In-situ quick precooling machine for fruits

A pre-cooler and fast technology, which is applied in the fields of fruit and vegetable preservation, preservation of fruits/vegetables through freezing/refrigeration, preservation of fruits/vegetables through radiation/electrical treatment, etc., and can solve problems affecting freshness preservation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

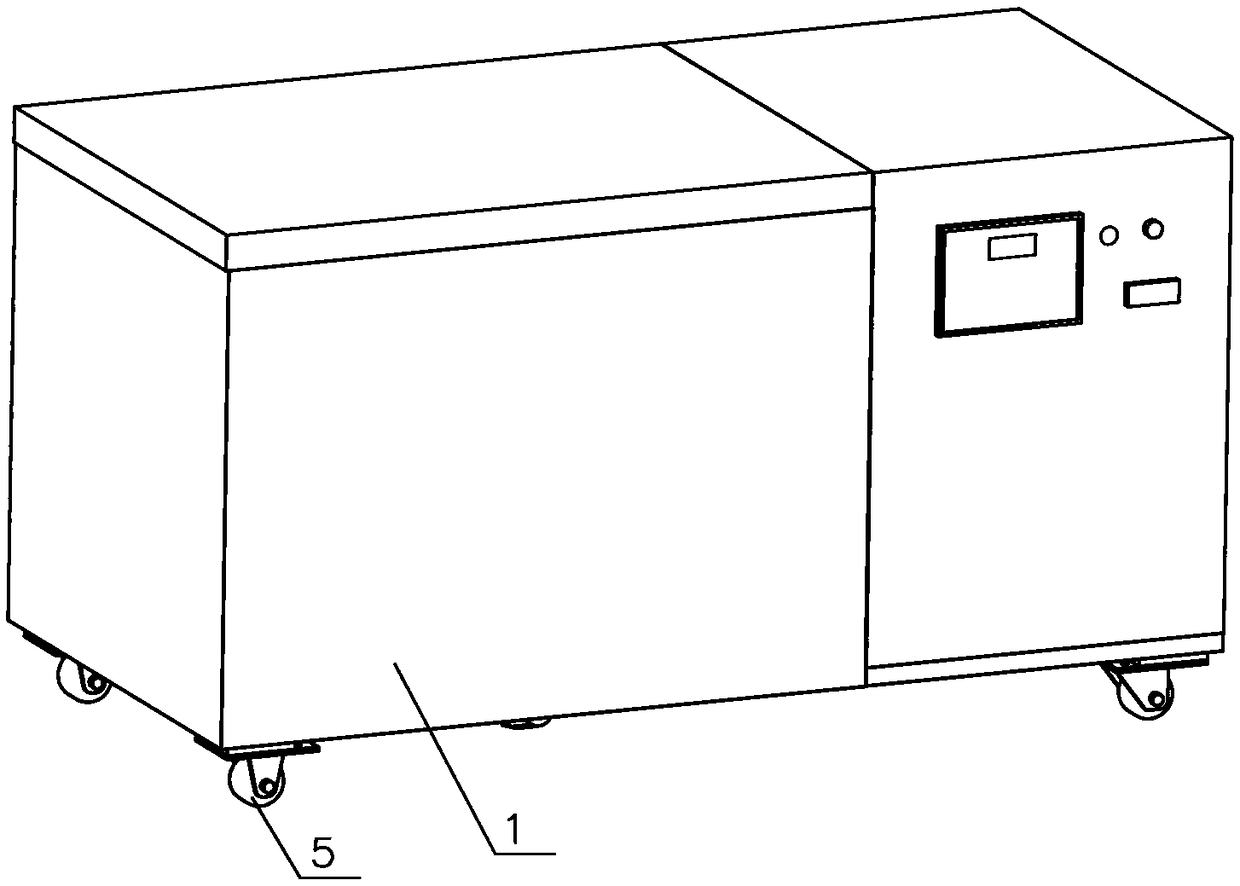

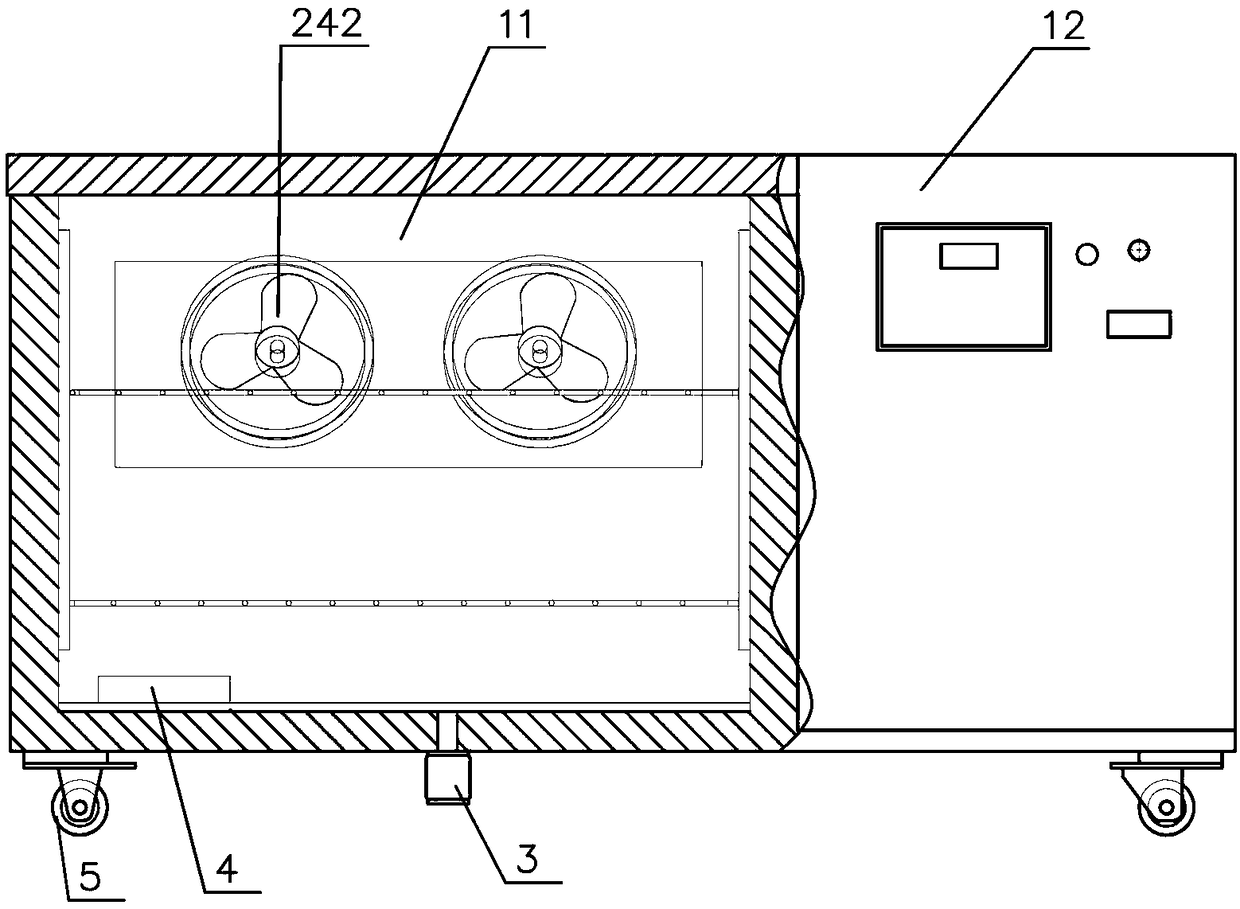

[0011] see figure 1 and figure 2 , the box 1 of the fruit in-situ rapid precooler is a square flat wall structure, filled with high-density insulation materials with stainless steel sheets, including inner walls, outer walls and insulation materials sandwiched between the inner and outer walls, and the inner and outer walls are made of stainless steel plates. The insulation material is polystyrene foam (EPS), which has good insulation performance and light weight of the cabinet. The box body 1 is provided with a pre-cooling chamber 11 and a refrigeration chamber 12 . The bottom of casing 1 is provided with 4 wheels, and the weight of the complete machine is less than 100 kilograms, which is convenient for field transportation.

