Technique for preparing advanced ultra-super critical heat-resisting alloy

An ultra-supercritical, heat-resistant alloy technology, applied in the field of heat-resistant alloy smelting, can solve the problem that harmful elements cannot be effectively eliminated, and achieve the effects of dispersed inclusions, small inclusions, and reduced burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In view of the requirements of advanced ultra-supercritical conditions on the purity of materials for heat-resistant alloys, the inventors have confirmed through a large number of experiments that the use of vacuum induction furnace melting to achieve more precise control of alloy elements, and the use of a protective atmosphere of argon to isolate oxygen to prevent Burning of easily oxidized elements during smelting, by adding excessive carbon and aluminum, the oxygen content in heat-resistant alloys can be effectively reduced, and harmful elements such as P and S can be effectively reduced through subsequent electroslag remelting under a protective atmosphere, and segregation can be improved It makes the alloy uniform and improves the compactness, thus establishing a new process of advanced ultra-supercritical heat-resistant alloy.

[0034] It mainly uses vacuum induction furnace and protective atmosphere electroslag remelting to smelt advanced ultra-supercritical heat...

Embodiment 2

[0050] The smelting equipment used in this embodiment is a 30kg vacuum induction furnace and a 50kg protective atmosphere electroslag remelting furnace. Among them, the ultimate vacuum degree of the vacuum induction furnace is 0.1Pa, the rated power of the power supply is 50kW, and the furnace loading capacity is 20.0kg to 21.5kg; The weight of the consumption electrode is 25kg~50kg.

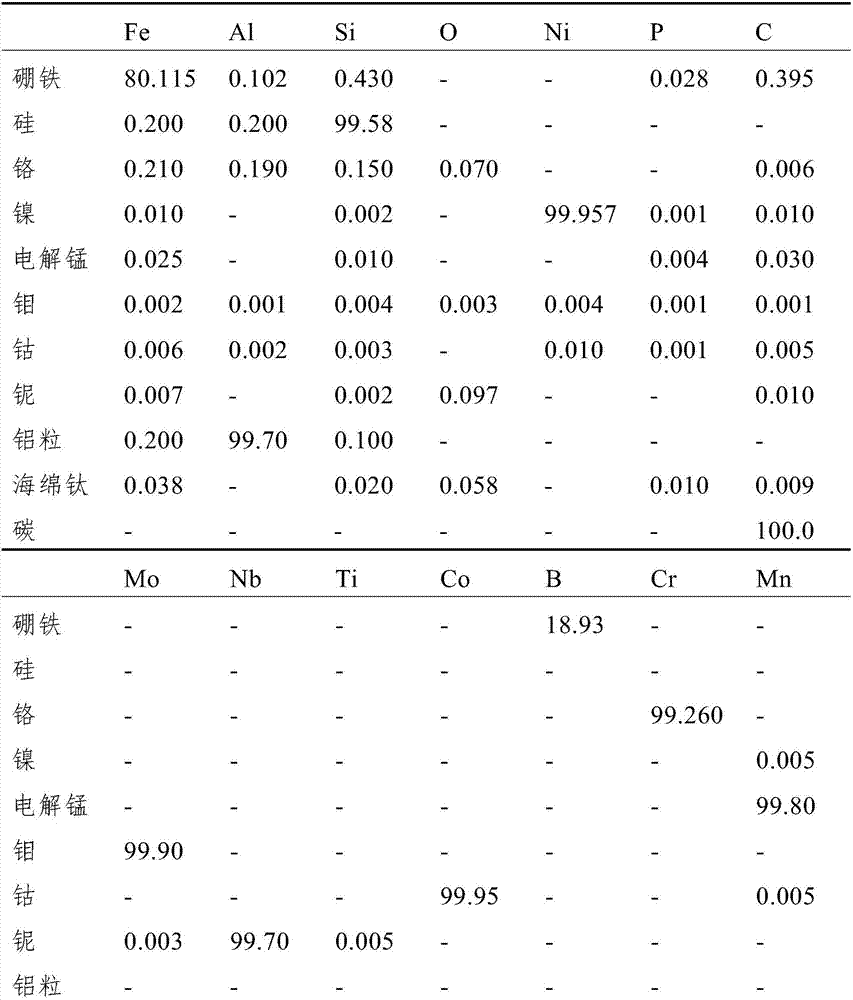

[0051] The main components of the smelting raw materials used in this example are shown in Table 1.

[0052] Table 1 Main components of smelting raw materials / wt%

[0053]

[0054]

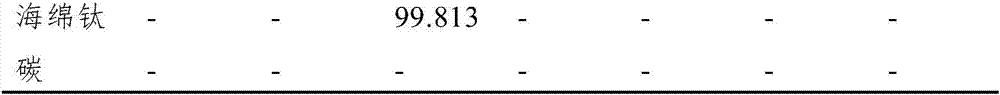

[0055] Vacuum induction furnace and protective atmosphere electroslag remelting are used to smelt the advanced ultra-supercritical heat-resistant alloy Inconel740H. The control range and target of the alloy composition are shown in Table 2, and the content in the table is the weight percentage.

[0056] Table 2 Inconel740H alloy composition control range and target / wt.%

[0057]

[0058] Specific steps a...

Embodiment 3

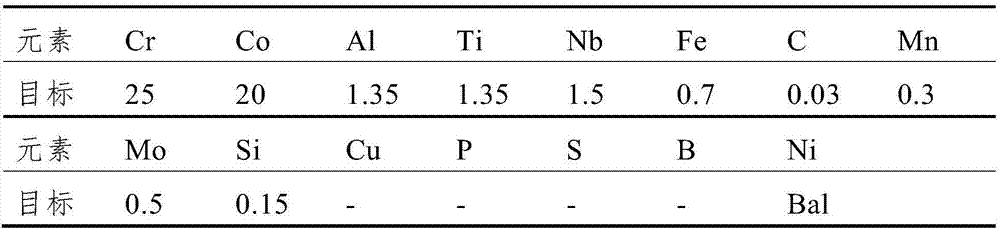

[0076] This example is an advanced ultra-supercritical heat-resistant alloy GH4700 prepared on the basis of Example 2, and its target composition control is shown in Table 5.

[0077] Table 5 GH4700 alloy target composition control / wt.%

[0078]

[0079] 1) Vacuum induction furnace melting stage:

[0080] (1) Ingredients and charging: ingredients according to alloy requirements, smelting raw materials and their quality are specifically nickel 10206.18g, chromium 5037.27g, cobalt 4002.00g, molybdenum 100.09g, niobium 300.91g, electrolytic manganese 63.91g, silicon 2.11g, carbon 7.91g, aluminum 309.09g, sponge titanium 316.45g. Among them, carbon and aluminum particles are added 0.03% and 0.3% respectively on the basis of the target composition for deoxidation. The furnace metal is added in sequence: nickel, cobalt, molybdenum, chromium, and niobium; the alloys that are added to the hopper in sequence include: carbon, deoxidizer aluminum, alloyed aluminum, silicon, titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com