Synthesis in situ of intermetallic compound nano-particle

A technology of intermetallic compounds and nanoparticles, which is applied in the field of in-situ synthesis of intermetallic compound nanoparticles, can solve the problems of complex process, high cost, and difficult control, and achieve the effect of simple preparation process, low cost, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

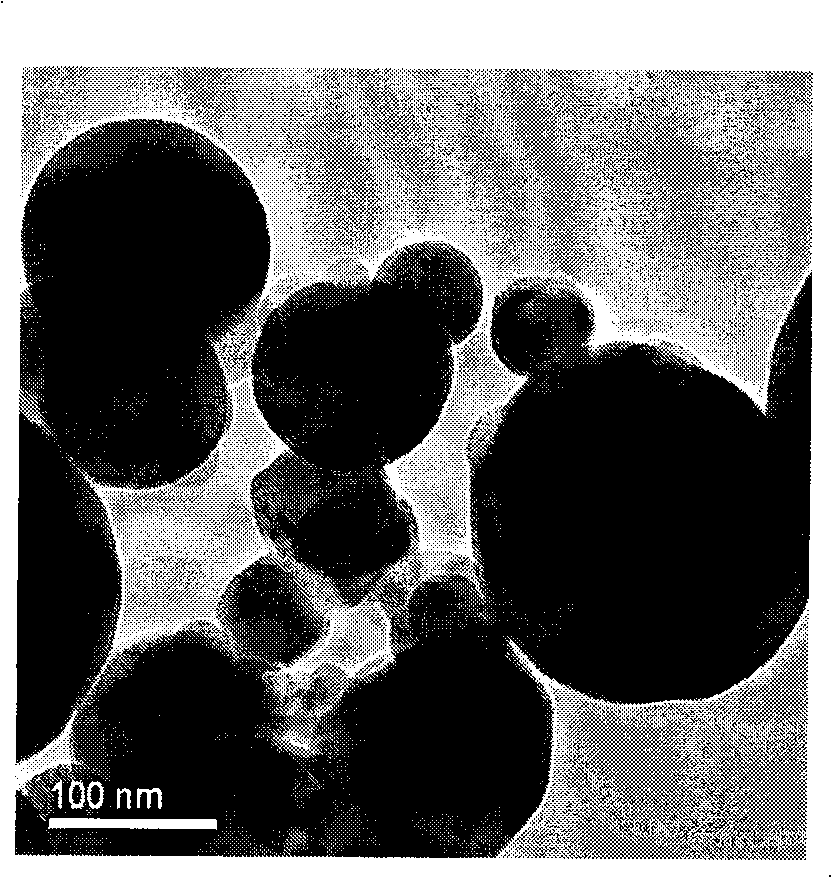

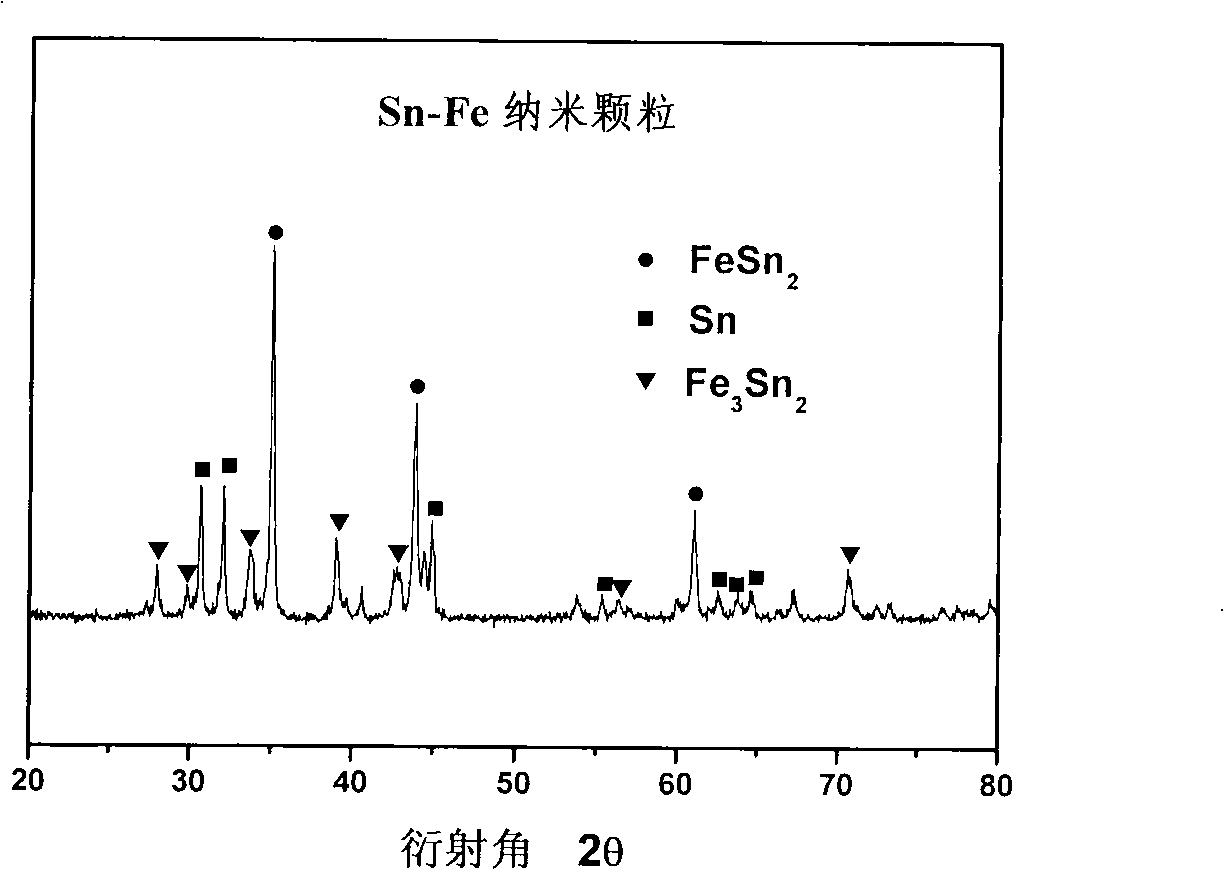

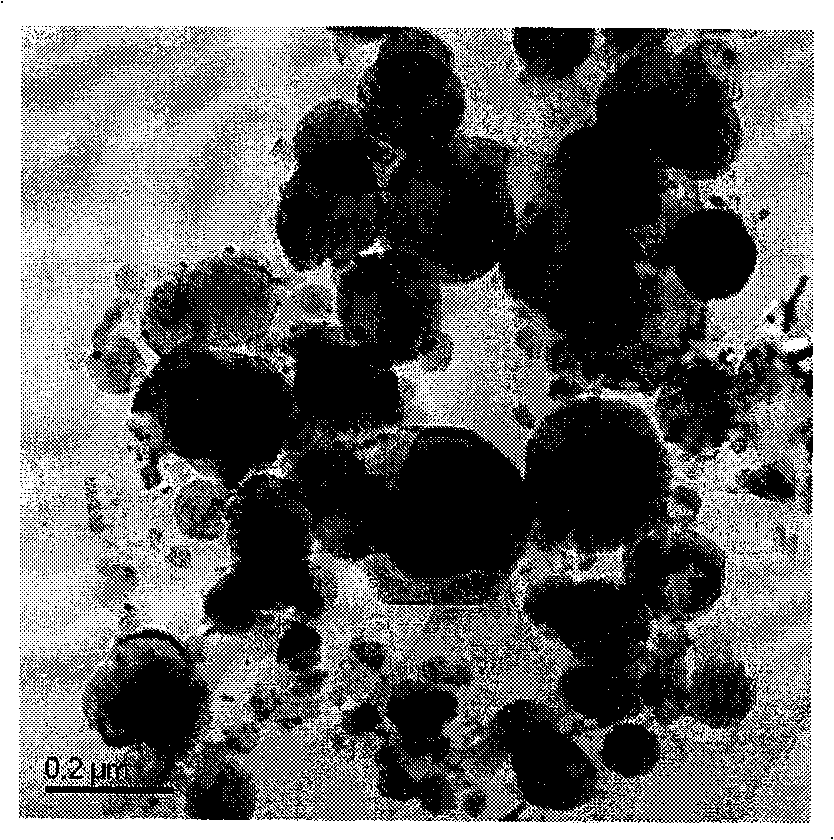

[0019] Synthesis of Sn-Fe intermetallic nanoparticles:

[0020] 1. Preparation of bulk composite targets. First, mix the micron powders of Sn and Fe according to a certain mass ratio (for example, Sn / Fc=40 / 60), and mix them evenly through a V or Y-type mixer, and then mix the mixture at 50KN / cm 2 Use a special mold to press into a cylindrical target (diameter is 10mm, height is 50mm) under the pressure. The pressed target can also be vacuum sintered at a temperature lower than the melting point of Sn to improve conductivity.

[0021] 2. Put the target into the reaction chamber as a self-consumable anode, use a tungsten rod or a carbon rod as a cathode, and water-cool the electrode.

