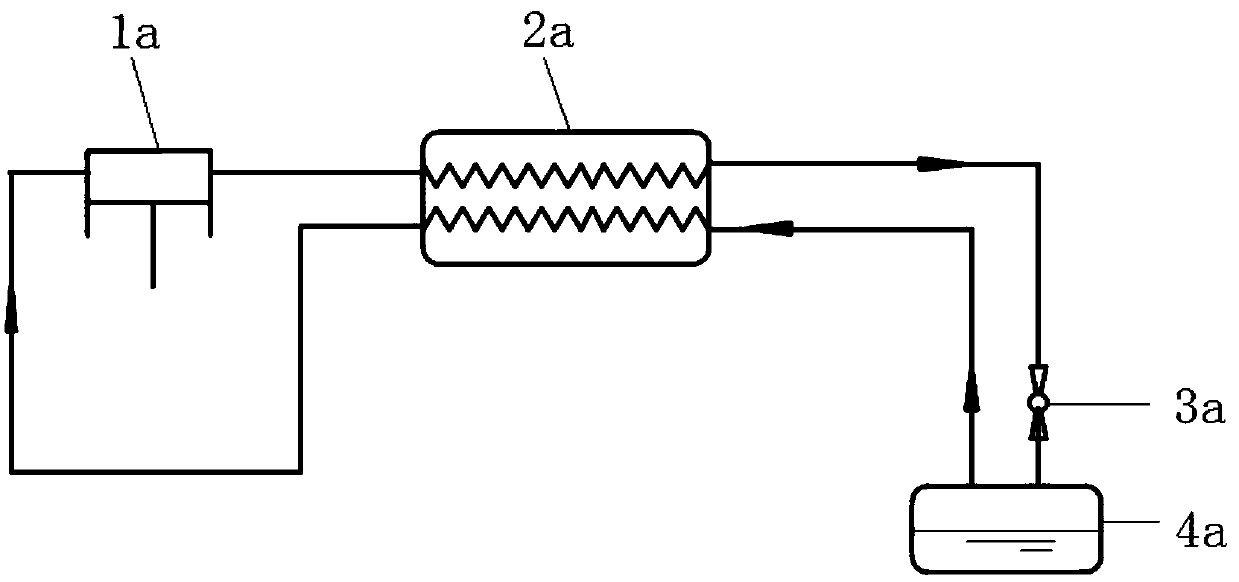

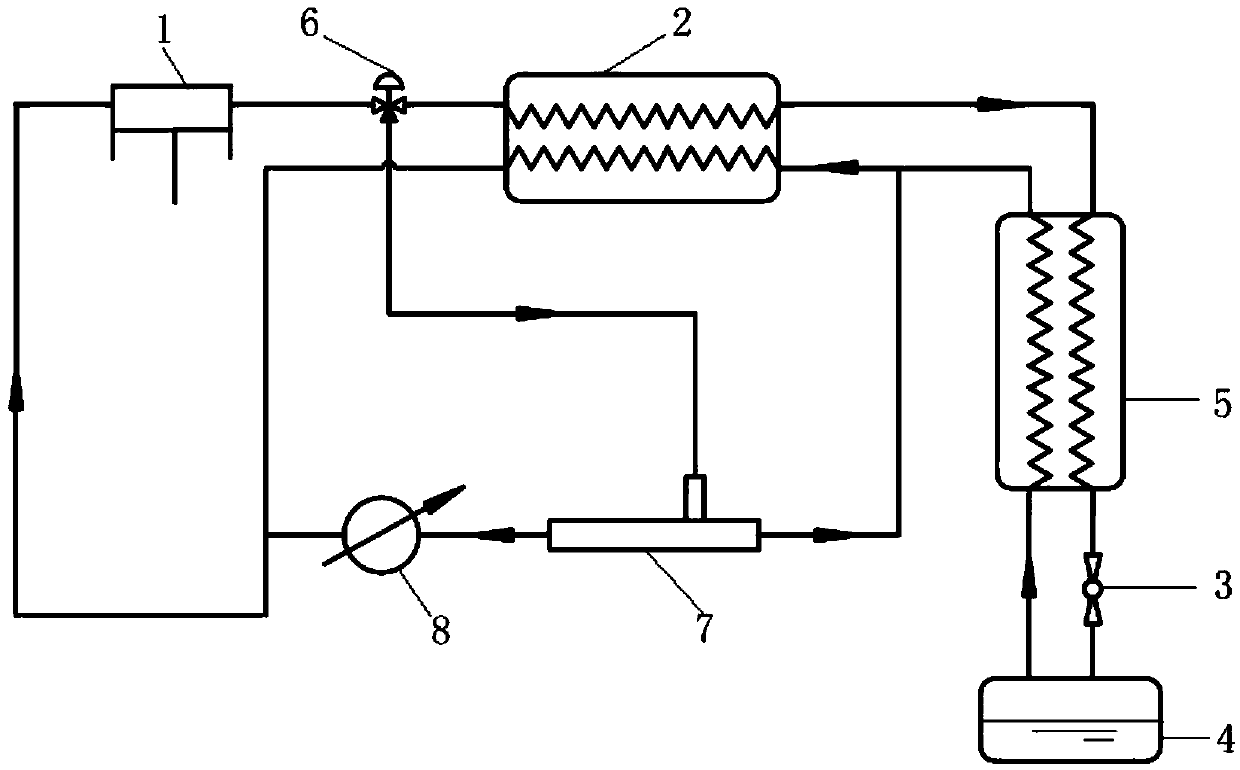

A low-temperature refrigeration system with one-time throttling for precooling by utilizing the energy separation effect of vortex tubes

ActiveCN108050722BSimple structureLarge expansion coefficientMechanical apparatusCompression machinesEngineeringRefrigeration

A throttling low-temperature refrigeration system for precooling using the energy separation effect of a vortex tube, comprising a compressor, a regenerator, a throttle valve and an evaporator, characterized in that the regenerator includes a first regenerator and a second regenerator The heater also includes a three-way flow regulating valve and a vortex tube, the outlet of the compressor is connected with the inlet of the three-way flow regulating valve, and the first outlet of the three-way flow regulating valve is connected with the hot end inlet of the first regenerator , the second outlet is connected with the inlet of the vortex tube, the outlet of the cold end of the vortex tube is merged with the outlet of the hot end of the second regenerator, and then connected with the inlet of the cold end of the first regenerator, the first regenerator The outlet of the hot end of the compressor is connected with the inlet of the compressor. The one-throttle low-temperature refrigeration system precooled by the energy separation effect of the vortex tube has a simple structure, can adopt internal precooling, and has high refrigeration efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

