Directional constant velocity ball cage universal joint

A constant velocity spherical cage and universal joint technology, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

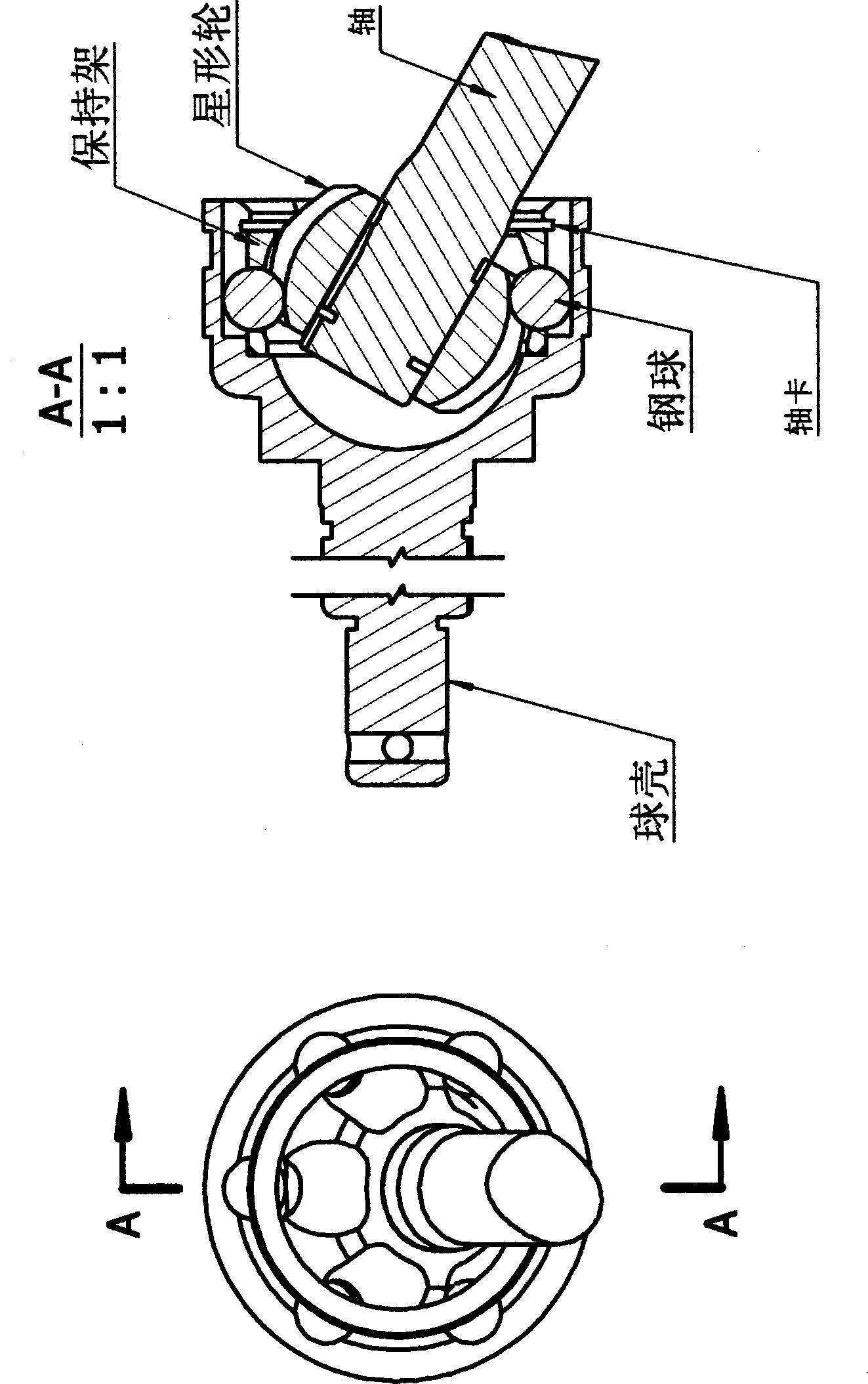

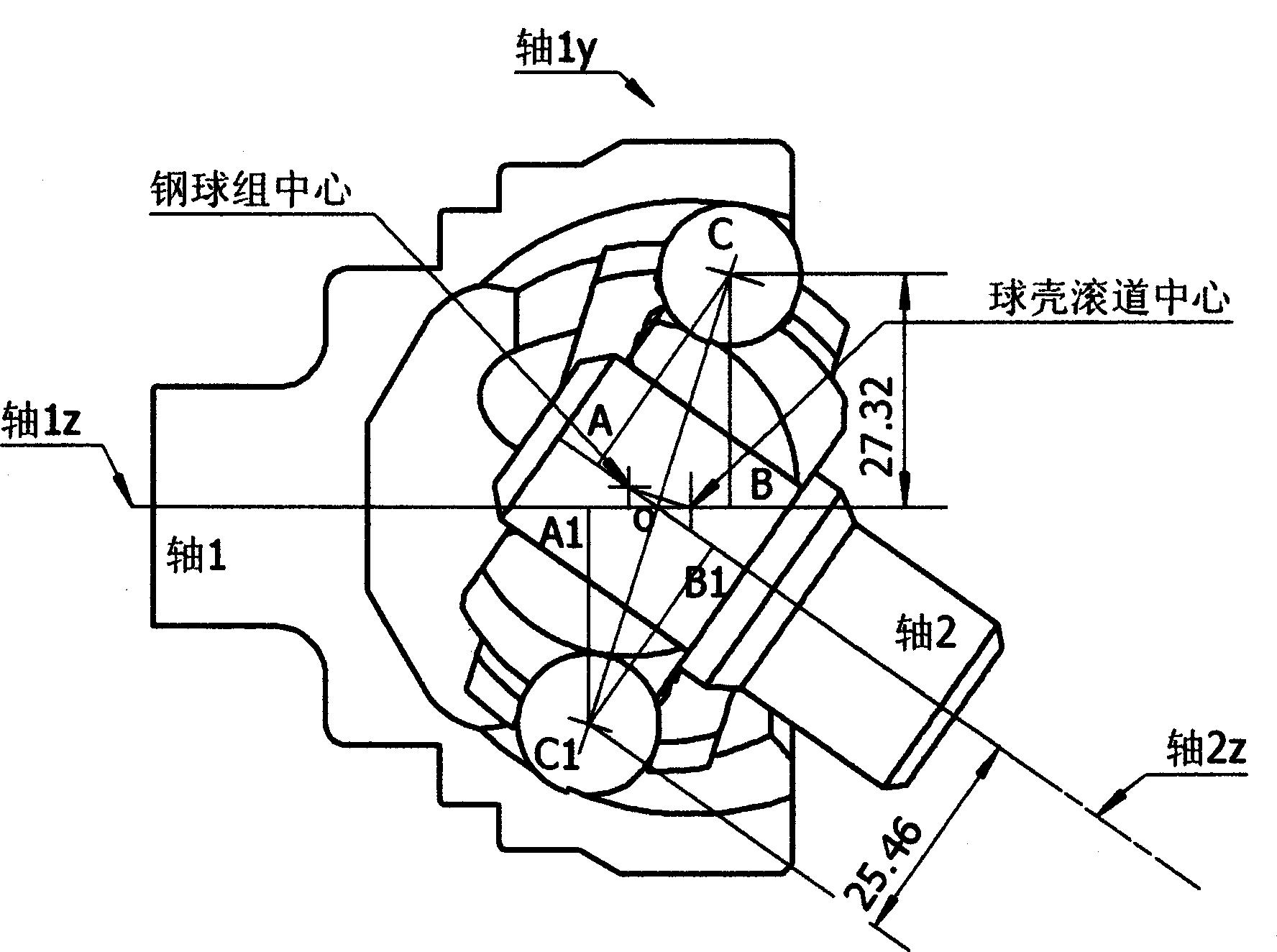

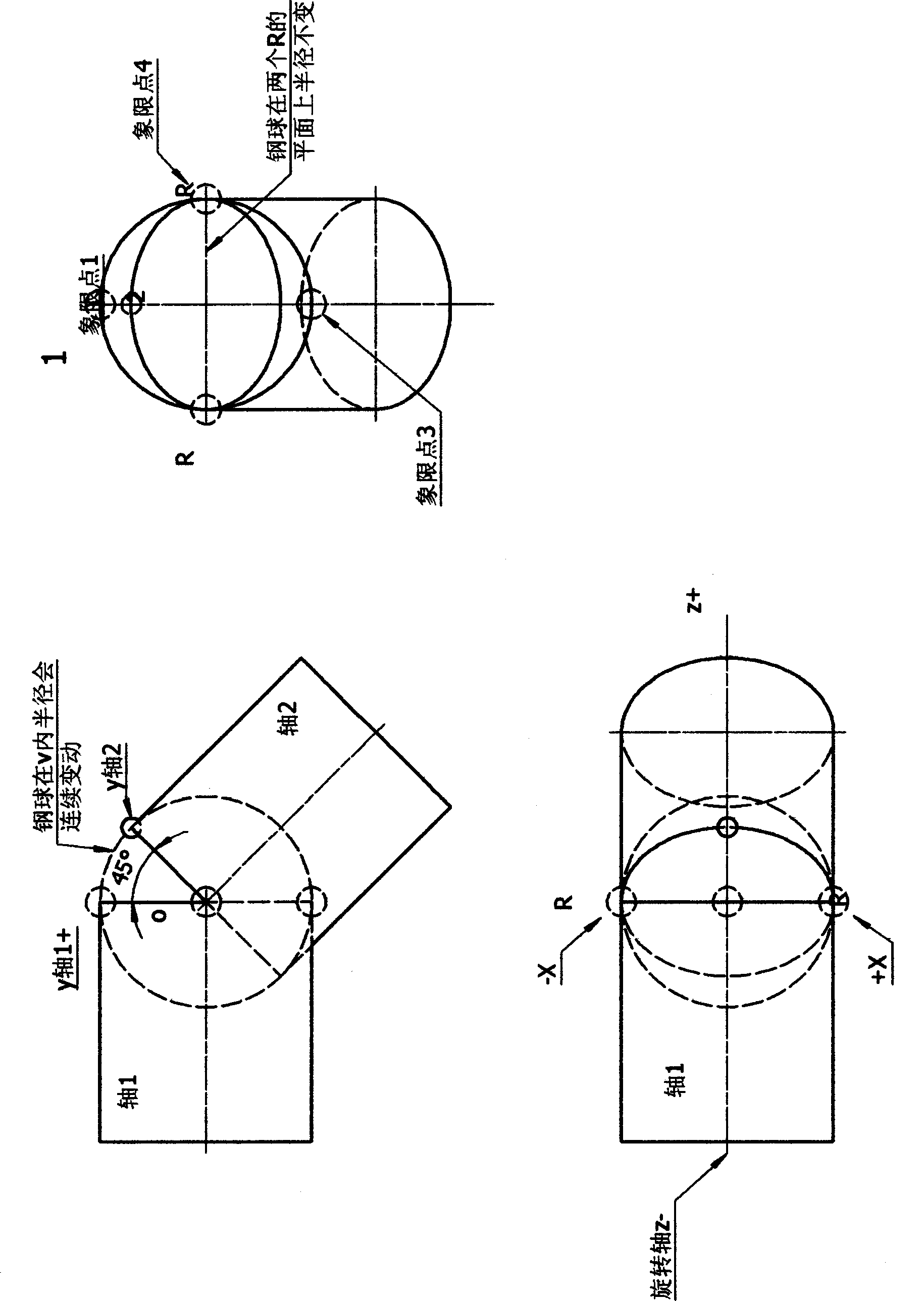

[0027] figure 1 ; The main feature of the directional ball cage is the fixed steel ball and the curved space raceway. After assembly, the concentricity of the main and driven shafts is guaranteed by the inner circle of the cage and the steel ball hole. The finished product has been statically twisted at the National Heavy-duty Vehicle Quality Supervision and Inspection Center. At 1960mn, the connecting flange with the torque machine will be twisted. The product is a miniature spherical cage with a maximum diameter of 50mm and a steel ball of 8mm. Report number;

[0028] 07-WT-DBJ-N059. In addition, at any steering angle on the inertial test bench, it can be pulled for a while and then slowly stop under inertia. Other universal joints and ball cages cannot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com