Preparation method for Fe3O4 nano particles

A technology of nanoparticles and particles, which is applied in the field of nanomaterials to achieve excellent performance and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Small size Fe 3 O 4 Synthesis of Nano Magnetic Particles:

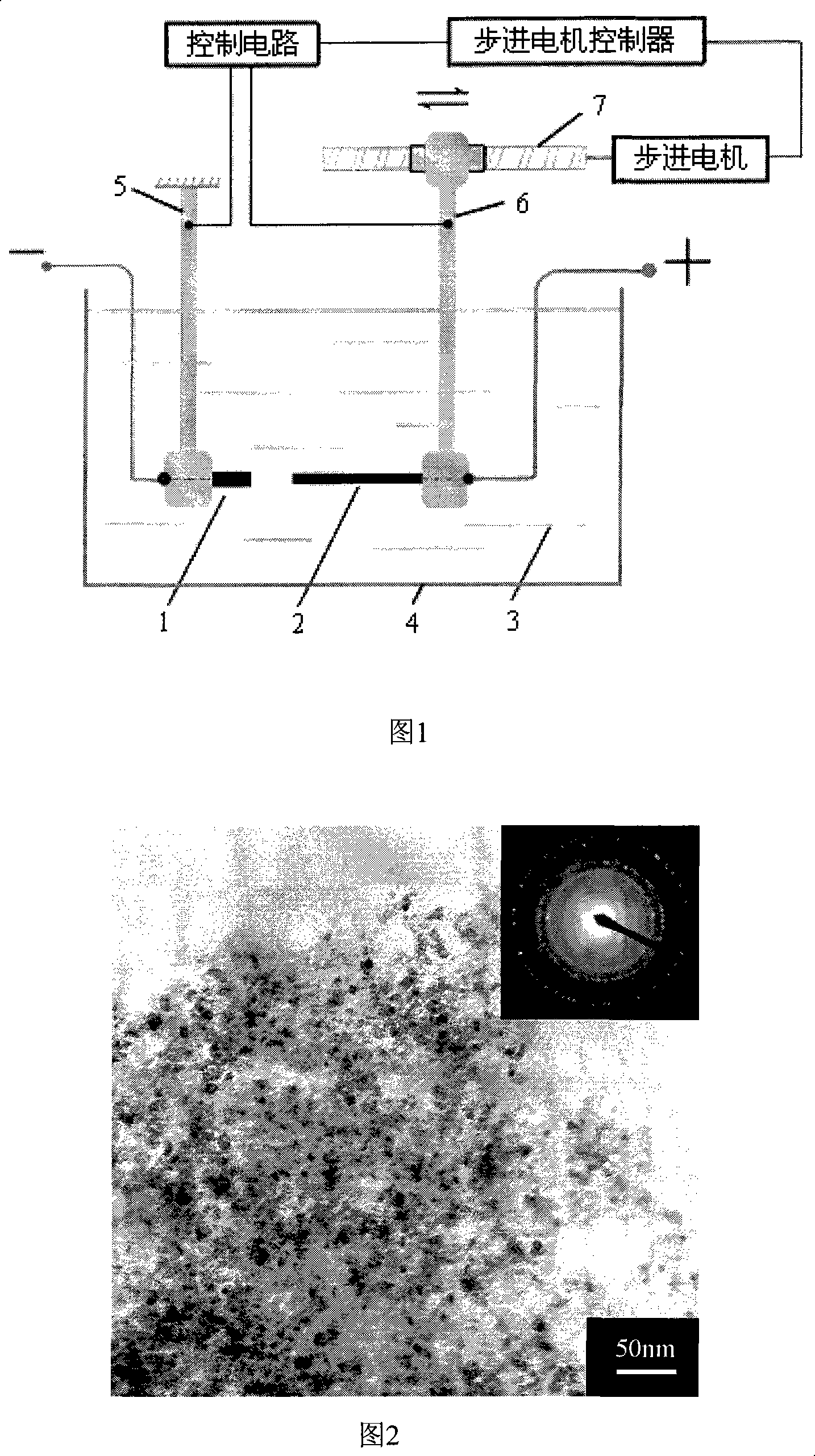

[0026] Using the equipment shown in FIG. 1, the material of the cathode electrode 1 is a spectral pure graphite rod, and the material of the anode electrode 2 is an industrial pure iron metal rod. Place the two poles in a reaction vessel 4 filled with deionized water 3, align the centers and maintain a certain initial distance. 5 and 6 are the holders of the cathode and anode respectively, and 7 is the guide rail, which is used to drive the anode forward and backward. Use DC power supply and adjust the distance between the two poles in time through the self-feedback system to maintain a stable output voltage and generate a stable arc between the cathode and anode. The self-feedback system includes a control circuit and a stepper motor controller; the detection signal input end of the control circuit is connected to the clamper of the cathode and anode, and the control signal input end of the stepper moto...

Embodiment 2

[0032] Example 2: Fe with an average particle size of about 20nm 3 O 4 Synthesis of Nano Magnetic Particles:

[0033] Other experimental conditions are the same as in Example 1. The power supply parameters are set as: discharge current: 60A, discharge current density: 2.1A / mm 2 ; Discharge voltage: 19V.

