Vehicle-mounted energy-saving and environment-friendly vacuum rapid precooling equipment for fruit and vegetable

A vacuum fast, energy-saving and environmentally friendly technology, applied in the field of fruit and vegetable cold chain logistics transportation, vacuum application, can solve the problems that the equipment cannot meet the needs of the processing site, can not achieve instant pre-cooling, cannot achieve the best effect, etc., to achieve practicality Strong, reduce gas convection, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

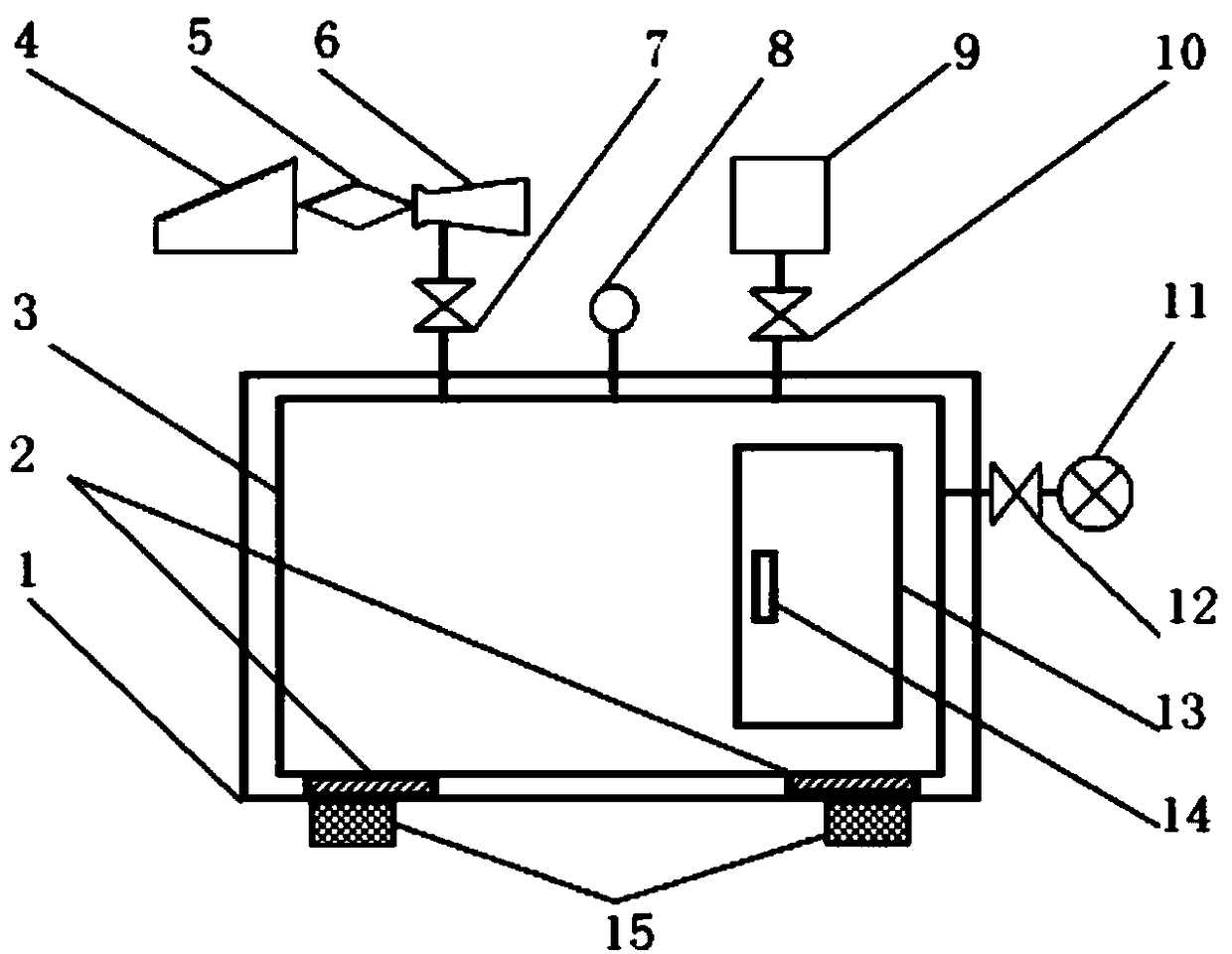

[0036] Such as figure 1 As shown, a vehicle-mounted energy-saving and environment-friendly vacuum rapid precooling equipment for fruits and vegetables includes: a vacuum insulation outer box 1, a honeycomb expansion plate heat sink inner box 3, a vehicle exhaust utilization device 4, a working medium generator 5, a jet pump 6, Differential pressure valve one 7, maintenance pump 9, differential pressure valve two 10, refrigerator 11 and cryogenic valve 12;

[0037] The honeycomb expansion plate heat sink inner box 3 is located inside the vacuum insulation outer box 1, and is used for storing fruits and vegetables; between the vacuum insulation outer box 1 and the honeycomb expansion plate heat sink inner box 3, a vacuum insulation Floor;

[0038] The bottom of the honeycomb expansion plate heat sink inner box 3 is fixedly connected to the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com