Multipurpose Ti-Ge series alloy with adjustable property for oral cavity and preparation method thereof

A multi-purpose, ti-ge technology, applied in the preparation of titanium alloys, non-toxic medical titanium alloys for oral prosthesis and its preparation, to achieve the effect of promoting the production of red blood cells, reducing the density and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

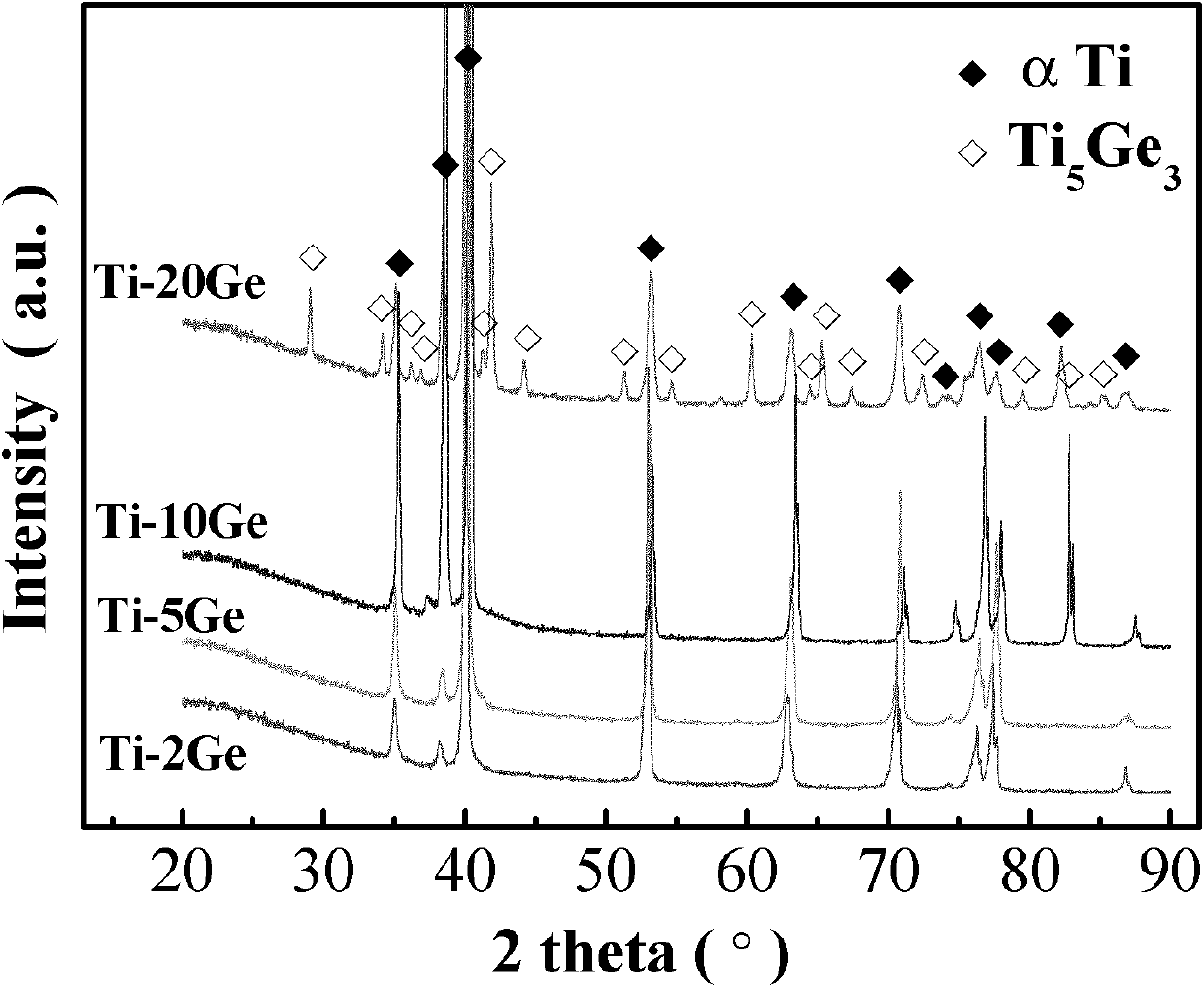

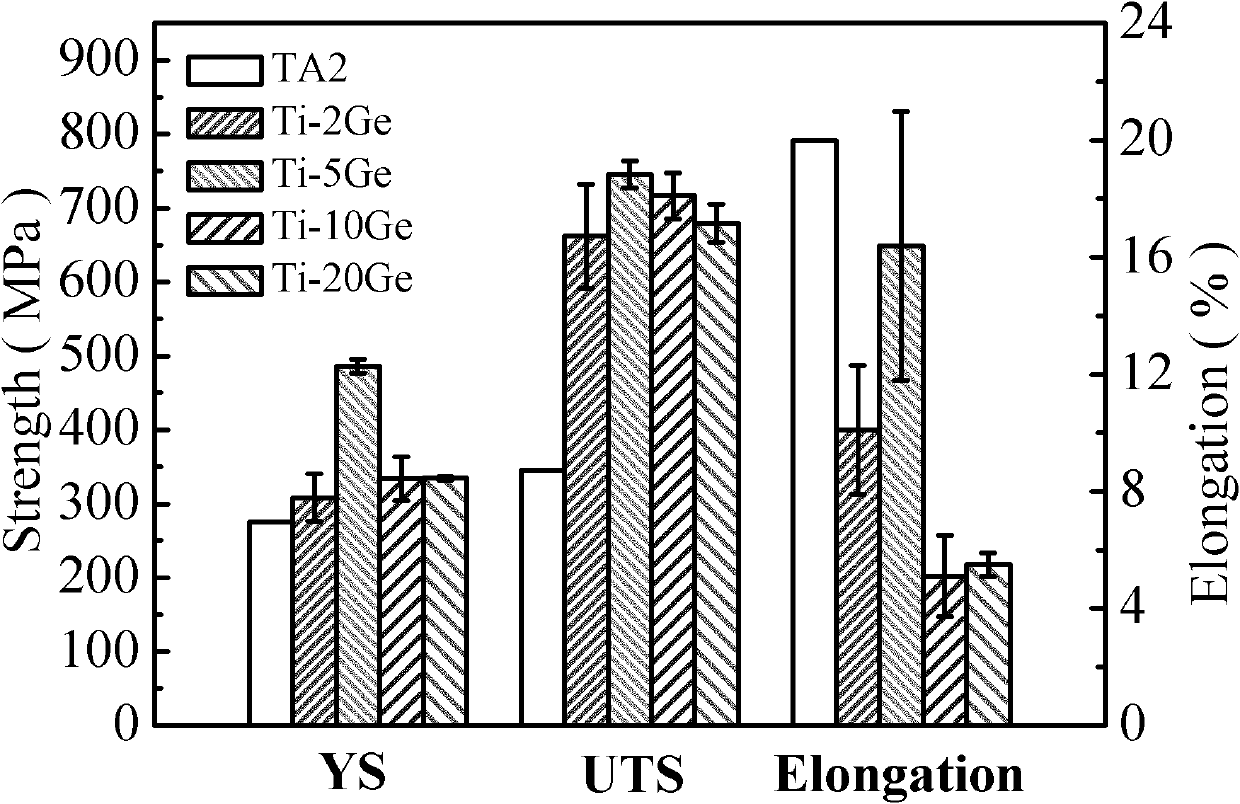

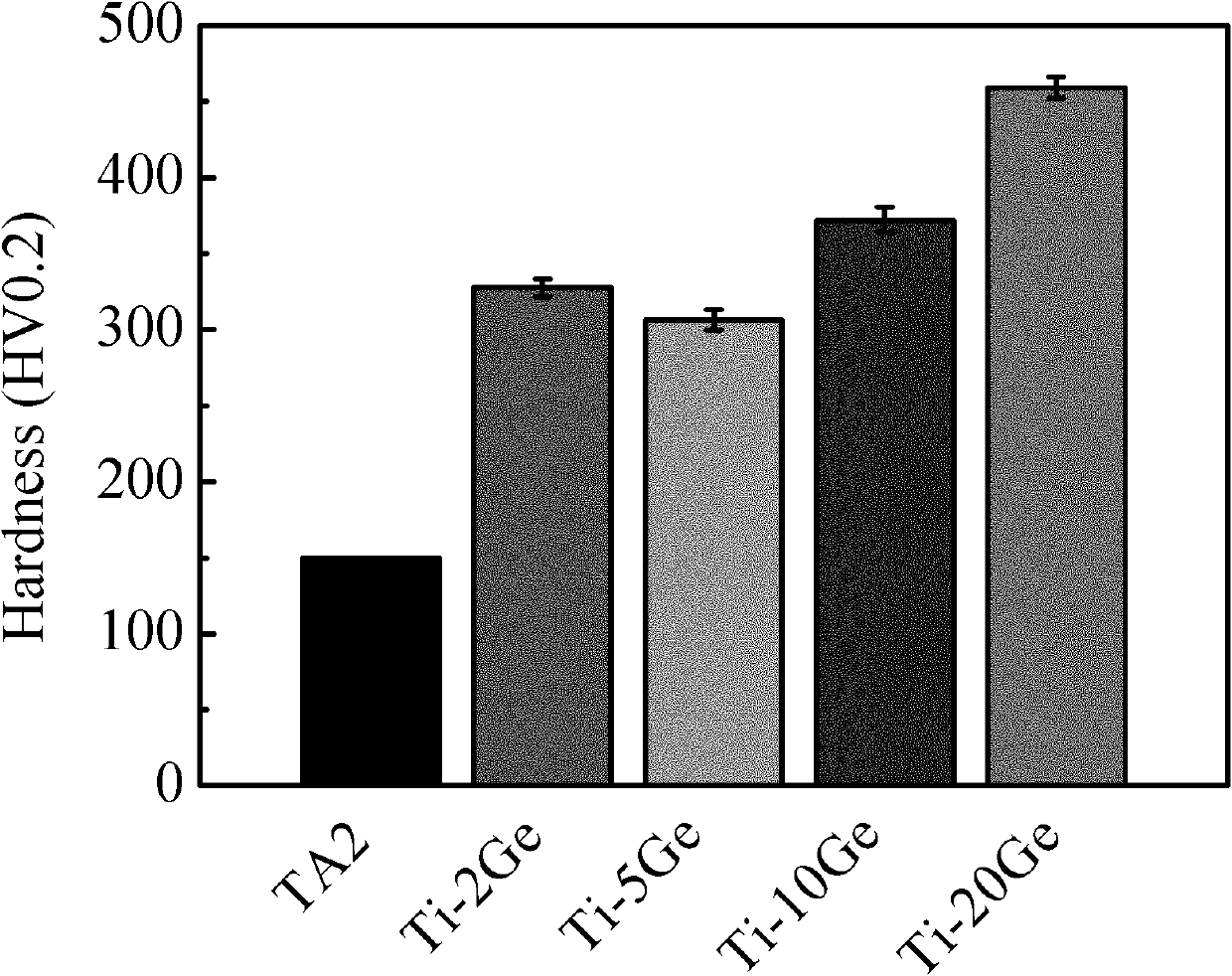

[0021]Example 1: Put 58.8 grams of titanium sponge with a mass of 99.7wt% and 1.2 grams of germanium grains with a mass of 99.9wt% into a water-cooled copper crucible in turn, and use a mechanical pump and a molecular pump to pump out the vacuum non-consumable arc melting furnace. Vacuum to 3×10 -4 Pa, and then poured into 99.999% pure argon gas, argon gas protection was used throughout the melting process, and the pre-placed pure titanium was smelted after the arc was started with a non-consumable tungsten electrode to further remove the oxygen in the vacuum chamber, and then the alloy of the present invention was smelted , the melting current is 500A, the