Patents

Literature

54results about How to "Increased idle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

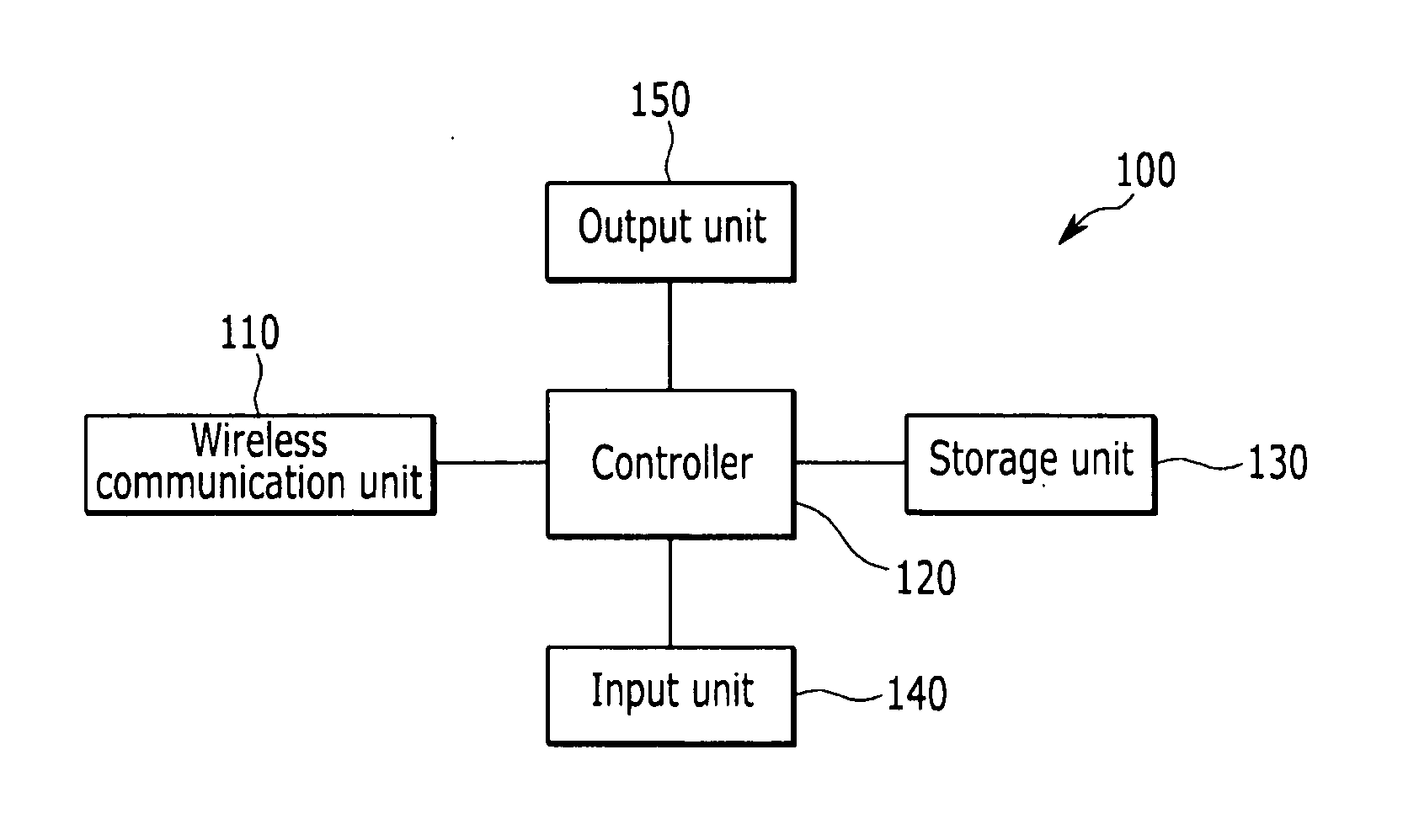

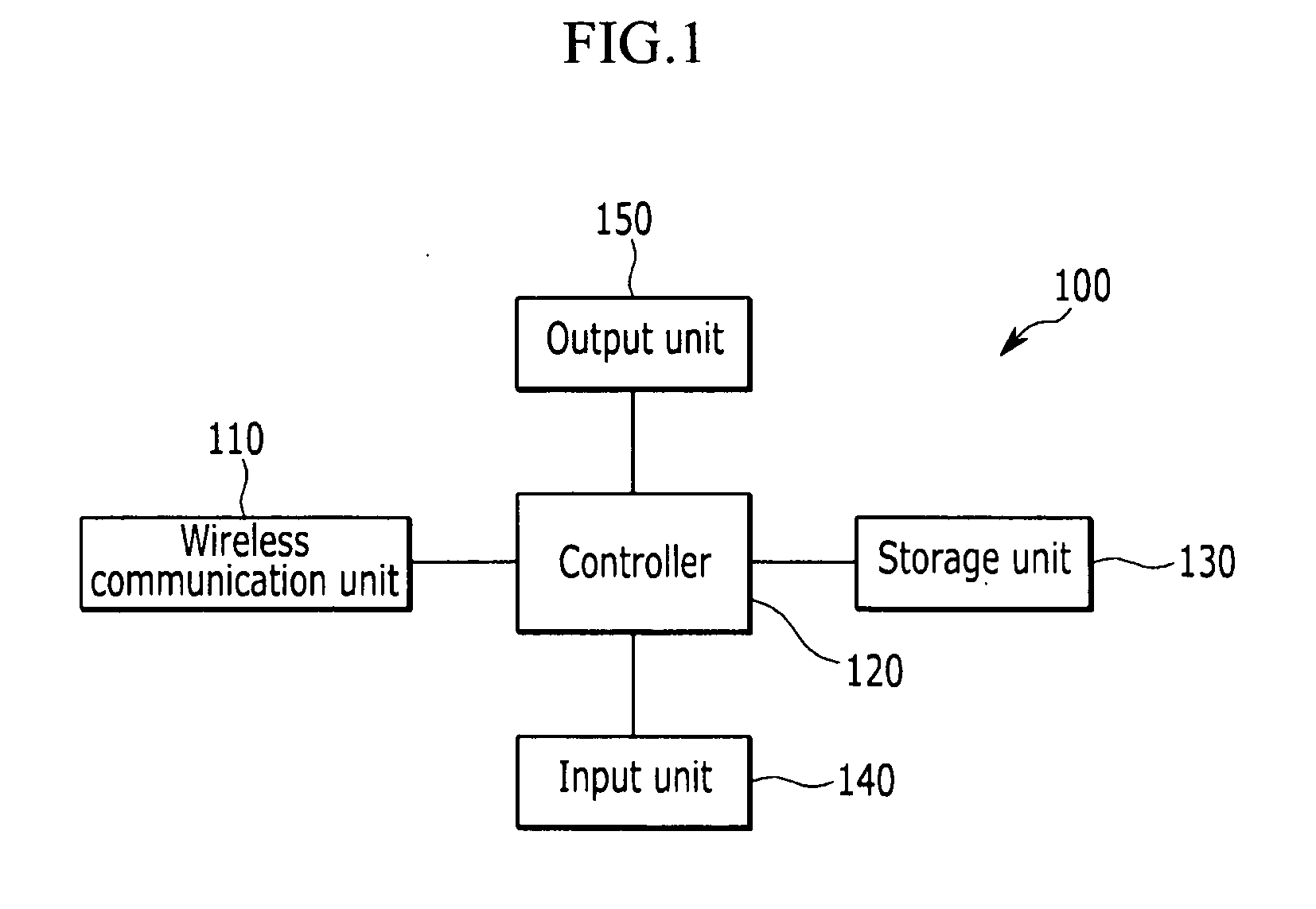

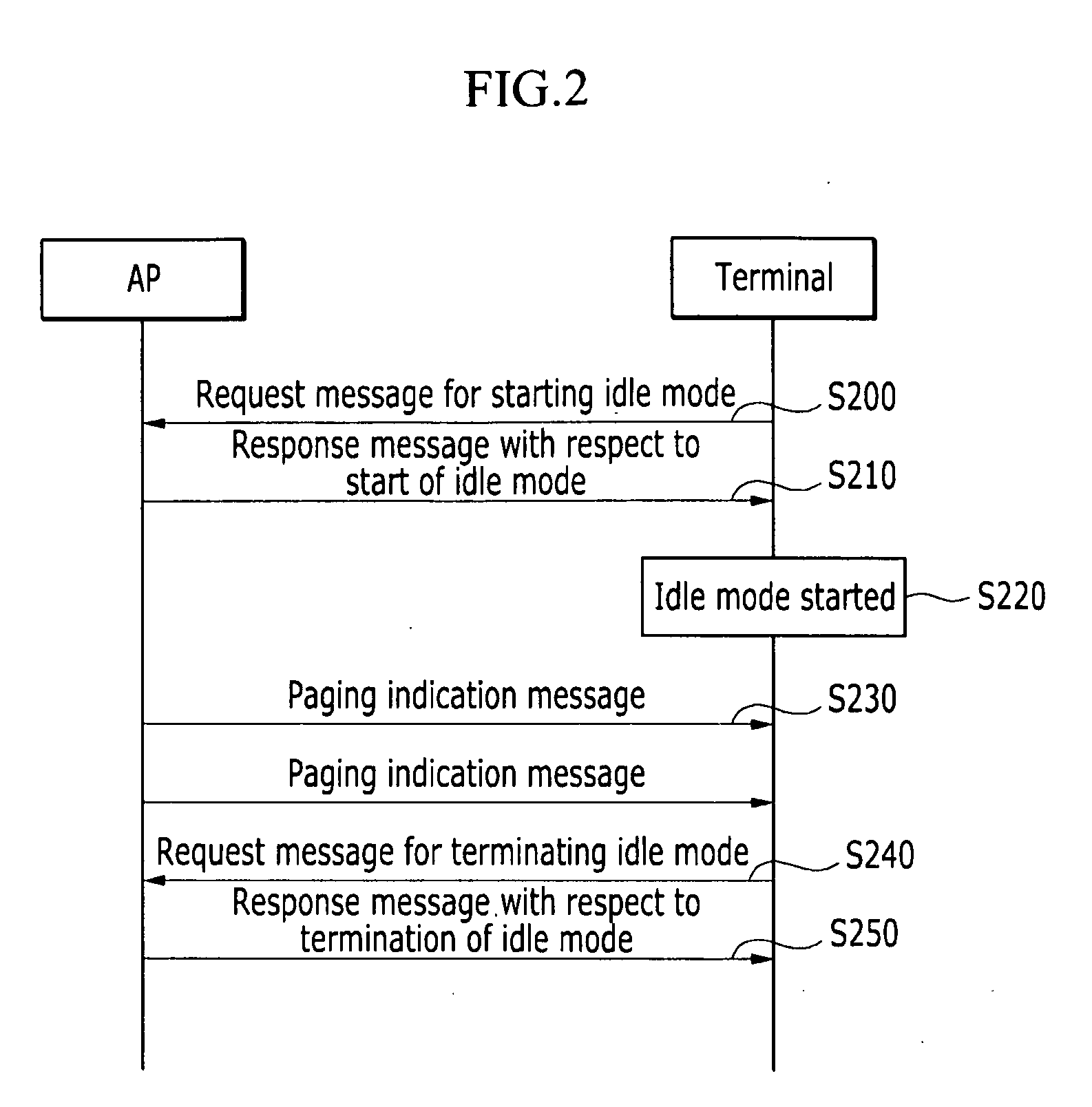

Method for supporting idle mode in wireless local area network system

InactiveUS20100322217A1Reduce power consumptionIncreased idle timeAssess restrictionNetwork topologiesComputer scienceReal-time computing