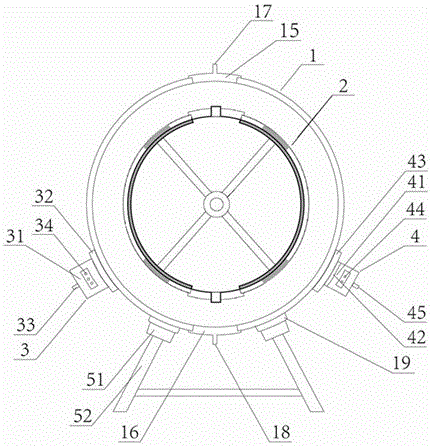

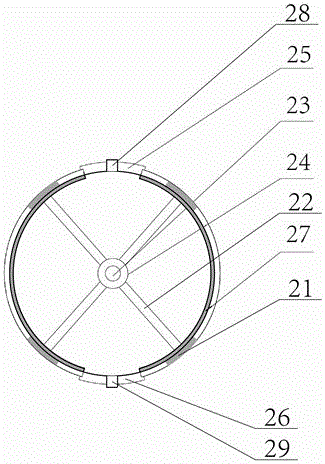

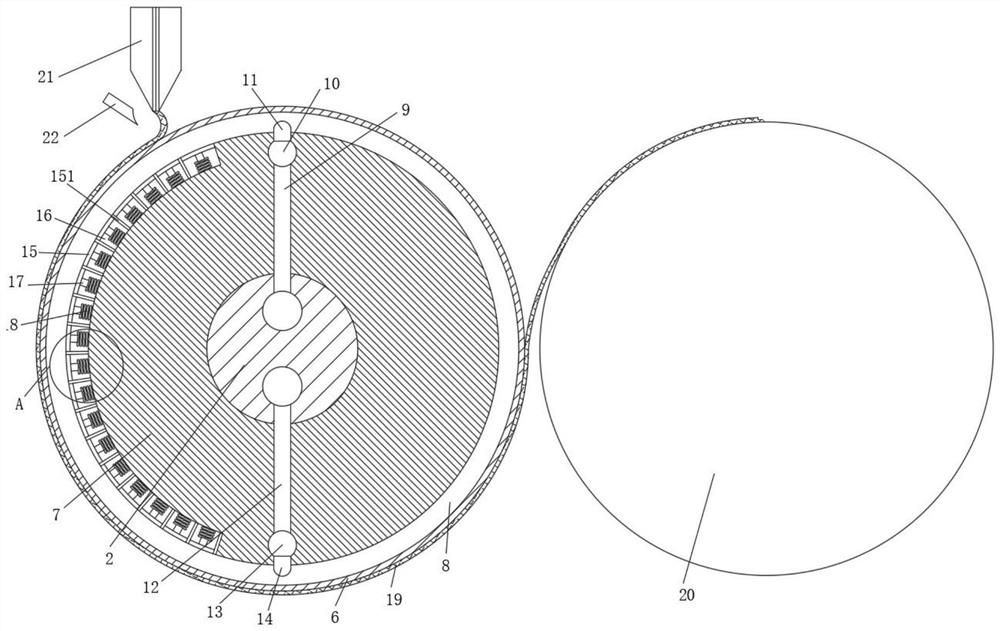

Spherical fruit and vegetable precooling and packaging gas prefilling integrated machine

ActiveCN109566725AGuaranteed freshness and qualityExtend storage and shelf lifeFruits/vegetable preservation by freezing/coolingPackaging gasEngineering

The invention discloses a spherical fruit and vegetable precooling and packaging gas prefilling integrated machine comprising a mobile platform, a liquid nitrogen tank, a nitrogen collecting chamber,a conveyor belt, a precooling box and a packaging box. The liquid nitrogen tank, the precooling box and the packaging box are arranged on the mobile platform, an outlet of the liquid nitrogen tank communicates with the precooling box through a nitrogen inlet pipe, the precooling box is provided with an openable box cover and a water inlet valve, and a lifting platform with an inclined slope capable of accommodating fruits and vegetables is arranged in the precooling box. A pressure sensor and an oxygen sensor for measuring the weight of fruits and vegetables are arranged in the packaging box,and an automatic sensing door which acts according to signals of the pressure sensor is arranged on the packaging box. Fruits and vegetables on the lifting platform slide down to the conveyor belt after being precooled, and the fruits and vegetables are conveyed into the packaging box through the conveyor belt after passing the automatic sensing door. The nitrogen collecting chamber communicates with the precooling box through an air inlet pipe, and the nitrogen collecting chamber communicates with the packaging box through an air outlet pipe, and the air outlet pipe is provided with an air outlet valve and a flow meter. Rapid precooling and air conditioning of fruits and vegetables are achieved by the invention, and freshness and quality of fruits and vegetables are ensured.

Owner:SOUTH CHINA AGRI UNIV

Fruit differential-pressure rapid precooling technology

InactiveCN102860353AGood effectShort pre-cooling timeFruits/vegetable preservation by freezing/coolingProcess engineeringCold air

The invention discloses a fruit differential-pressure rapid precooling technology. A differential-pressure refrigeration storage is arranged in a high-temperature refrigeration storage, a sealing door, an exhaust pump, a pressure gauge and a gas inlet are arranged on the differential-pressure refrigeration storage, and a humidifier is arranged inside the differential-pressure refrigeration storage; and a rapid differential-pressure precooling process includes that the exhaust pump is started, gas is discharged out of the storage, a negative pressure state in the storage in achieved, heat caused by fruits enter the storage is discharge out of the storage rapidly, when the negative pressure in the storage reaches a low value, the exhaust stops discharging gas, the gas inlet is opened, cold air in the high-temperature refrigeration storage is led into the differential-pressure refrigeration storage by using differential pressure, the fruits are cooled down rapidly, when the inner differential pressure and the outer differential pressure of the differential-pressure refrigeration storage are balanced, the exhaust pipe is started and discharges gas outwards, 'discharging and leading' are performed, a circulation is achieved every three or five minutes for 2-3 hours, and the temperature of the fruits is reduced to the lowest. The fruit differential-pressure rapid precooling technology has the advantages of being fast in precooling, good in effect, low in water loss rate and capable of saving electrical power. Internal tissue cells of the fruits can not be damaged, and the storage and conveying quality and time of the fruits also can not be affected.

