Internal combustion engine with double rotor pistons

A technology of internal combustion engine and double rotor, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of difficult processing and manufacturing, small size of sealing components, inconvenient compression ratio, etc., to achieve environmental protection, Reduce the exhaust temperature and ensure the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

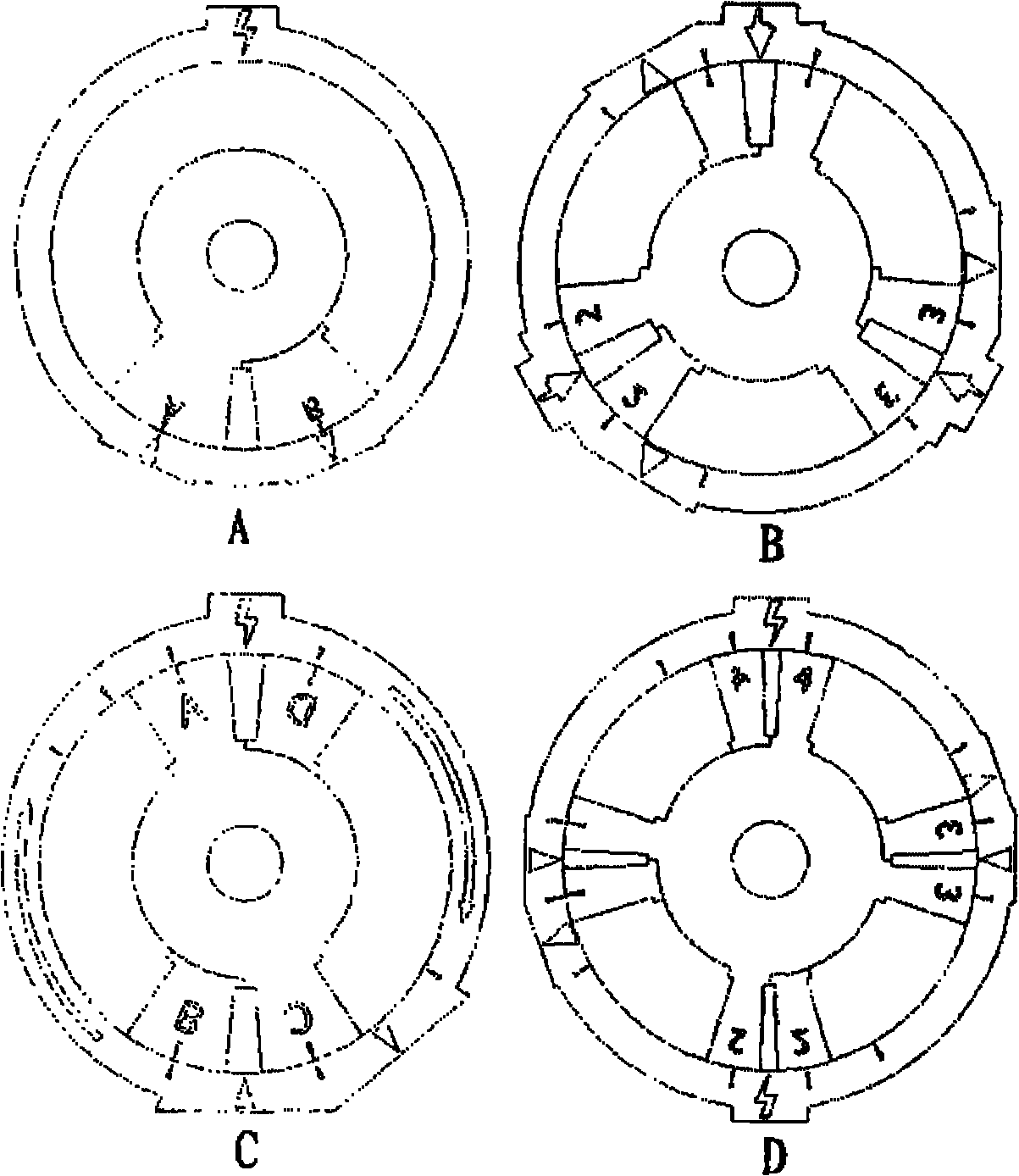

[0199] The following will further introduce three specific solutions that are preferred and recommended in the present invention in conjunction with the accompanying drawings.

