Mobile vacuum precooling device

A mobile, vacuum technology, applied in the direction of household refrigeration equipment, coolers, cold rooms, etc., can solve the problems of low efficiency and backwardness, and achieve the effect of high economic benefit, high degree of automation, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and embodiments.

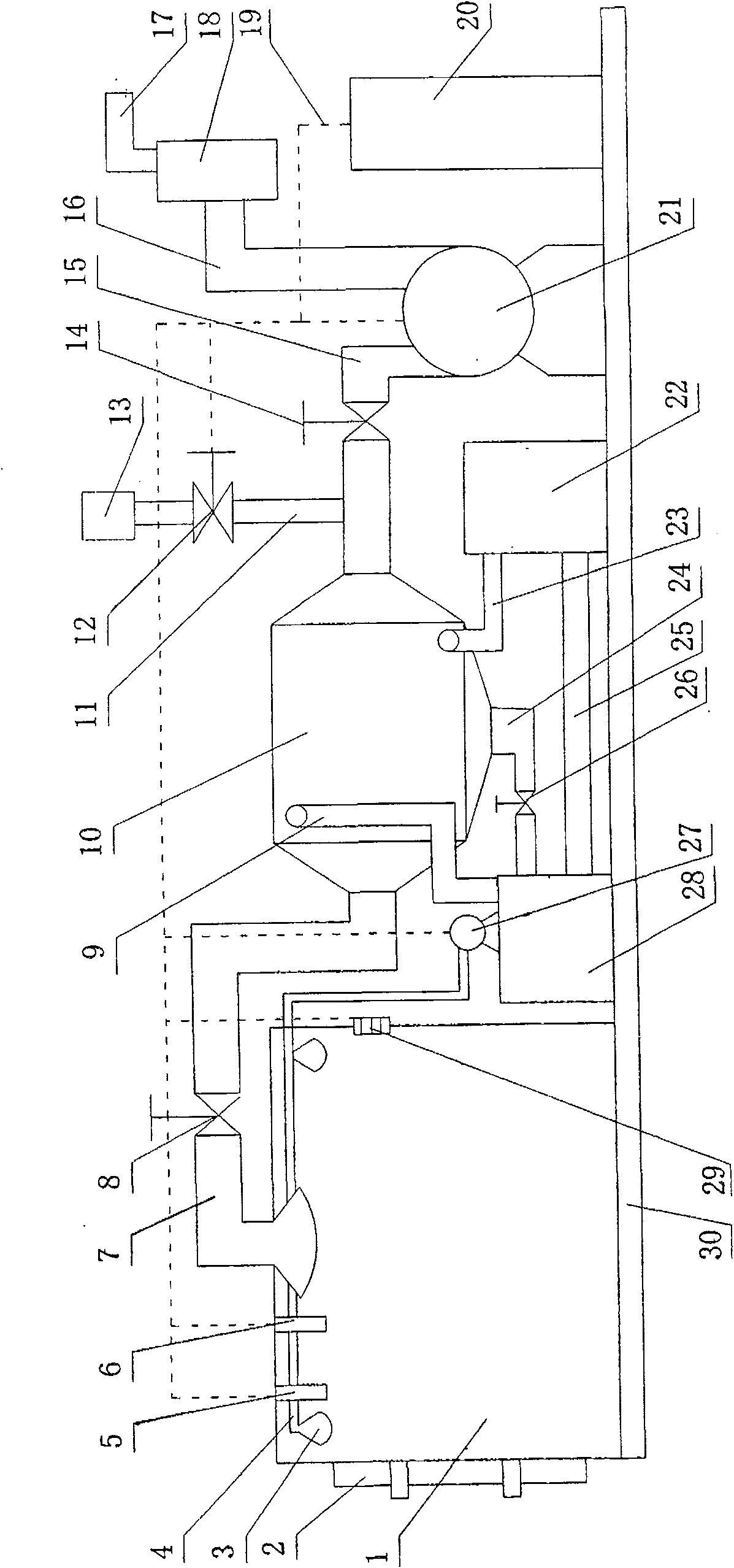

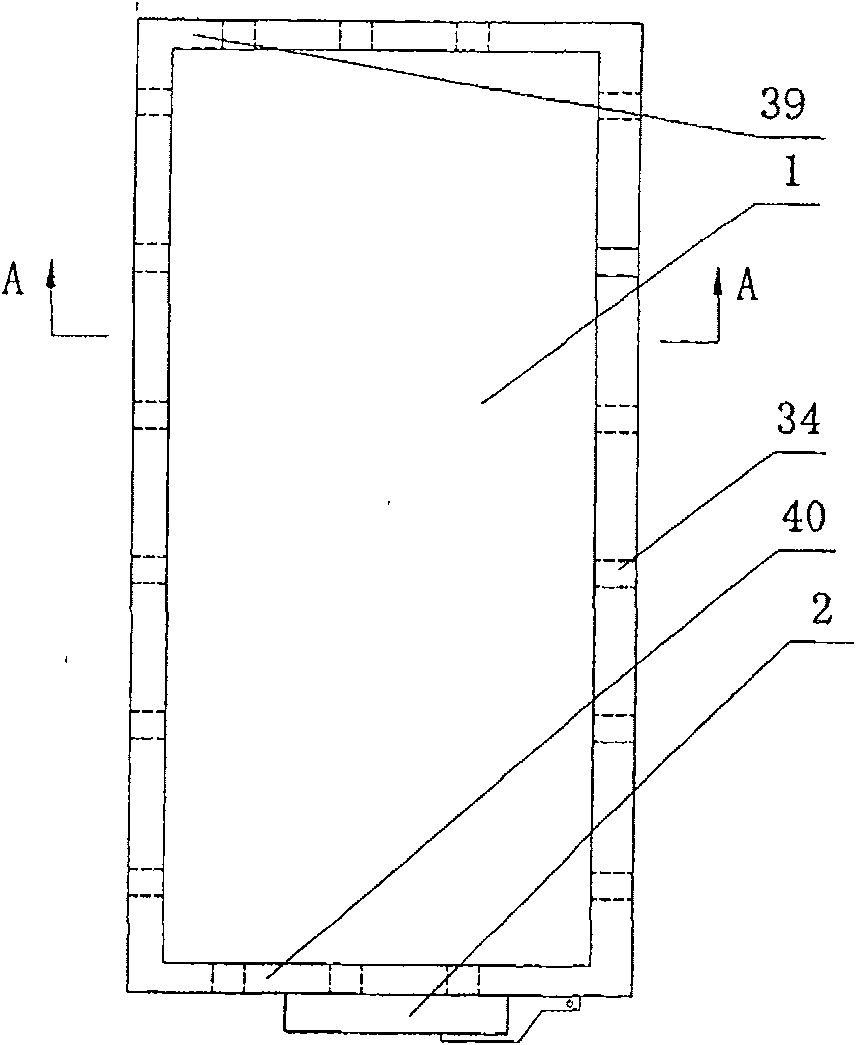

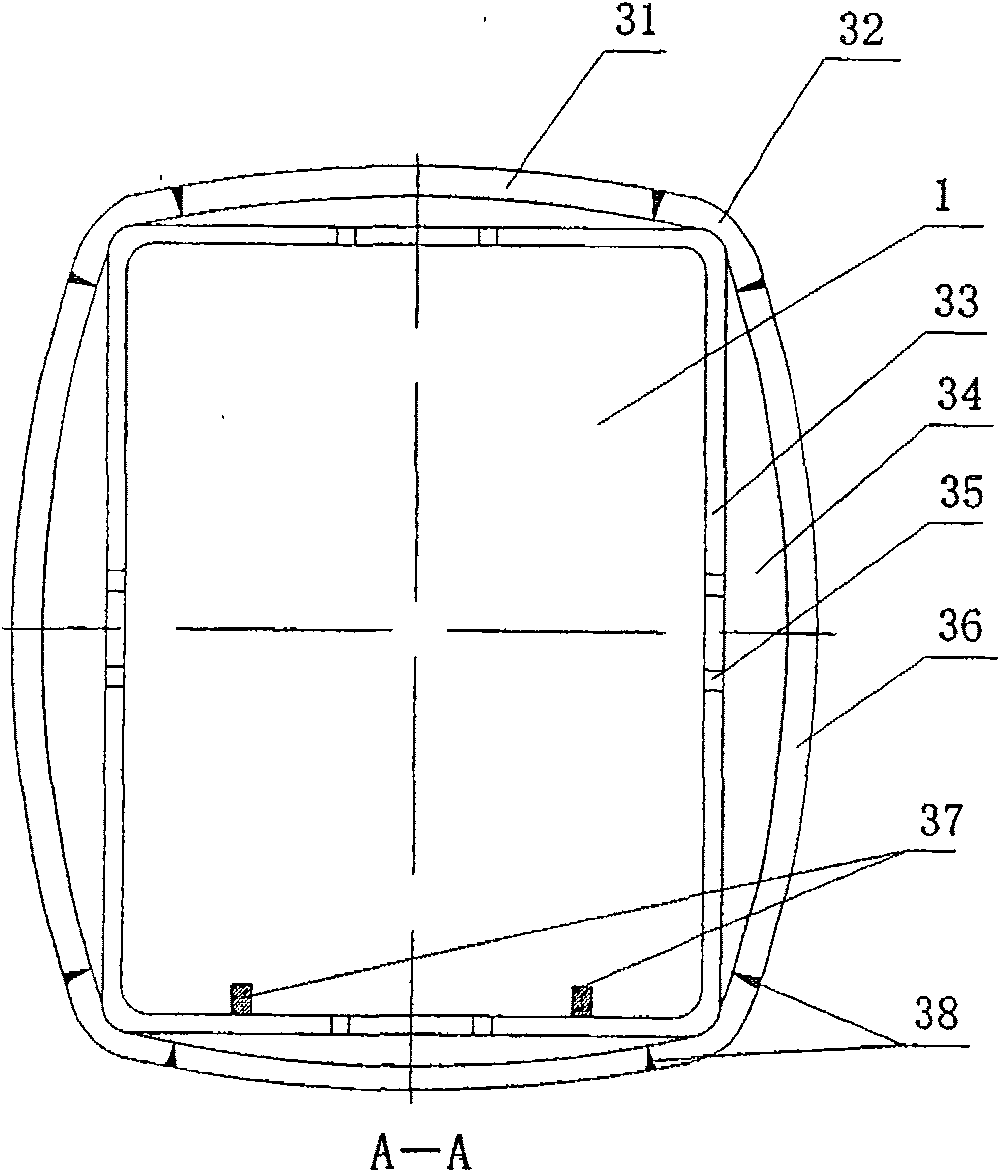

[0019] Such as figure 1 As shown, the present invention has a vacuum tank 1 for vacuum pre-cooling of agricultural products. The vacuum tank 1 is provided with a pressure equalizing device 29 and a quick opening door 2, and the top is provided with a temperature and humidity sensor 5 and a pressure sensor 6; the inlet of the vacuum pump 21 After the rear vacuum pipe 15 and the rear valve 14, it is divided into two paths. One path is connected to the muffler 13 through the intake pipe 11 and the intake valve 12, and the muffler communicates with the atmosphere; the other path is through the water vapor trap 10 and the front valve 8. Connect the front vacuum tube 7 to the vacuum tank 1; the outlet of the vacuum pump 21 is connected to the vacuum gas outlet 17 through the vacuum outlet pipe 16 and the dust collector 18; one end of the refrigerant inlet pipe 9 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com