Patents

Literature

58 results about "Fading rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of fade (rate) Fade (Rate): A reduced rate authorized for use when a guest seeking a reservation exhibits price (rate) resistance. Sometimes called "flex" rate. Source : http://college.vatc.edu.vn/attachments/article/152/Glossary%20-%20Hotel%20Operations%20Management.doc. link: http://college.vatc.edu.vn/.

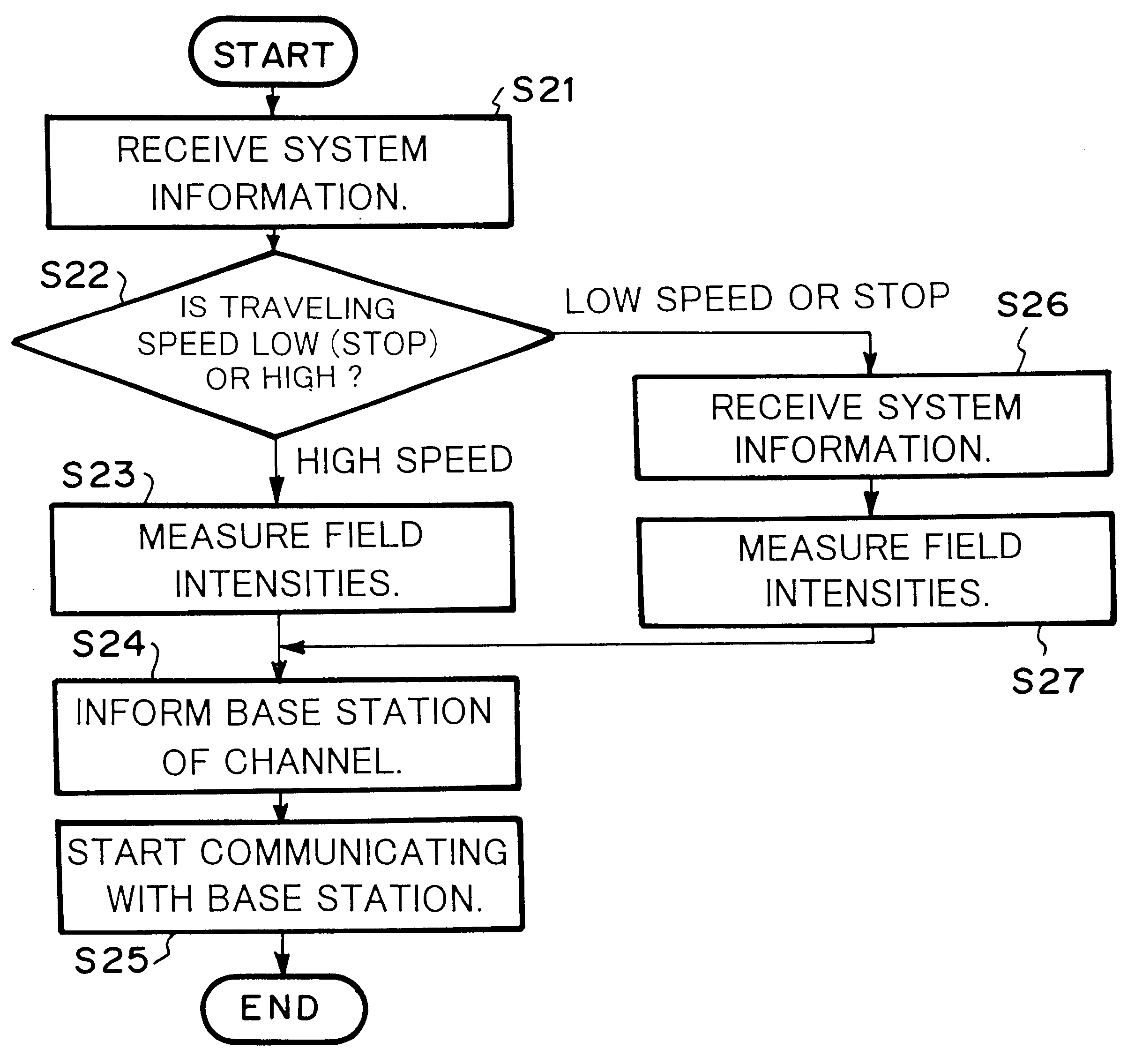

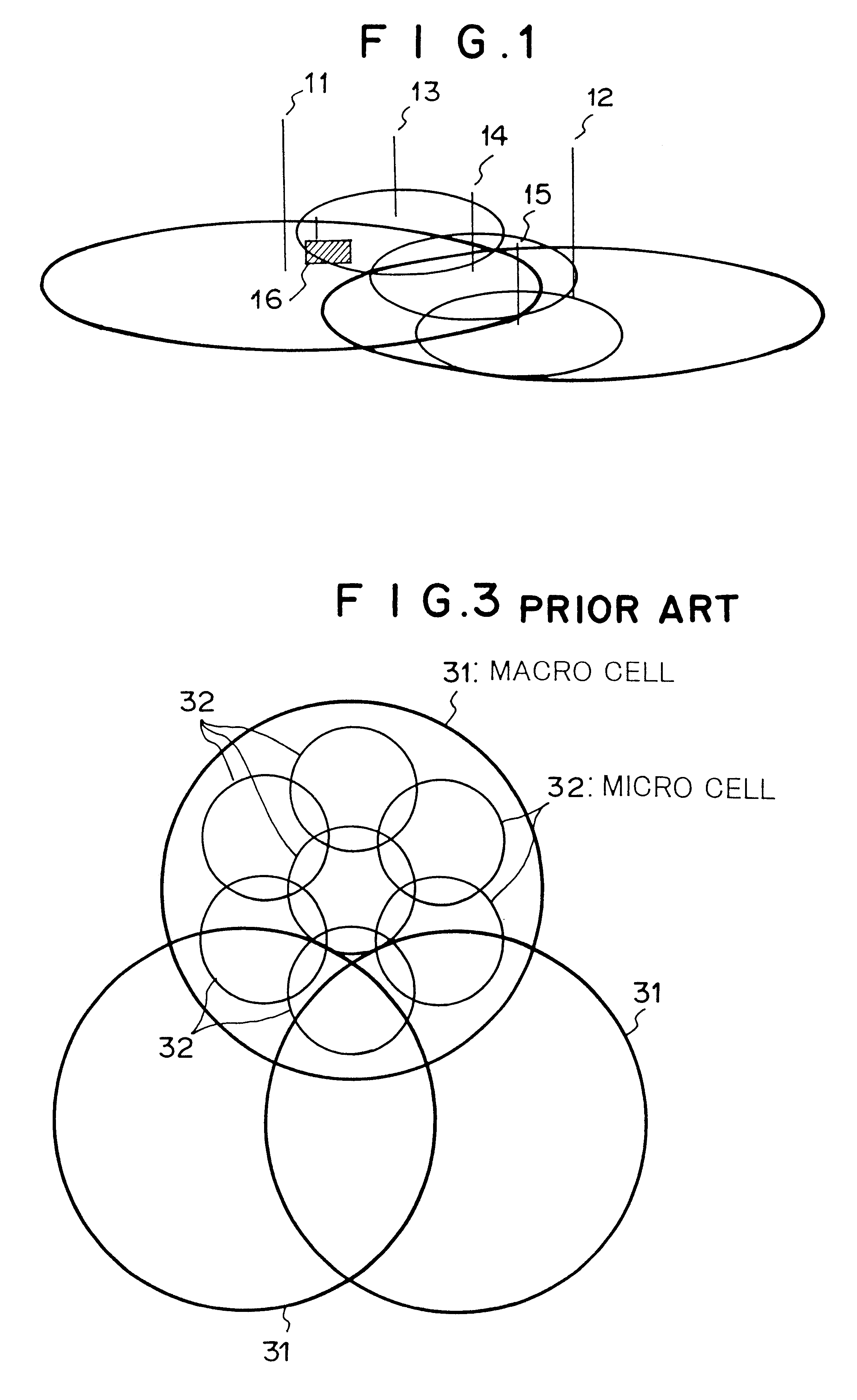

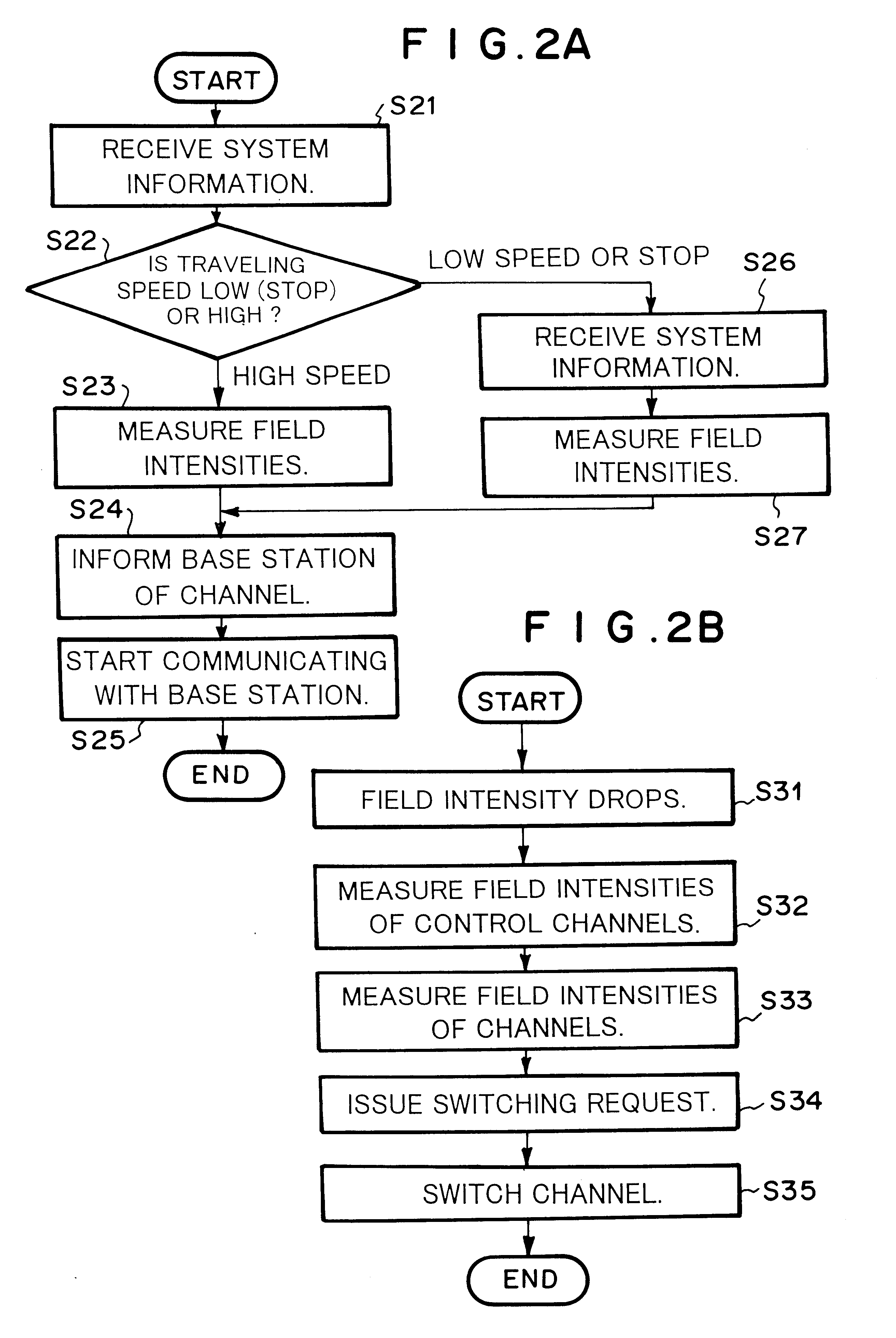

Mobile radio communication system with macro and micro cell handoff based on mobile determined crossing rates and fading rates

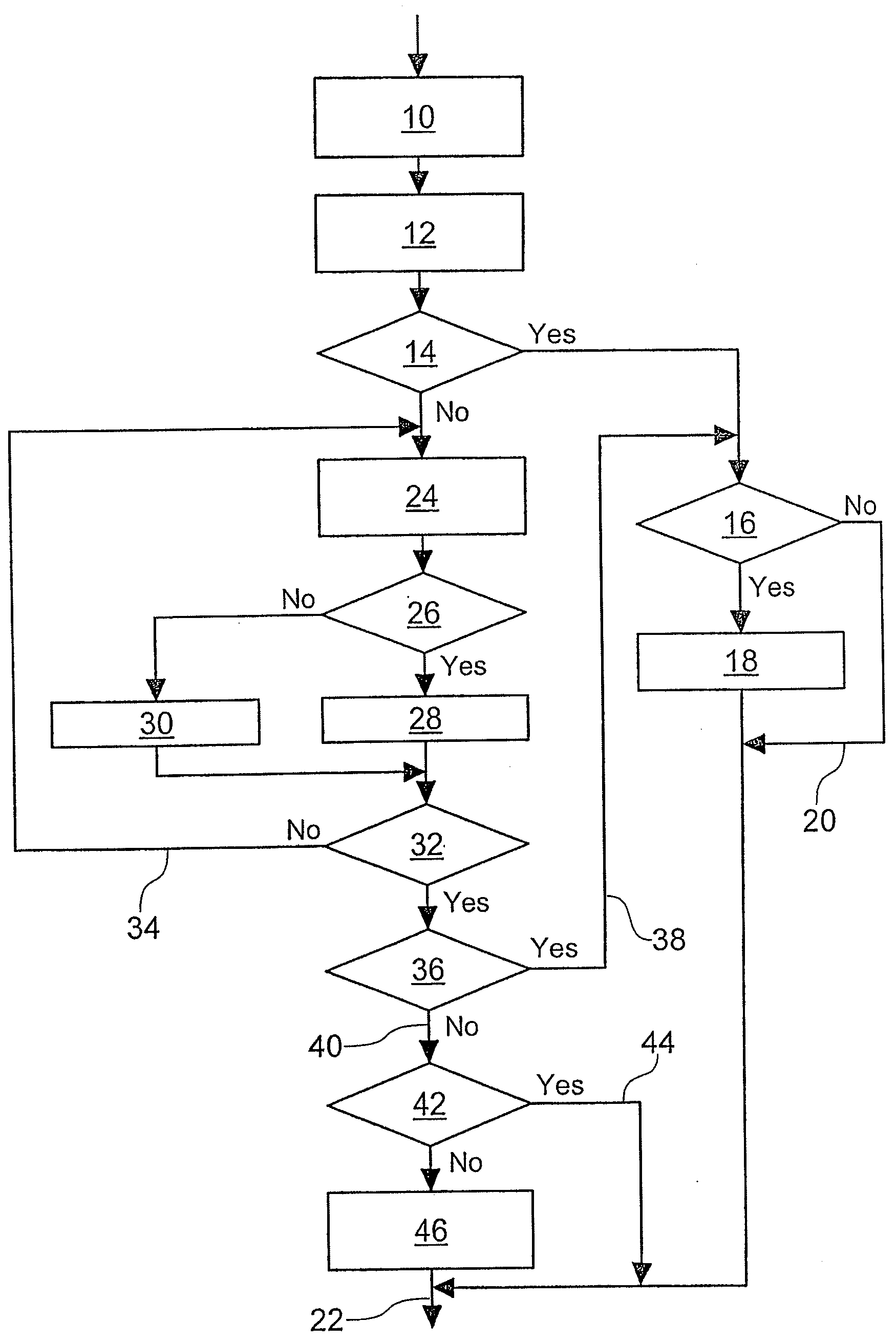

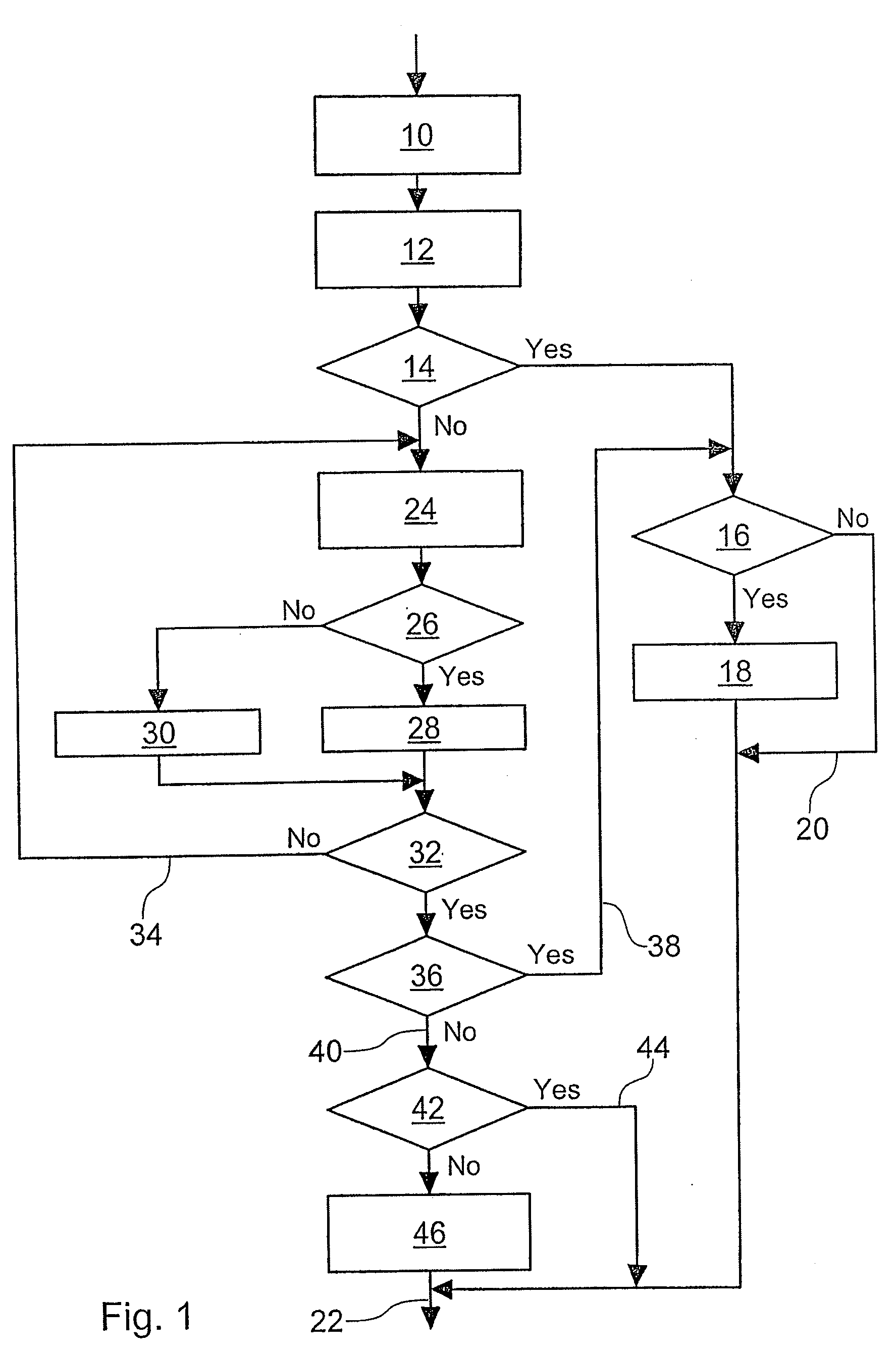

A radio base station broadcasts system information through a control channel. Each mobile station receives system information (at step S21) and determines the moving speed thereof (at step S22). When the mobile station is moving at high speed, the mobile station measures the field intensities of available channels on which the mobile station can communicate with a macro cell radio base station (at step S23 or S27). When the mobile station is moving at low speed, the mobile station measures the field intensities of available channels on which the mobile station can communicate with a micro cell radio base station (at step S27 or S23). However, when the radio base station to which the mobile station is moving is different from the radio base station from which the mobile station has received the control channel at first, the mobile station receives new system information from the relevant base station at step S26. The mobile station selects a channel corresponding to the measured result and starts communicating with the new radio base station (at steps S24 and S25).

Owner:NEC CORP

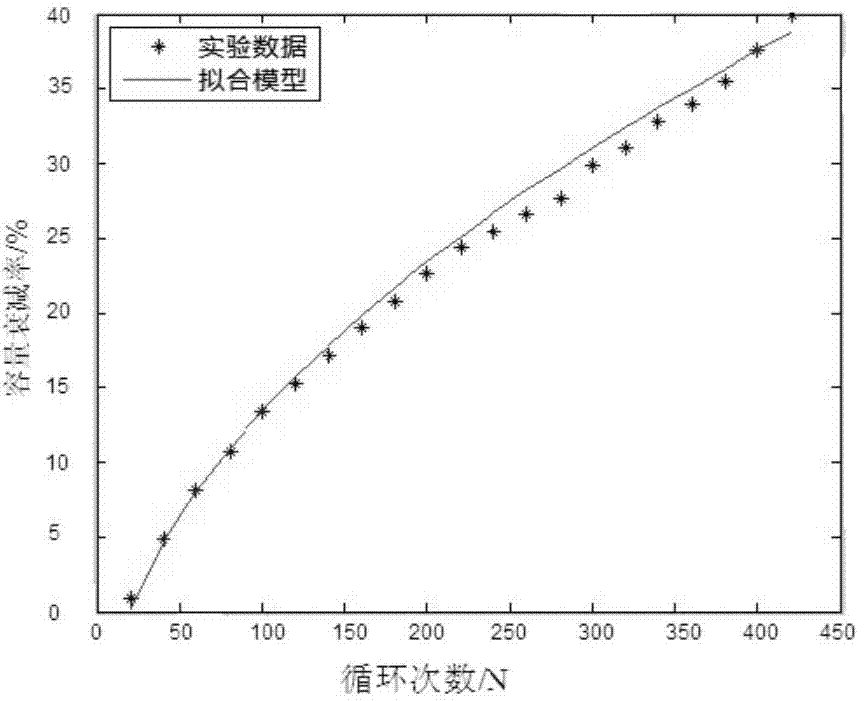

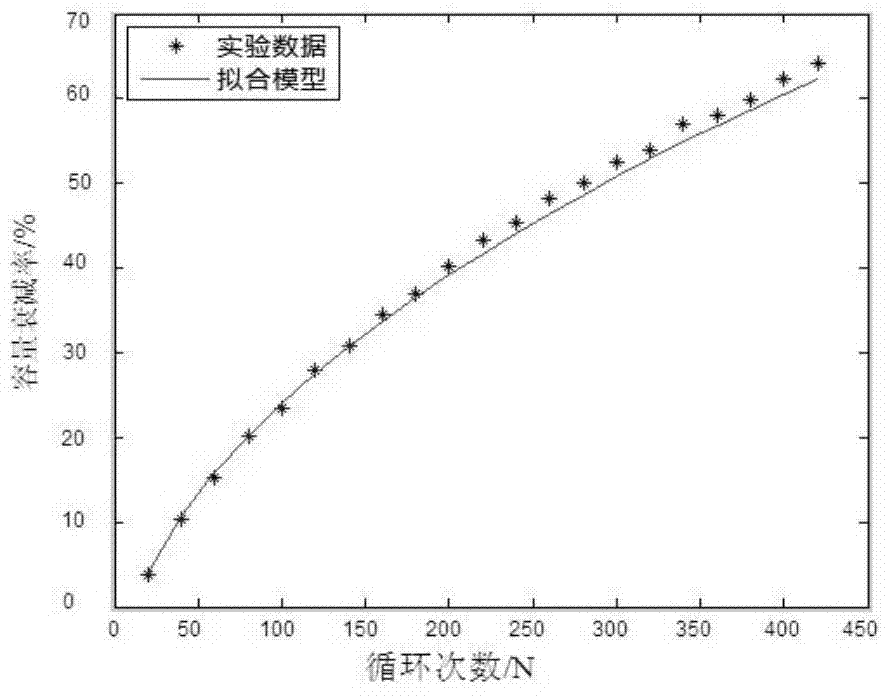

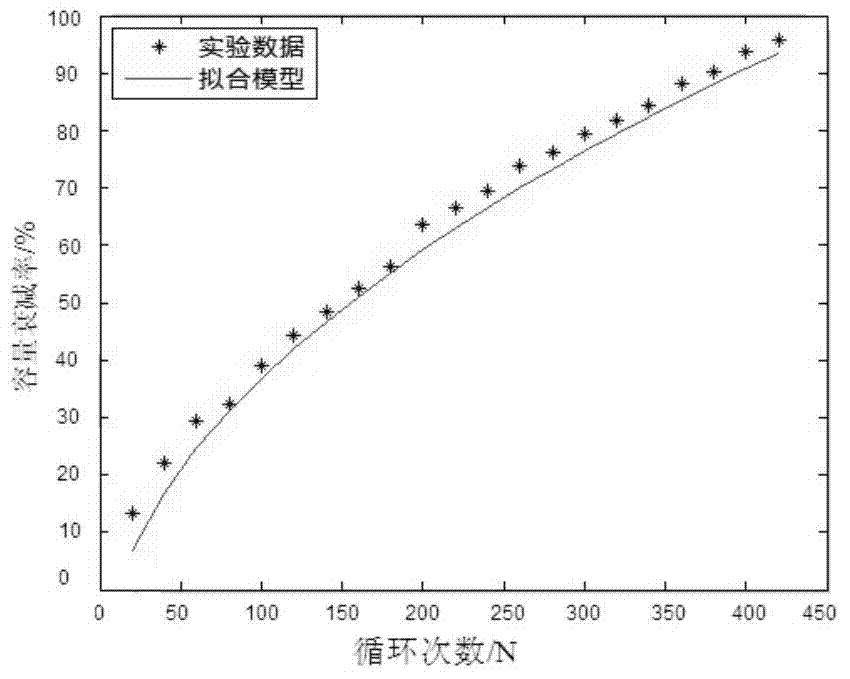

Prediction method for life cycle of battery

InactiveCN103698710AExtend your lifeGood for determining performanceElectrical testingCyclic testTested time

The invention discloses a prediction method for a life cycle of a battery. The prediction method comprises the following steps: drawing a curve of the number of discharge and capacity fading rate; determining a function model of the capacity fading rate Qloss of the battery and the number of discharge N of the battery; substituting data of a certain impact factor impacting the life of the battery into the function model, wherein Qloss is 50-80 percent of the nominal capacity of the battery; calculating to obtain the expected cycle period N of the battery. According to the prediction method disclosed by the invention, as long as little cyclic test is performed on the battery, the residual life of the battery can be judged, and therefore, the test time is greatly shortened and the test cost is greatly reduced; the objective condition of capacity fading during the actual use process of the battery can be truly and comprehensively described, the life and the residual life of the battery can be obtained, the performance of the battery can be helped to be determined, and the life of the battery is prolonged. As the established model is universal, the prediction method disclosed by the invention is suitable for establishing life fading models of various storage batteries.

