Copper ion antibacterial/antiviral thermosetting powder coating and preparation method thereof

A powder coating and anti-virus technology, applied in powder coatings, antifouling/underwater coatings, polyester coatings, etc., to achieve energy saving, easy promotion, and shorten curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

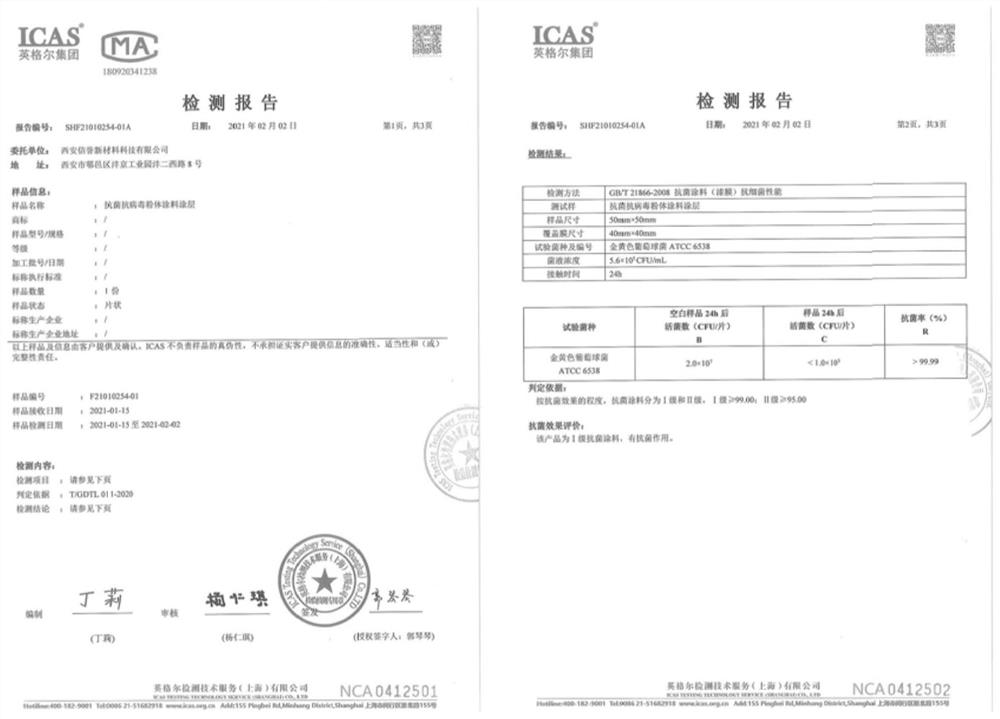

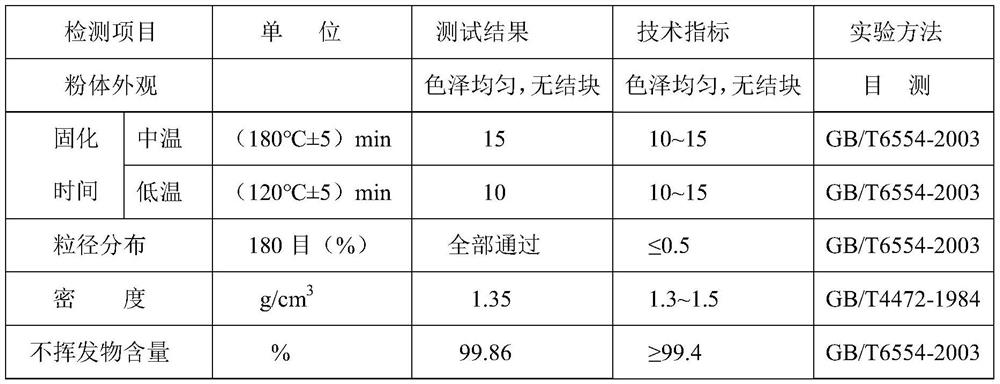

Image

Examples

preparation example Construction

[0037] A preparation method of a copper ion antibacterial / antiviral thermosetting powder coating, comprising the following operations:

[0038] 1) Measuring raw materials according to the composition: 50-70 parts of polyester resin and / or epoxy resin, 0-10 parts of curing agent, 30-50 parts of pigment / filler, 0.3-1 part of accelerator, 3-5 parts 1-2 parts of leveling agent, 1-2 parts of antibacterial nano-copper oxide, 2-4 parts of composite copper oxide antibacterial agent and 1.5-3 parts of antioxidant;

[0039] Place the weighed raw materials in a high-speed mixer and mix them evenly;