Owner:XINJIANG XINJIYUAN AGRI & ANIMAL HUSBANDRY DEV

Technology and device for fruit and vegetable phase-temperature precooling compatible multi-coupling anti-aging treatment

ActiveUS11252973B2Rapid pre-coolingEasy to operateFruits/vegetable preservation by freezing/coolingMechanical engineeringFruits and vegetables

A device for fruit and vegetable phase-temperature precooling compatible multi-coupling anti-aging treatment comprises a refrigeration house with a plurality of differential pressure precooling devices placed therein. The differential pressure precooling device comprises a hermetic seal tunnel precooling box, a separator plate is fixedly mounted at an upper part inside the tunnel precooling box and in parallel to a top wall of the tunnel precooling box with a space formed therebetween; the separator plate extends to the bottom of the tunnel precooling box; a venting plate is fixedly mounted to one side of the separator plate and in parallel to a side wall of the tunnel precooling box with a space formed therebetween; a section of wind shield is vertically and downwardly mounted to an end of the other side of the separator plate; an axial flow fan is mounted at a corner of the tunnel precooling box between the separator plate and the venting plate.

Owner:TIANJIN LVXIN CRYOGENIC SCI & TECH CO LTD

Fast precooling and purification and residue removing system for fruits and fruit products and application of fast precooling and purification and residue removing system

InactiveCN105685206AEfficient killingEfficient removalFruit and vegetables preservationFood ingredient for microbe protectionBiotechnologyPesticide residue

The invention discloses a fast precooling and purification and residue removing system for fruits and fruit products and application of the fast precooling and purification and residue removing system.The system comprises an outer box device, an inner box device, a box cover device, a control device, a water supply port, a draining port and a power supply port.The system has the advantages that the system is designed aiming at the defect that the fruits contain microorganisms, viruses and bacteria, worm eggs, heavy metal, hormone, antibiotics, soil impurities and pesticide residues; the technical principle that a low-temperature-controlled sealed or non-sealed device environment can inhibit ozone decomposition and volatilization and the fact that the low-temperature ozone aqueous solution has effects of fast pre-cooling, sterilizing, and purifying and removing residues are utilized to perform fast pre-cooling, sterilizing and purification and residue removing on the fruits; the respiratory climacteric and enzyme activity effect of the fruits are effectively controlled and inhibited, original nutritional substances are kept, the preservative storage time is prolonged, weight loss caused by mildew and deterioration is reduced, and the system is simple in structure, safe and easy to operate, and the like.

Owner:王宏峰

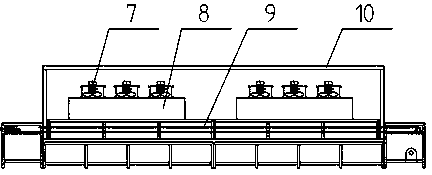

Tail end module for modular combined ice chest and ice chest

PendingCN108302869ARealize standardized productionLow costLighting and heating apparatusStationary refrigeration devicesModular compositionModularity

The invention relates to the technical field of refrigerating devices, in particular to a tail end module for a modular combined ice chest and the ice chest. The tail end module for the modular combined ice chest comprises a tail end module main body which comprises a power distribution and control sub module and a plurality of sub functional modules, wherein each of the sub functional modules isconnected to the power distribution and control sub module and a cold source module of the ice chest; one of the sub functional modules comprises a heat exchanger module, the power distribution and control sub module coordinates a heat exchanger module and other sub functional modules so as to provide a box body module of the modular combined ice chest with one or more functions of a refrigerating / heating mode, a humidifying / dehumidifying mode, a gas component adjusting mode, an air flow circulation and ventilation mode and a lighting mode. The tail end module manufactured modularly can be produced in a standardized manner, so that the advantages of prefabricated and assembled buildings are achieved. The tail end module is low in cost and short in period, and the quality can be guaranteed.The tail end module is simple in structure, reasonable in design and convenient to disassemble and assemble and transport.

Owner:中集冷链发展有限公司

Primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect

ActiveCN108050722ASimple structureLarge expansion coefficientMechanical apparatusCompression machinesEngineeringSystem structure

The invention discloses a primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect. The system comprises a compressor, heat regenerators, a throttling valve and an evaporator, and is characterized in that the heat regenerator comprises a first heat regenerator and a second heat regenerator; the system further comprises a three-way flow regulating valve and a vortex tube; an outlet of the compressor communicates with an inlet of the three-way flow regulating valve, a first outlet of the three-way flow regulating valve communicateswith a hot end inlet of the first heat regenerator, and a second outlet of the three-way flow regulating valve communicates with an inlet of the vortex tube; a cold end outlet of the vortex tube and ahot end outlet of the second heat regenerator are combined into one path to communicate with a cold end inlet of the first heat regenerator; and a hot end outlet of the first heat regenerator communicates with an inlet of the compressor. The primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect has the advantages that structure issimple, internal pre-cooling can be adopted, and the refrigerating efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