Owner:CENT SOUTH UNIV +2

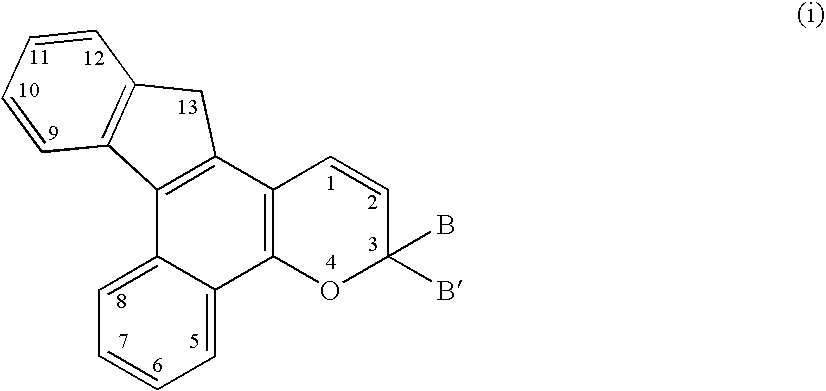

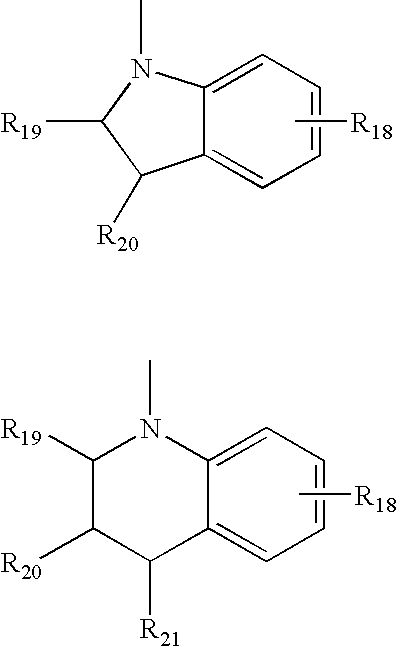

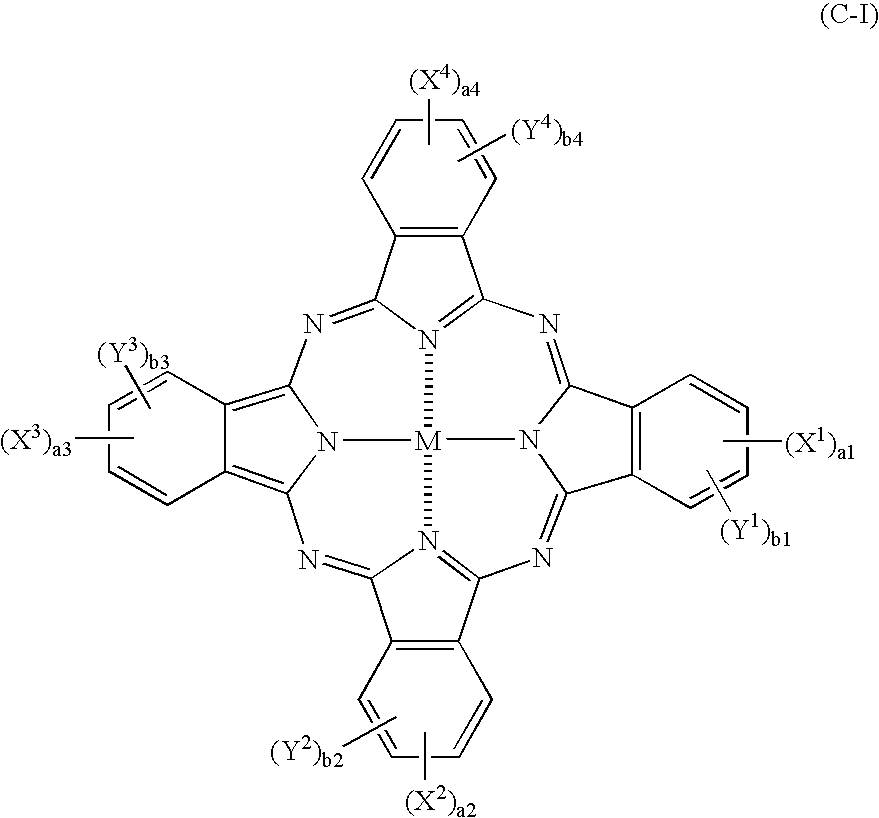

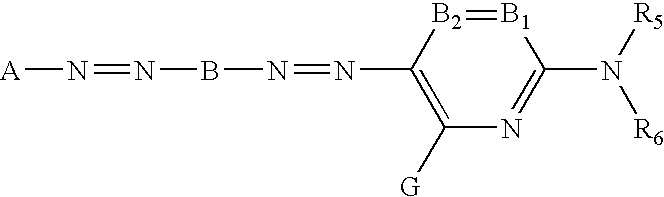

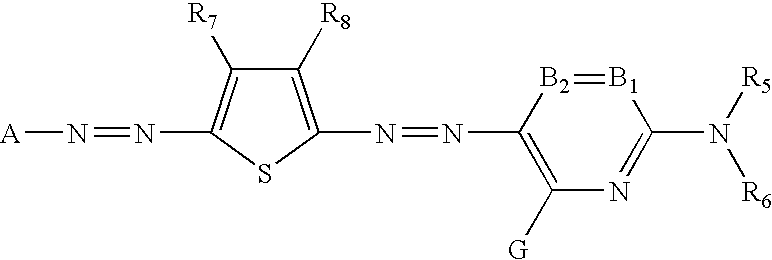

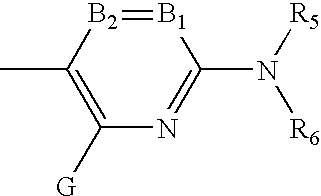

Photochromic materials demonstrating improved fade rates

Various photochromic materials are provided that are essentially free of polymerizable unsaturated groups, and comprise: a) an indeno[2′,3′:3,4]naphtho[1,2-b]pyran; and b) an electron-withdrawing, non-conjugating group bonded at the 11-position of the indeno[2′,3′:3,4]naphtho[1,2-b]pyran. Alternative embodiments include various substituents at other positions of the indeno[2′,3′:3,4]naphtho[1,2-b]pyran. Also provided are photochromic articles including a substrate and one of the above photochromic materials, in contact with at least a portion of the substrate.

