Interpenetration bypass type laminated rapid pre-cooling throttling refrigerator and control method

A bypass stacking and refrigerator technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of small flow of refrigerators, inability to adapt to the application of cold head temperature, and large heat capacity of specimens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, achievement goals and effects of the present invention easy to understand, the following embodiments will specifically describe the cross-pass type laminated rapid precooling throttling refrigerator and its control method in conjunction with the accompanying drawings.

[0026]

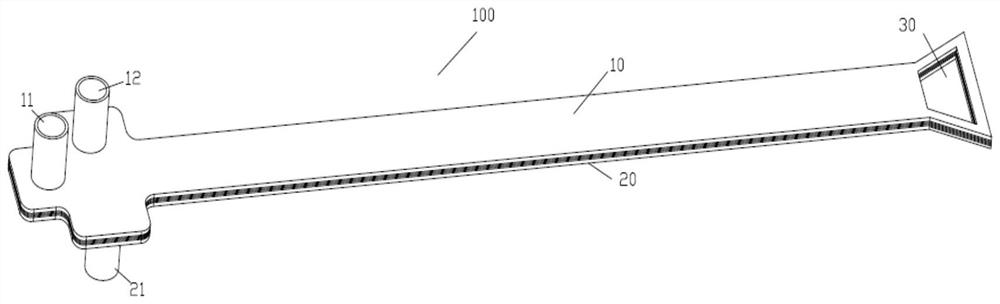

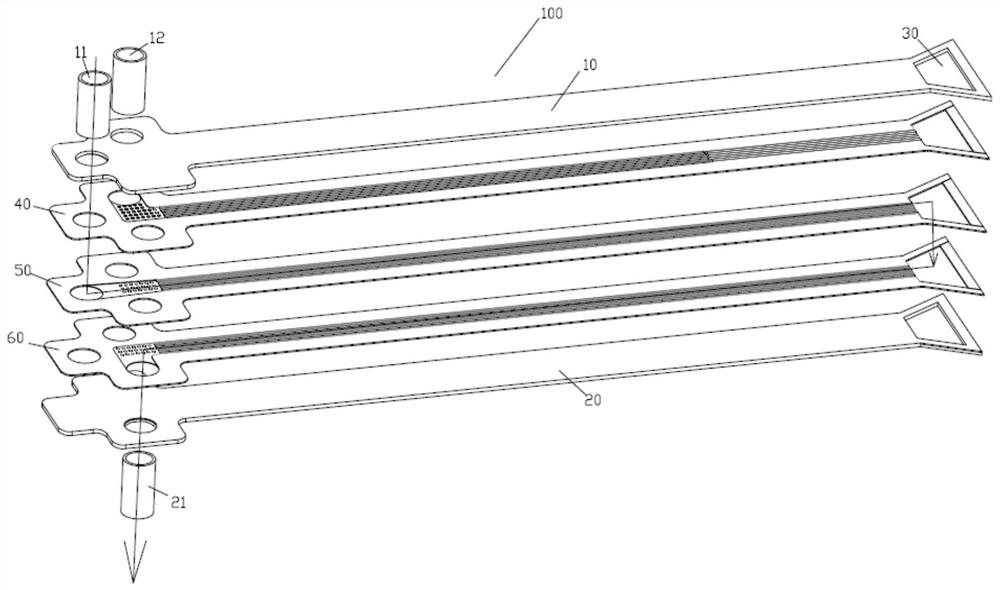

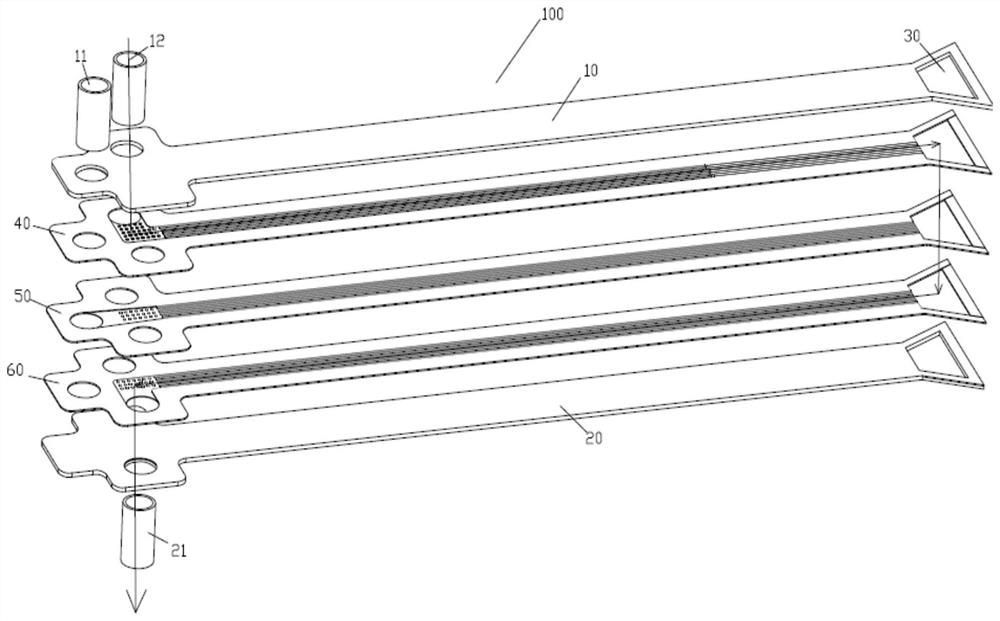

[0027] figure 1 It is a schematic diagram of the appearance of the interspersed bypass type laminated rapid pre-cooling throttling refrigerator in the embodiment of the present invention. figure 2 It is an exploded diagram of the interspersed bypass type laminated rapid pre-cooling throttling refrigerator in the rapid bypass pre-cooling stage in the embodiment of the present invention; image 3 This is an exploded view of the interspersed bypass type laminated rapid pre-cooling throttling refrigerator in the normal refrigeration stage in the embodiment of the present invention.

[0028] like Figures 1 to 3 As shown, this embodiment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com