Non-phosphate degreasant

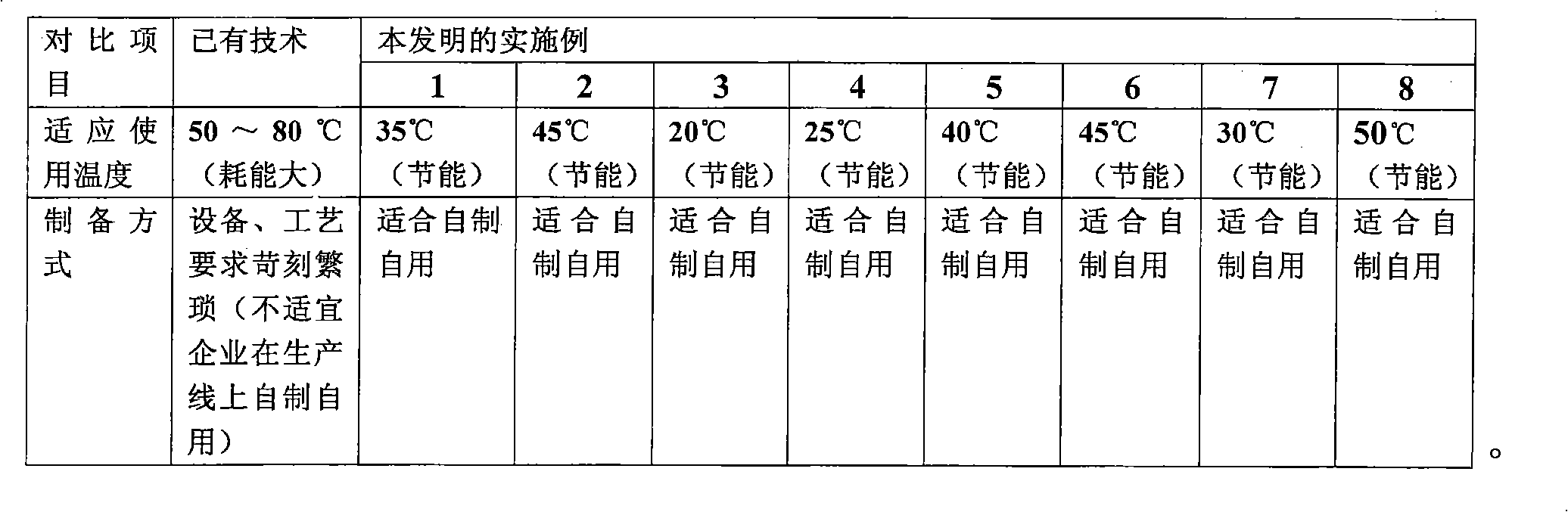

A technology of degreasing agent and emulsifier, applied in detergent composition, surface active detergent composition, inorganic/elemental detergent composition, etc., can solve the problems of complicated manufacturing process, long manufacturing process, and large energy consumption, and achieve Convenience and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1.8 parts of sodium lignosulfonate;

[0023] 1 part of fatty alcohol ethoxylate A;

[0024] Carbonyl alcohol ethoxylate 1.2 parts;

[0025] 2 parts of LW20 self-defoaming emulsifier;

[0026] 20 parts of sodium hydroxide;

[0027] Sodium citrate 2 parts;

[0028] 5 parts of sodium carbonate;

[0029] 6 parts of sodium silicate nonahydrate;

[0030] 50 parts of water.

[0031] The above-mentioned raw materials can be put into use by manual stirring, and the applicable temperature for use is 35°C. In this example, the fatty alcohol ethoxylate A is Lutensol XL70 C10 fatty alcohol produced and sold by BASF. Ethoxylates, the carbonyl alcohol ethoxylates are Lutensol TO10 C13 carbonyl alcohol ethoxylates produced and sold by BASF,

Embodiment 2

[0033] 2.5 parts of sodium lignosulfonate;

[0034] 1.6 parts of fatty alcohol ethoxylate B;

[0035] 2.9 parts of carbonyl alcohol ethoxylates;

[0036] 1.5 parts of LW20 self-defoaming emulsifier;

[0037] 15 parts of sodium hydroxide;

[0038] 3 parts sodium citrate;

[0039] 3 parts sodium carbonate;

[0040] 9.5 parts of sodium silicate nonahydrate;

[0041] 60 parts of water.

[0042] The fatty alcohol ethoxylate B is Lutensol XA50 C10 fatty alcohol ethoxylate produced and sold by BASF, and the applicable temperature is 45°C. All the other are the same as the description of embodiment 1.

Embodiment 3

[0044] Sodium lignosulfonate 2 parts;

[0045] 0.5 part of fatty alcohol ethoxylate compound A;

[0046] 2.7 parts of fatty alcohol ethoxylates B;

[0047] Carbonyl alcohol ethoxylate 1 part;

[0048] 5 parts of LW20 self-defoaming emulsifier;

[0049] 24.2 parts of sodium hydroxide;

[0050] 0.6 parts of sodium citrate;

[0051] Sodium carbonate 1 part;

[0052] 2 parts of sodium silicate nonahydrate;

[0053] 42 parts of water.

[0054] The above-mentioned raw materials are suitable for use at a temperature of 20°C. All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com