Owner:TRANSITIONS OPTICAL INC +1

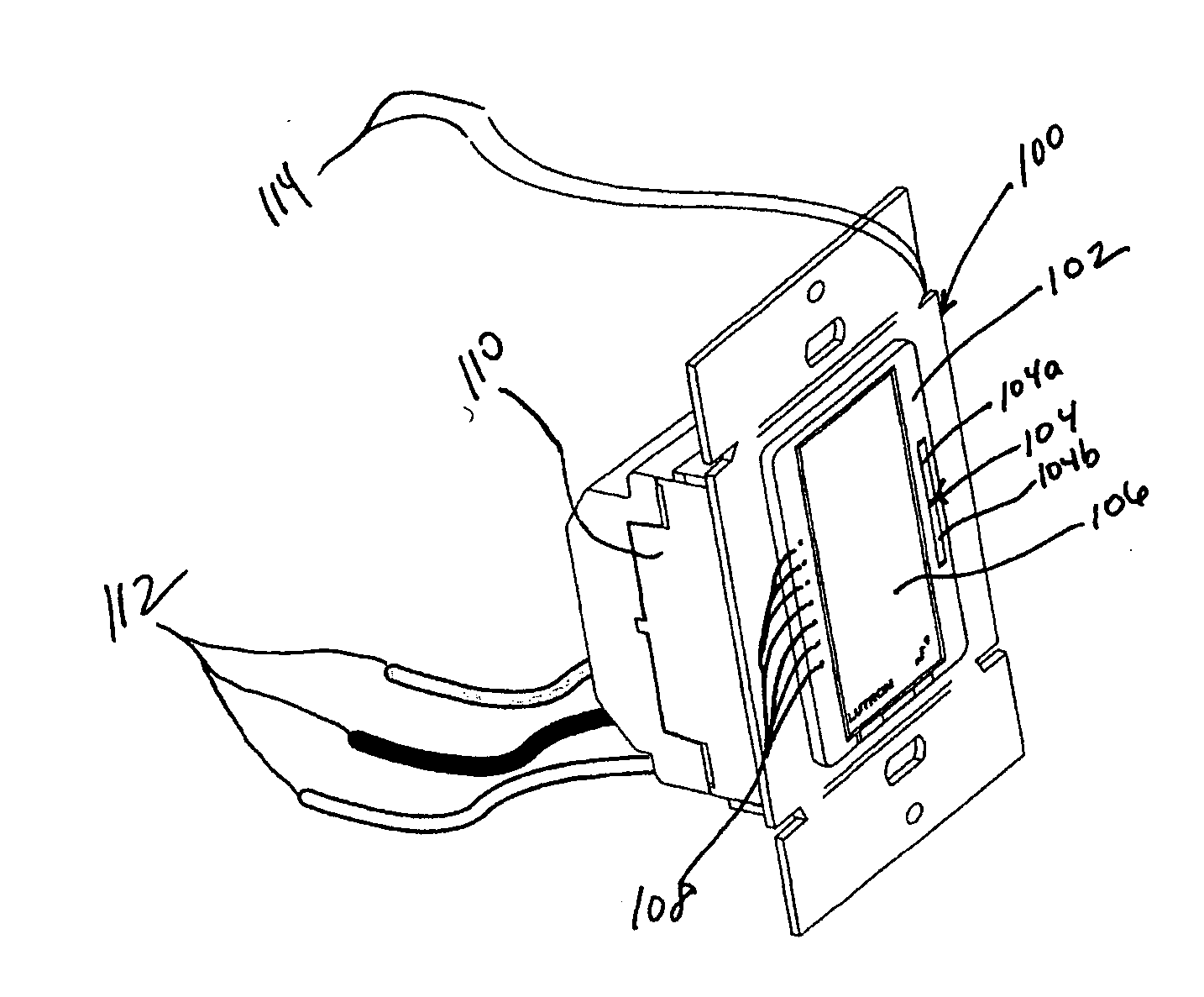

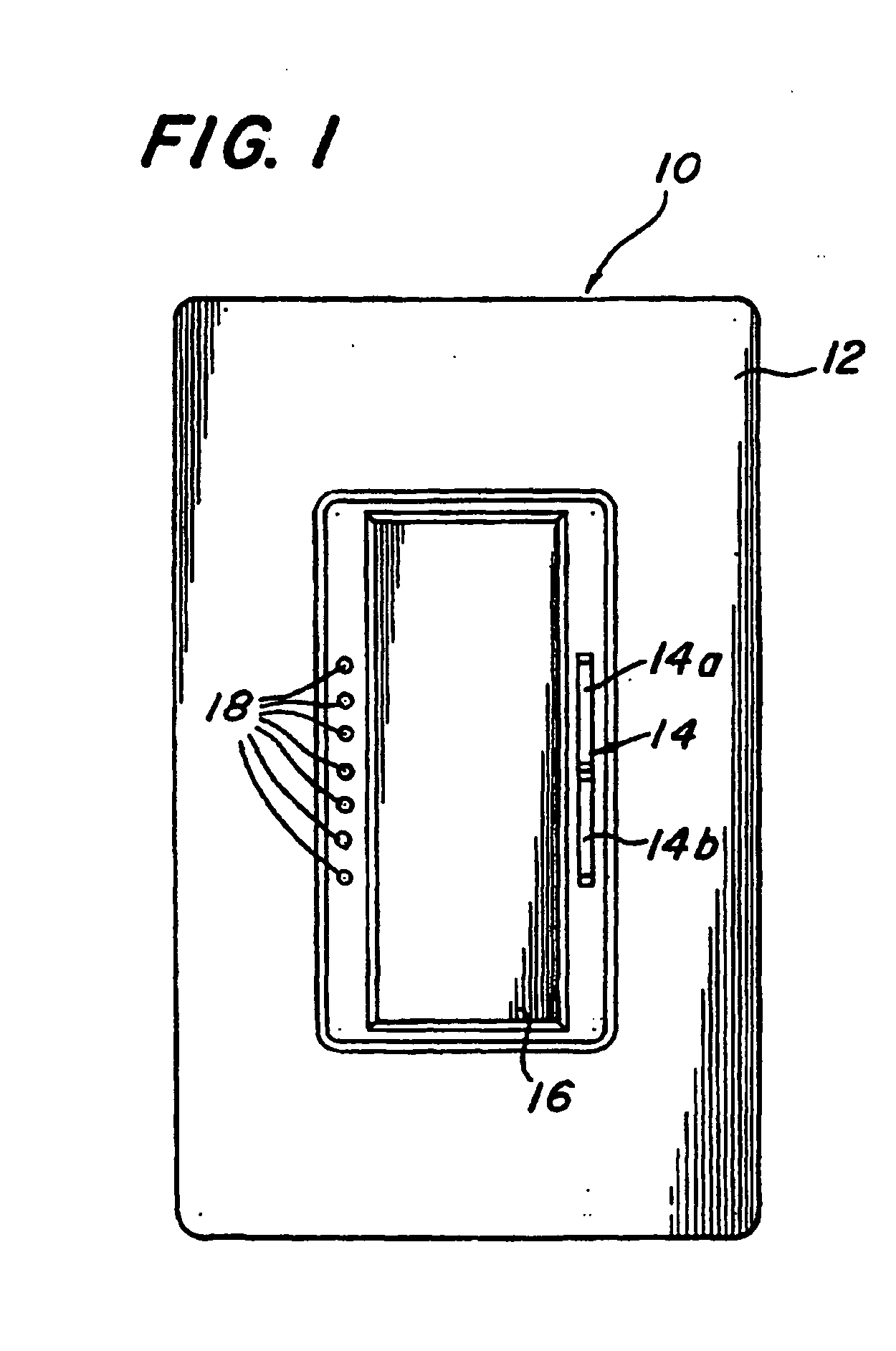

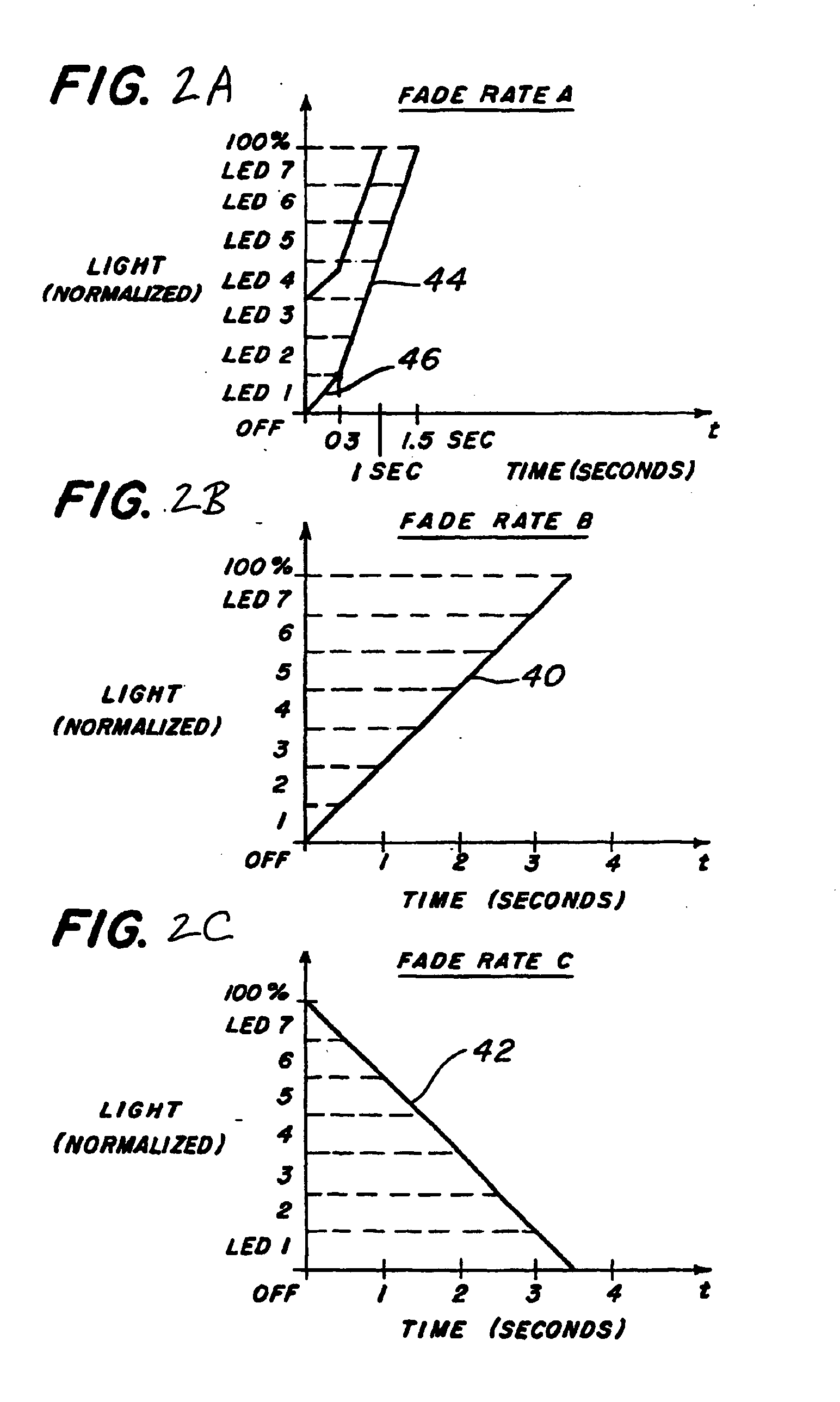

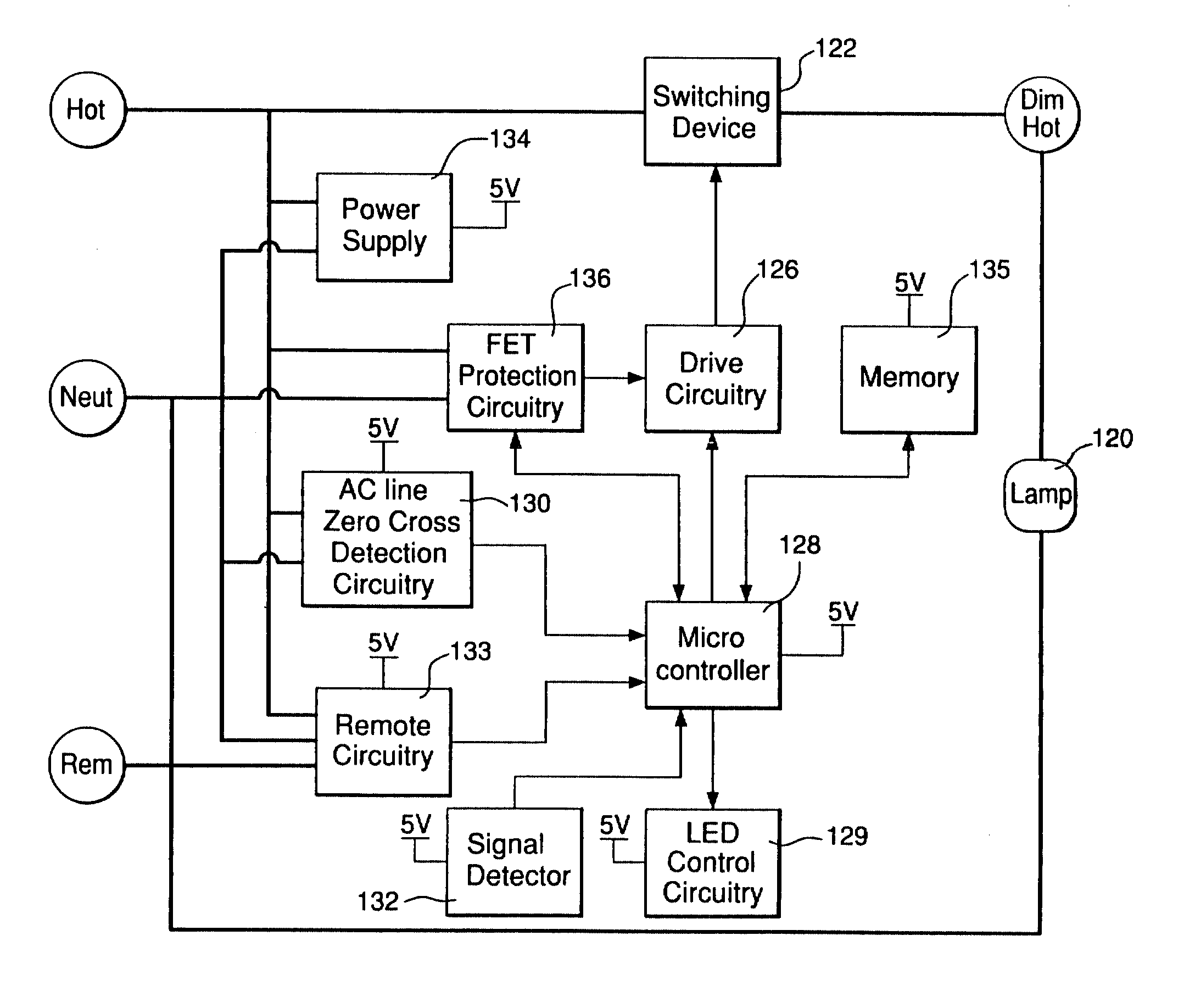

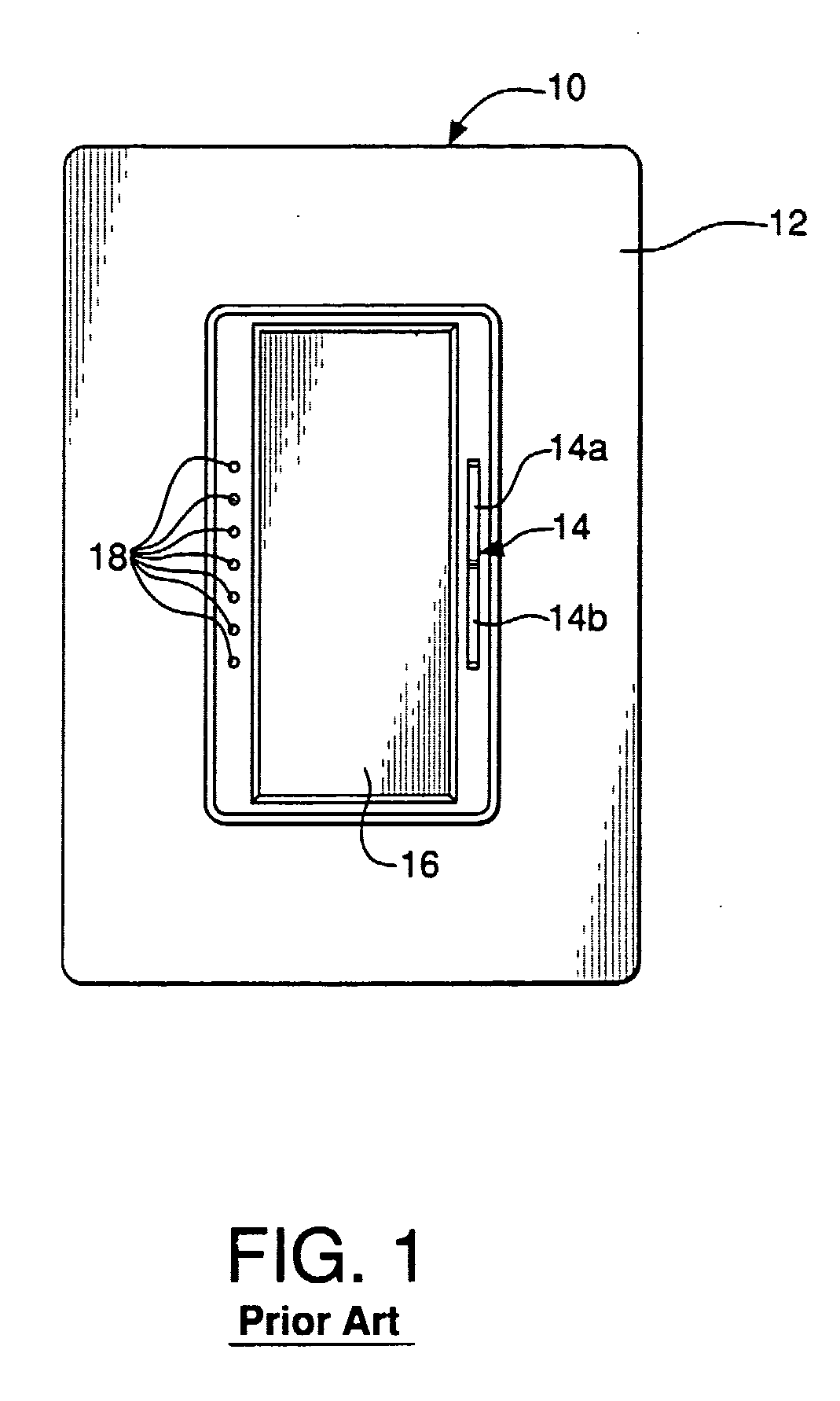

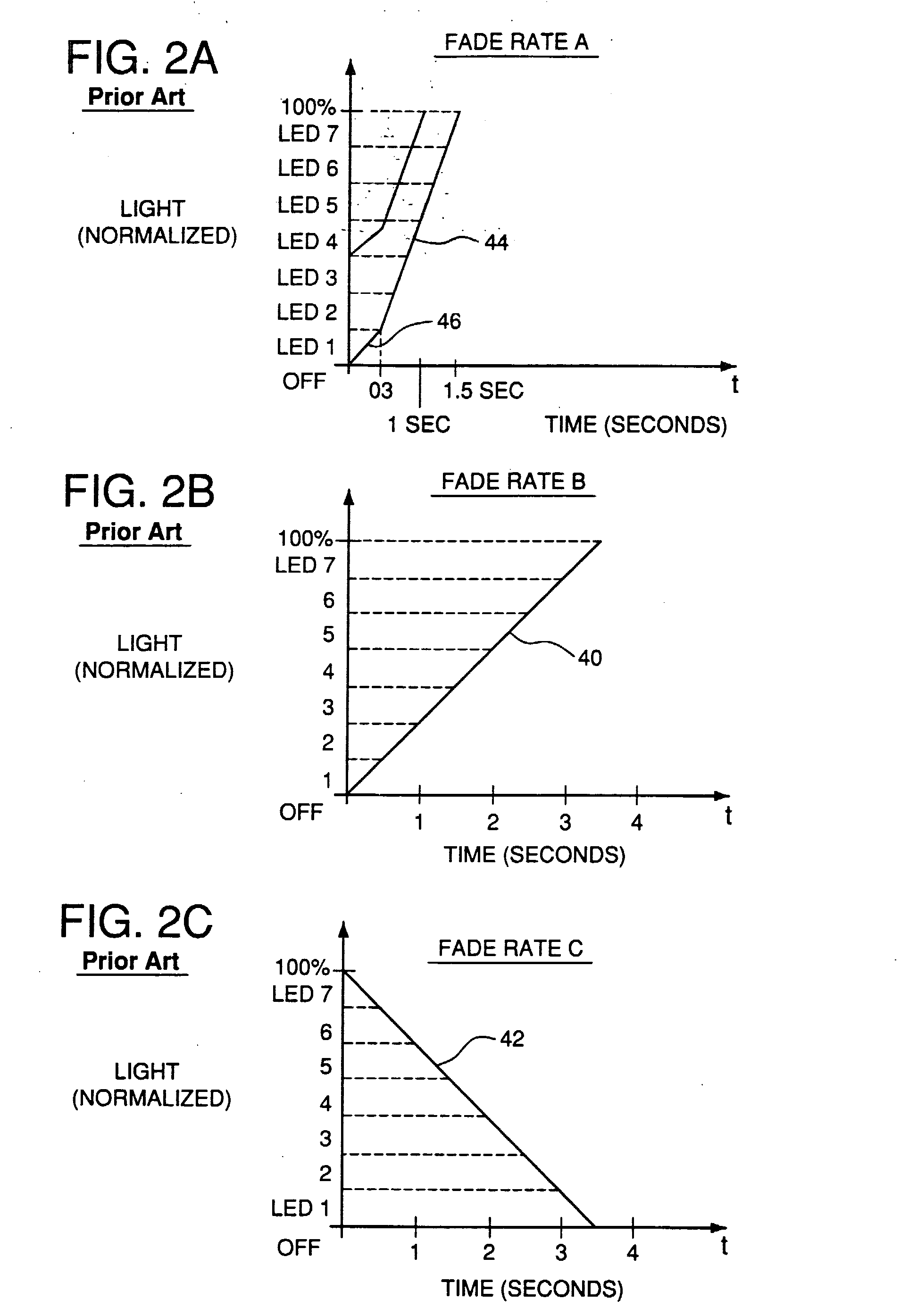

Lighting control device having improved long fade off

ActiveUS20050146288A1Electric light circuit arrangementElectric discharge lampsMicrocontrollerActuator

A lighting control device for controlling the light intensity level of at least one lamp is disclosed. The lighting control device includes a microcontroller and a user-actuatable switch controller that is operatively coupled to the microcontroller. The microcontroller causes the light intensity level of the lamp to fade at a first fade rate when the switch controller is actuated. If the microcontroller determines that the switch controller has been actuated for at least a predefined actuator hold time, the microcontroller causes the light intensity level of the lamp to fade at a second fade rate for a predefined long fade time. After the long fade time elapses, the microcontroller causes the light intensity level of the lamp to fade to off at a third fade. The first fade rate is based on a predefined fade-off time that represents a time allotted for fading the light intensity level of the lamp from its initial light intensity level to off. To prevent the light intensity level from fading to off before the actuation time elapses, the fade off time may be defined to be longer than the actuation time. The second fade rate may be slower than the first fade rate and have an exponential fade profile. The third fade rate may be a predefined rate at which the microcontroller is programmed to cause the light intensity level to fade from full on to full off. The third fade rate may be quicker than the second fade rate.

Owner:LUTRON TECH CO LLC

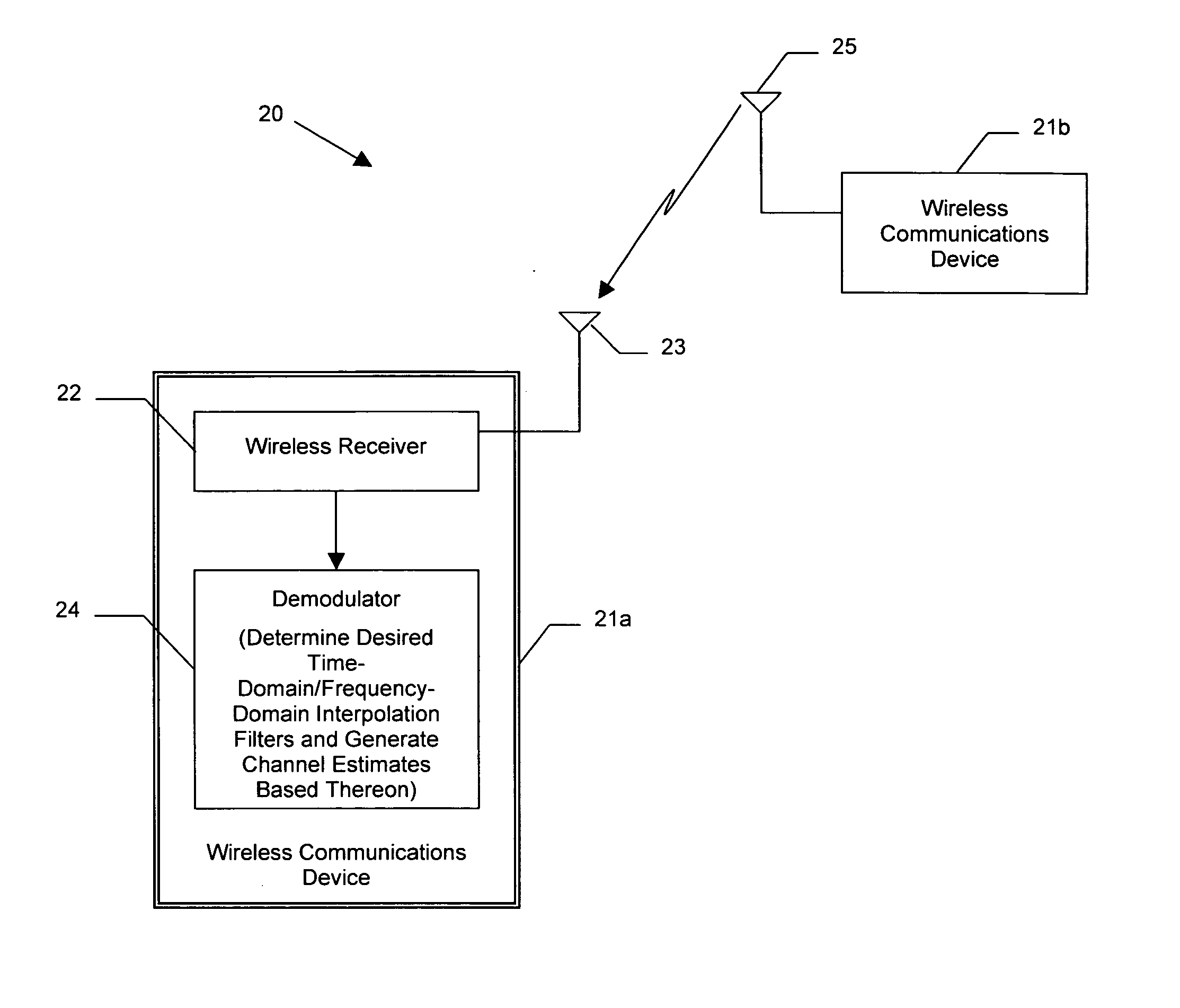

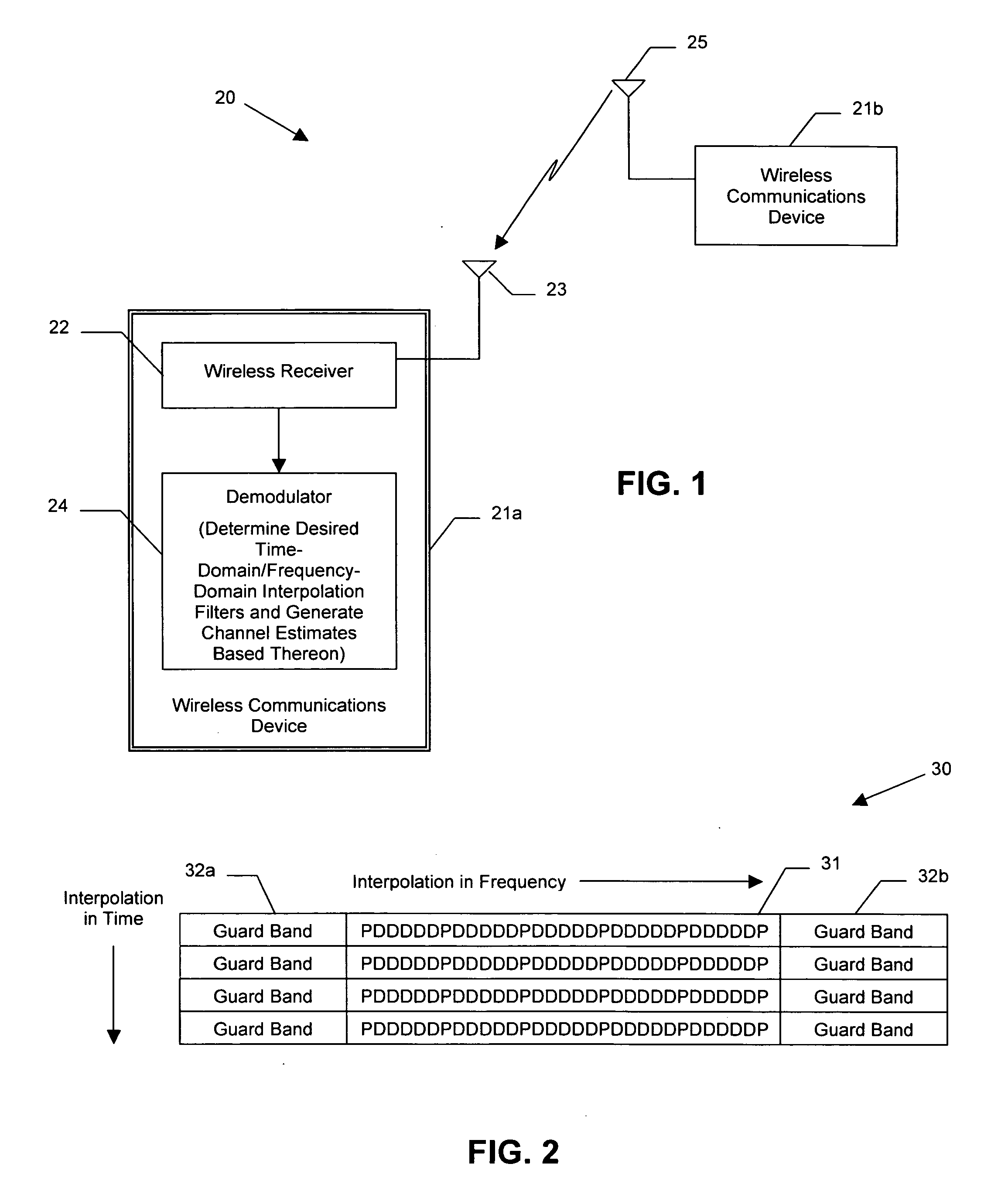

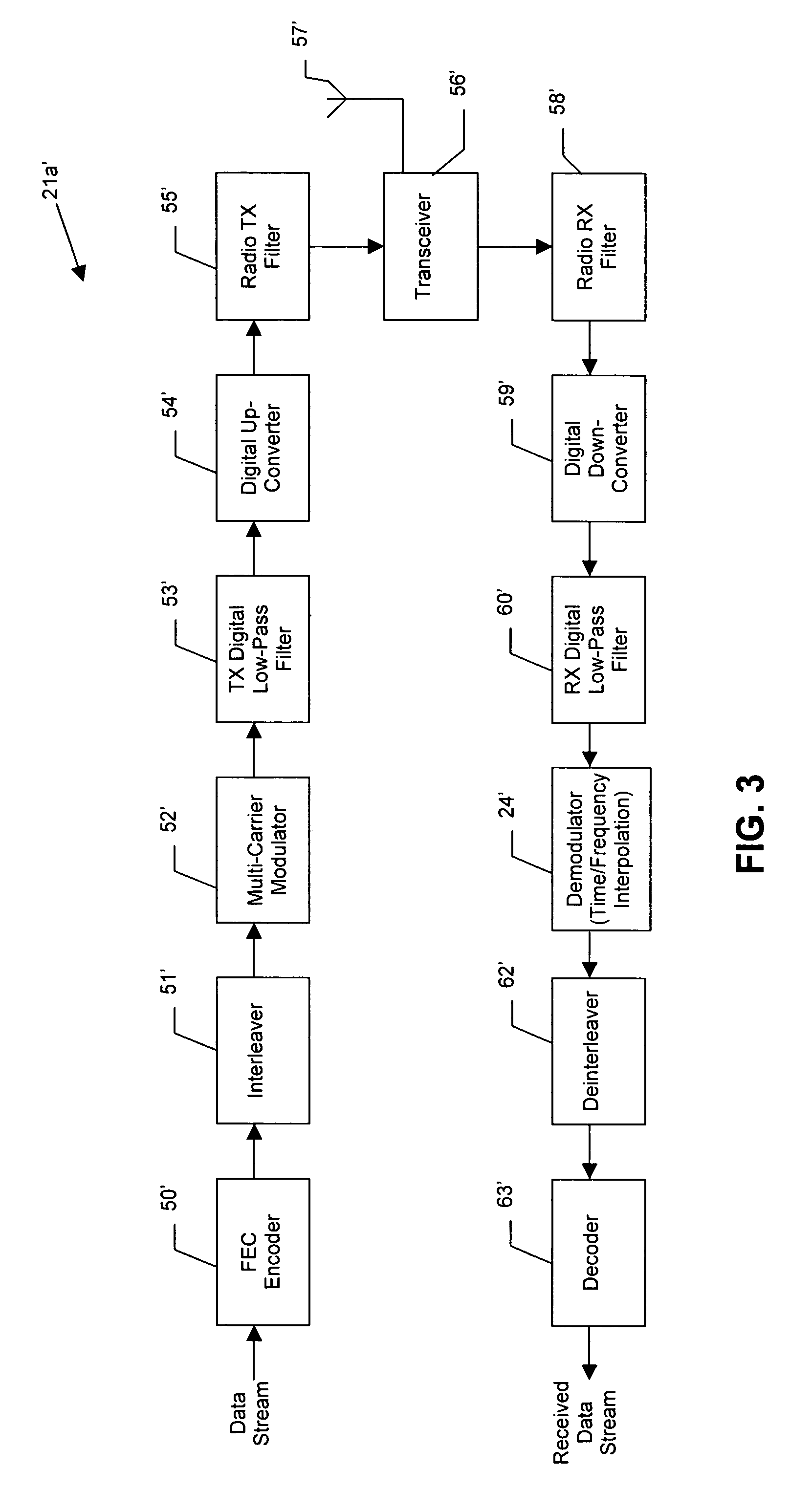

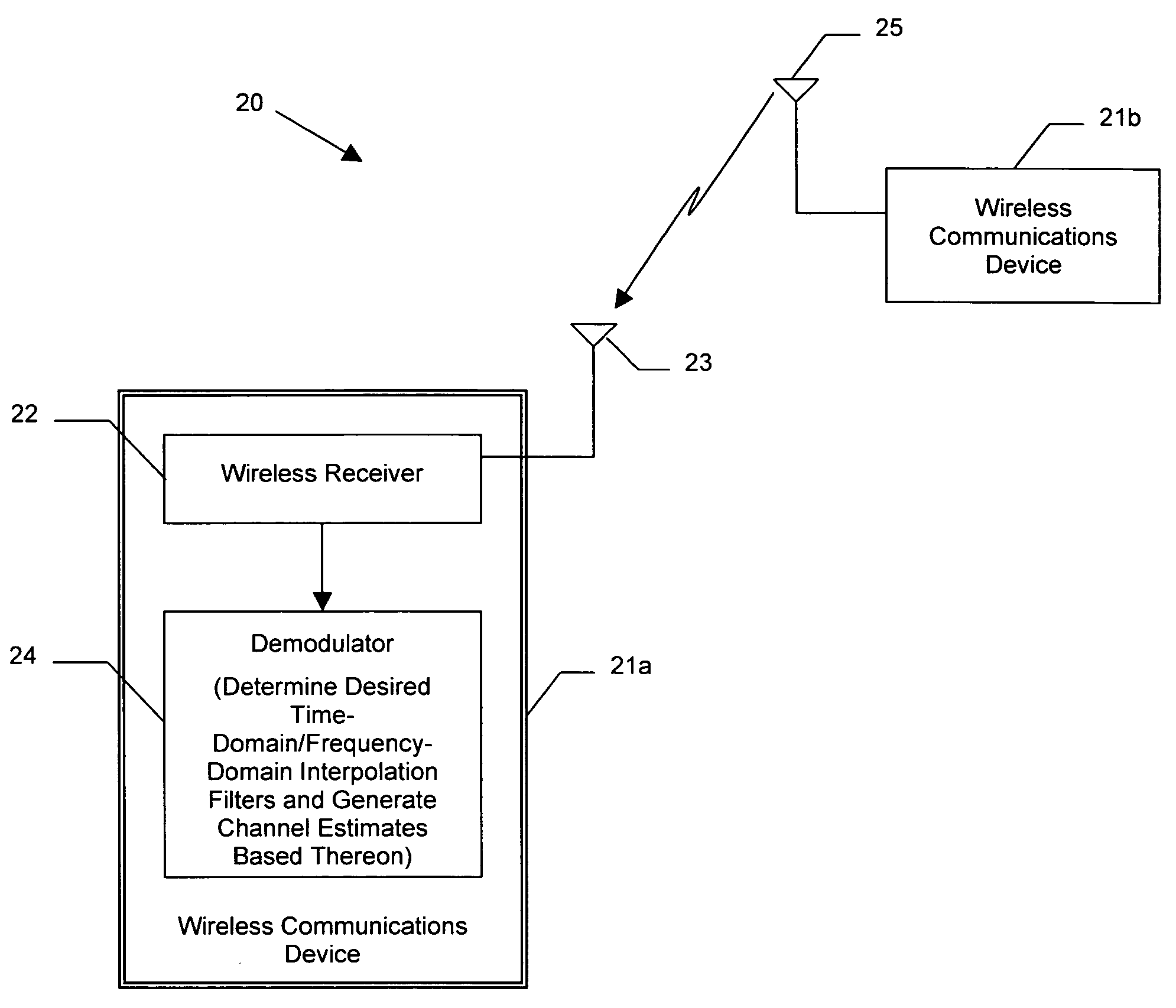

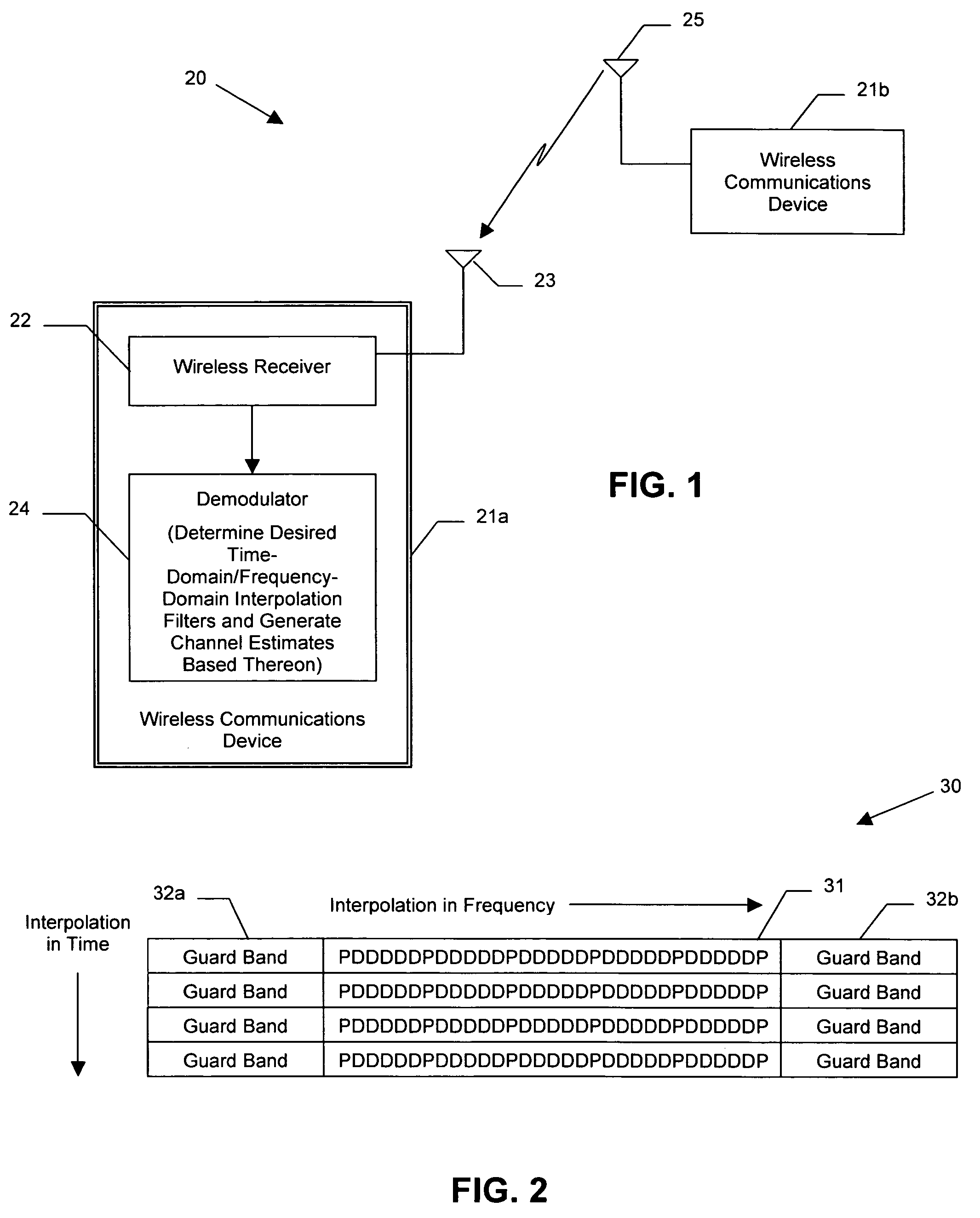

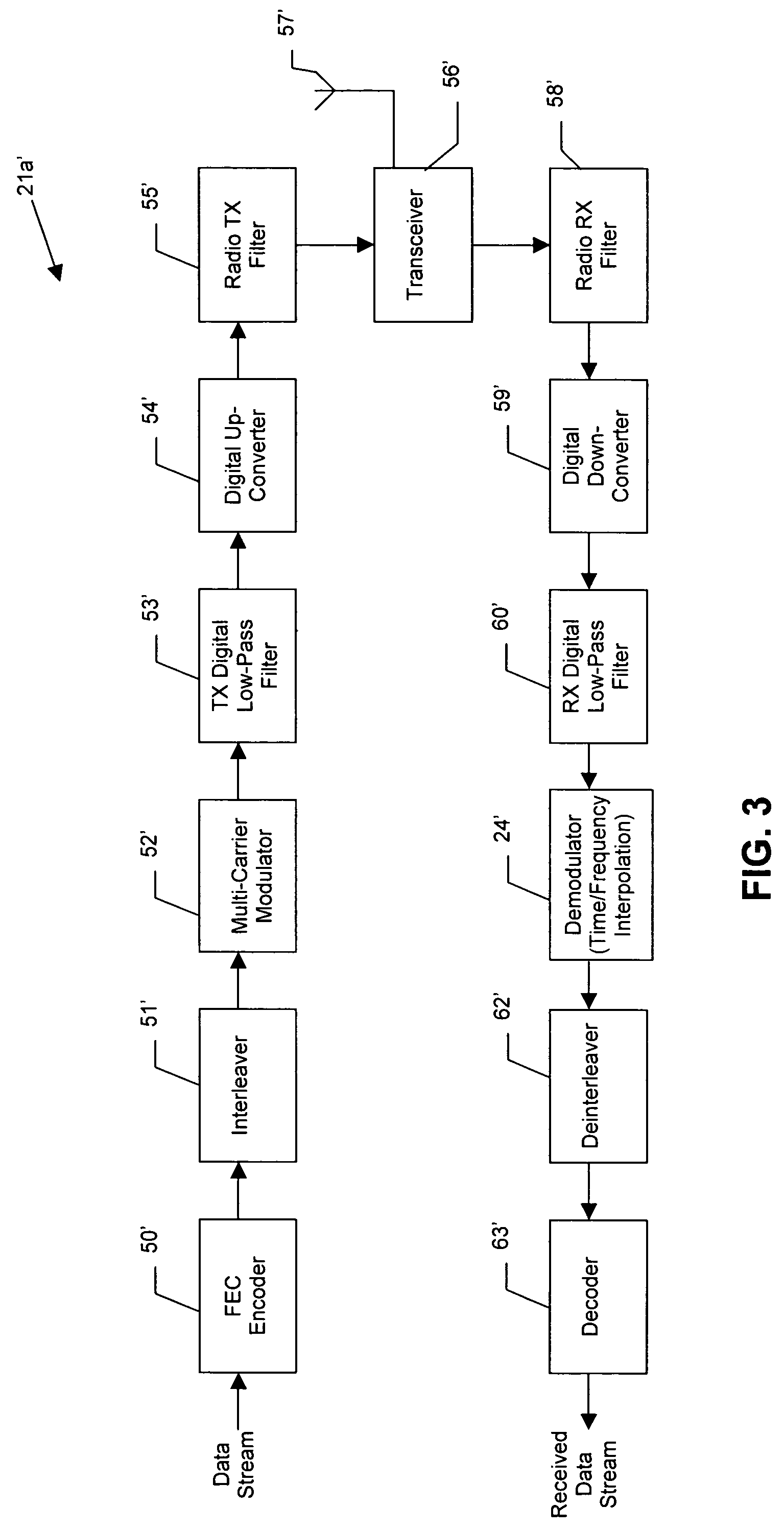

Wireless communications device providing time and frequency-domain channel estimates interpolation and related methods

ActiveUS20060109919A1Improved channel estimationImprove methodError preventionLine-faulsts/interference reductionDelay spreadTime domain

A wireless communications device which may include a wireless receiver for receiving wireless signals comprising unknown data portions over a channel, and a demodulator connected to the wireless receiver. The demodulator may be for estimating a delay spread and a fade rate associated with the channel, determining a desired time-domain interpolation filter based upon the estimated fade rate, and determining a desired frequency-domain interpolation filter based upon the estimated delay spread. The demodulator may further generate channel estimates for the unknown data portions based upon the desired time-domain interpolation filter and the desired frequency-domain interpolation filter, and determine the unknown data portions based upon the channel estimates.