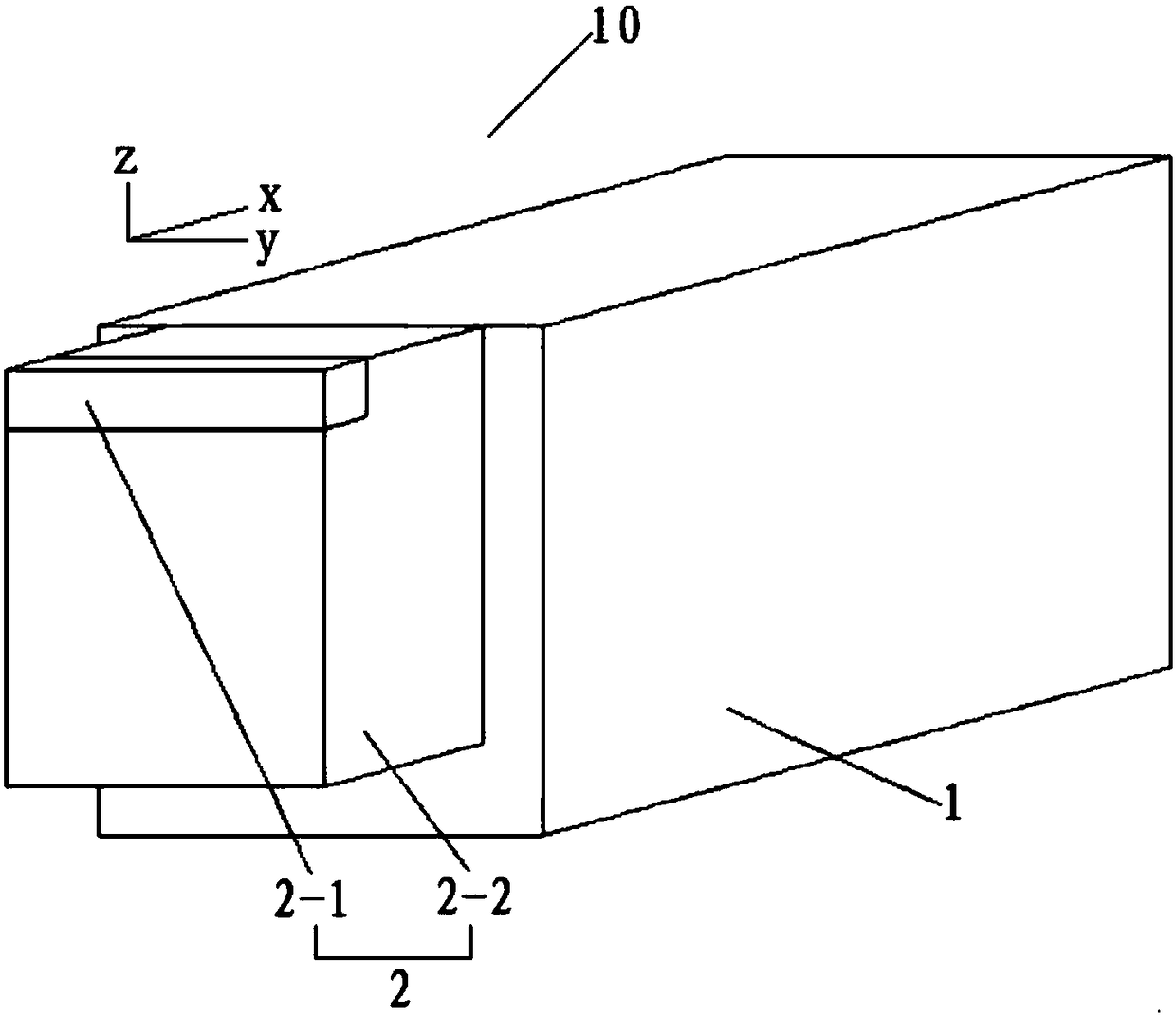

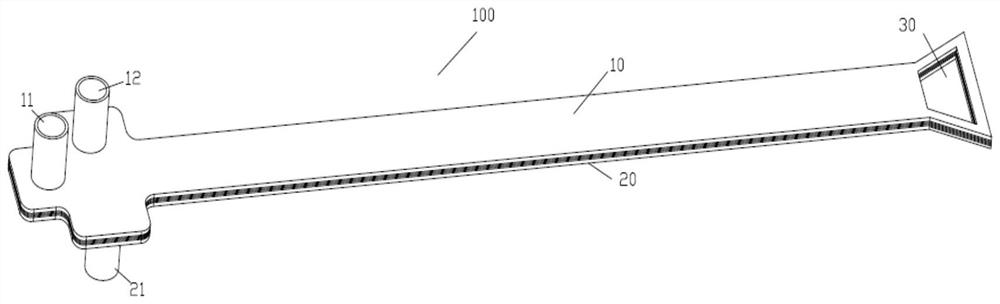

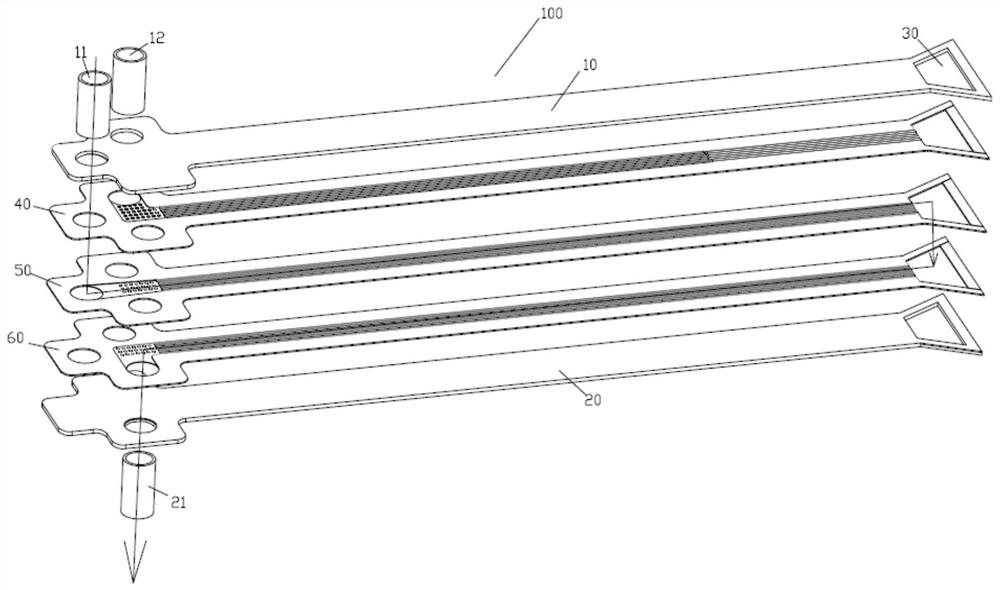