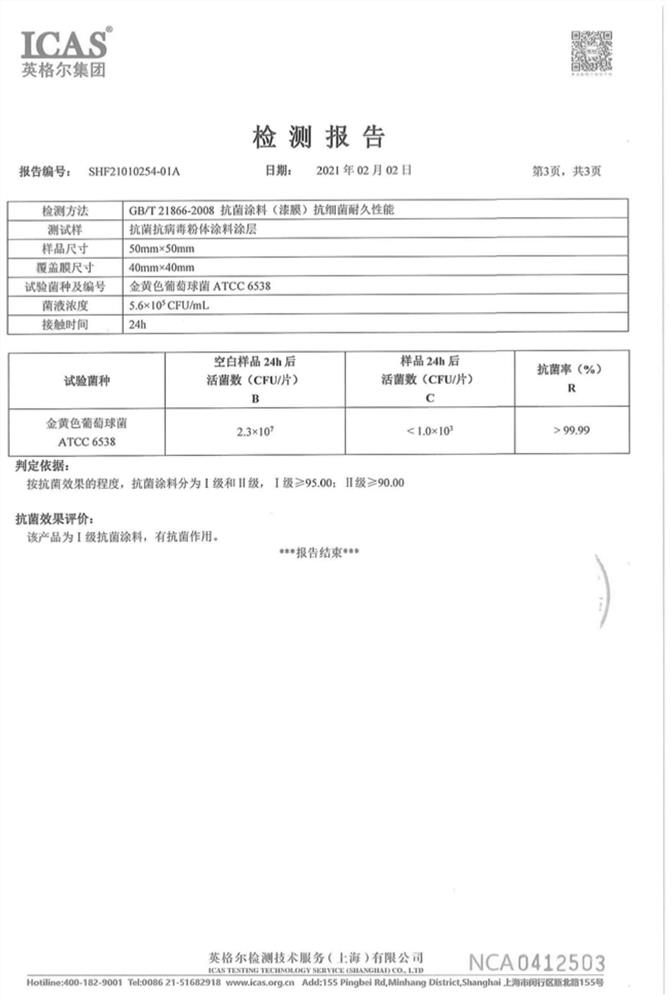

[0040] 2) Put the mixed material into the extruder for hot-melt extrusion, wherein the curing temperature and time of hot-melt extrusion are: 185-195°C, 10-15min to solidify into a film, or 125-135°C, 5- 6min to solidify into film, or 105~115℃, 10~15min to cure into film, or 205~215℃, 8~10min to solidify into film;

[0041] The extruded tablet is cooled at room temperature;

[0042] 3) pu...

Embodiment 1

[0047] An anti-UV pure polyester powder coating for outdoor use, adding copper factor antibacterial nano-copper oxide and composite copper oxide antibacterial agent to the polyester powder coating, the finished product obtained through mixing, hot-melt extrusion, and crushing;

[0048] Composed of the following mass percent raw materials:

[0049] Saturated polyester 50-65%, curing agent 7-8.5%, pigment and filler 38-50%, accelerator 0.3-1%, leveling agent 3-5%, antibacterial nano-copper oxide 1-2%, composite copper oxide Antibacterial agent 2-4%, antioxidant 1.5-3%, anti-ultraviolet agent 2-4%;

[0050] Described pigment, filler are BaSO4, SIO2, mica powder and pigment, can produce the pure polyester powder coating of medium temperature and low temperature curing of outdoor use, and its curing temperature and time are: medium temperature 190 ℃ ± 5 / 15min solidify into Film, low temperature: 130℃±5 / 6min to cure and form a film.

Embodiment 2

[0052] An epoxy / polyester powder coating for indoor modification. In the epoxy / polyester powder coating, copper factor antibacterial nano-copper oxide and composite copper oxide antibacterial agent are added. After mixing, hot-melt extrusion, The finished products obtained by crushing and screening are used for indoor metal coating;

[0053] It is composed of the following mass percentage raw materials: 20-30% epoxy resin, 30-40% polyester resin, 0.5-1% accelerator, 3-5% leveling agent, 40-60% pigment and filler, antibacterial nano-oxidation Copper 1-2%, composite copper oxide antibacterial agent 2-4%, antioxidant 1.5-2%, described pigment, filler are BaSO4, SiO2, CaCO3, and pigment;

[0054] Modified epoxy powder coatings with medium and low temperature curing can be produced. The curing temperature and time are: medium temperature 180°C±5 / 15min, low temperature 130°C±5 / 10min to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com