Rapid pre-cooling and purification and residue-removal system for fresh bamboo shoots and products and application thereof

A technology for products and fresh bamboo shoots, applied in the field of rapid pre-cooling and purification and removal of residue systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

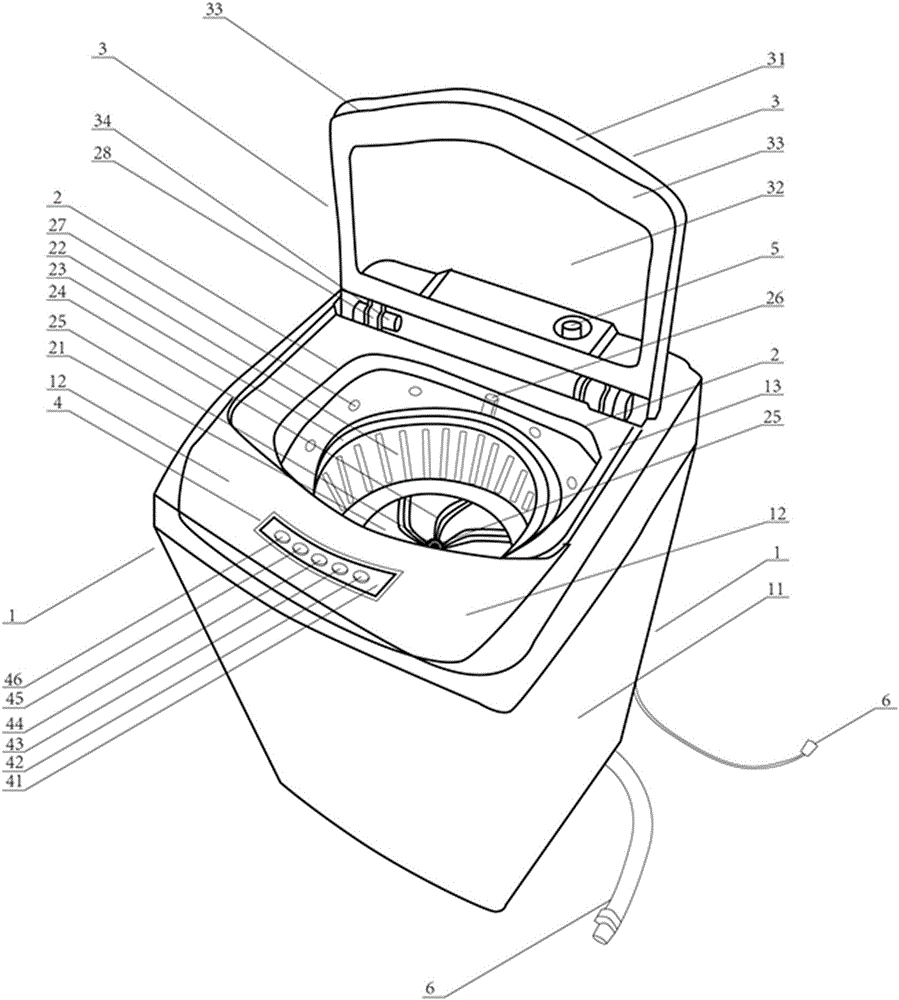

[0081] Referring to accompanying drawing, a kind of fast pre-cooling and purifying and removing residual system of fresh bamboo shoots and products is to realize the embodiment that applies the main structure assembly of the device developed by the present invention through the following steps:

[0082] A rapid precooling, purification and removal system for fresh bamboo shoots and products, comprising an outer box device 1, an inner box device 2, a box cover device 3, a control device 4, a water supply port 5, a drainage port 6 and a power port 7 etc. seven parts. The above-mentioned devices all adopt the OEM production method of component outsourcing and ordering to complete the component assembly procedure of the device of the present invention: the first step is to adopt separate assembly or integrated assembly process according to the application and design requirements, and complete the outer box device 1 set in the inner box The external assembly and connection of the b...

Embodiment 2

[0084] Referring to accompanying drawing, a kind of fast pre-cooling and purification de-residue system of fresh bamboo shoots and products is to realize the embodiment that the device developed by the present invention has the operating procedure performance of rapid pre-cooling purification de-residue through the following steps:

[0085] A rapid pre-cooling and purification system for fresh bamboo shoots and products. After completing the device structure assembly program of the present invention, the application program of the device is completed according to the following operation process: first open the box cover device 3 → put the pre-prepared The fresh bamboo shoots and products removed by cold purification are put into the inner box device 2 → close the box cover device 3 to make the device in an airtight state → start the power switch key 42 on the computer operation panel 41 of the control device 4 to turn on the device power →Start the water supply key 43, accordin...

Embodiment 3

[0087] Referring to accompanying drawing, a kind of fast pre-cooling and purifying and removing residual system of fresh bamboo shoots and products is the embodiment that realizes the airtight heat preservation performance that the device developed by the present invention has through the following steps:

[0088] A rapid pre-cooling and purification system for fresh bamboo shoots and products, which is developed according to the application of the technical principles of the present invention. 1 and the inner box device 2, the heat preservation design scheme of the hollow insulation space, and the airtight panel 33 with airtight heat preservation performance and The airtight heat insulation performance of the thermal insulation material realizes the design purpose of the present invention and the device developed by applying the technical solution of the present invention to have airtight heat insulation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com