Disclosed is a method for supporting an idle mode of a terminal in a wireless local area network (WLAN) system. In the method, a first request message for starting an idle mode is transmitted to a first access node to which the terminal is currently connected and a first response message with respect to the first request message is received from the first access node, and in this case, when the first response message includes acceptance information with respect to the start of the idle mode, the idle mode starts.

Owner:ELECTRONICS & TELECOMM RES INST

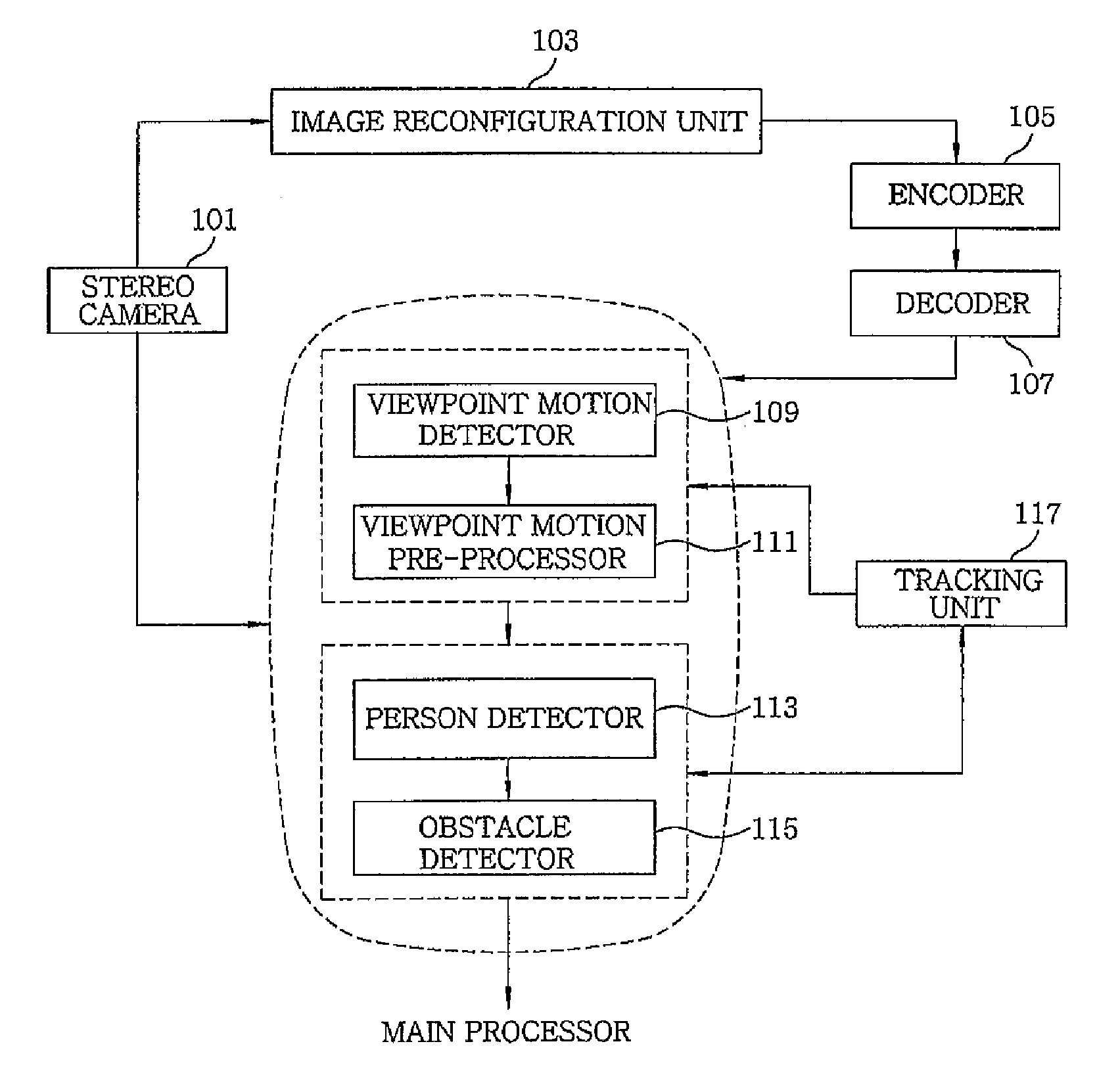

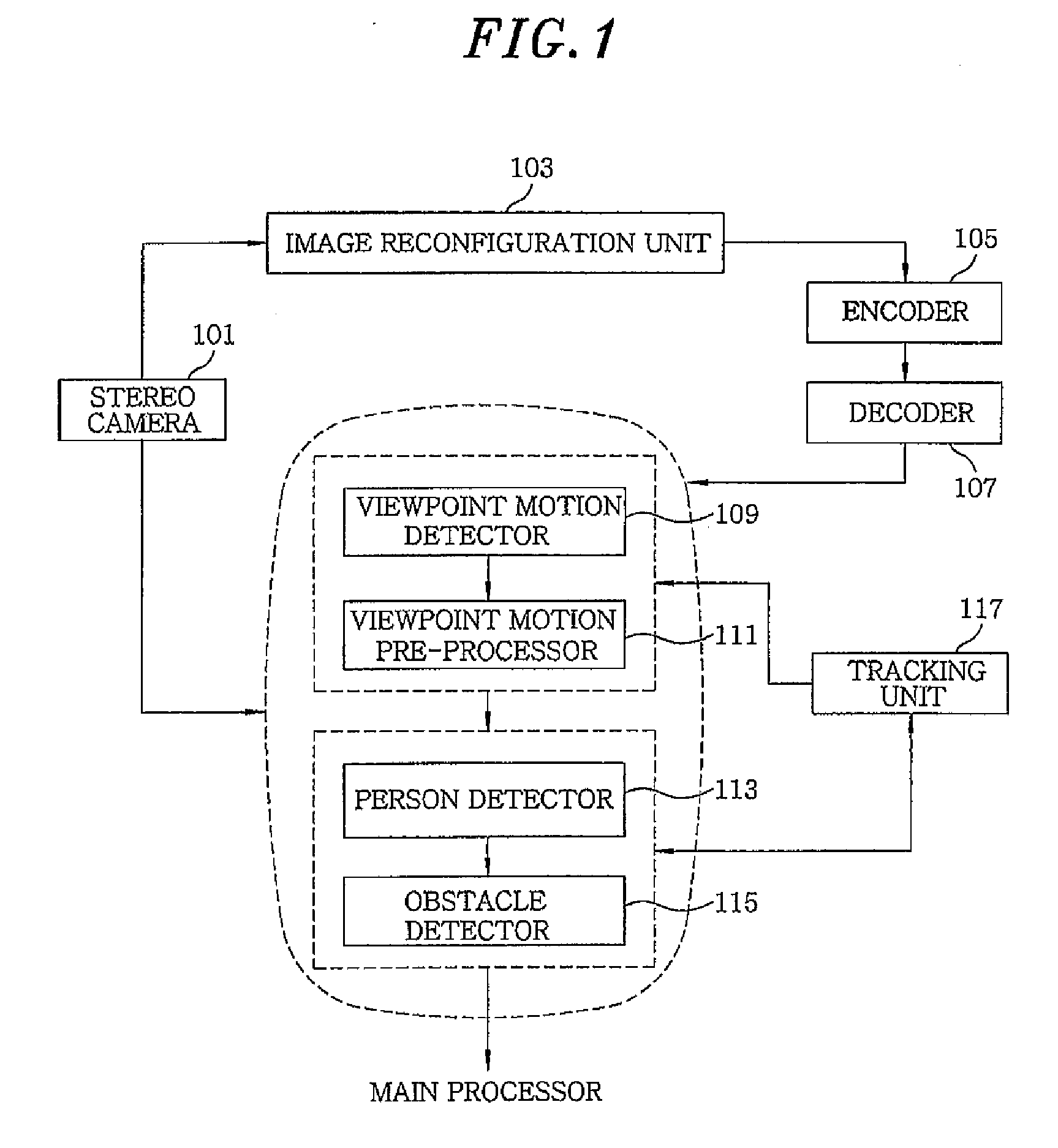

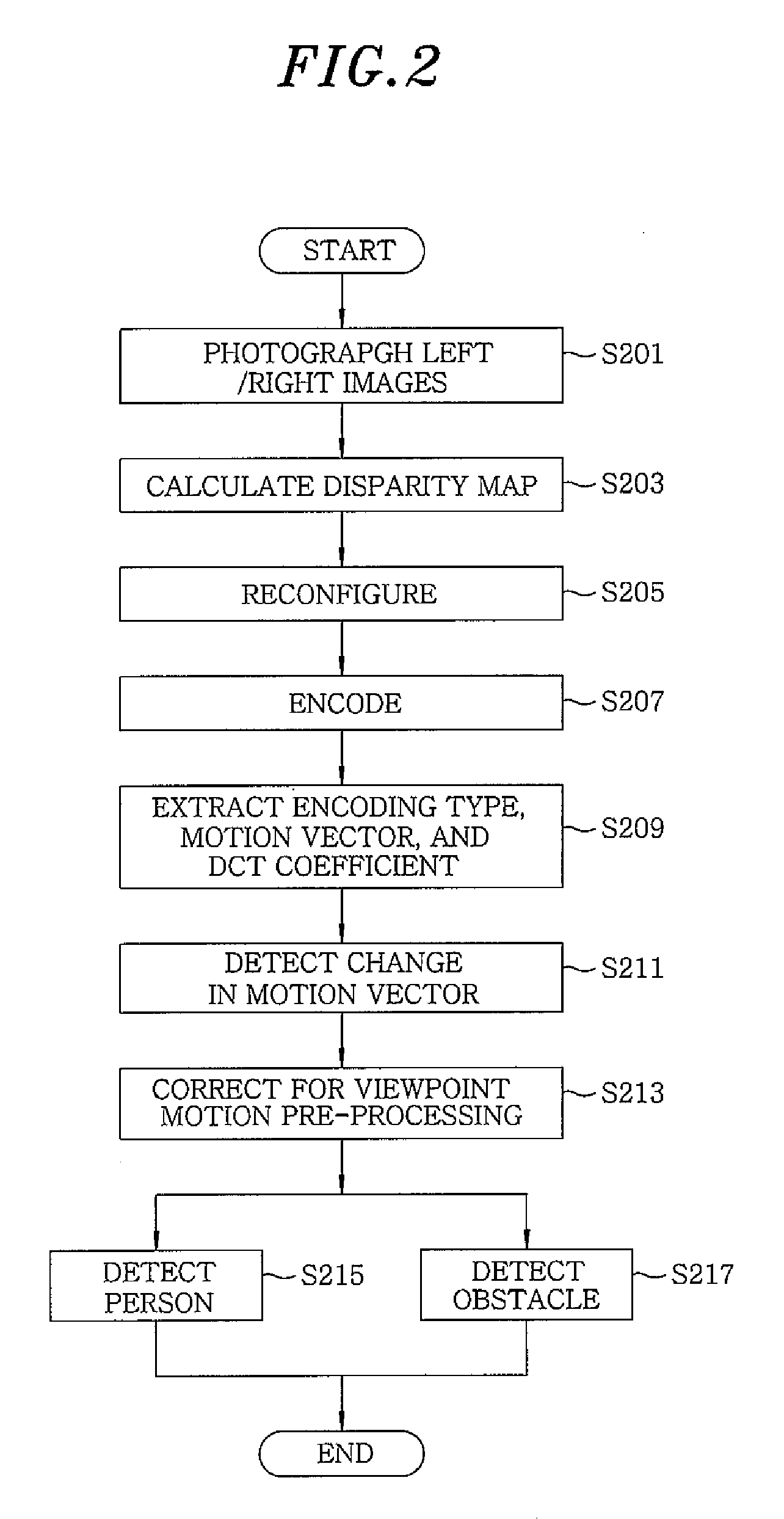

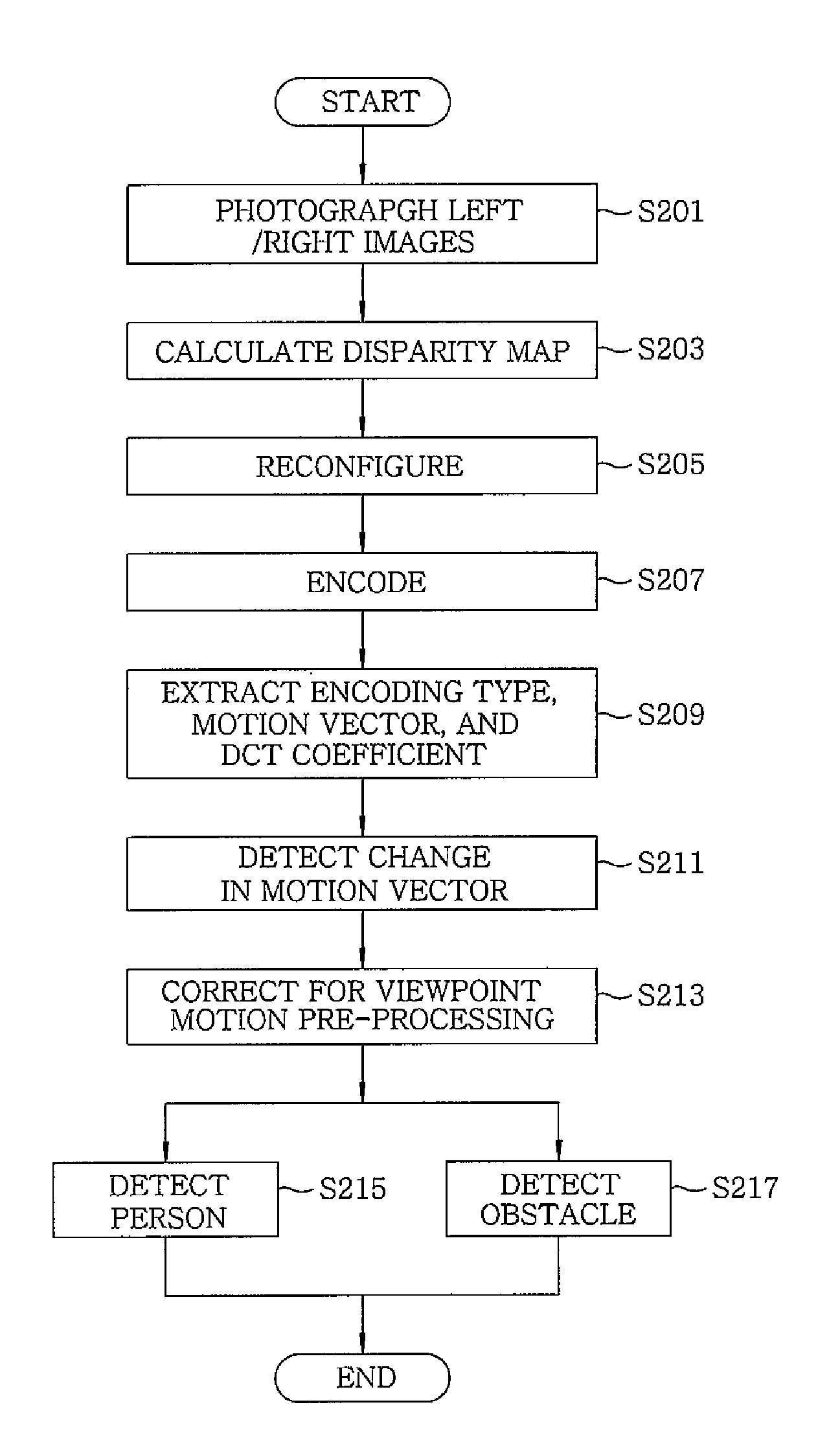

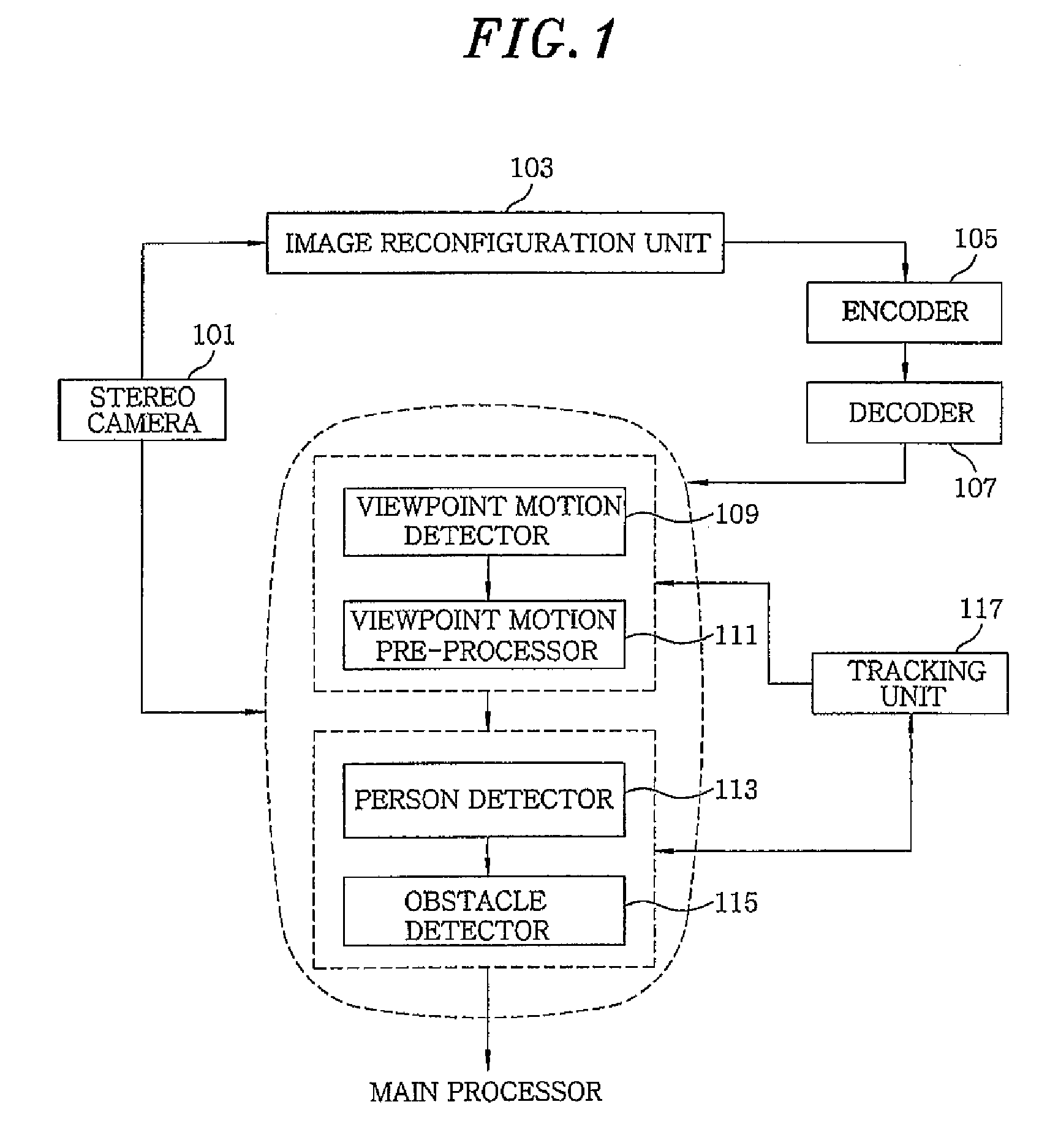

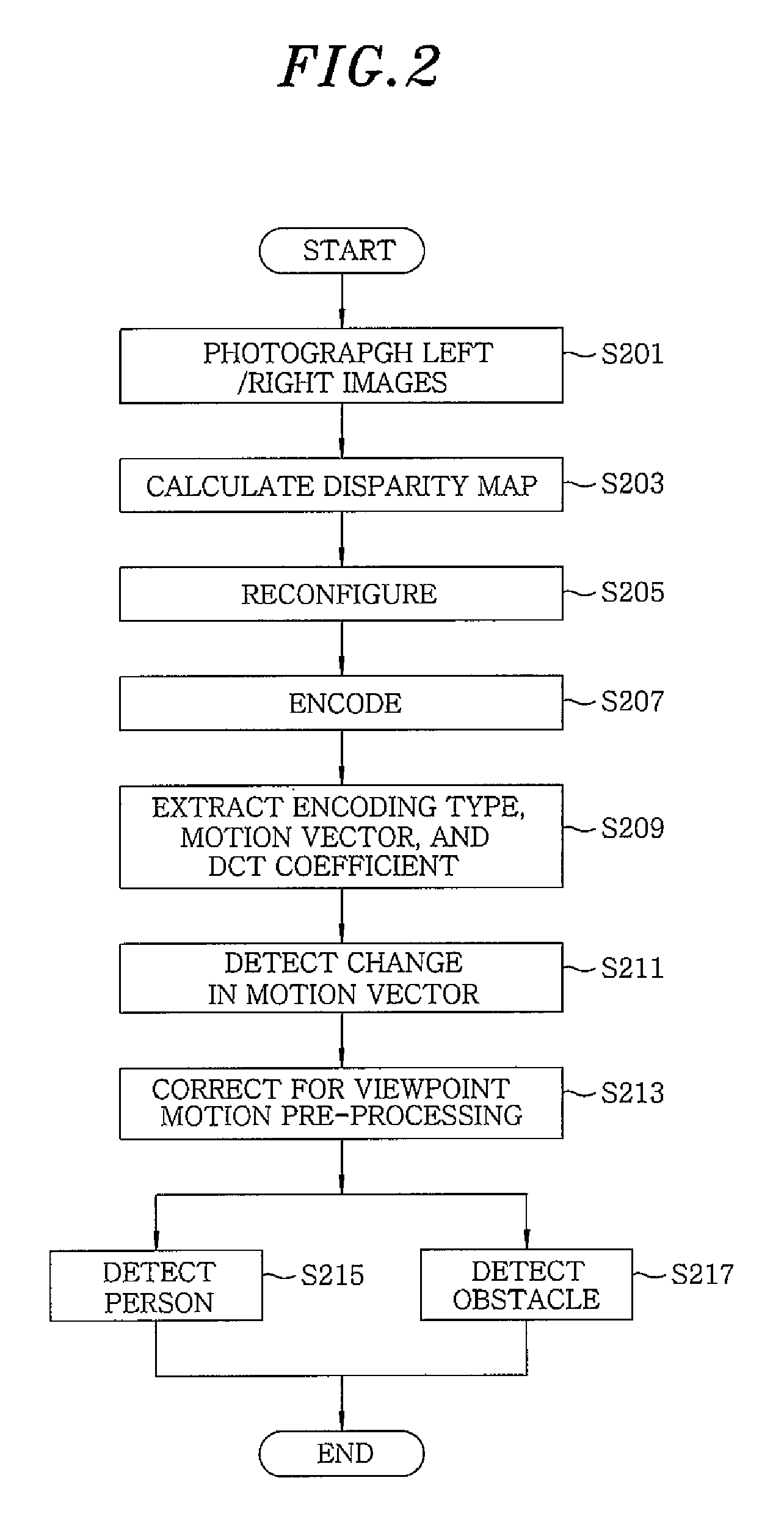

Robot vision system and detection method

InactiveUS20090141938A1Low complexityLess consumeImage enhancementImage analysisDct coefficientVideo bitstream

A robot vision system for outputting a disparity map includes a stereo camera for receiving left and right images and outputting a disparity map between the two images; an encoder for encoding either the left image or the right image into a motion compensation-based video bit-stream; and a decoder for extracting an encoding type of an image block, a motion vector, and a DCT coefficient from the video bit-stream. Further, the system includes a person detector for detecting and labeling person blocks in the image using the disparity map between the left image and the right image, the block encoding type, and the motion vector, and detecting a distance from the labeled person to the camera; and an obstacle detector for detecting a closer obstacle than the person using the block encoding type, the motion vector, and the DCT coefficient extracted from the video bit-stream, and the disparity map.