[0022] 3. Evacuate the reaction chamber to 10 -3 Torr, about 350 Torr of hydrogen and about 350 Torr of argon (or helium), open the circulating cooling water. The arc is ignited, the discharge evaporation is carried out in the DC arc plasma, and the arc distance is adjusted at any time to stab...

Embodiment 2

[0026] Synthesis of Mg-Cu intermetallic nanoparticles:

[0027] 1. Preparation of bulk composite targets. First mix the micron powders of Mg and Cu according to a certain molar ratio (for example, Mg / Cu=2 / 1), mix them evenly through a V or Y-type mixer, and then mix the mixture at 50KN / cm 2 Pressed into a cylindrical target under high pressure. (diameter is 10mm, height is 50mm).

[0028] 2. Put the cylindrical target into the reaction chamber and use it as a consumable anode, use a tungsten rod as the cathode, and water-cool the electrode.

[0029] 3. Evacuate the reaction chamber to 10 -3 Torr, about 350 Torr of hydrogen and about 350 Torr of argon (or helium), open the circulating cooling water. The arc is ignited, the discharge evaporation is carried out in the DC arc plasma, and the arc distance is adjusted at any time to stabilize the arc. The discharge current is 150-300 amperes; the voltage is 20-40 volts.

[0030] 4. After the powder preparation is completed, cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com