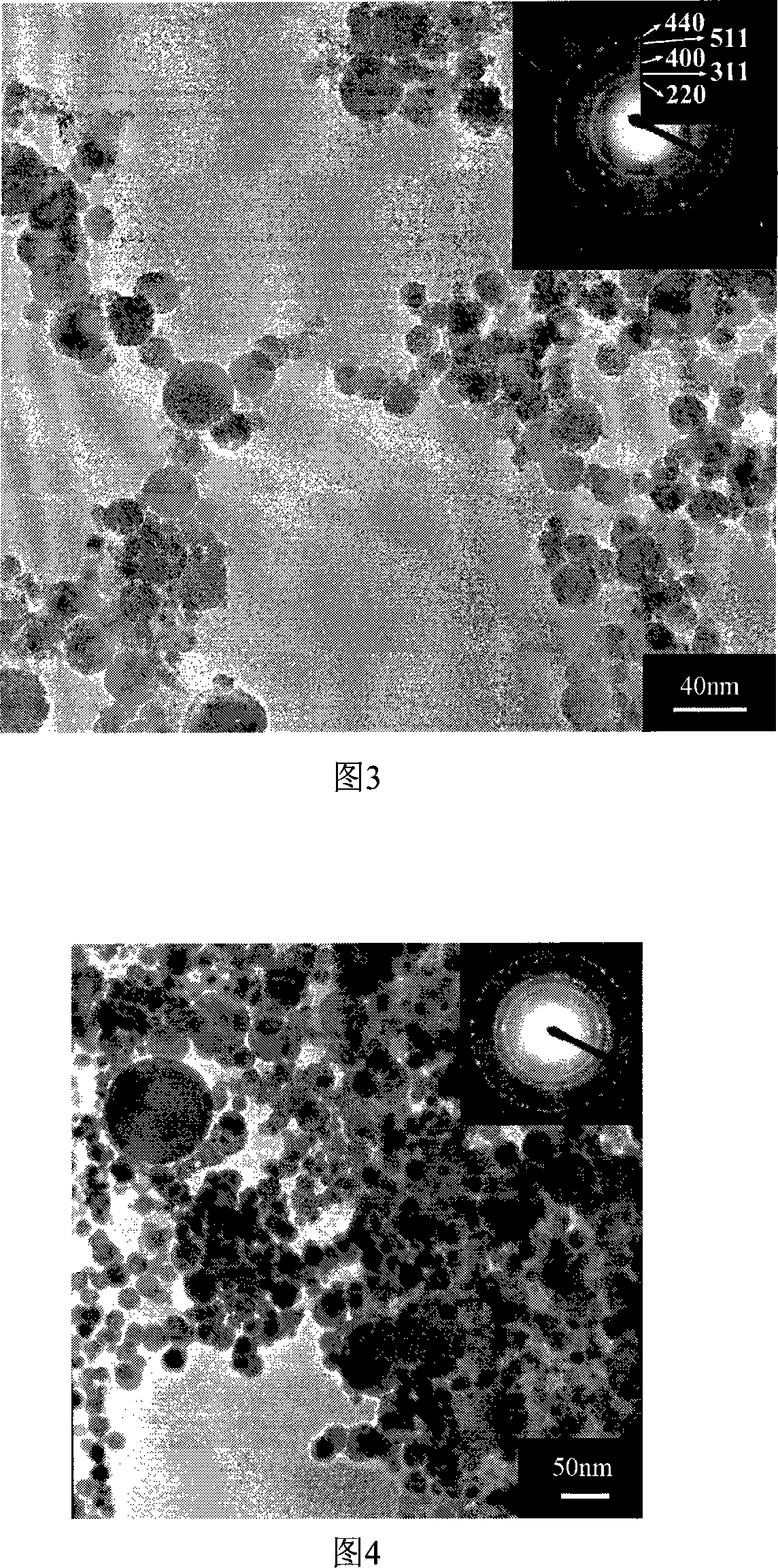

[0034] Fe prepared 3 O 4 The nano particles are basically spherical, the particle size is basically distributed in the range of 15-35nm, and the average size is about 20nm. About 80% of the product is spherical Fe 3 O 4 Nano particles, and a small amount of nano carbon film. The saturation magnetization of the product is about 64.97emu / g. Figure 3 shows that the discharge current is 60A, and the discharge current density: 2.1A / mm 2 , The morphology of the synthesized product when the output voltage is 19V. The upper corner inset in the figure shows the electron diffraction pattern of the product, indicating that the product is Fe3 O 4 Nano particles. Example 3: Fe with an average...

Embodiment 3

[0034] Fe prepared 3 O 4 The nano particles are basically spherical, the particle size is basically distributed in the range of 15-35nm, and the average size is about 20nm. About 80% of the product is spherical Fe 3 O 4 Nano particles, and a small amount of nano carbon film. The saturation magnetization of the product is about 64.97emu / g. Figure 3 shows that the discharge current is 60A, and the discharge current density: 2.1A / mm 2 , The morphology of the synthesized product when the output voltage is 19V. The upper corner inset in the figure shows the electron diffraction pattern of the product, indicating that the product is Fe3 O 4 Nano particles. Example 3: Fe with an average size of about 30-40 nanometers 3 O 4 Synthesis of Nano Magnetic Particles:

[0035] Other experimental conditions are the same as in Example 1. The power supply parameters are set to: 80A, and the discharge current density: 2.8A / mm 2 , Output voltage: 21V.

[0036] Fe prepared 3 O 4 The nanoparticles are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com