Eddy current retarder electronic controller

A technology of eddy current retarder and electronic controller, which is applied in the direction of controlling electromechanical brakes, control systems, electric braking systems, etc., and can solve the problems of easy aging and damage, easy damage of power components, easy spark ablation, etc. , to achieve the effects of easy aging and damage, reducing overheating and reducing the rate of thermal decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

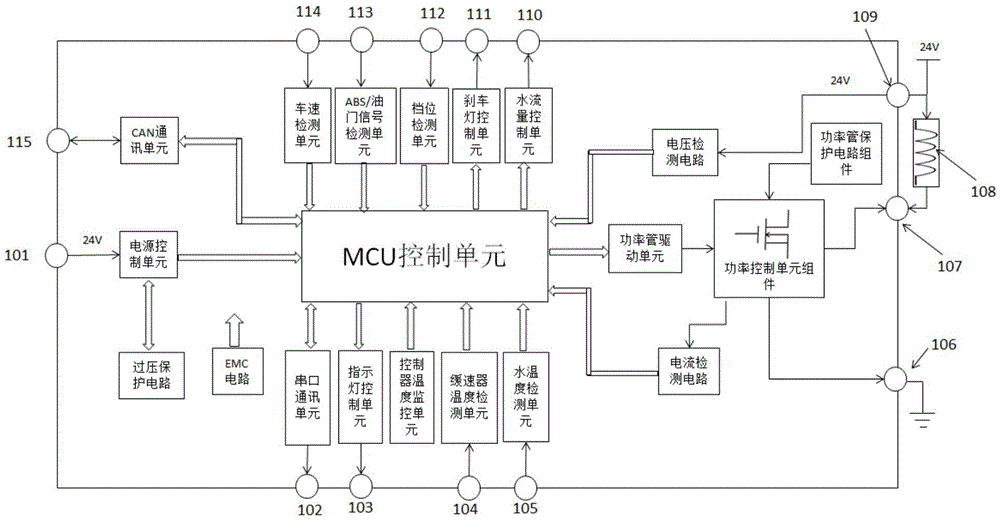

[0015] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] Such as figure 1 As shown, this embodiment includes a power control unit, an overvoltage protection voltage, an EMC circuit, a brake light control unit, a serial communication unit, an indicator light control unit, a controller temperature monitoring unit, a current detection circuit, a power tube drive unit, and a power control unit. Unit assembly, power tube protection circuit assembly, voltage detection circuit, gear position detection unit, ABS / throttle signal detection unit, vehicle speed detection unit, CAN communication unit, water temperature detection unit, retarder temperature detection unit, water flow cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com