Owner:HARRIS GLOBAL COMMUNICATIONS INC

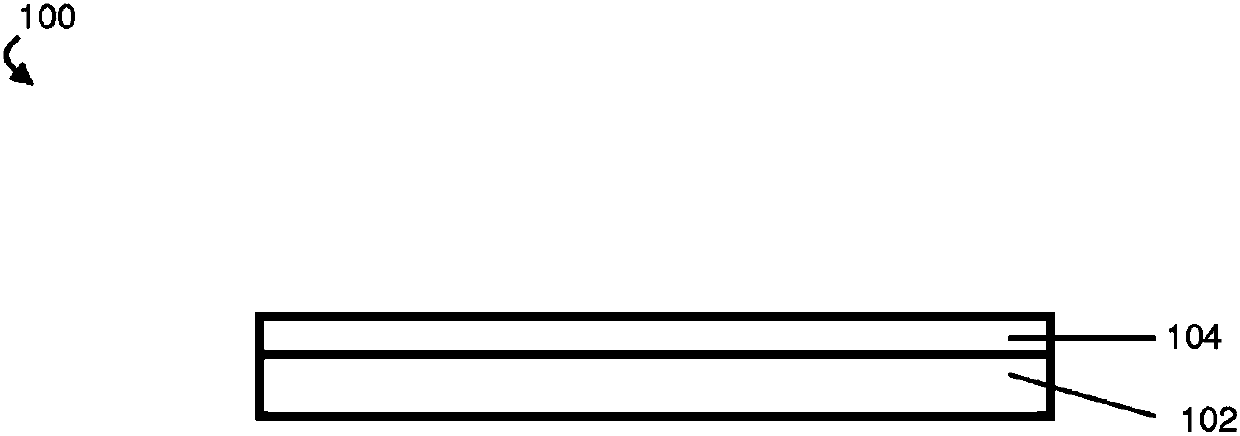

Curable photochromic compositions and optical articles prepared therefrom

The present invention provides a curable, organic polymeric photochromic composition comprising: a photochromic amount of at least one photochromic material; a polymeric polyol having carbonate groups along its backbone and having a number average molecular weight greater than 5000 g / mole; and a curing agent having reactive functional groups capable of reacting with hydroxyl groups on the polymeric polyol. After curing and after the Photochromic Performance Test the composition demonstrates a T1 / 2 fade rate of less than 200 seconds.Also provided is a photochromic article comprising a rigid substrate and a photochromic organic polymeric coating applied to a surface of the substrate. The photochromic organic polymeric coating comprises the composition described above.

Owner:TRANSITIONS OPTICAL INC

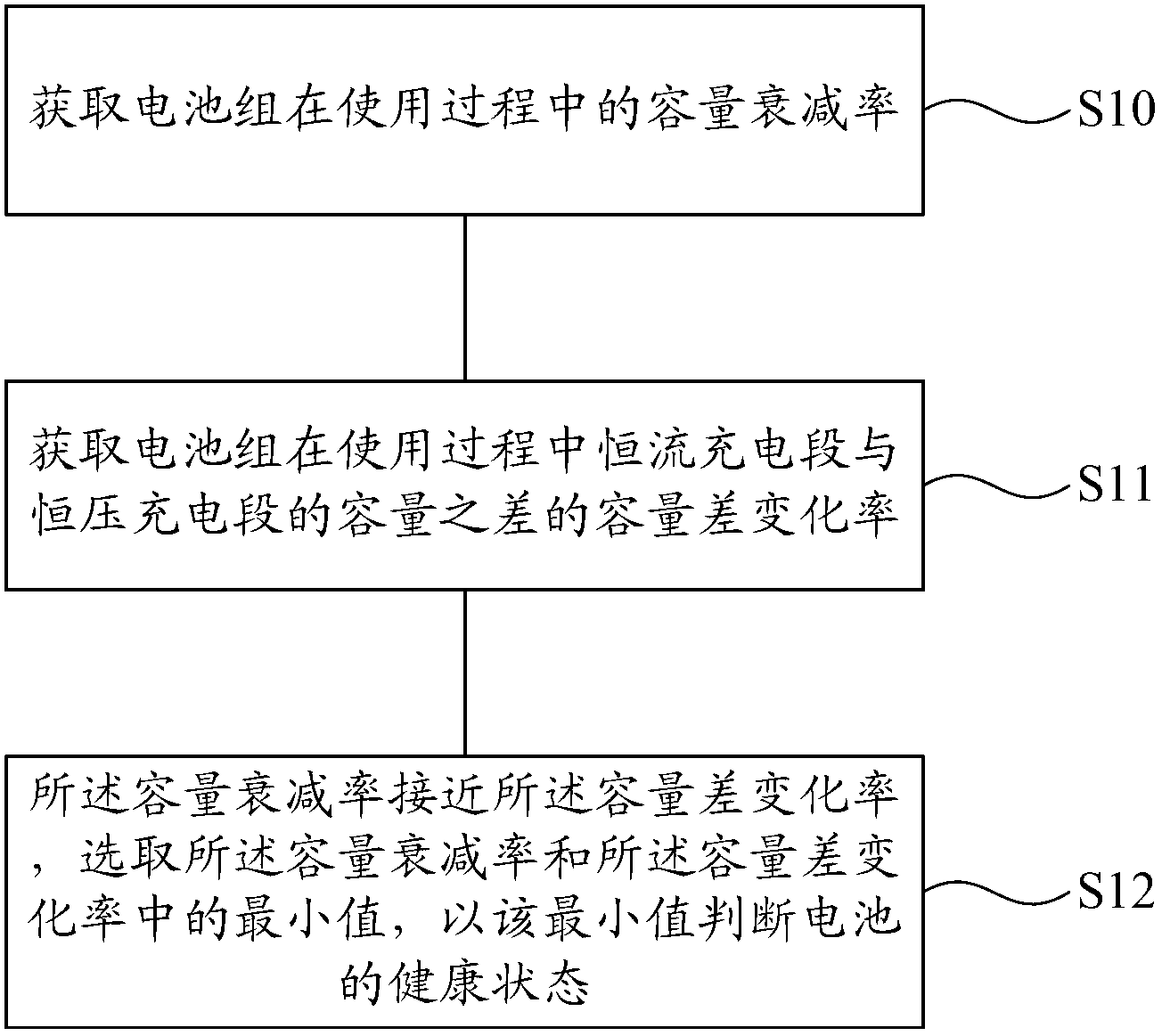

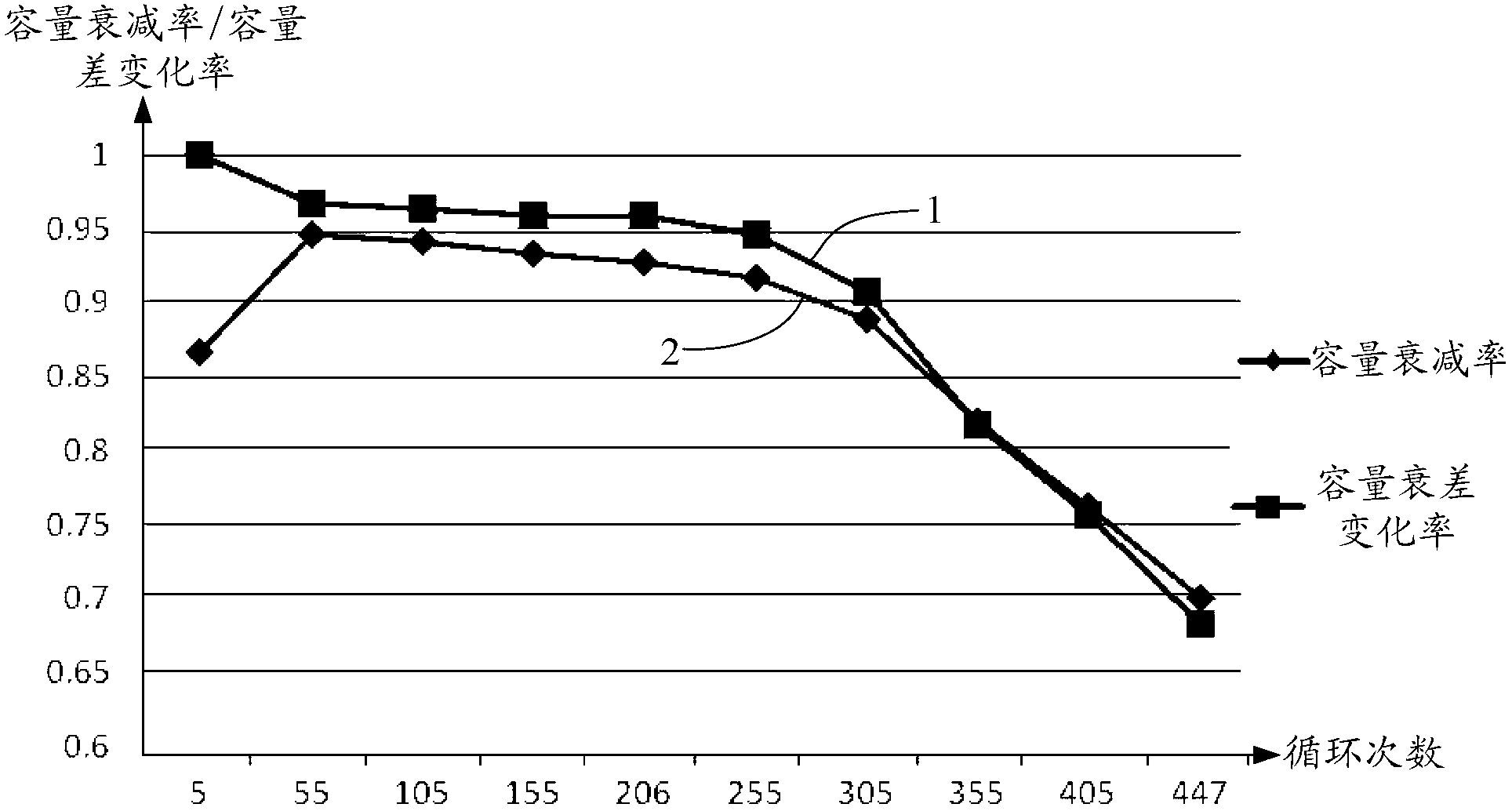

Method for estimating health state of lithium battery

ActiveCN103163480AImprove estimation accuracyThe evaluation method is simpleElectrical testingEstimation methodsEngineering

The embodiment of the invention discloses a method for estimating the health state of a lithium battery, and relates to the technical field of batteries. In order to fulfill the aims of high accuracy of data estimation, simple estimation method and low cost, the invention provides the method. The method comprises the following steps of: acquiring the capacity fading rate of a battery pack in the using process; acquiring the capacity difference change rate of difference between capacity at a constant-current charge section and capacity at a constant-voltage charge section of the battery pack in the using process; and selecting a minimum value in the capacity fading rate and the capacity difference change rate, and judging the health state of the battery by the minimum value, wherein the capacity fading rate is close to the capacity difference change rate. The method is mainly applied to the judgment of the health state of the battery.

Owner:GREAT WALL MOTOR CO LTD

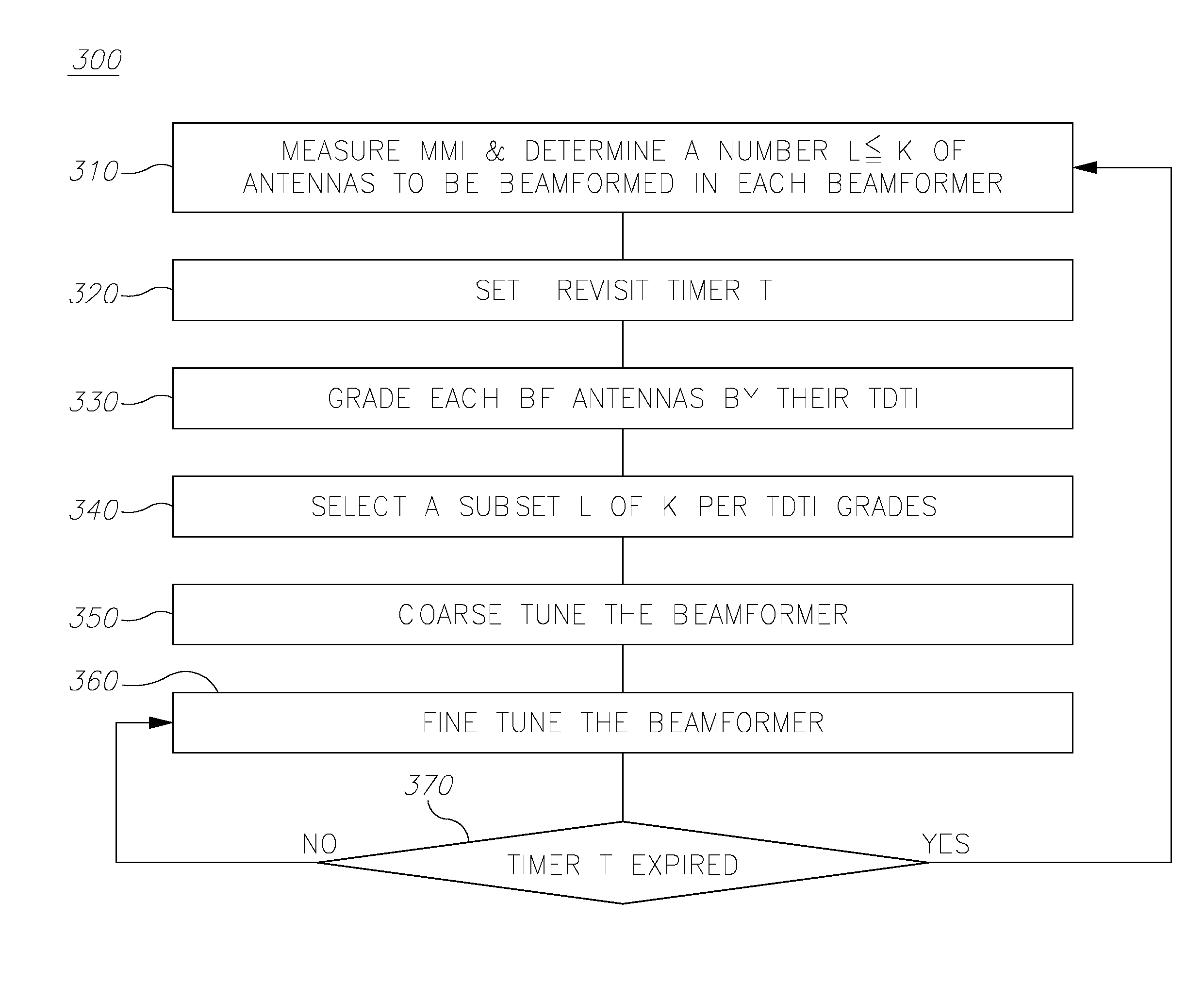

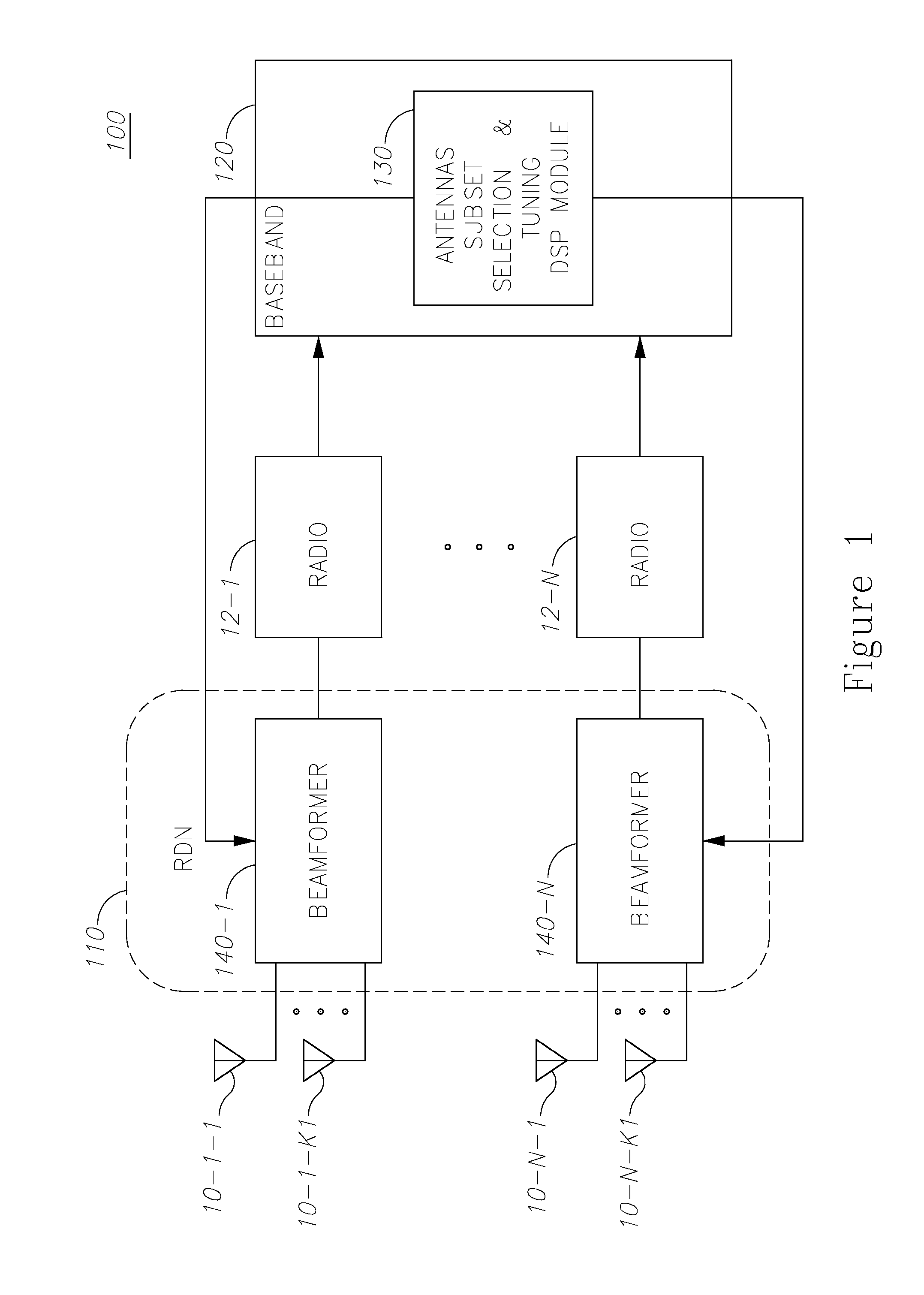

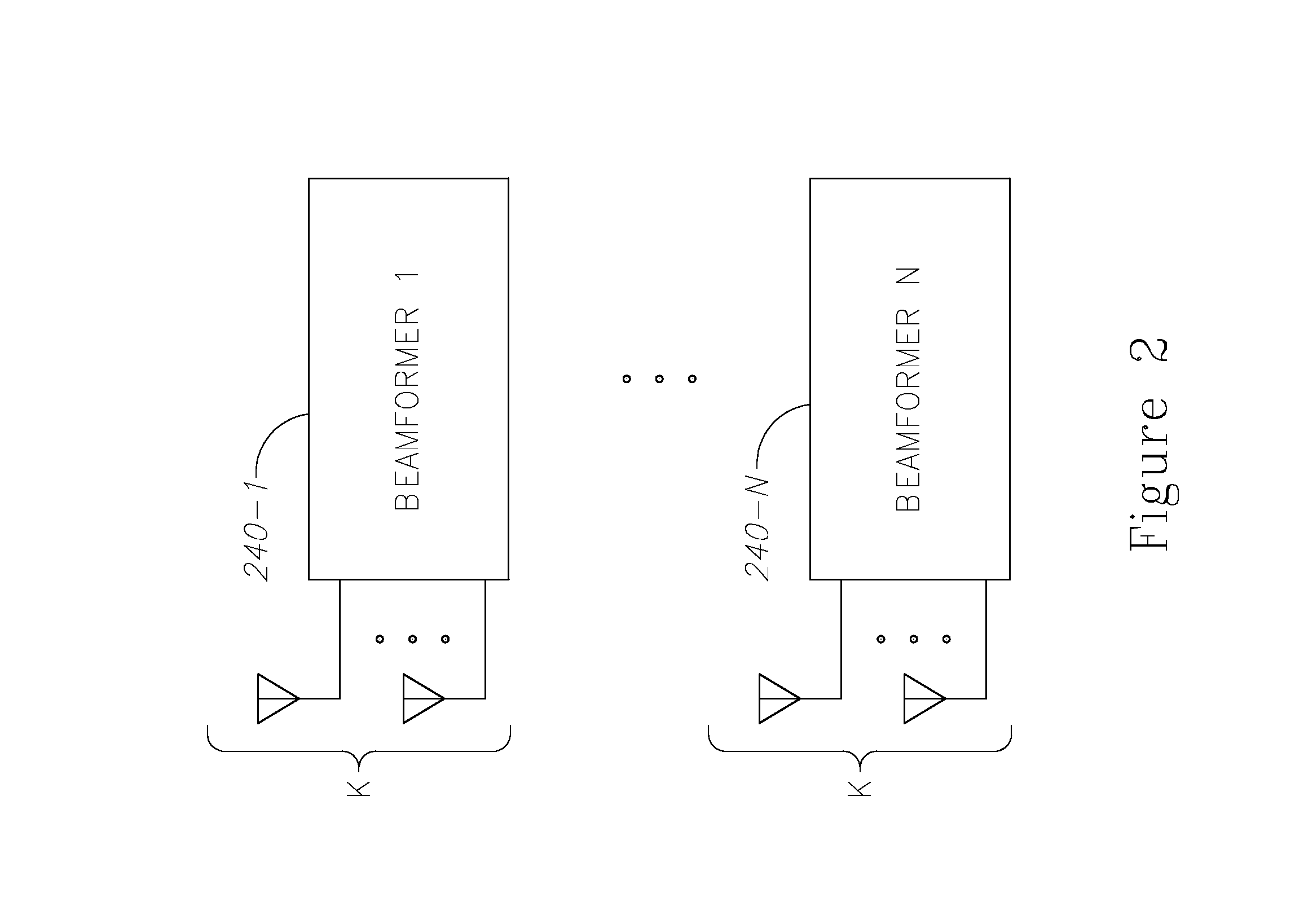

Implementing blind tuning in hybrid MIMO RF beamforming systems

InactiveUS8644413B2Keep for a long timeModulated-carrier systemsDiversity/multi-antenna systemsEngineeringFading rate

A system and a method for applying a blind tuning process to M antennas coupled via N beamformers to a multiple input multiple output (MIMO) receiving system having N channels, wherein M>N, are provided herein. The method includes the following steps: Periodically measuring channel fading rate at a baseband level to determine the number of antennas L out of K antennas connected to each one of the beamformers, to be combined at each one of the N beamformers; assigning the antennas to the subset L according to some criteria such as best quality indicator; repeatedly applying a tuning process to L antennas in each one of the N beamformers.

