Low-temperature propellant rapid pre-cooling transmission pipeline structure

A low-temperature propellant and transmission pipeline technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of increasing the thickness of the gas film layer and affecting the heat exchange effect, etc., and achieve low resistance and low The effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

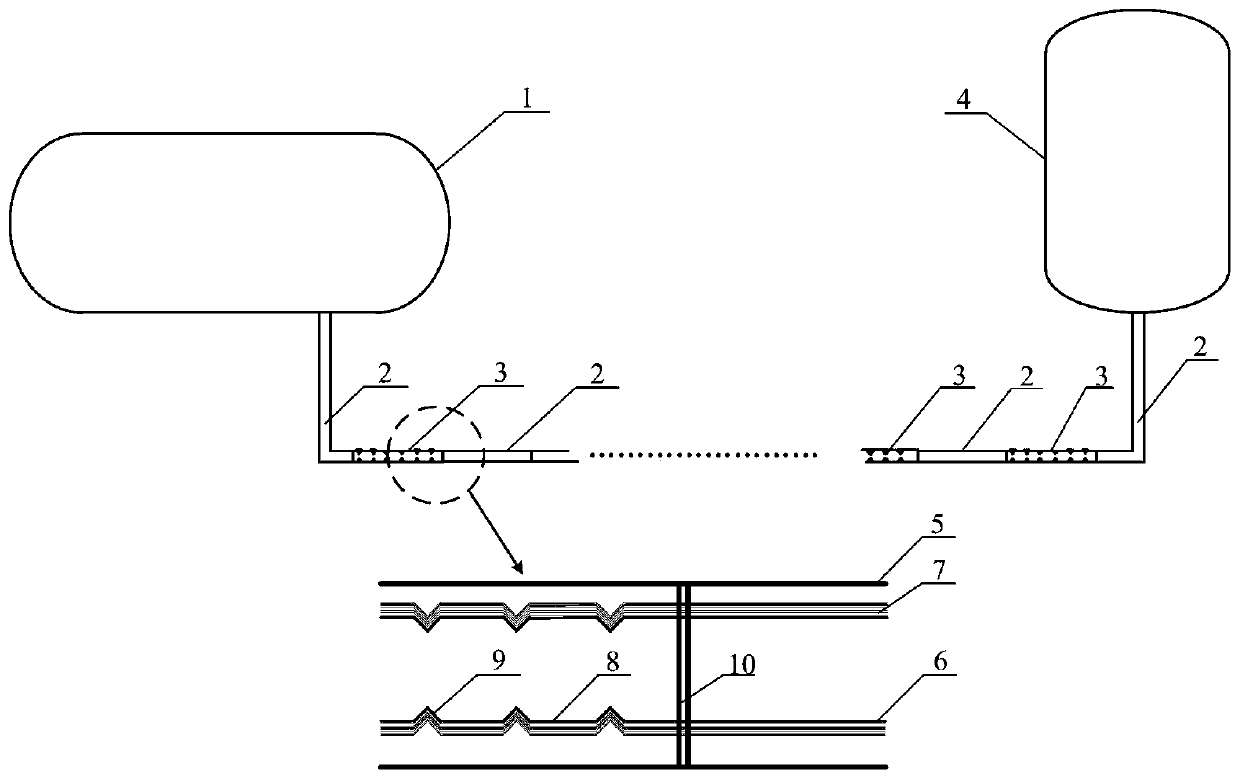

[0026] Such as figure 1 As shown, a cryogenic propellant rapid precooling transmission pipeline structure, including ground storage tank 1, the cryogenic liquid outlet of ground storage tank 1 is connected to the inlet of the low-temperature transmission pipeline, the outlet of the low-temperature transmission pipeline and the storage tank on the arrow The propellant filling port of 4 is connected, and the low-temperature liquid in the ground storage tank 1 is injected into the low-temperature transmission pipeline and cooled and pre-cooled;

[0027] The low-temperature transmission pipeline includes an inner micro-ribbed vacuum tube 3 and a straight vacuum tube 2; the straight vacuum tube 2 is composed of an inner straight tube 6 and an outer tube 5 to form an annular cavity, and the annular cavity is evacuated to reduce the pressure from the outside. The heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com