Fruit and vegetable producing area precooling vehicle

A fruit and vegetable pre-cooling technology, which is applied to vehicle parts, refrigerated cargo transportation, heating/cooling equipment, etc., can solve the problems of shortage, and the pre-cooling technology of fruits and vegetables has not been applied and promoted, and achieves strong mobility and pre-cooling operations High efficiency and fast pre-cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

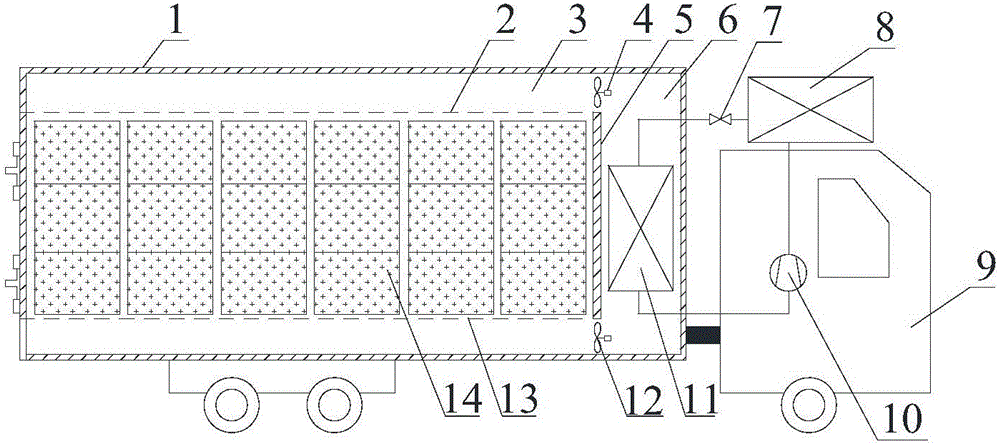

[0015] A pre-cooling car for fruit and vegetable production areas, including a pre-cooling compartment 1, a return air roof 2, a fruit and vegetable pre-cooling chamber 3, a return fan 4, a compartment inner partition 5, an air treatment chamber 6, a throttle valve 7, a condenser 8, and a pre-cooling compartment. Cold car body 9, compressor 10, evaporator 11, air blower 12, air supply floor 13, fruit and vegetable pre-cooling box 14.

[0016] The precooling compartment 1 is on the precooling vehicle body 9 , and the precooling compartment 1 is divided into an air treatment chamber 6 and a fruit and vegetable precooling chamber 3 by an interior partition 5 . The upper position in the fruit and vegetab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com