Owner:MAGNOLIA BROADLAND INC

Ink set, ink cartridge, ink jet printer and recording method

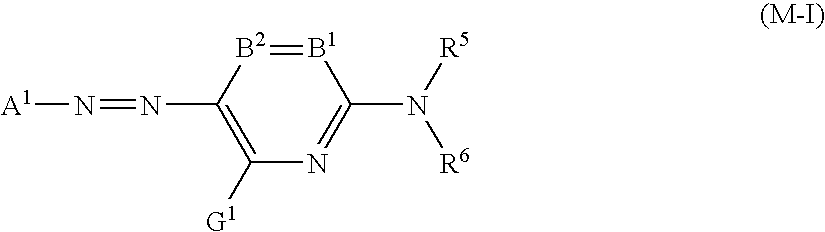

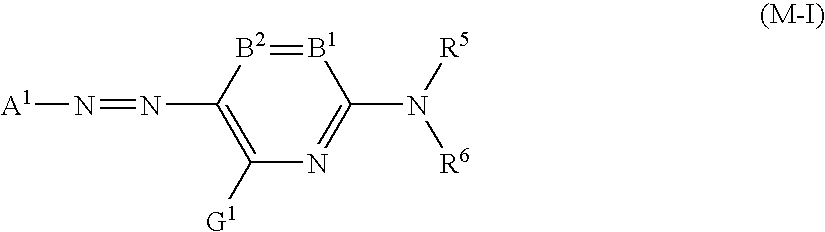

ActiveUS20040050291A1Excellent in handleabilityExcellent in odorMonoazo dyesMeasurement apparatus componentsComputer printingImage recording

The ink set of the present invention provides a high ejection stability, gives an image having an excellent hue, light-resistance and waterproofness and improves the image preservability under severe conditions in ink jet recording, in which the ink set comprising a plurality of inks different in hues, wherein the plurality of inks includes a yellow ink containing a coloring agent that is a dye having: a lambdamax of from 390 nm to 470 nm; an I(lambdamax+70 nm) / I(lambdamax) ratio of not greater than 0.4, in which I(lambdamax) is the absorbance at lambdamax and I(lambdamax+70 nm) is the absorbance at (lambdamax+70 nm); and a forced fading rate constant of not greater than 5.0x10<-2 >[hour<-1>], an ink cartridge having the ink set received therein, an ink jet printer comprising the ink cartridge mounted therein and an image recording method.

Owner:FUJIFILM HLDG CORP +1

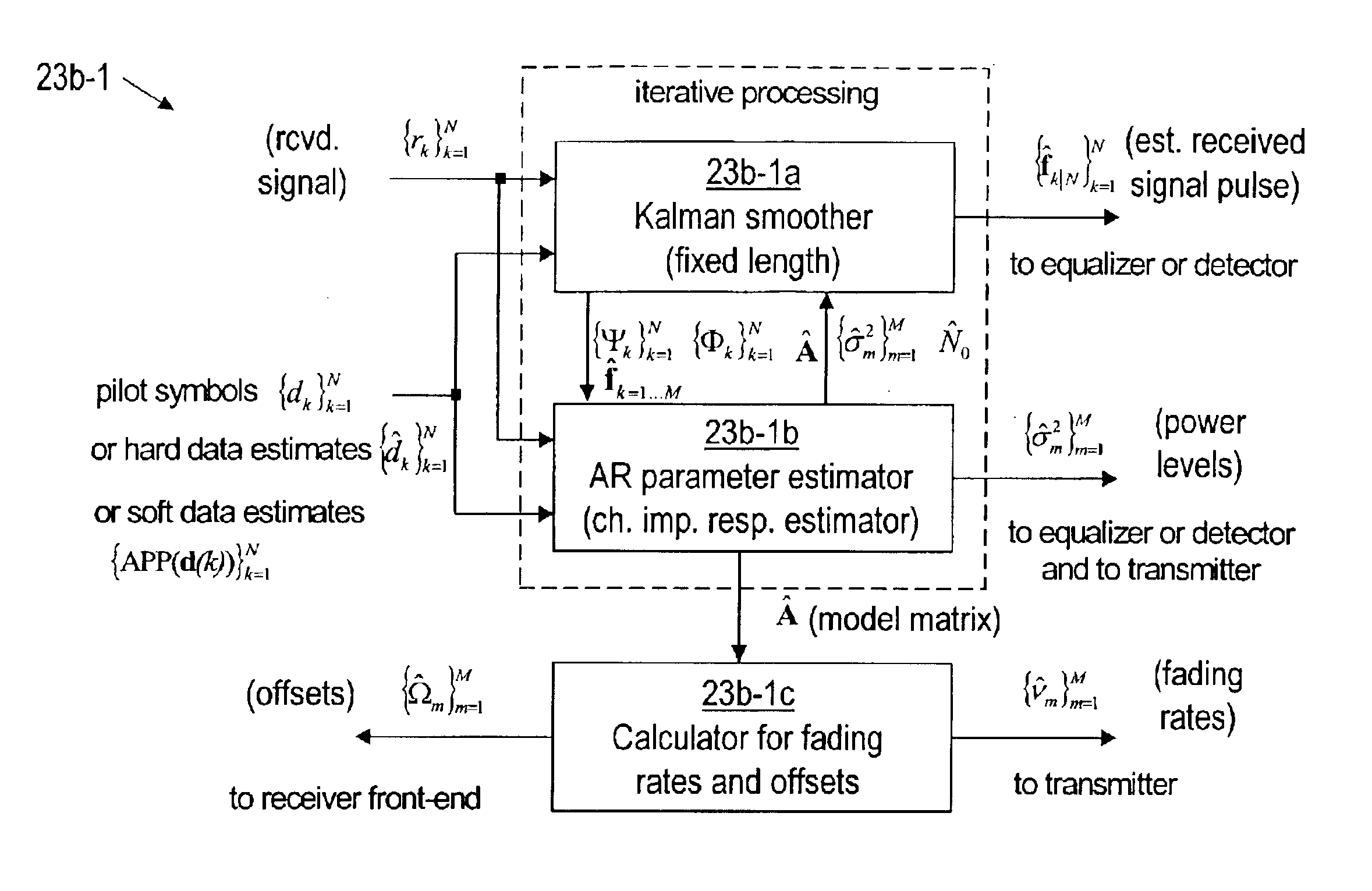

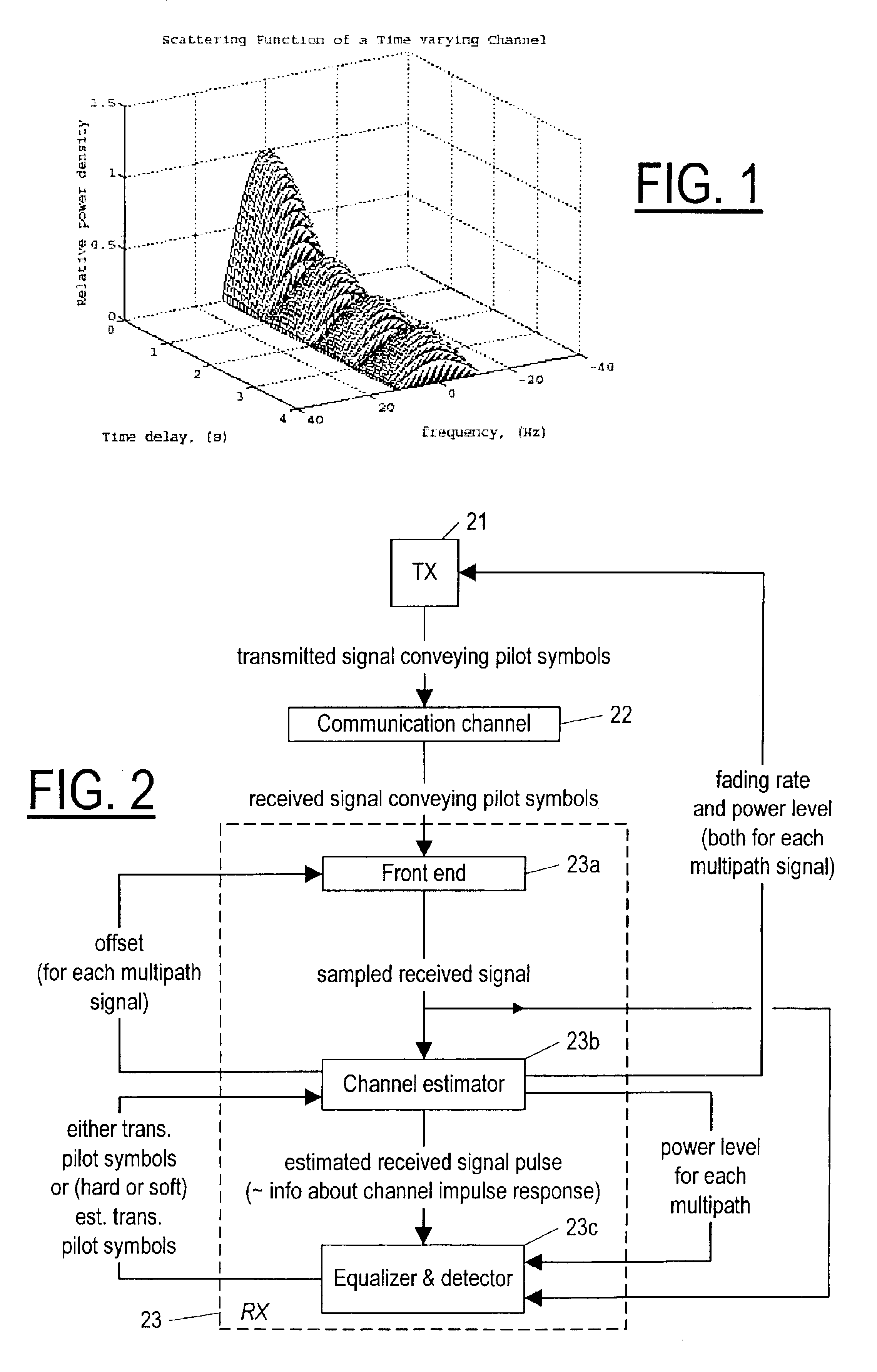

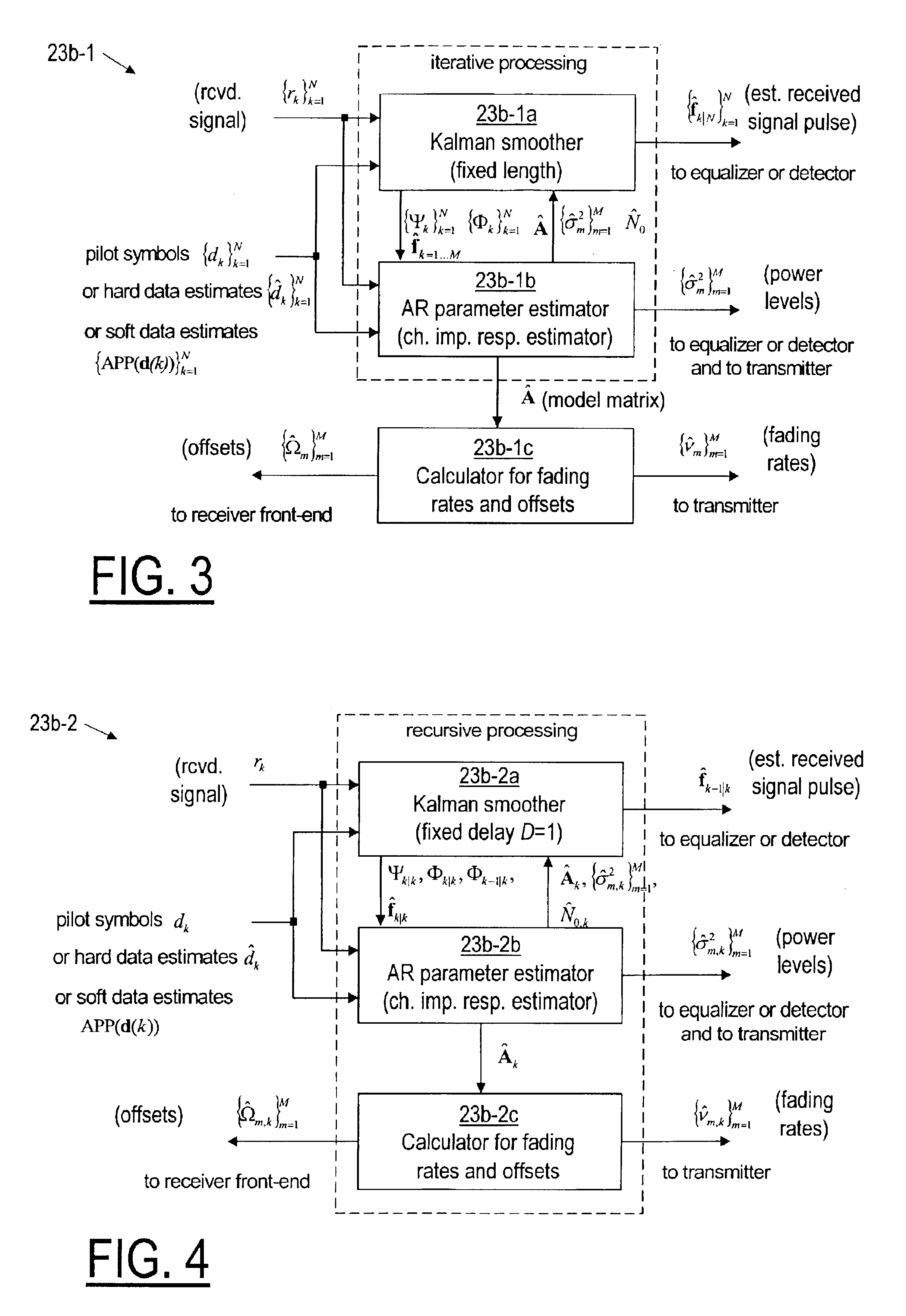

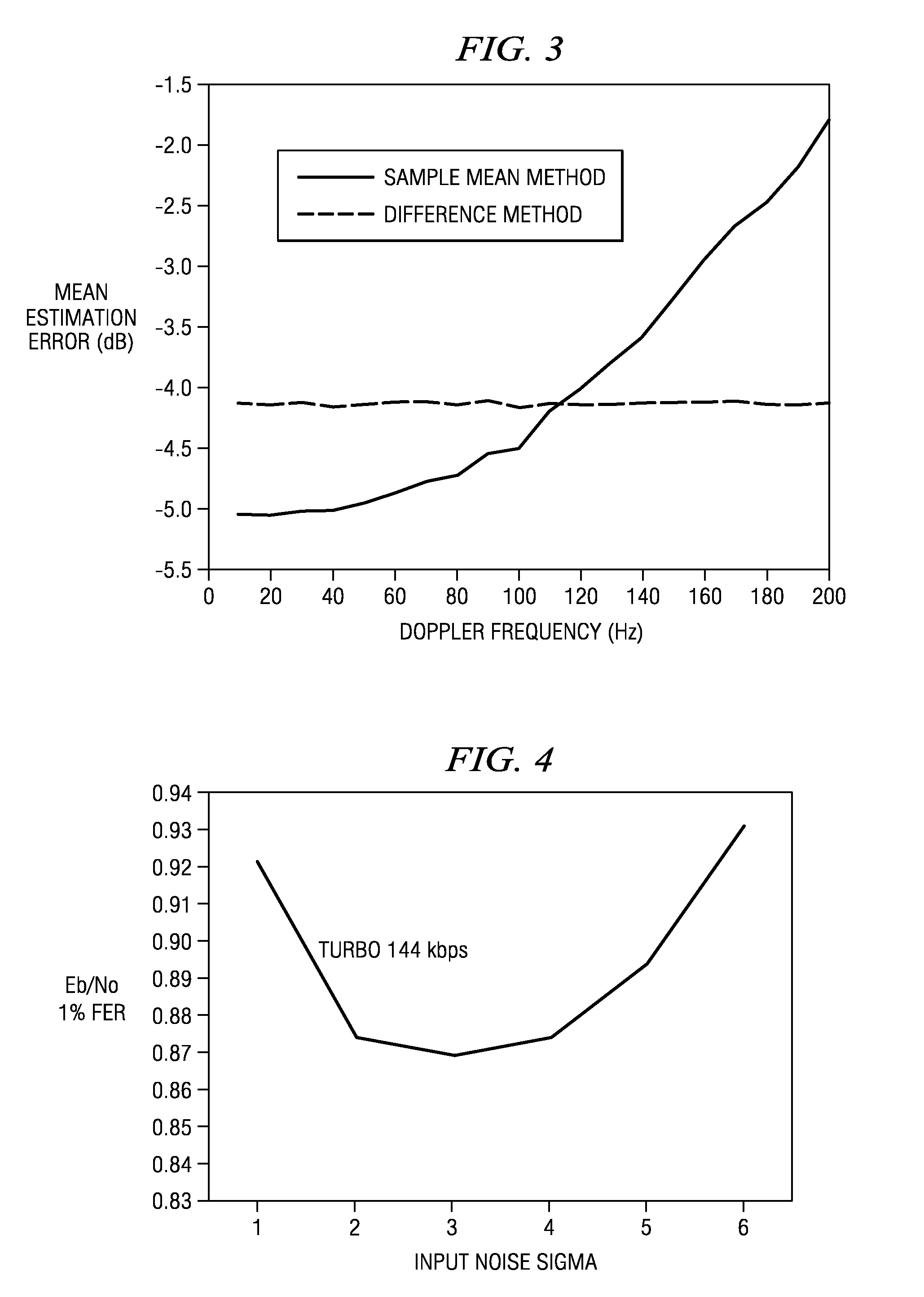

Method and apparatus for estimating carrier frequency offset and fading rate using autoregressive channel modeling

InactiveUS6868276B2Baseband system detailsReceiver specific arrangementsChannel impulse responseCommunications system

A method for use by a receiver of a wireless communication system in providing information of use in adapting to changing characteristics of a communication channel (22) over which the receiver (23) receives a signal at an offset from a carrier frequency due to changes in the characteristics of the communication channel characteristics, the changing communication channel characteristics also causing from time to time changes in other characteristics of the communication channel (22), the method characterized by: a step (23b-1a 23b-1b) of providing expectation maximization estimates of autoregressive parameters representing the changing communication channel (22) using received signal samples extracted from the received signal and corresponding to transmitted pilot symbol; and a step (23b-1a 23b-1c) of providing an estimate of the channel impulse response and an estimate of a frequency offset of at least one multipath signal based on the estimated values of the autoregressive parameters.

Owner:NOKIA TECHNOLOGLES OY

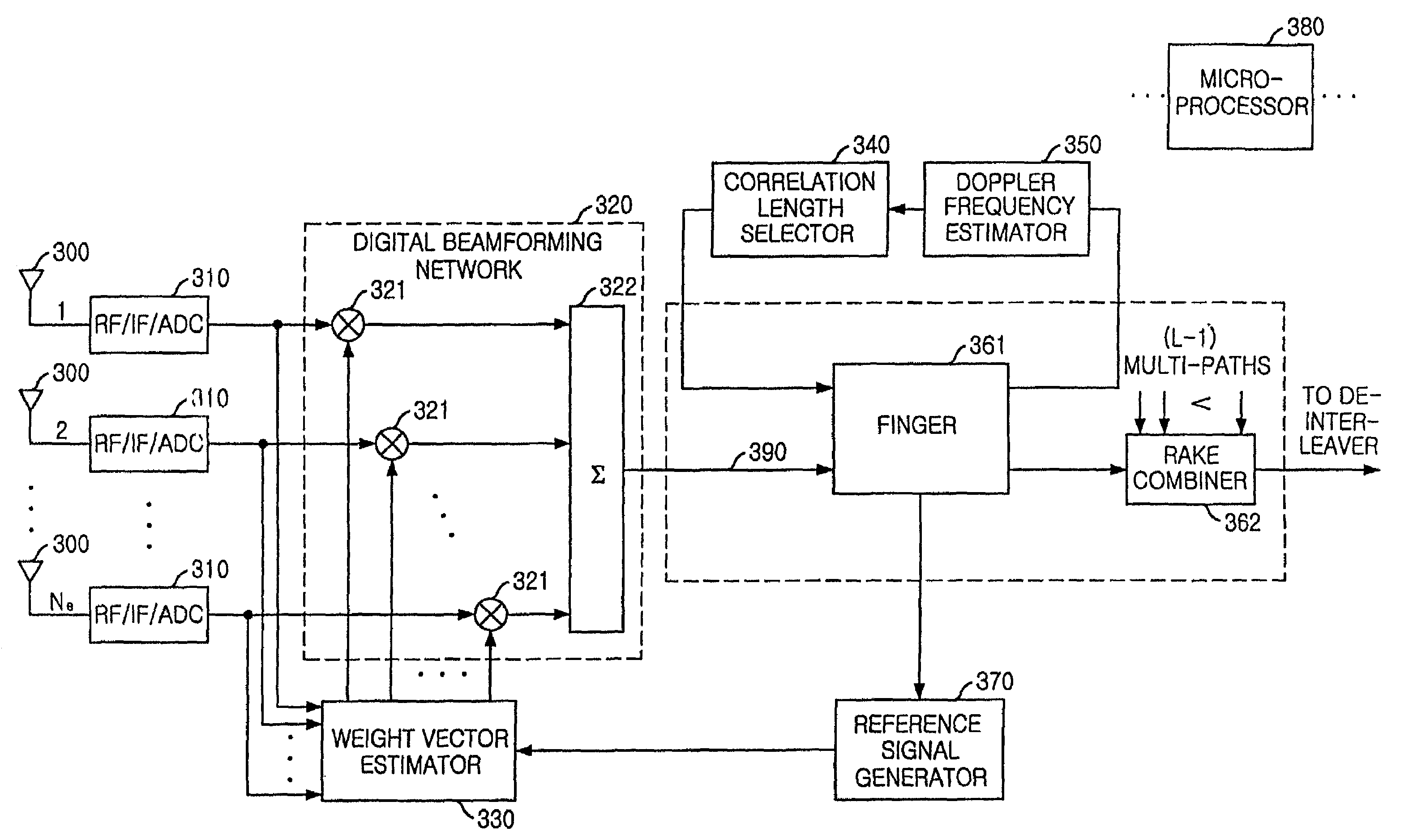

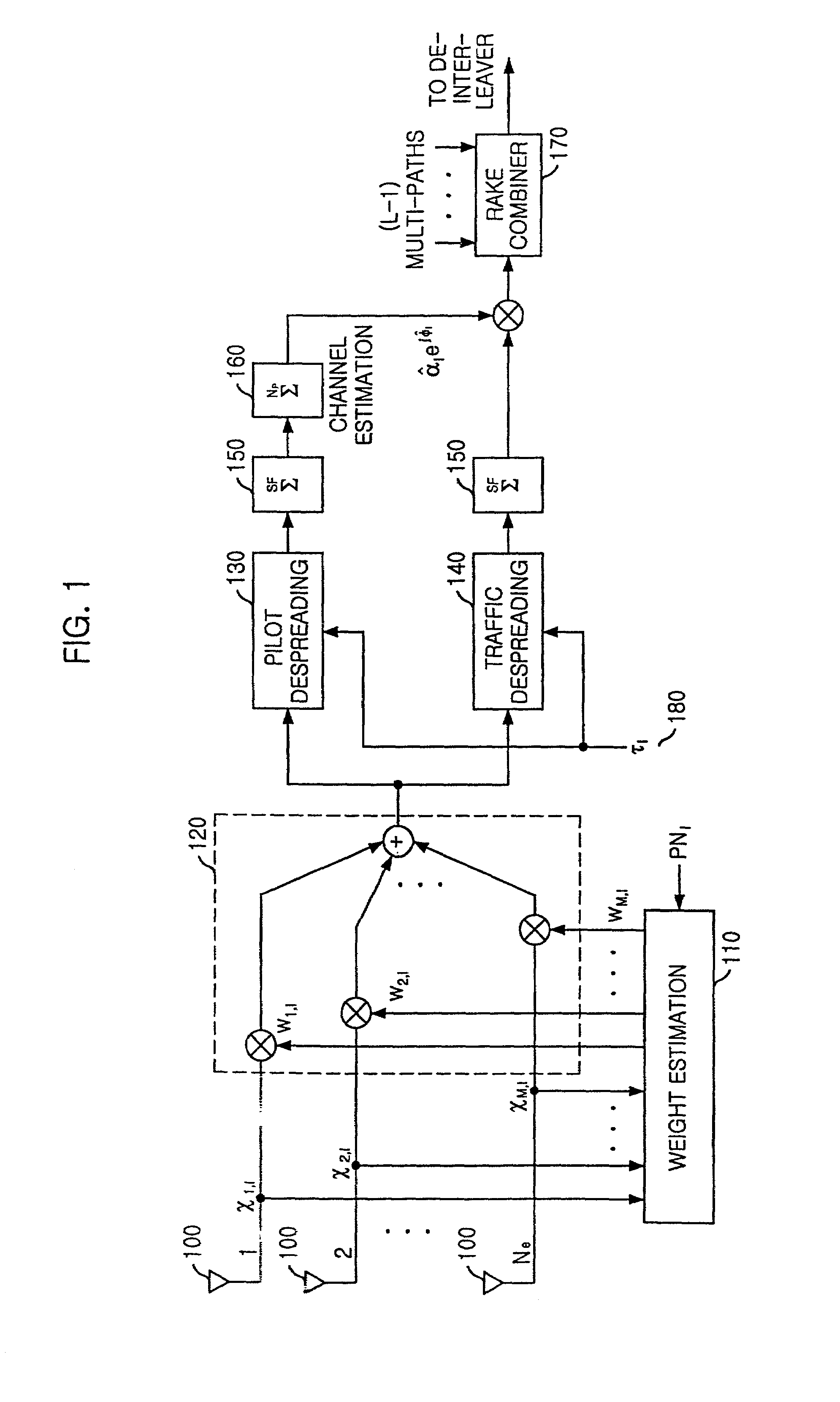

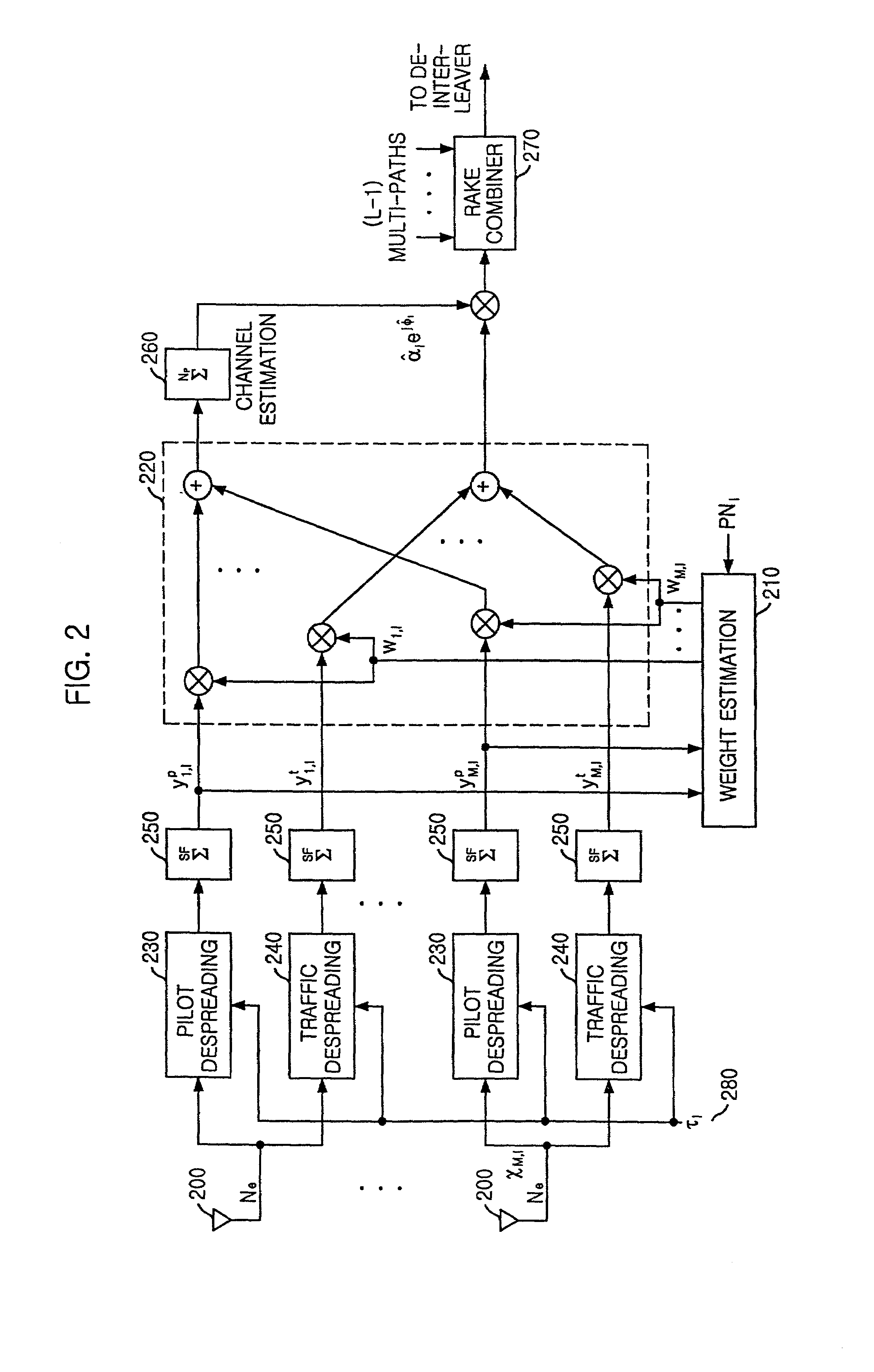

Apparatus and method for very high performance space-time array reception processing using chip-level beamforming and fading rate adaptation

