Rapid pre-cooling and purification and residue-removal system for fresh bamboo shoots and products and application thereof

A technology for products and fresh bamboo shoots, applied in the field of devices and equipment developed by the technical method of the present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

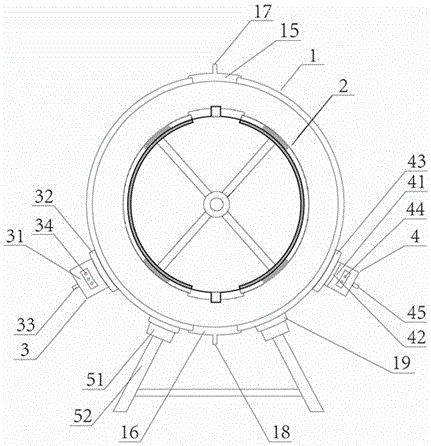

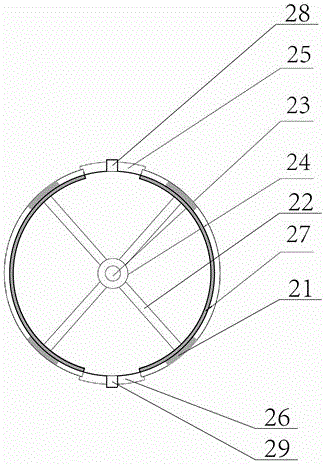

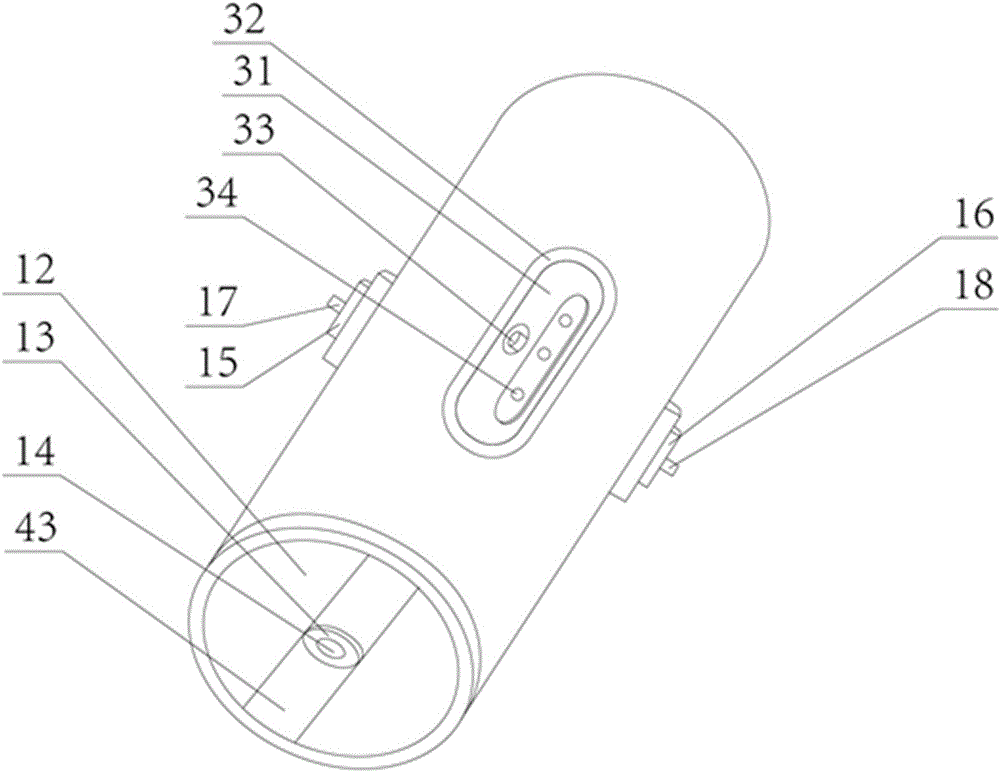

[0080] see Figure 1~Figure 3 , a fast precooling and purification system for removing residues of fresh bamboo shoots and products, is an embodiment of the device structure and assembly of the application of the invention developed by the following steps:

[0081] A rapid precooling and purification and removal system for fresh bamboo shoots and products, comprising five parts: an ozone sterilizing device 1 , a purification and removal device 2 , an ozone supply device 3 , an automatic control device 4 and a support frame device 5 . The above-mentioned 5 devices complete their component assembly procedures in the way of component outsourcing and ordering: the first step, using the component assembly process, respectively complete the ozone sterilization device 1, the purification and removal device 2, the ozone supply device 3, the automatic control device 4, and the support frame The main body structure assembly of device 5 device is assembled; The second step, adopt fitting...

Embodiment 2

[0083] see Figure 1~Figure 3 , a fast pre-cooling and purification and removal system for fresh bamboo shoots and products, which is to complete the rapid pre-cooling, sterilization, purification and removal of fresh bamboo shoots and products, inhibit enzyme activity and decompose heavy metals by the following steps. Examples of applications for hormone and foodborne drug residues:

[0084] A rapid pre-cooling and purification and removal system for fresh bamboo shoots and products, which is to complete the rapid pre-cooling, sterilization, purification and removal of fresh bamboo shoots and products, inhibit the survival of enzymes and decompose heavy metals, hormones and Application of food-borne drug residues: the first step is to put fresh bamboo shoots and products into low-temperature airtight pre-cooling tanks or barrels, and make them all soaked in ice-water critical state or artificially controlled low-temperature ozone aqueous solution , quickly prompting fresh ba...

Embodiment 3

[0086] see Figure 1~Figure 3 , a fast precooling and purification system for fresh bamboo shoots and products, is an embodiment of the present invention to realize the rapid precooling performance of fresh bamboo shoots and products through the following steps:

[0087] A rapid pre-cooling and purification system for fresh bamboo shoots and products, which utilizes the performance principle of low-temperature ozone aqueous solution to quickly reduce the temperature of fresh bamboo shoots and products. The critical state of ice water in the pre-cooling tank or the low-temperature ozone aqueous solution that can artificially control its temperature completes the pre-cooling program for rapidly reducing the temperature of the bamboo shoots, and the device and equipment developed by the present invention and the application of the technical scheme of the present invention are effective for fresh bamboo shoots and bamboo shoots. The design purpose of the rapid pre-cooling performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com