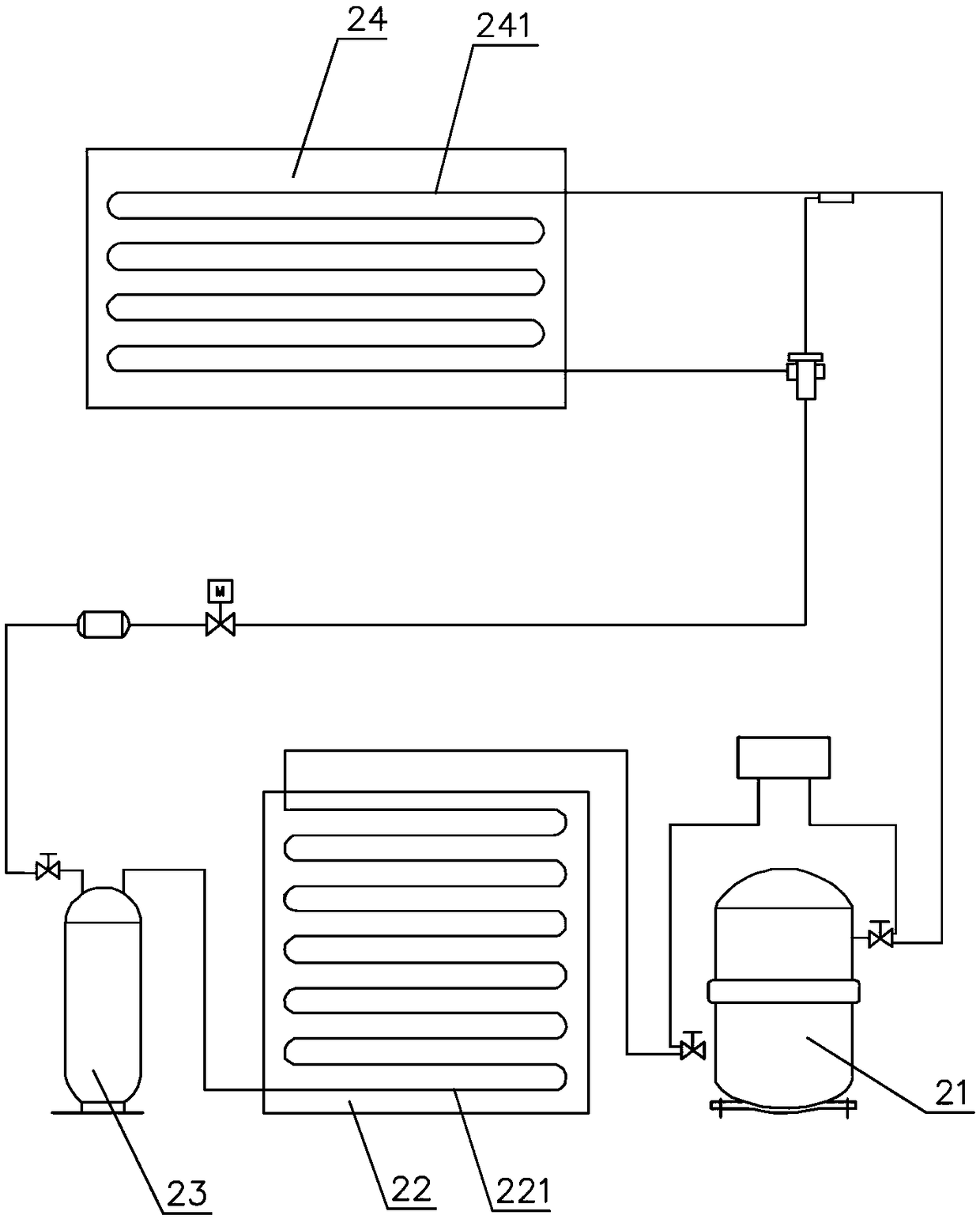

[0012] see image 3 , the refrigerating device includes a compressor 21, a condenser 22, a liquid storage cylinder 23 and an evaporator 24 connected in sequence through pipelines, the compressor 21, the condenser 22 and the liquid storage cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com