InactiveUS7095814B2Increase capacityExpand coverageSpatial transmit diversityPolarisation/directional diversityEngineeringFading rate

An apparatus for very high performance space-time array reception processing using chip-level beamforming and fading rate adaptation is disclosed. The space-time array receiving system includes a plurality of digital beamforming networks for forming beams of signals by spatial-filtering the signals, to thereby generate spatial-filtered signals; a plurality of demodulating unit for demodulating the spatial-filtered signals to generate demodulated signals; correlating unit for estimating a fading channel signal based on pilot channel signals; Doppler frequency estimating unit for estimating Doppler frequency of the fading channel signal to generate Doppler frequency estimated values; correlation length selection unit for selecting a correlation length of the pilot channel signals based on the Doppler frequency estimated values; a plurality of reference signal generation unit for generating reference signals based on output signals from the correlating unit; and a plurality of weight vector estimating unit for generating weight vectors based on the reference signals and the signals and for providing the weight vector to the digital beamforming networks.

Owner:ELECTRONICS & TELECOMM RES INST

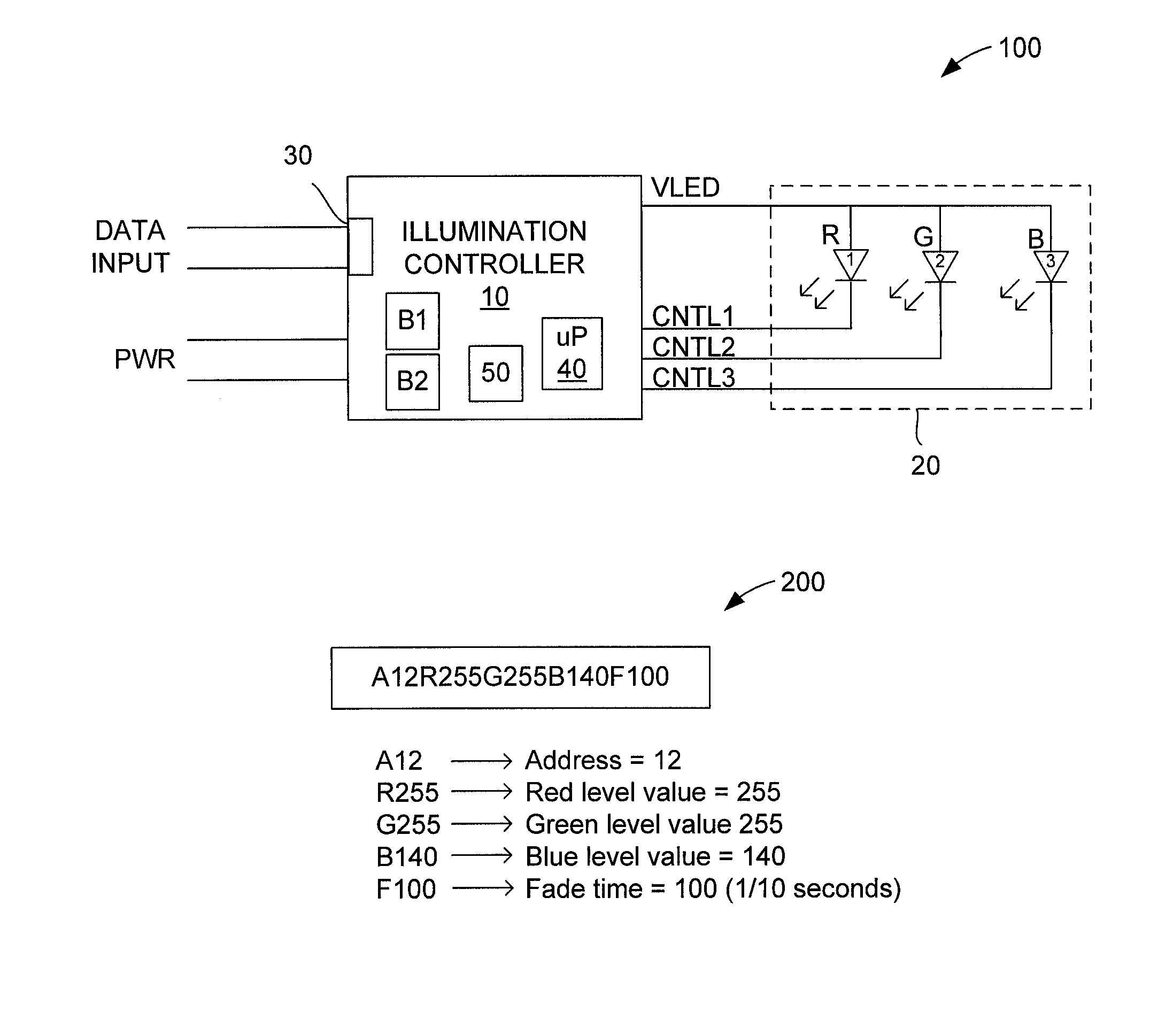

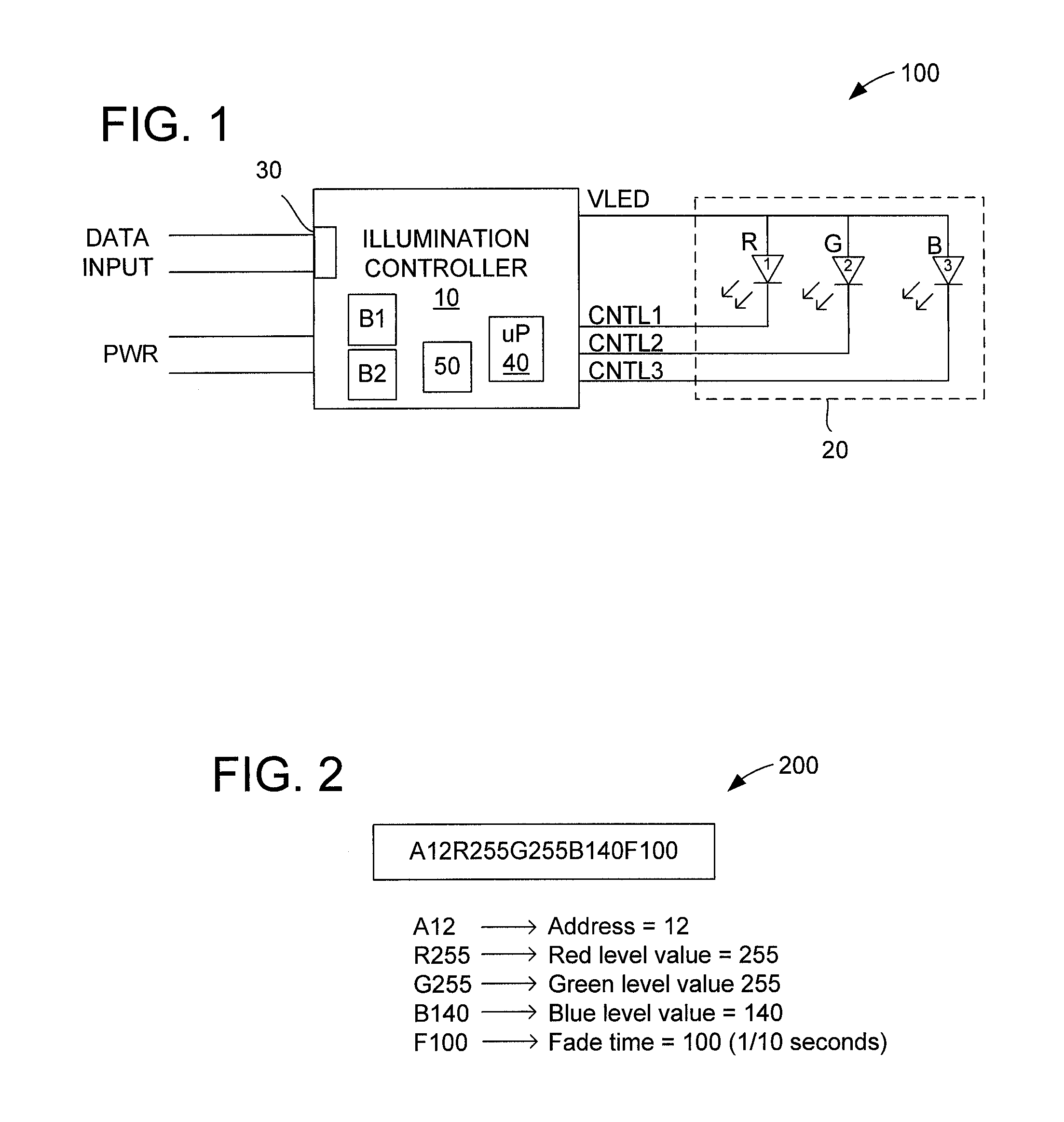

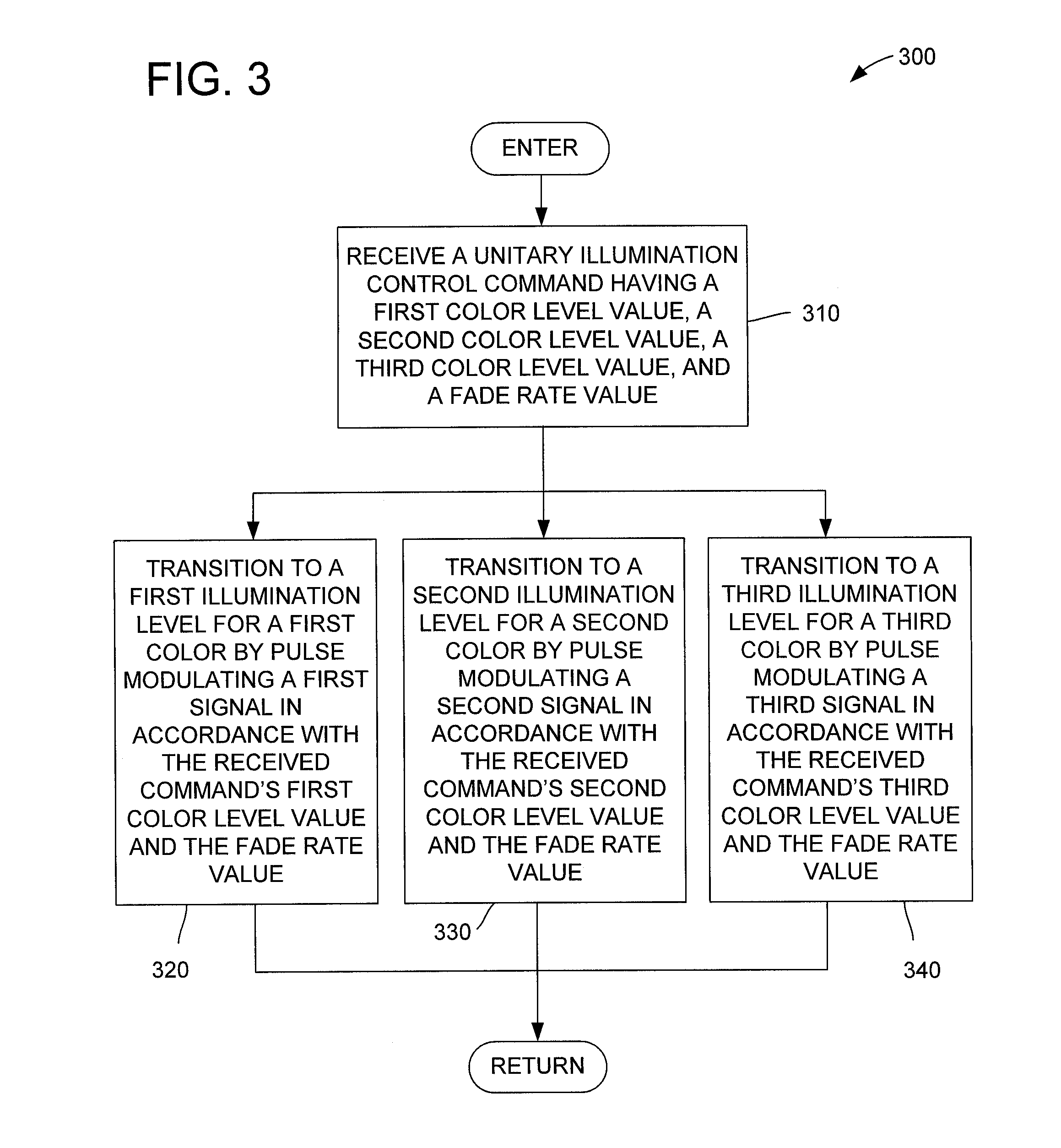

LED illumination control using simple digital command structure

Owner:MECHOSHADE SYST LLC

Localised and distributed scheduling control method and apparatus

ActiveUS20090175226A1Signal overheadMaintain performanceBaseband system detailsTransmission control/equalisingControl selectionMobile radio

The present invention provides for a method of controlling selection of a localised scheduling scheme or a distributed scheduling scheme within an OFDMA downlink and including the step of estimating a fading characteristic and initiating switching between the scheduling schemes responsive to the result of the said estimation, wherein the fading characteristic can comprise one of fading rate or fading type, and wherein the invention can provide for such estimating functionality within a mobile radio communications device.

Owner:LENOVO INNOVATIONS LTD HONG KONG

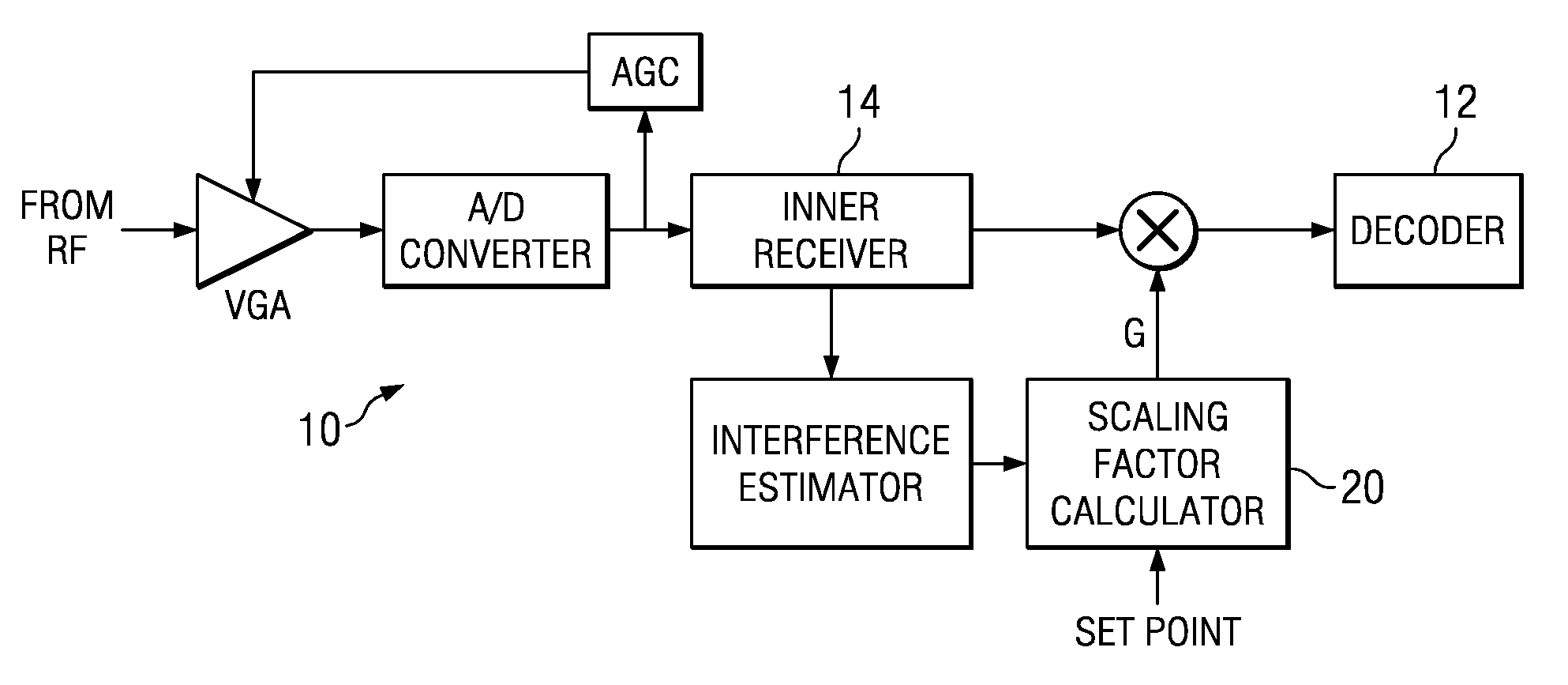

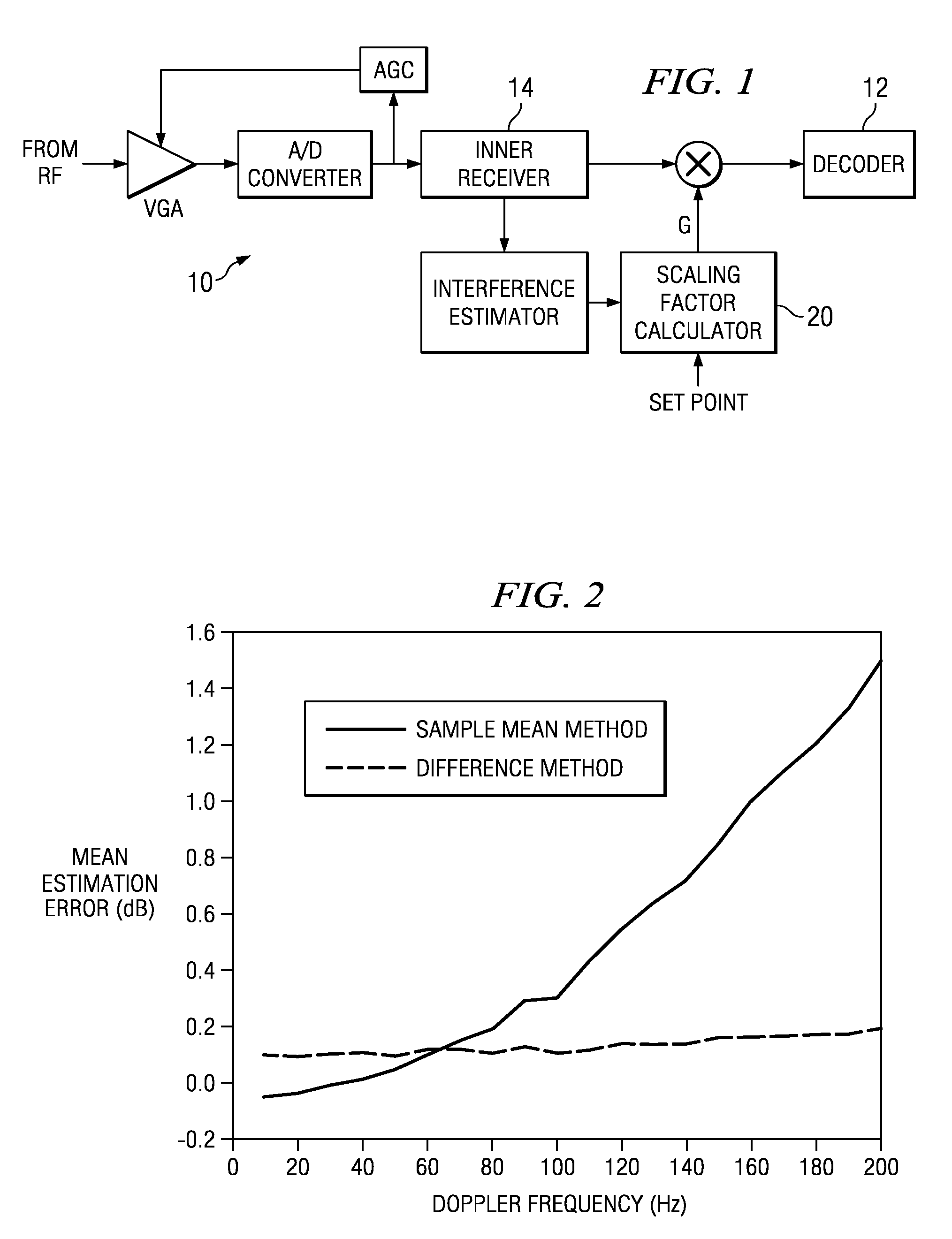

Method and apparatus for decoder input scaling based on interference estimation in CDMA

InactiveUS7555067B2Improve performanceAvoid estimation bias problemError preventionLine-faulsts/interference reductionRake receiverFading rate

A method and apparatus adaptively scales the decoder input for a low-cost user equipment (UE) to reduce the memory requirement without degrading decoder performance. In order to optimize the decoder performance for a small number of input bits, the method estimates the interference of the inner receiver output and scales the decoder input such that its variance is kept constant. The method further estimates the interference of the Pilot channel and translates it into the interference of the data channel in order to avoid the estimation bias problem in a noisy channel. The method then uses a difference value of the phase-corrected pilot symbol to solve the fading rate dependency problem of the sample mean method. For a Rake receiver, the method sums up the interference estimated from each finger. For a multi-antenna receiver, the method sums up the interference estimated from each antenna demodulating element.

