Rigid frame continuous beam of portal pier

A rigid frame and portal technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as cover beams intruding into railway boundaries, reducing the vertical space between the bottom of cover beams and existing railway boundaries, and endangering the safety of railway traffic, etc. , to achieve the effect of reducing the amount of concrete and steel bars, ensuring the railway limit requirements, and reducing the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

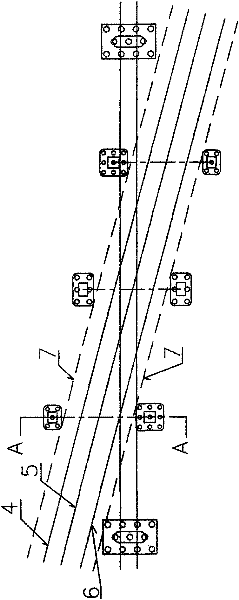

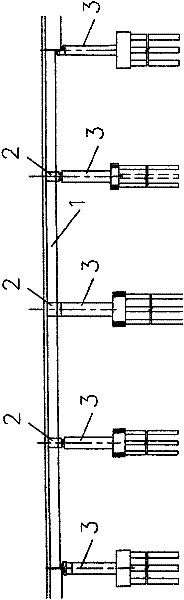

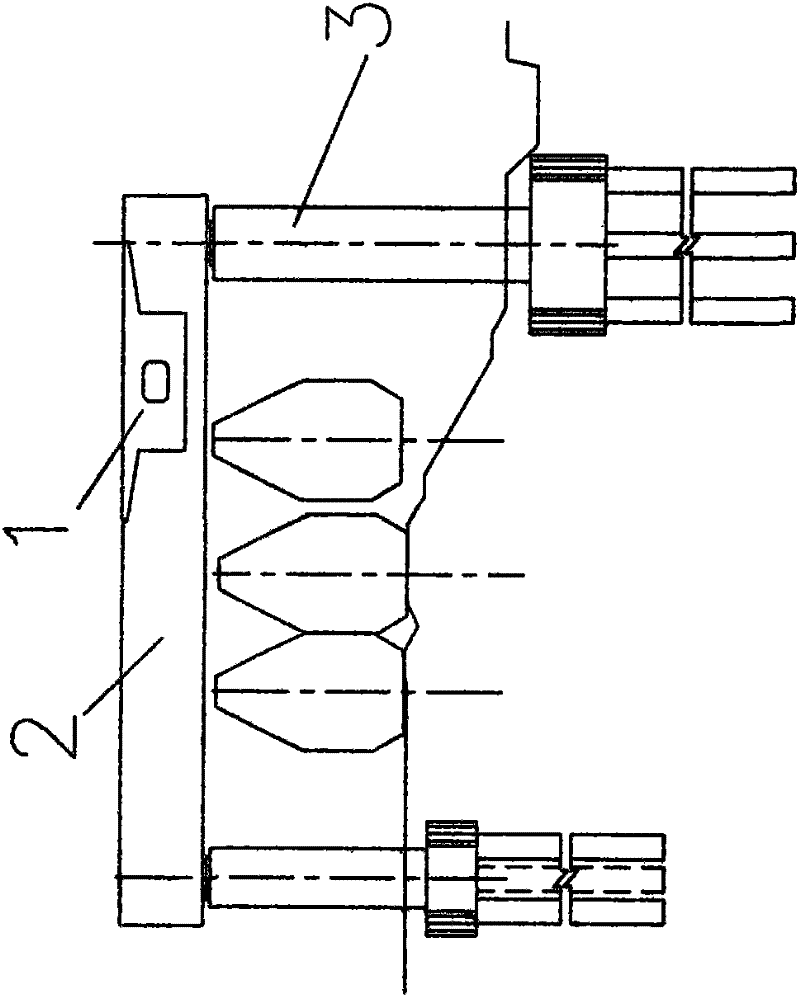

[0015] As shown in the attached figure, it is a rigid frame continuous girder spanning the existing railway line. Its longitudinal direction is rigid frame continuous beam 1, and its lower support structure adopts portal pier 3, and the upper part of portal pier 3 is horizontally arranged. Portal pier cap beam 2. At the junction of the continuous rigid frame beam 1 and the portal pier cover beam 2, the continuous rigid frame beam 1 is embedded in the portal pier cover beam 2, and the continuous rigid frame beam 1 and the portal pier cover beam 2 are integrated by pouring concrete , the upper surface of the rigid continuous beam 1 is flush with the upper surface of the portal pier cap beam or the upper surface of the rigid continuous beam is higher than the upper surface of the portal pier cap beam.

[0016] The other parts of this embodiment ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com