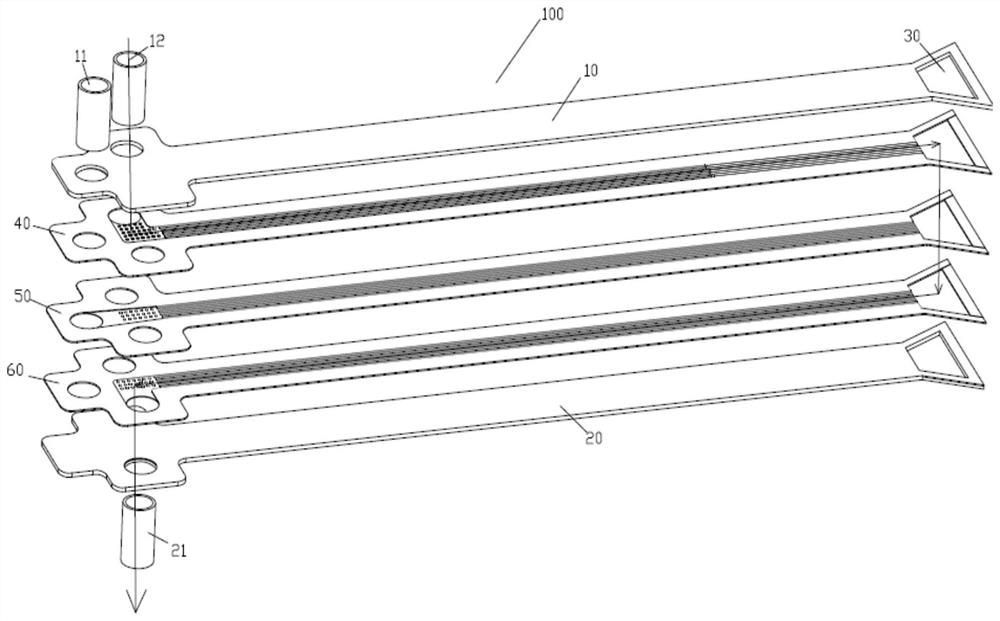

Interpenetration bypass type laminated rapid pre-cooling throttling refrigerator and control method