melting voltage is 10V, after the alloy is completely melted, electromagnetic stirring is added for 10s-1min, the electromagnetic stirring current is 15A, the alloy ingot is turned over 180° and remelted 4 times repeatedly to obtain an alloy with uniform composition. After testing, the alloy has a tensile strength of 662MPa...

Embodiment 2

[0022] Example 2: Put 66.5 grams of titanium sponge with a mass of 99.9wt% and 3.5 grams of germanium grains with a mass of 99.99wt% into a water-cooled copper crucible in turn, and use a mechanical pump and a molecular pump to link the vacuum non-consumable arc melting furnace. Vacuum down to 1×10 -4 Pa, and then poured into 99.999% pure argon gas, argon gas protection was used throughout the melting process, and the pre-placed pure titanium was smelted after the arc was started with a non-consumable tungsten electrode to further remove the oxygen in the vacuum chamber, and then the alloy of the present invention was smelted , The melting current is 750A, the melting voltage is 15V, after the alloy is completely melted, electromagnetic stirring is added for 10s-1min, the electromagnetic stirring current is 17A, the alloy ingot is turned over 180° and remelted 5 times repeatedly to obtain an alloy with uniform composition. After testing, the tensile strength of the alloy is 74...

Embodiment 3

[0023] Example 3: 54 grams of titanium sponge with a mass of 99.7wt% and 6 grams of germanium grains with a mass of 99.99wt% were placed in a water-cooled copper crucible in turn, and a mechanical pump and a molecular pump were used to link the vacuum non-consumable arc melting furnace. Vacuum down to 1×10 -4 Pa, and then poured into 99.999% pure argon gas, argon gas protection was used throughout the melting process, and the pre-placed pure titanium was smelted after the arc was started with a non-consumable tungsten electrode to further remove the oxygen in the vacuum chamber, and then the alloy of the present invention was smelted , The melting current is 750A, the melting voltage is 15V, after the alloy is completely melted, electromagnetic stirring is added for 10s-1min, the electromagnetic stirring current is 17A, the alloy ingot is turned over 180° and remelted 6 times repeatedly to obtain an alloy with uniform composition. After testing, the tensile strength of the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com