Owner:TEXAS INSTR INC

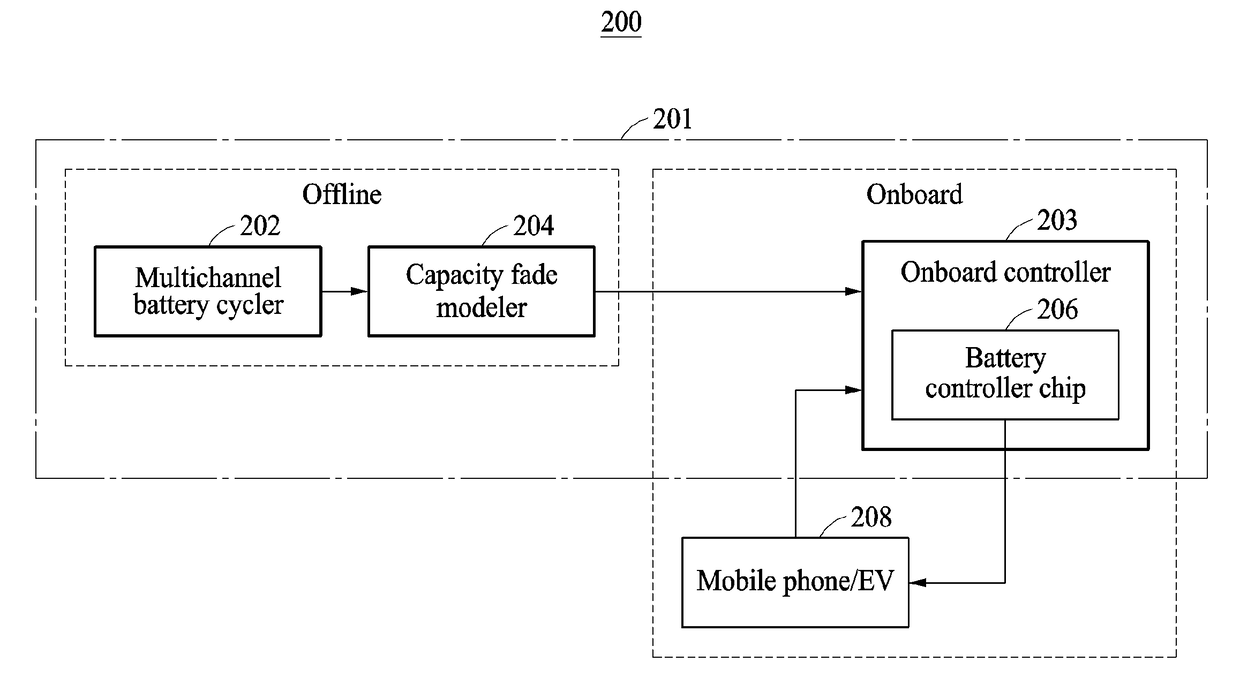

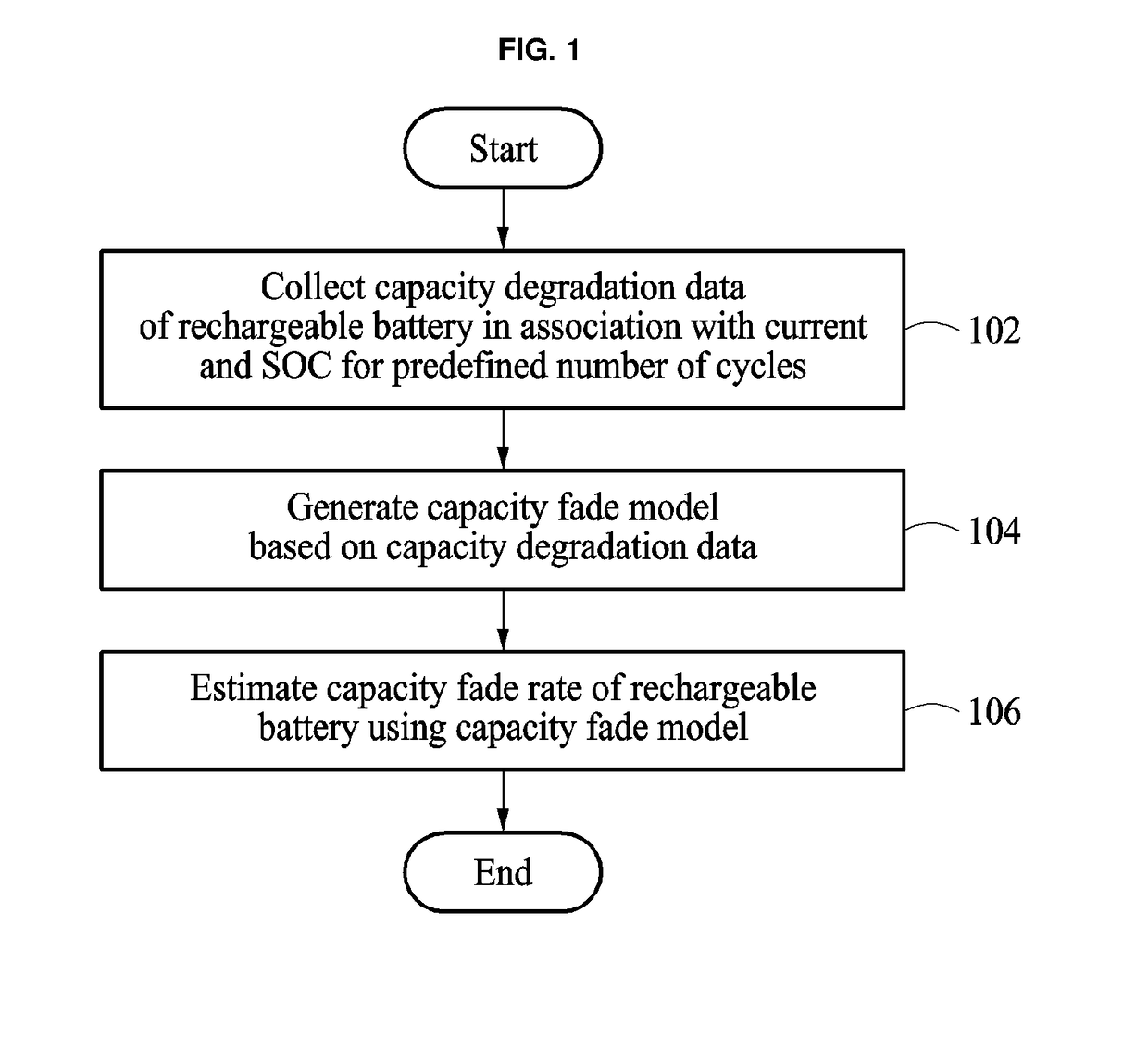

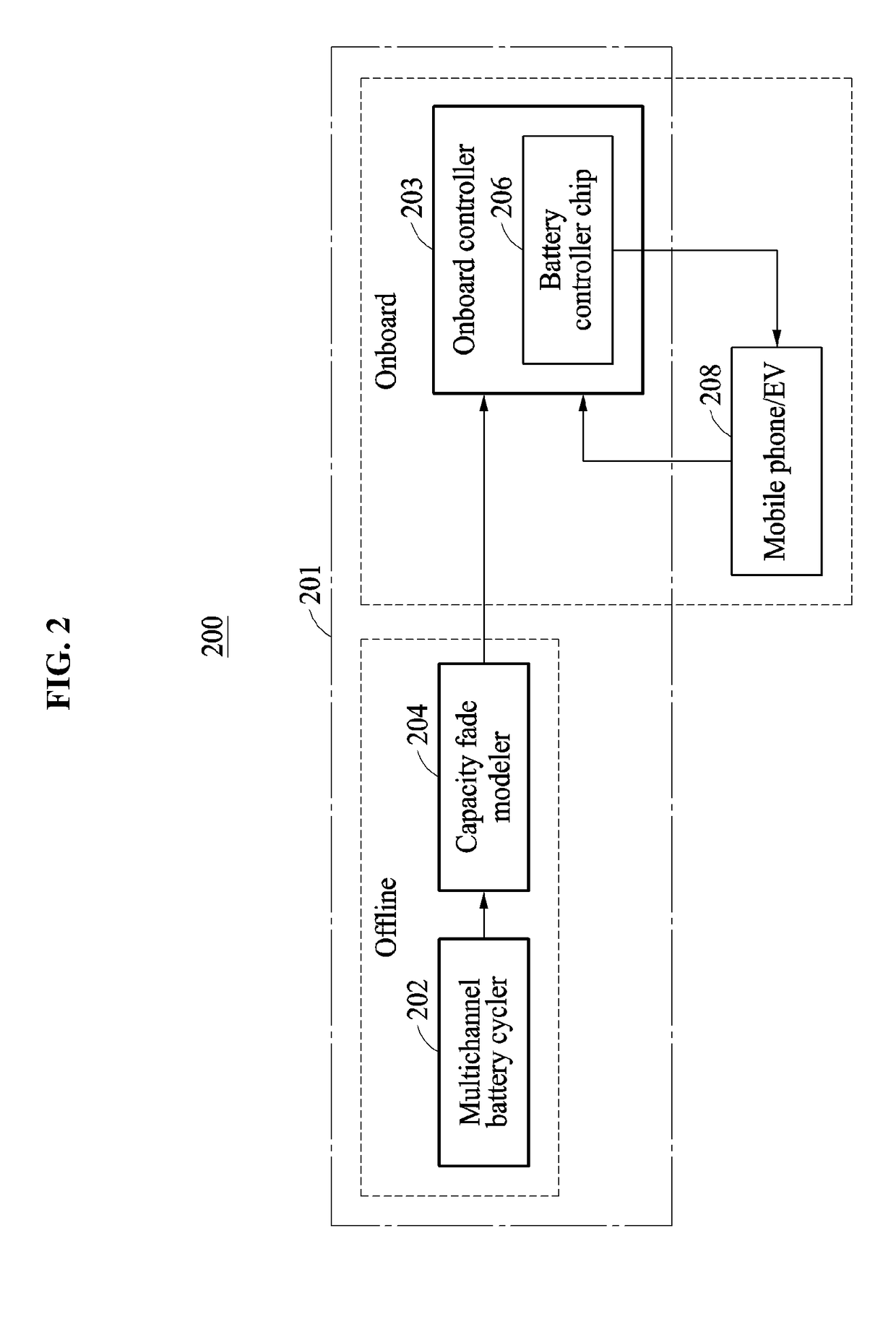

Method and apparatus to predict capacity fade rate of battery

ActiveUS20180316204A1Well formedCircuit monitoring/indicationDifferent batteries chargingState of chargeEngineering

A method and apparatus for predicting a capacity fade rate of a battery are provided. The method includes collecting capacity degradation data of a battery based on a current and a state of charge (SOC) for a predefined number of cycles, generating a capacity fade model based on the capacity degradation data, and estimating a capacity fade rate of the battery using the capacity fade model.

Owner:SAMSUNG ELECTRONICS CO LTD

Elastic heat transfer printing lettering film and production method thereof

An elastic heat transfer printing lettering film comprises a bearing bottom material, protection layer back coating liquid, a release layer pressure-sensitive adhesive, color layer printing ink and a bonding layer hot melt adhesive. The formula of the protection layer back coating liquid comprises 14 parts of amino resin, 4 parts of acrylic resin, 3 parts of silicon dioxide, 1 part of an amino resin cross-linking agent and 78 parts of a mixing solvent. The formula of the release layer pressure-sensitive adhesive comprises 10 parts of organosilicone pressure-sensitive adhesive, 15 parts of silica gel, 2 parts of a platinum catalyst and 73 parts of a 120# solvent. The formula of the color layer printing ink comprises 25 parts of high-elasticity high-temperature-resisting TPU resin, 10 parts of toner, 3 parts of a wetting dispersing leveling assistant and 62 parts of the mixing solvent. The formula of the bonding layer hot melt adhesive comprises 65 parts of high-elasticity and low-temperature type TPU resin, 30 parts of high-melting-index low-temperature type TPU resin and 5 parts of a TPU opening agent. According to the elastic heat transfer printing film, the same-batch same-color difference delta E is smaller than or equal to 4, the thermoprint layer abrasion resistance is larger than or equal to 90%, the release force is equal to (0.10-3.00)N / 25 mm, washing resistance is achieved, the washing color fading rate is smaller than or equal to 10%, and the basic safety technology requirement conforms to the B type in the GB18401.

Owner:青艺(福建)烫画科技有限公司

Ink set and inkjet recording method

InactiveUS7273519B2Improve image qualityHigh fastnessMonoazo dyesDuplicating/marking methodsColor imageImage recording

An ink set where constituent inks all are an ink containing at least one dye having an oxidation potential more positive than 1.0 V (vs SCE), particularly where the ratio k1 / k2 of the fading rate constant (k1) of an image drawn by using the ink alone to the fading rate constant (k2) of a mixed color image drawn by using all constituent inks constituting the ink set in equivalent amounts with the same density measurement light as in the measurement of k1 is 0.7 to 1.3 in all inks. According the present invention, an inkjet ink set capable of giving an image having good image quality and excellent image fastness regardless of the color of image, such as aging stability, light fastness and water resistance, and an inkjet image recording method using the ink set are provided.

Owner:FUJIFILM HLDG CORP +1

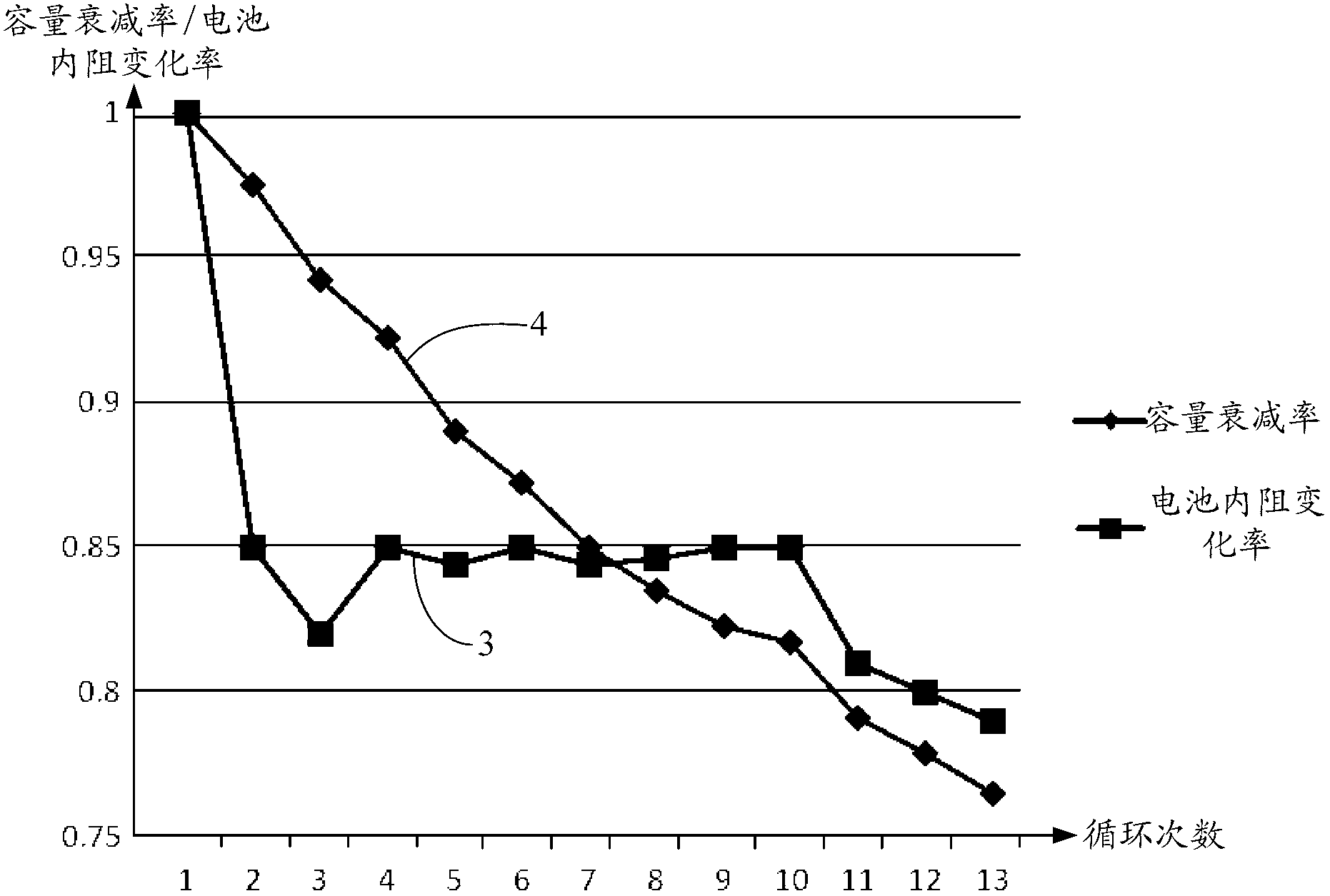

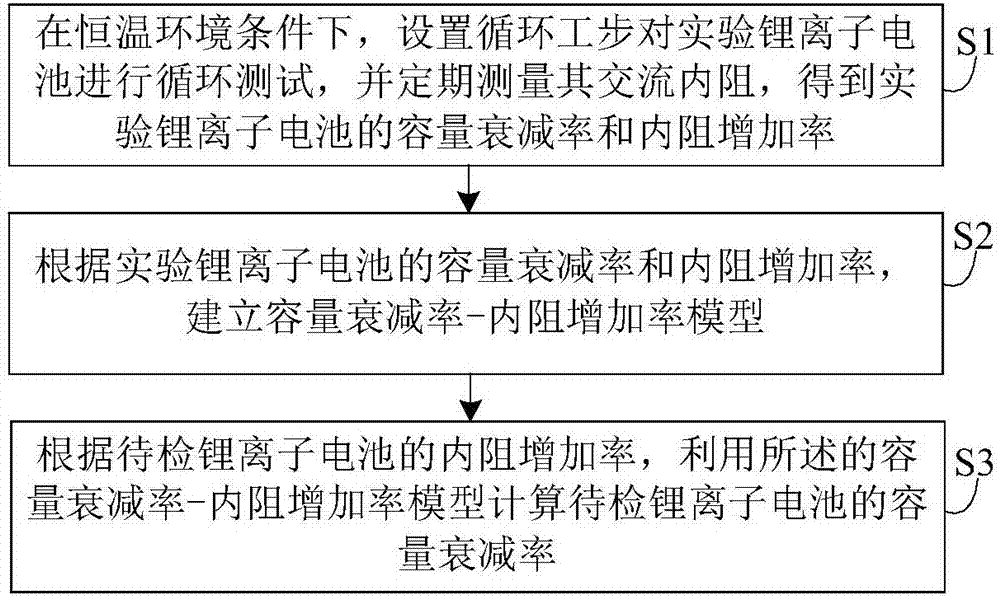

Lithium battery capacity fading rate calculating method

InactiveCN107064806ATimely replacementUniversalElectrical testingVehicular energy storagePower batteryInternal resistance

The invention discloses a lithium battery capacity fading rate calculating method, and belongs to the technical field of a power battery. The lithium battery capacity fading rate calculating method includes the steps: in a constant temperature environment condition, setting a circulation process step for taking a circulation test for an experiment lithium ion battery, periodically measuring the alternating current internal resistance of the lithium ion battery, and obtaining the capacity fading rate and the internal resistance increment rate of the experiment lithium ion battery; according to the capacity fading rate and the internal resistance increment rate of the experiment lithium ion battery, establishing a capacity fading rate-internal resistance increment rate model; and according to the internal resistance increment rate of the lithium ion battery to be detected, and utilizing the capacity fading rate-internal resistance increment rate model to calculate the capacity fading rate of the lithium ion battery to be detected. By establishing the capacity fading rate-internal resistance increment rate model for the lithium ion battery, according to the internal resistance increment rate of the lithium ion battery, the lithium battery capacity fading rate calculating method can obtain the capacity fading rate of the lithium ion battery, is suitable for any lithium ion batteries, and has strong universality and higher practicality.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

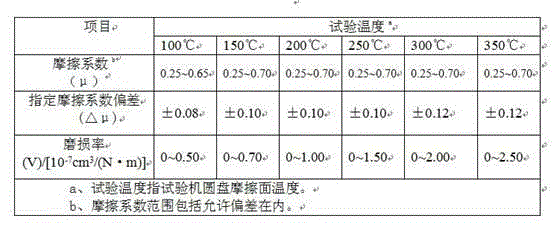

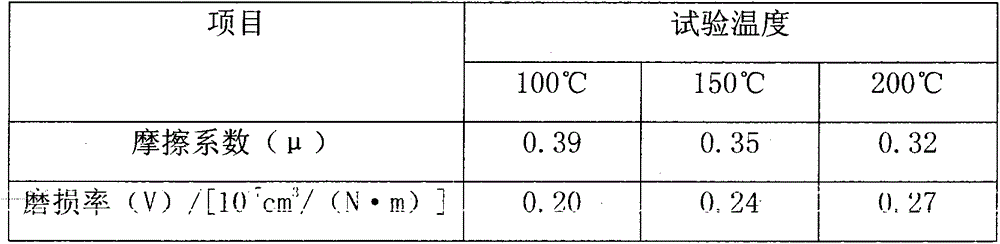

Low-fading-rate NAO friction material and preparation method thereof

ActiveCN103059808AEnhancement effect is goodPlay a role in bondingOther chemical processesFiberAcrylonitrile

The invention discloses a low-fading-rate NAO friction material and a preparation method thereof. The low-fading-rate NAO friction material has the characteristics of low cost, stable friction factor, low fading rate at high temperature, favorable restorability, low wear rate, high inner shear strength, small specific gravity and moderate hardness. The low-fading-rate NAO friction material disclosed by the invention is prepared from the following raw materials in parts by weight: 3-8 parts of resin, 2-6 parts of friction powder, 1-3 parts of butadiene-acrylonitrile rubber powder, 2-5 parts of tire powder, 20-22 parts of fiber and 63-68 parts of filler. The preparation method comprises the following steps: (1) mixing: weighing all raw materials according to the formula, putting into a high-speed mixer, and stirring for 2 minutes; (2) pre-pressure forming: putting the mixture into a cold-press mold, and carrying out pressure forming to obtain a cold blank; (3) hot pressing: putting the cold blank into a mold, and pressing; and (4) heat treatment: carrying out heat treatment in an oven, heating to 200 DEG C from room temperature, and baking for 4-16 hours.

Owner:珠海华莱汽车零部件有限公司

Protective layers in lithium-ion electrochemical cells and associated electrodes and methods

ActiveCN107078277ASolid electrolytesFinal product manufactureLithium oxideMetal–air electrochemical cell

Protective layers in lithium-ion electrochemical cells, and associated electrodes and methods, are generally described. The protective layers may comprise lithium-ion-conductive inorganic ceramic materials, such as lithium oxide, lithium nitride, and / or lithium oxysulfide. The resulting lithium-ion electrochemical cells may exhibit enhanced performance, including reduced capacity fade rates and reduced self-discharge rates.

Owner:SION POWER CORP

Asbestos-free friction material for electromobile/motorcycle brake pads and preparation method thereof

InactiveCN104946200AFully decompose and solidifyReduce releaseOther chemical processesFriction liningEpoxyAcrylonitrile

The invention relates to an asbestos-free friction material for electromobile / motorcycle brake pads and a preparation method thereof. The material comprises the following components in parts by weight: 12-20 parts of steel fiber, 1-8 parts of aramid fiber, 10-30 parts of butadiene-acrylonitrile rubber, 5-15 parts of styrene-butadiene rubber, 10-20 parts of carbon black, 5-12 parts of composite mineral fiber, 1-3 parts of sulfur, 1-4 parts of vermiculite, 2-7 parts of epoxy resin, 6-15 parts of barium sulfate, 3-8 parts of graphite and 0.5-1 part of accelerator. The preparation sequentially comprises the following steps: proportioning, stirring, cooling, crushing, screening, compacting and curing heat treatment to obtain the asbestos-free friction material for electromobile / motorcycle brake pads. The asbestos-free friction material overcomes the defect that the existing electromobile / motorcycle brake pad can not easily satisfy multiple performance demands, and has the advantages of high wear resistance, high compression resistance, stable friction factor, low fading rate, no noise, simple production technique, high efficiency, low production cost and the like.

