Saltwater spraying and quick-freezing device

A quick-freezing device and brine technology, applied in food processing, food science, food preservation, etc., can solve the problems of slow heat conduction process, low production efficiency, long freezing channel, etc., achieve high conductivity, improve production efficiency, and improve the quality of frozen products Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

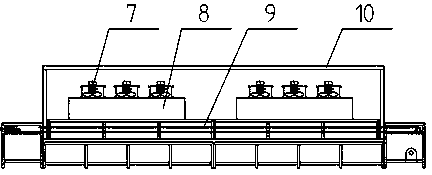

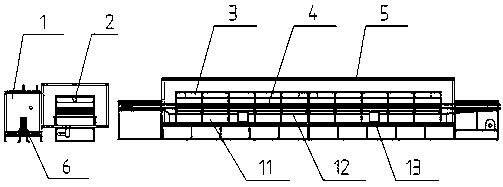

[0013] A salt water spray quick-freezing device, comprising a low-temperature deep-freezing device, said low-temperature deep-freezing device comprising a first insulated box 10, penetrated from the entrance on the left side of the first insulated box 10, The outlet on the right side of the box body 10 passes through the first conveying network 9, and at least one group of refrigerant evaporators 8 are arranged in the first insulated box body 10 and above the first conveying network 9, and the axial flow fan 7 drives the The air in the first thermal insulation box 10 blows over the surface of the evaporator 8 and blows to the first conveying network 9, which is characterized in that it also includes a salt water spray prefreezing device, and the salt water spray prefreeze device Including the second heat preservation box body 5, the second conveying net 4 passing through the entrance on the left side of the second heat preservation box body 5 and passing out from the exit on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com