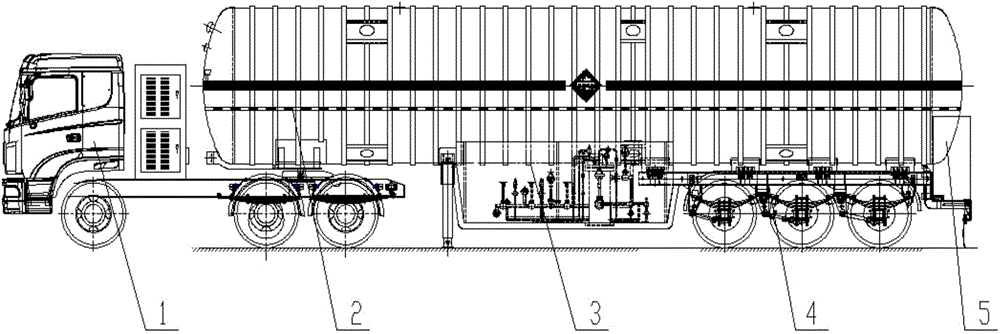

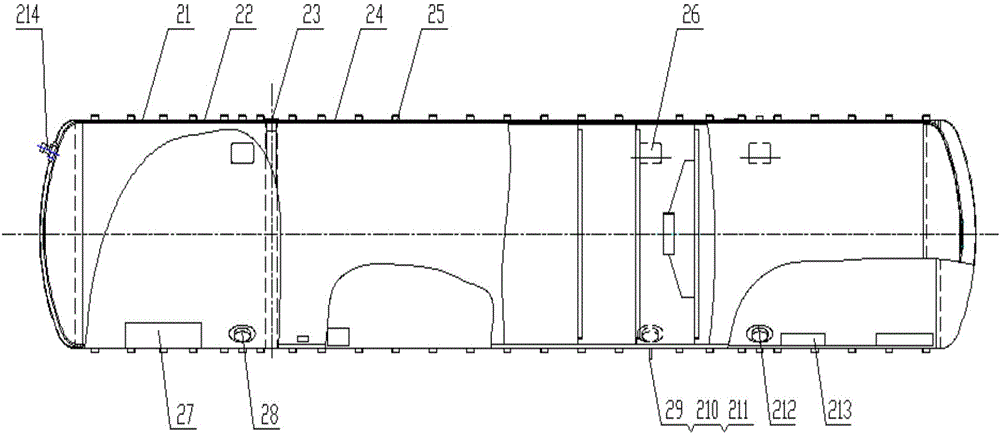

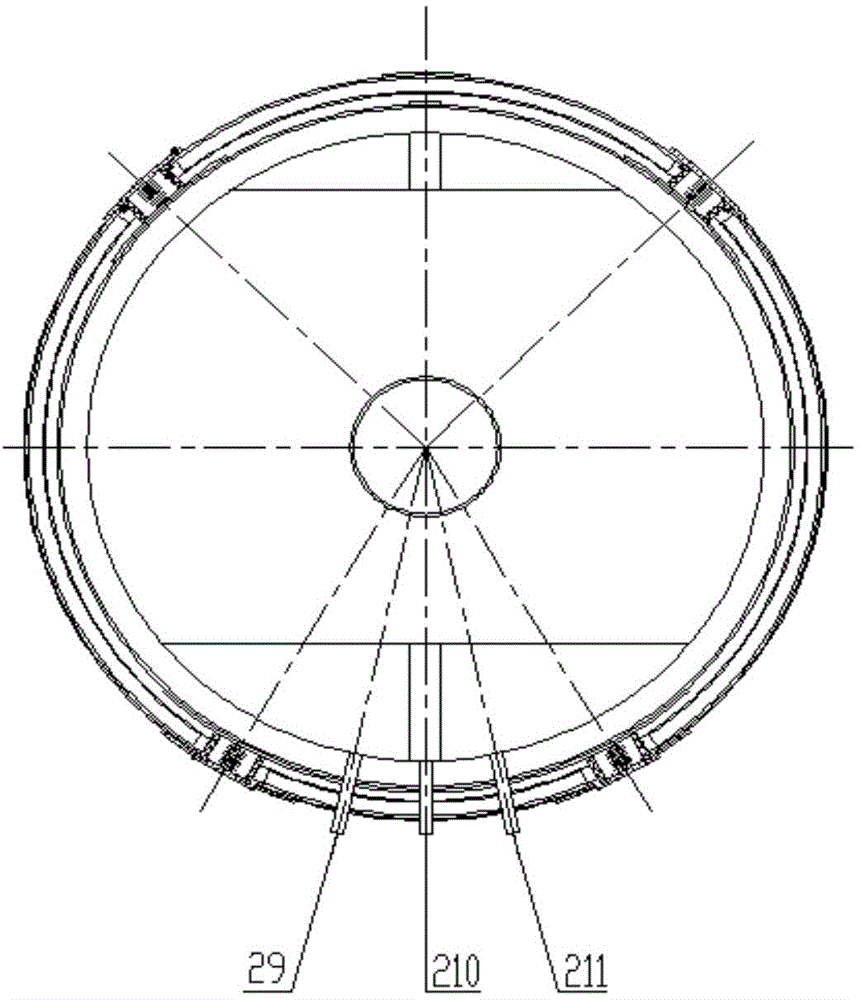

LNG (Liquefied Natural Gas) mobile filling vehicle with filling structure

A filling system and tractor technology, applied in the field of cryogenic liquid vehicles, can solve the problems of long construction period, difficult qualification approval, large investment, etc., and achieve the effect of reducing vertical space, facilitating rapid pre-cooling, and shortening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] Figure 6 It is the first specific embodiment of the present invention, including an LNG mobile filling vehicle 6 , a hose filling gun 7 , and an LNG vehicle 8 . Wherein the LNG mobile filling vehicle 6 is the present invention, connects the filler port of the LNG vehicle 8 through the hose filling gun 7, directly fills the LNG to the LNG vehicle 8 after opening the filling system of the LNG mobile filling vehicle 6, and fills The operation is performed according to the pre-cooling process and filling process described above.

[0036] Figure 7 It is the second specific embodiment of the present invention, including a mobile LNG filling vehicle 6 and a hose filling gun 7 . Wherein the LNG mobile filling vehicle 6 is the present invention, connects the tractor filling port of the LNG mobile filling vehicle 6 through the hose filling gun 7, and directly adds to the tractor vehicle after opening the filling system of the LNG mobile filling vehicle 6. For LNG injection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com