Owner:GUANGXI UNIV FOR NATITIES

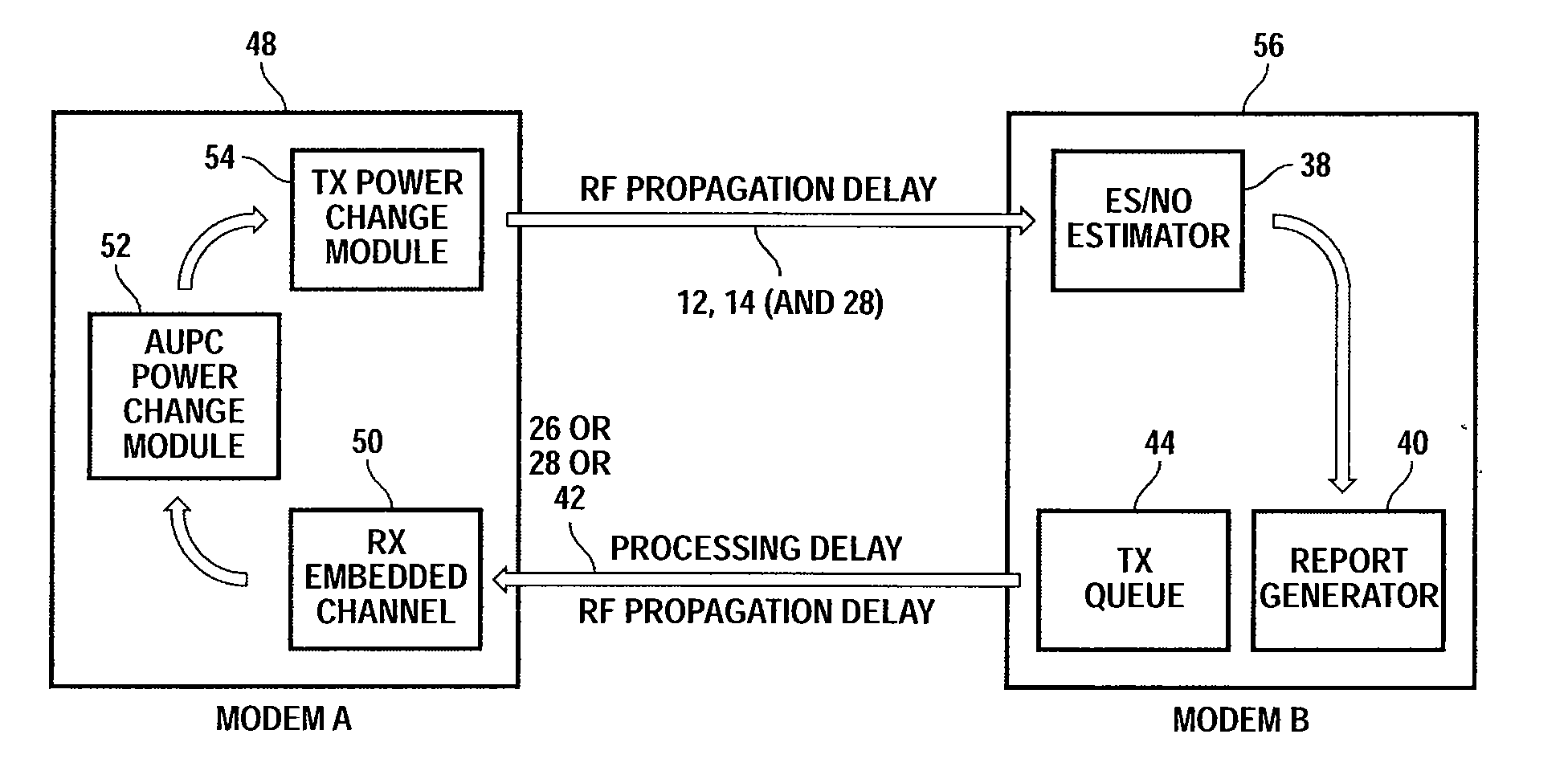

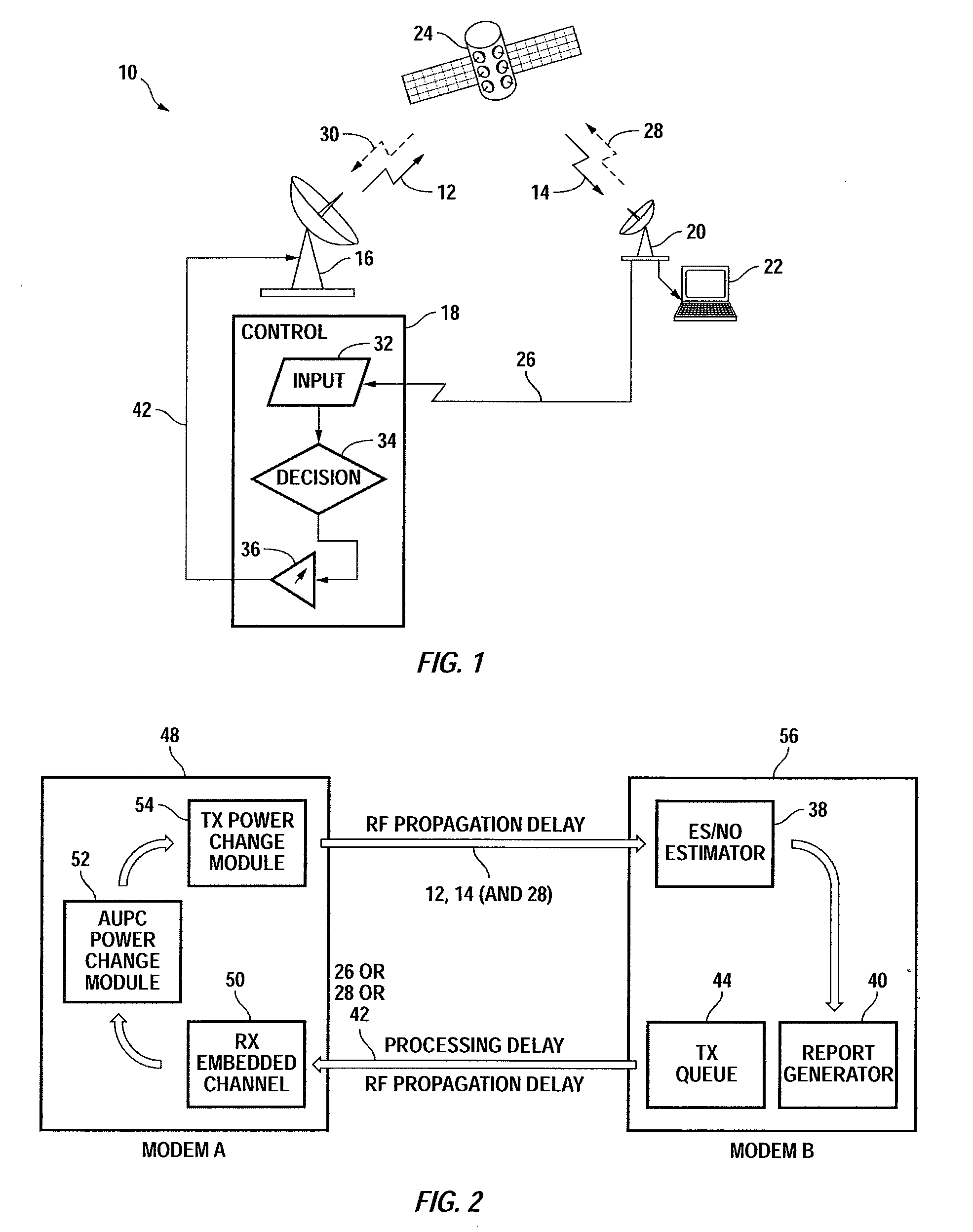

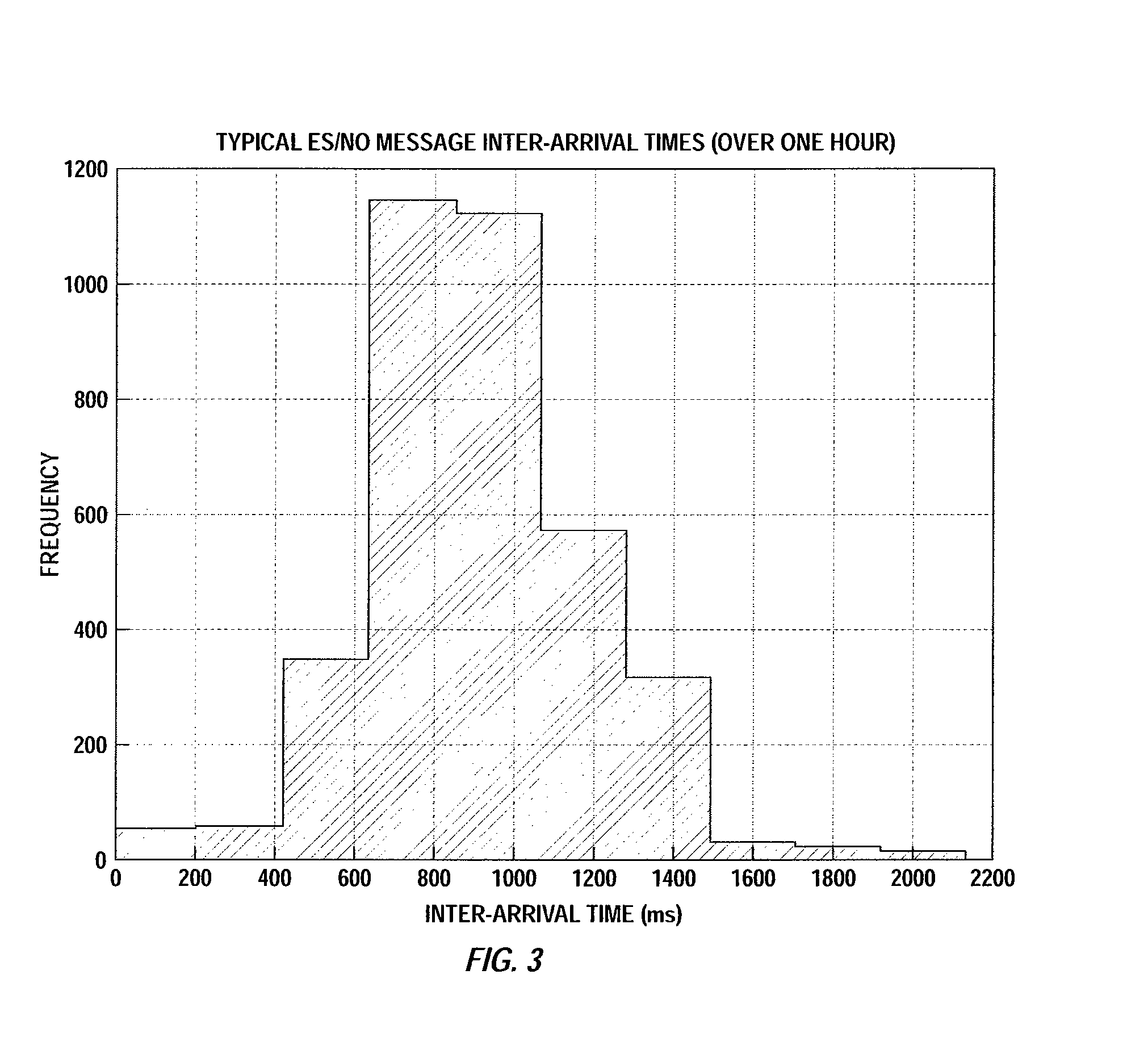

Method and system for automatic uplink power control in wireless communication

InactiveUS20090117854A1Reduces and eliminates planned power level changeImprove signal qualityPower managementEnergy efficient ICTAutomatic controlSignal quality

Automatic control of transmitted power of a transmitted signal at a local transmitter in response to intermittent signal quality reports from a remote receiver about a received communication signal originating as the transmitted communication signal is provided by distinguishing between improving link conditions and degrading link conditions and at least derating a scheduled signal power change if there are changes in the signal quality reports, such as if the power change is scheduled to occur too soon after a previous signal power change. A fast attack power increase and slow decay power decrease may also be employed. The method is designed to maintain signal quality (e.g. distant Es / No) in the presence of these variations and uncertainties, for time-varying link conditions that have a fade rate range from less than 0.01 dB / s to more than 1 dB / s.

Owner:VIASAT INC

Wireless communications device providing time and frequency-domain channel estimates interpolation and related methods

A wireless communications device which may include a wireless receiver for receiving wireless signals comprising unknown data portions over a channel, and a demodulator connected to the wireless receiver. The demodulator may be for estimating a delay spread and a fade rate associated with the channel, determining a desired time-domain interpolation filter based upon the estimated fade rate, and determining a desired frequency-domain interpolation filter based upon the estimated delay spread. The demodulator may further generate channel estimates for the unknown data portions based upon the desired time-domain interpolation filter and the desired frequency-domain interpolation filter, and determine the unknown data portions based upon the channel estimates.

Owner:HARRIS GLOBAL COMM INC

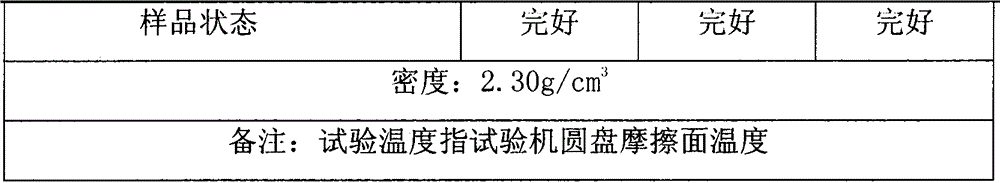

Method for preparing brake pad from basalt superfine fibers and application of basalt superfine fibers in preparation of brake pad

ActiveCN106117955AGood physical and chemical stabilityGood resistance to high temperature decayOther chemical processesBraking membersFiberCarbon fibers

The invention discloses a method for preparing a brake pad from basalt superfine fibers and application of the basalt superfine fibers in preparation of the brake pad. The method comprises the following steps that 1, 8-16 parts by weight of phenolic resin, 5-15 parts by weight of steel fibers, 2-5 parts by weight of carbon fibers and 15-45 parts by weight of basalt superfine fibers are added into a mixer to be mixed; 2, 3-8 parts by weight of crystalline flake graphite, 3-12 parts by weight of delanium graphite particles, 3-10 parts by weight of chromite powder, 5-8 parts by weight of dolomite powder, 3-8 parts by weight of fluorite powder, 2-5 parts by weight of butadiene-acrylonitrile rubber powder and 5-10 parts of by weight of wollastonite are sequentially poured into the mixer to be mixed; 3, the obtained mixture is placed in a brake pad mold for hot pressing, and mold stripping is carried out; 4, the brake pad obtained after mold stripping is subjected to heat treatment; 5, the brake pad obtained after discharge is subjected to machining treatment, label printing and packaging, and the brake pad is obtained. The shock strength of the prepared brake pad can reach 5.5 dj.cm<3> or above, and the high temperature fading rate is smaller than 15%; the experiment is completed according to GB6763-2008, the total wear rate is smaller than 0.23.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

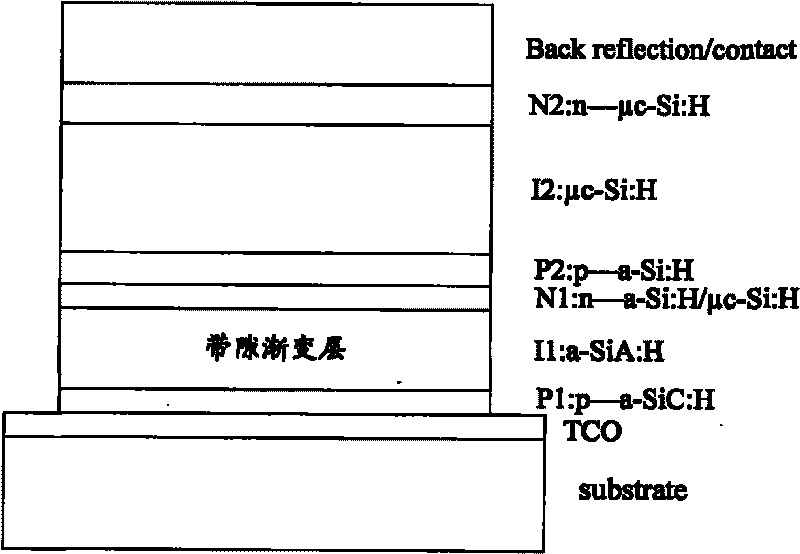

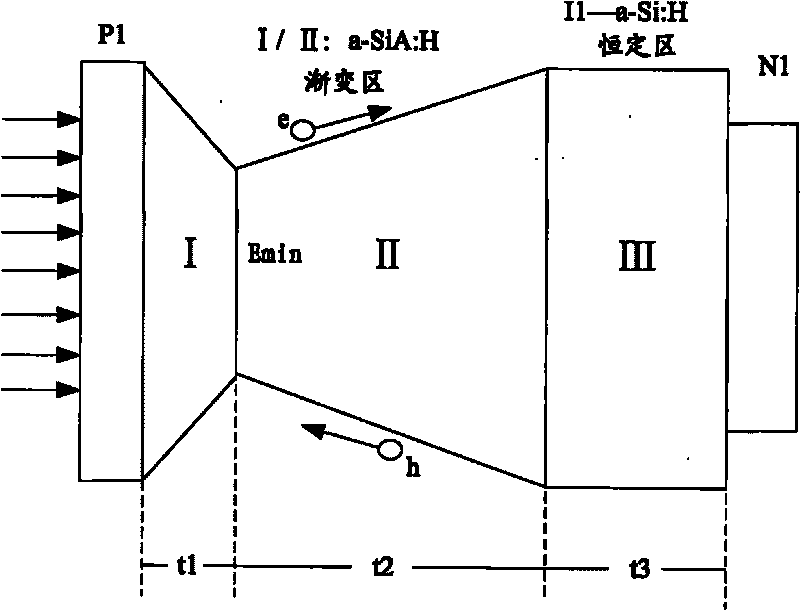

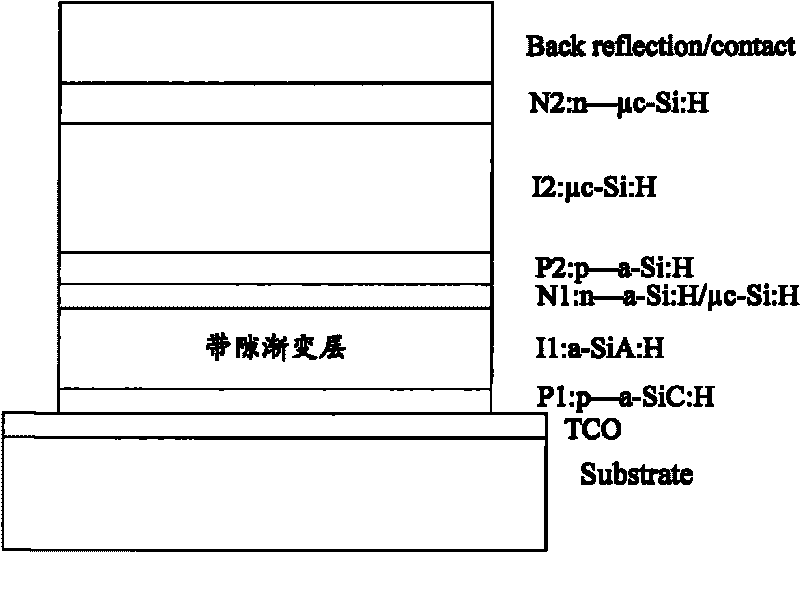

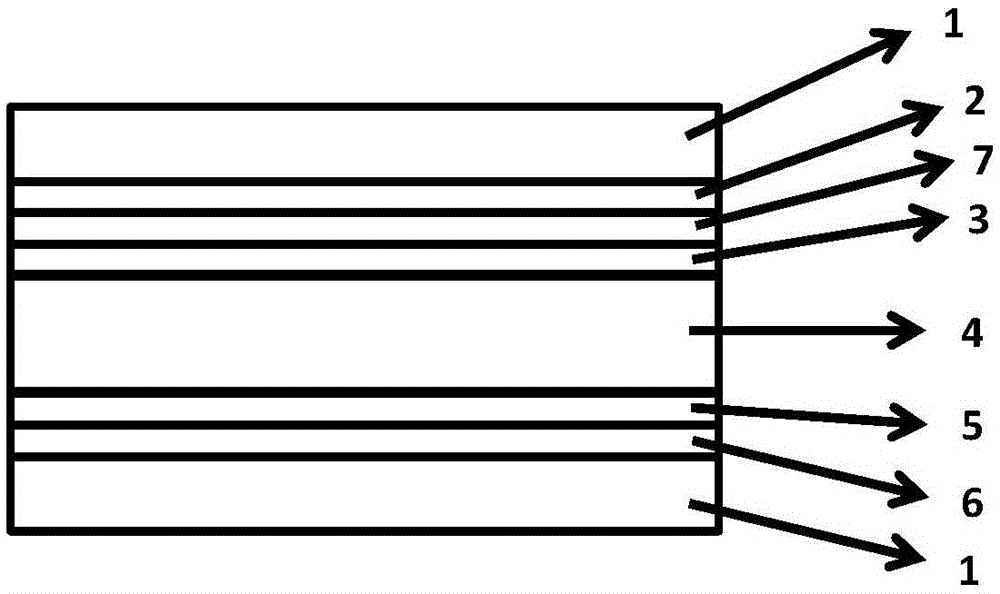

Solar cell

ActiveCN101697359ALow costPromote absorptionPhotovoltaic energy generationSemiconductor devicesSpectral responseEngineering

The invention discloses a solar cell for realizing low photo-induced fading rate, wherein the solar cell comprises alpha-SiA:H / mu c-Si:H bi-node laminated cell unit (A represents elements, such as G3, C and O), wherein layer I of a top cell unit is thinned and adopts design of gradually changing energy band, so that spectral response of the top cell expands to a long wave as the spectral response of a bottom cell expands to a short wave. Therefore, the thicknesses of the top cell and the bottom cell are greatly reduced, and the photo-induced fading rate and cost are lowered.

Owner:ENN SOLAR ENERGY

Method for preparing low-metallic brake pads by utilizing sodium titanate whisker

InactiveCN102619913AImprove high temperature resistanceReduce decomposition rateFriction liningFiberPorosity

The invention provides a preparing formula of low metallic brake pad by utilizing sodium titanate whisker, which comprises (by weight) 5%-15% of adhesive, 15%-25% of reinforced fiber, 10%-20% of abrasive, 8%-15% of lubricant, 10%-20% of modifier and 30%-50% of filler. By the aid of the brake pad prepared according to the formula, the air porosity can be effectively improved and the high-temperature resistance of materials can be enhanced, thus the decomposition rate of organic materials at a high temperature can be reduced, the escaping speed of gas on friction surfaces in brake fading can be lowered simultaneously, and the fading rate and the changing rate of frictional coefficient at high speed can be reduced to below 15%.

Owner:DONGYING BORUI BRAKE SYST

Photographing device based on high-stability light transmittance adjustable function

InactiveCN105554359ASimple structureReduce light transmittanceTelevision system detailsColor television detailsElectricityMaterials preparation

The invention discloses a photographing device based on a high-stability light transmittance adjustable function. An electrochromic device is installed on the camera surface of the photographing device, and the current of the electrochromic device is adjusted to adjust the light transmittance of the camera through the electrochromic principle, the light transmittance of the camera can be adjusted according to different ambient brightness to optimize the photographing effect. In addition, the electrochromic device adopts a solid complementary structure, the electrochromic material respectively comprises tungsten oxide and nickel oxide, the structure and the material preparation process are optimized to improve the sensitivity and the coloration efficiency of the device, the discoloration and fading rates are fast, the light transmittance of the photographing device in a coloration state is greatly reduced, the adjustment range of the light transmittance is increased, a continuous and fast adjustable function of the photographing device is realized, and the photographing device is simple and convenient to use, thereby being conducive to industrial production.

Owner:林业城

Lighting control device having improved long fade off

ActiveUS20060103331A1Electric light circuit arrangementElectric discharge lampsMicrocontrollerActuator

A lighting control device for controlling the light intensity level of at least one lamp is disclosed. The lighting control device includes an actuator and a controller, such as a microcontroller, for example. The controller is operable to cause the light intensity level of the lamp to fade at a first fade rate when the actuator is actuated. If the controller determines that the actuator has been actuated for at least a predefined hold time, the controller causes the light intensity level of the lamp to fade at a second fade rate for a predefined long fade time. After the long fade time elapses, the controller causes the light intensity level of the lamp to fade to off at a third fade. The first fade rate is based on a predefined fade-off time that represents a time allotted for fading the light intensity level of the lamp from its initial light intensity level to off. To prevent the light intensity level from fading to off before the hold time elapses, the fade off time may be defined to be longer than the hold time. The second fade rate may be slower than the first fade rate and have an exponential fade profile. The third fade rate may be a predefined rate at which the controller is operable to cause the light intensity level to fade from full on to full off. The third fade rate may be faster than the second fade rate.

Owner:LUTRON TECH CO LLC

High-stability and adjustable-light-transmittance environment monitoring window

InactiveCN105511192ASimple structureReduce light transmittanceNon-linear opticsElectricityTransmittance

The invention discloses a high-stability and adjustable-light-transmittance environment monitoring window. An electrochromic device is arranged on the environment monitoring window; light transmittance adjustment of the environment monitoring window is achieved by adjusting the current of the electrochromic device according to the principle of electrochromism; continuous adjustment of the light transmittance can be achieved; and examination by a user is facilitated. A solid complementary structure is adopted by the electrochromic device; and electrochromic materials include a tungsten oxide material and a nickel oxide material, so that, through optimization of the structure and the preparation technology of the material, the sensitivity and the coloration efficiency of the device are improved, the discoloration rate and the fading rate are high, the light transmittance of the environment monitoring window in a colored state is greatly reduced, the adjusting range of the light transmittance is increased, and a continuous and fast adjustment function of the monitoring process is achieved; and the high-stability and adjustable-light-transmittance environment monitoring window is simple and convenient to use, and beneficial to industrial production.

Owner:林业城

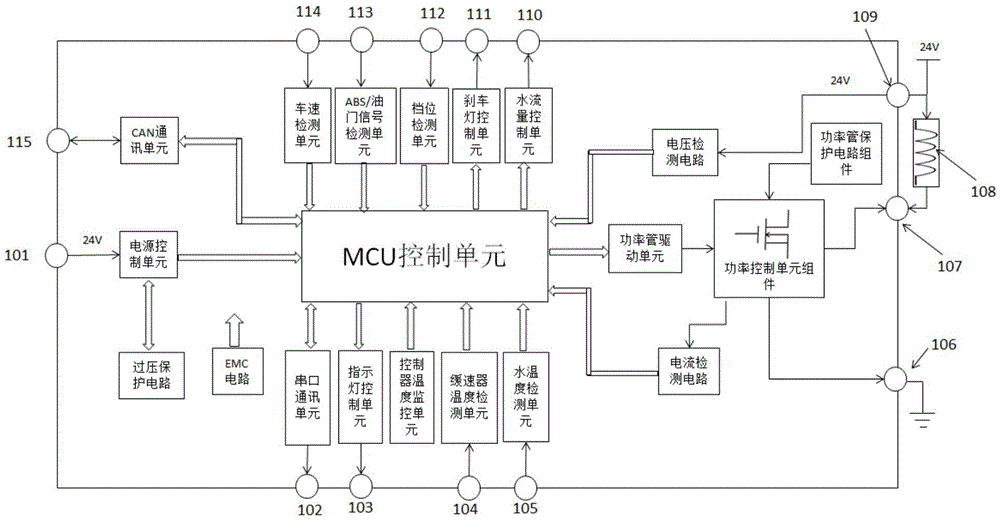

Eddy current retarder electronic controller

InactiveCN105577055AReduce overheating problemsNot easy to burn outElectrodynamic brake systemsElectric machinesElectronic controllerEngineering

The invention relates to an eddy current retarder electronic controller. The controller is mainly formed by an MCU control unit, a power tube drive unit and a power control unit assembly and the like. The temperature of a retarder is reduced through a water flow control unit, a retarder temperature monitoring unit and a water temperature detection unit, and thus heat fading rate of the retarder is reduced; the output power of the retarder is reduced when the voltage is low through a voltage detection unit, and thus an energy-saving and consumption-reducing effect is achieved; a controller temperature monitoring unit protects a power tube assembly from being damaged by high temperature; and corresponding currents are output to all exciting windings through PWM(pulse width modulation) signals, so that corresponding moment is generated to play a braking role on an advancing automobile.

Owner:CHANGZHOU DAMI ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com