[0200] 1. The piston gear of the fixed-axis gear train has missing teeth, and the outer shaft gear has all teeth and the locking arc pair mechanism;

[0201] 2. The piston gear of the fixed-axis gear train has missing teeth, and the scheme of matching the outer shaft gear with all teeth and the L-shaped lever mechanism;

[0202] 3. The output of the central gear of the epicyclic gear train, the scheme of cooperating with the A-shaped groove wheel and cam mechanism with the tooth removal of the inner ring gear.

[0203] I. Overview

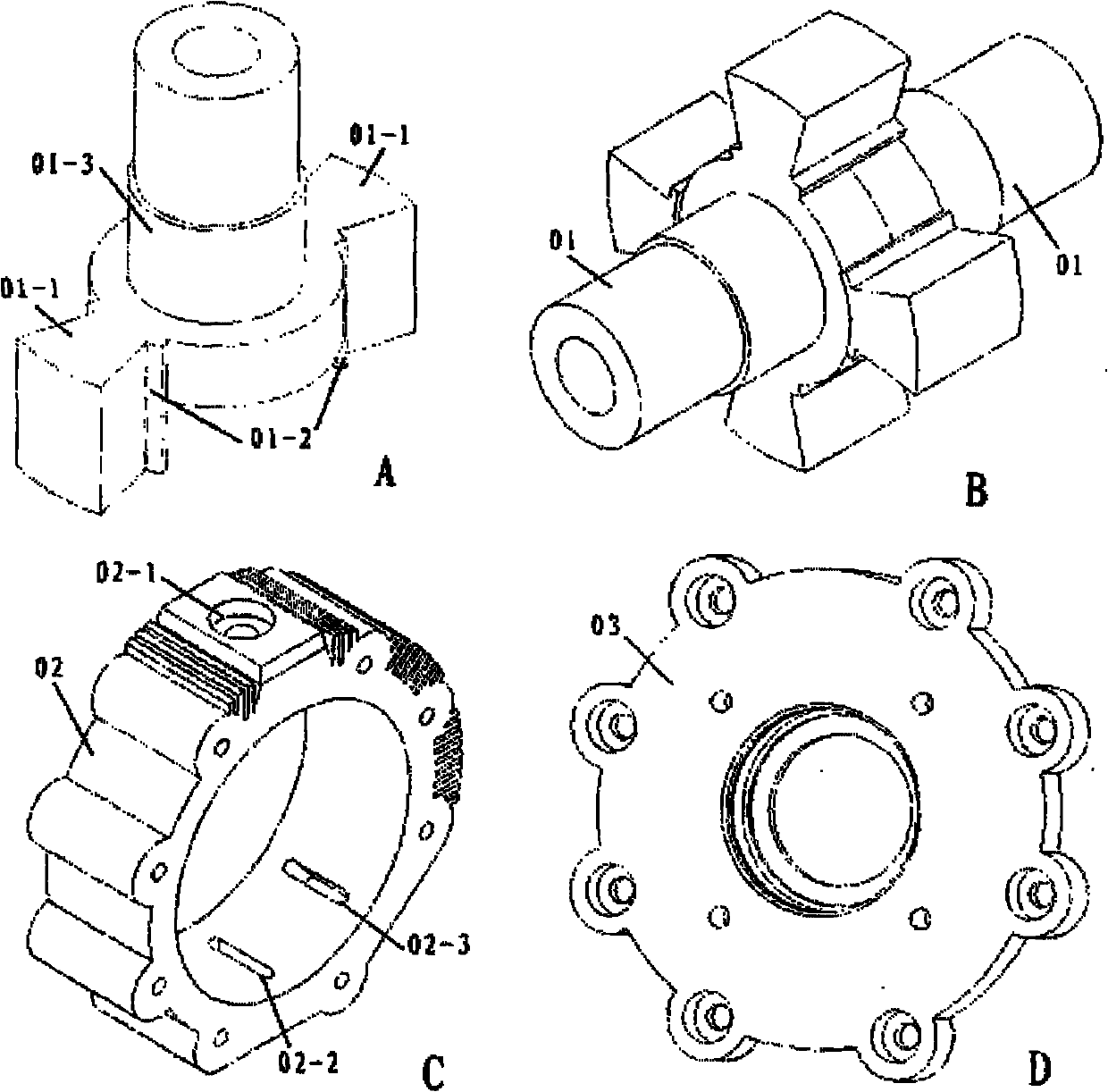

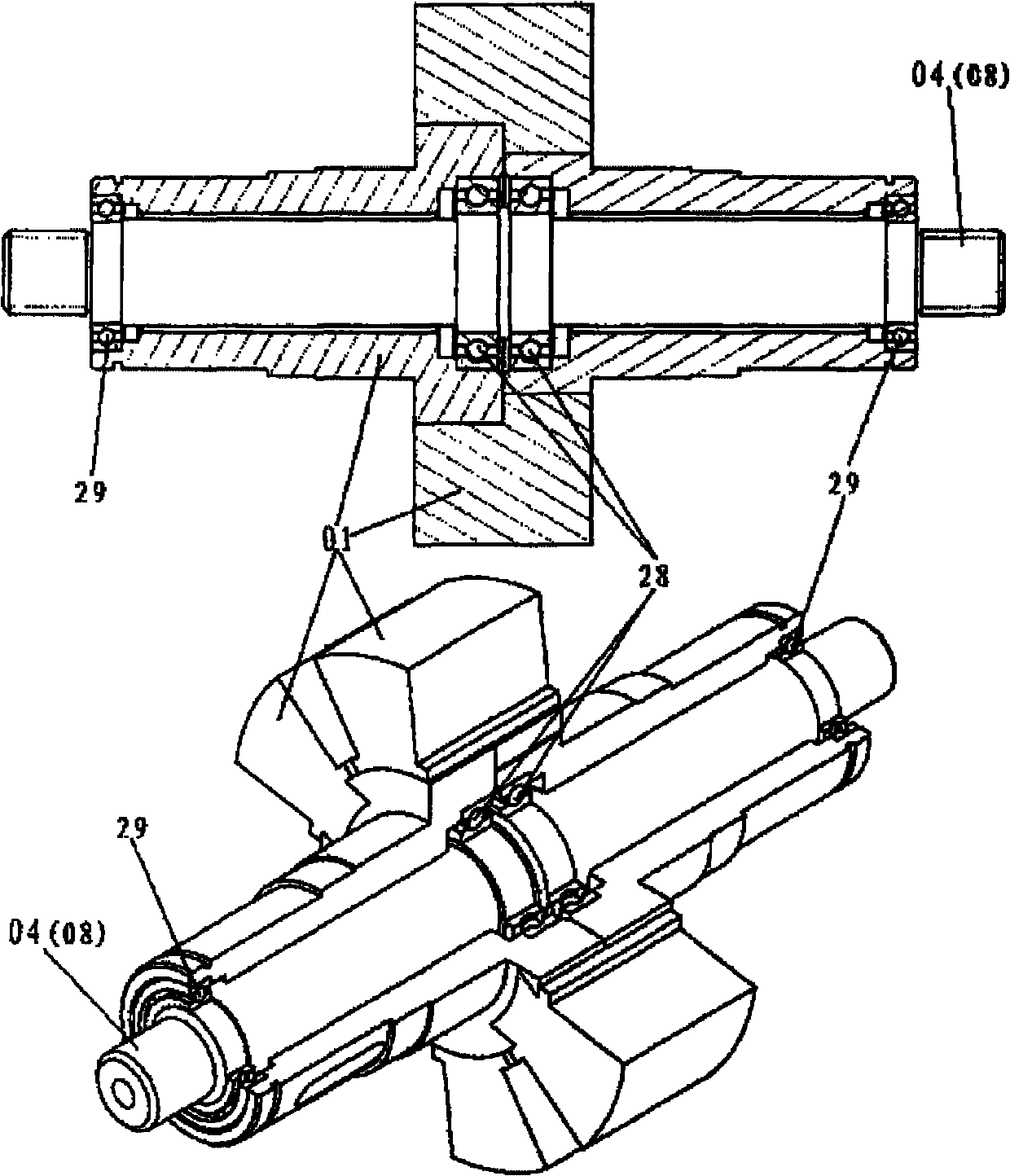

[0204] 1. About the power generating part: no matter whether the fixed-axis gear train or the epicyclic gear train is used, the power generating part of the present invention is basically the same, the difference is that the fixed-axis gear train adopts the inner shaft 04,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com