ActiveCN114562827ARapid pre-coolingRapid coolingCompression machinesEfficient regulation technologiesRefrigerationPhysics

The invention provides a penetrating bypass type laminated rapid precooling throttling refrigerator which comprises a fixing unit and a cooling unit, the fixing unit comprises an upper cover plate and a lower cover plate, the upper cover plate is provided with a first main inlet and a second main inlet, and the lower cover plate is provided with a main outlet; the at least one refrigeration unit is arranged between the upper cover plate and the lower cover plate and comprises a high-pressure plate sheet, a rapid bypass pre-cooling plate sheet and a low-pressure plate sheet, the high-pressure plate sheet comprises a first inlet part, a regenerative throttling part and a first expansion cavity, the first inlet part comprises a first rapid pre-cooling inlet and a first normal refrigeration inlet, and the second inlet part comprises a second rapid pre-cooling inlet and a second normal refrigeration inlet; the first rapid pre-cooling inlet is communicated with the first main inlet, the first normal refrigeration inlet is communicated with the second main inlet and the regenerative throttling part, the first expansion cavity is located at the tail of the high-pressure plate and communicated with the regenerative throttling part, and the rapid bypass pre-cooling plate is arranged between the high-pressure plate and the low-pressure plate in a penetrating mode. Comprising a second inlet part, a rapid pre-cooling part and a second expansion cavity, the low-pressure plate sheet comprises an evaporation cavity, a backheating backflow part and an outlet part, and the outlet part is provided with a low-pressure outlet communicating with the main outlet.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Mobile vacuum precooling device

InactiveCN100574620CReduce field lossesEasy to moveLighting and heating apparatusStationary refrigeration devicesAutomatic controlEngineering

The present invention discloses a movable vacuum pre-cooling device; the device consists of a vacuum groove, a vapor collecting system, a refrigeration system, a vacuum system and an automatic control system. The vacuum groove is a combined structure which is a little bent and equipped with stiffener and with a stainless steel thin plate as the lining; the structure is characterized by high external pressure resistance and light weight and the structure is convenient for movement. The vapor collecting system consists of the refrigeration system and a vapor collector and the vapor collecting system is used for removing vapor and ensuring the normal operation of the vacuum system. The automatic control system can set different vacuum degrees and operational times according to the different natures of processed agricultural product and different pre-cooling temperatures and times; the automatic control system can also control a vacuum pump and a water charging system according to different temperatures and humidity in the vacuum groove to make the temperature and humidity in the vacuum groove meet the required value. The device is equipped on a movable support, which can be moved. The vacuum pre-cooling device is characterized by great handling capacity, fast per-cooling speed, high automation level and good economic benefit.

Owner:ZHEJIANG UNIV

Quick pre-cooling and purification residue removal system for fresh mushroom products and application of quick pre-cooling and purification residue removal system

InactiveCN105685205ADelayed decayExtend fresh storage timeFruit and vegetables preservationFood ingredient for microbe protectionMicroorganismDecomposition

The invention discloses a quick pre-cooling and purification residue removal system for fresh mushroom products and application of the quick pre-cooling and purification residue removal system.The quick pre-cooling and purification residue removal system comprises an outer tank device, an inner tank device, a tank cover plate device, a control device, a water supply port, a drain port and a power port.The quick pre-cooling and purification residue removal system is designed for overcoming the shortcoming that mushrooms contain microorganisms, mildew, heavy metal, hormone, additives, worm eggs, soil impurities and medicinal residues.Ozone decomposition can be inhibited by the aid of low-temperature control closed or non-closed device environments, quick pre-cooling, sterilization and disinfection and purification residue removal effects can be realized by the aid of volatilization technical principles and low-temperature ozone aqueous solution, and quick pre-cooling, sterilization and disinfection and purification residue removal operation can be implemented.The quick pre-cooling and purification residue removal system and the application have the performance advantages of quick pre-cooling, sterilization and disinfection, purification residue removal, simple structure, safety, easiness in operation and capabilities of keeping the fresh quality and original nutrient substances of mushrooms and reducing weight reduction loss due to rotting, deterioration and damage by worm and the like.

Owner:王宏峰

Rapid pre-cooling and purification residue-removing system of vegetable type plants and application of rapid pre-cooling and purification residue-removing system

InactiveCN105595153AReduce mildewExtend fresh storage timeFood preservationMicroorganismPesticide residue

The invention discloses a rapid pre-cooling and purification residue-removing system of vegetable type plants and application of the rapid pre-cooling and purification residue-removing system. The rapid pre-cooling and purification residue-removing system comprises an outer box body device, an inner box body device, a box body cover plate device, a control device, a water supply end opening, a water discharging port and a power supply port, wherein the outer box body device is arranged at the outer part of the inner box body device; the inner box body device is arranged in the outer box body device; the box body cover plate is arranged above the outer box body device; the control device is arranged at the upper end of the outer box body device; the water supply port is arranged at the upper end of the outer box body; the water discharging port is arranged at the lower end of the outer box body; and the power supply port is arranged at the rear end of the outer box body. The rapid pre-cooling and purification residue-removing system is designed aiming at the disadvantages that vegetables contain microorganisms, mold, ova and pesticide residues. By utilizing a technical principle that a low-temperature controlled sealed or non-sealed device environment can inhibit ozone decomposition and volatilization, and a low-temperature ozone water solution which has the effects of rapidly pre-cooling, sterilizing and disinfecting, purifying and removing residues, sterilization and disinfection, purification and residue removal operation can be realized; and the rapid pre-cooling and purification residue-removing system has the advantages of rapid pre-cooling, purification and residue removal, reduction of rotting and deterioration, simple structure and easiness of operation and the like.

Owner:王宏峰

Rapid pre-cooling and purification and residue-removal system for fresh bamboo shoots and products and application thereof

InactiveCN105707212AExtend fresh storage timeEfficient killingFruits/vegetable preservation by freezing/coolingBiotechnologyMicroorganism

The invention discloses a rapid pre-cooling and purification and residue-removal system for fresh bamboo shoots and products and an application thereof. The rapid pre-cooling and purification and residue-removal system comprises an outer box body device, an inner box body device, a box body cover plate device, a control device, a water supply port, a water drainage port and a power port. The rapid pre-cooling and purification and residue-removal system is designed aiming at the defects that microorganisms cannot be killed in the course of harvesting, storage and transportation and processing of the fresh bamboo shoots, dehydration, enzyme activity, lignification and a mildew loss are not effectively controlled and additives are used; the technical principles that ozone decomposition and volatilization can be inhibited in a low temperature-controlled closed or non-closed device environment and a low temperature ozone water solution has the efficacies of rapid pre-cooling, sterilization and disinfection and purification and residue-removal are adopted to realize operations of rapid pre-cooling and purification and residue-removal for the fresh bamboo shoots. The rapid pre-cooling and purification and residue-removal system has the property advantages that the quality of the fresh bamboo shoots is kept, the loss of original nutrient substances is reduced, the dehydration, the lignification and the putrid loss are reduced, no additive is used, and the structure is simple and easy to operate.

Owner:抚州冰中笋科技有限公司

Device and production process for preparing BOPP (Biaxially-oriented Polypropylene) packaging film

The invention relates to the technical field of BOPP film manufacturing, and discloses a device and a production process for preparing a BOPP (Biaxially-oriented Polypropylene) packaging film. The device for preparing the BOPP packaging film comprises a positioning base, a motor, a thick sheet, a stripping roller, an extrusion die head and an air knife, wherein the positioning base is movably sleeved with a center roller; the center roller is fixedly sleeved with a movable roller; the top of the center roller is fixedly sleeved with a water inlet pipe; and the top end of the water inlet pipe is fixedly connected with a water distribution pipe. According to the device and the production process for preparing the BOPP packaging film provided by the invention, through designing an elastic rubber layer, a cavity, an extrusion plate and a spring, when cooling water in a cooling cavity flows downwards and absorbs heat of a thick sheet to cause temperature rise, the elastic rubber layer is softened, and gas in the cavity is thermally expanded, so that the extrusion plate is lifted upwards, the elastic rubber layer is expanded, a gap of the cooling cavity in an expanded area is reduced, the flow speed of the cooling water is increased, more heat is taken away in unit time, the top and the bottom of the cooling cavity are self-adjusted, and the cooling effect on each part of the thick sheet is uniform.

Owner:QINGDAO ENER PACKAGING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com