Owner:ELECTRONICS & TELECOMM RES INST

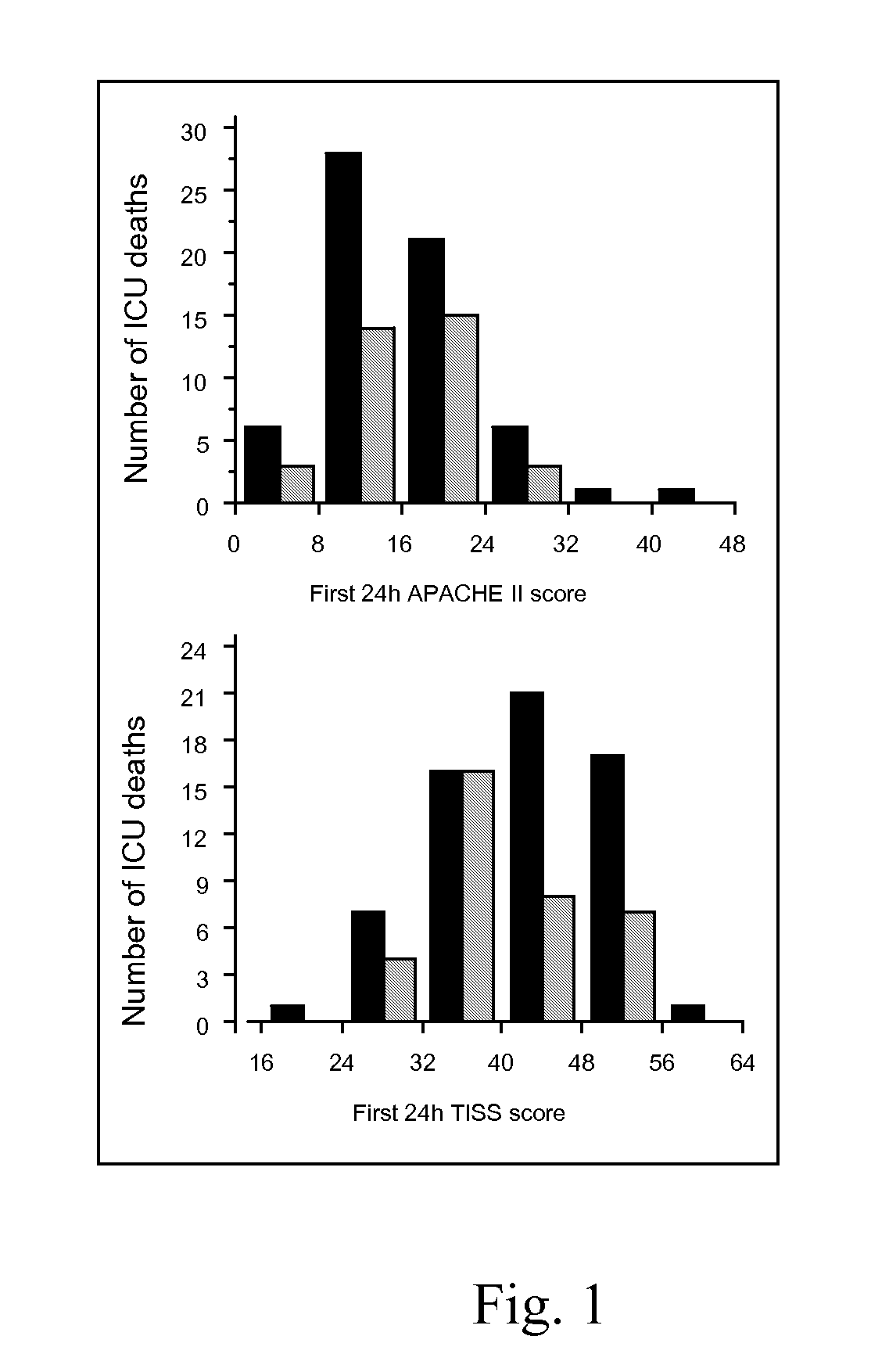

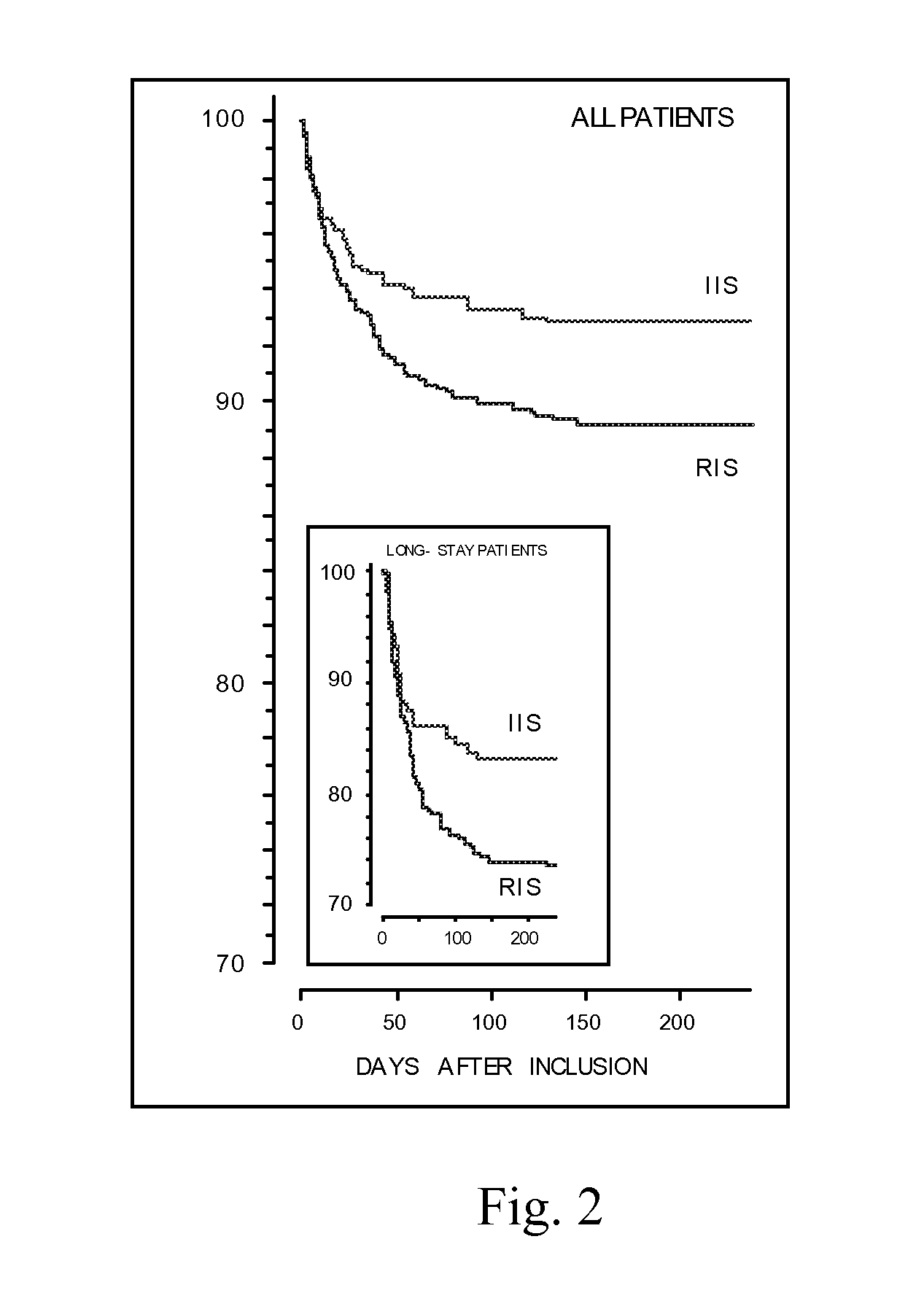

Methods and preparations for curing clinically ill patients

This invention relates to a life saving medicament for critically ill patients and a method of treatment. The composition is a pharmaceutically effective amount of a blood glucose regulator which is used to control the blood glucose level.

Owner:NOVO NORDISK AS

Pigmented inkjet ink

The present invention provides pigmented inks comprising self-dispersing pigment and an amino-containing compound. The addition of an amino-containing compound to the self-dispersing pigment can improve the reliability and performance of the ink in an inkjet printhead. The present invention also provides methods for making a surface modified pigment comprising associating a self-dispersing pigment with an amino-containing compound having no more than one primary amino group or one secondary amino group.

Owner:BRADY JOHN A +1

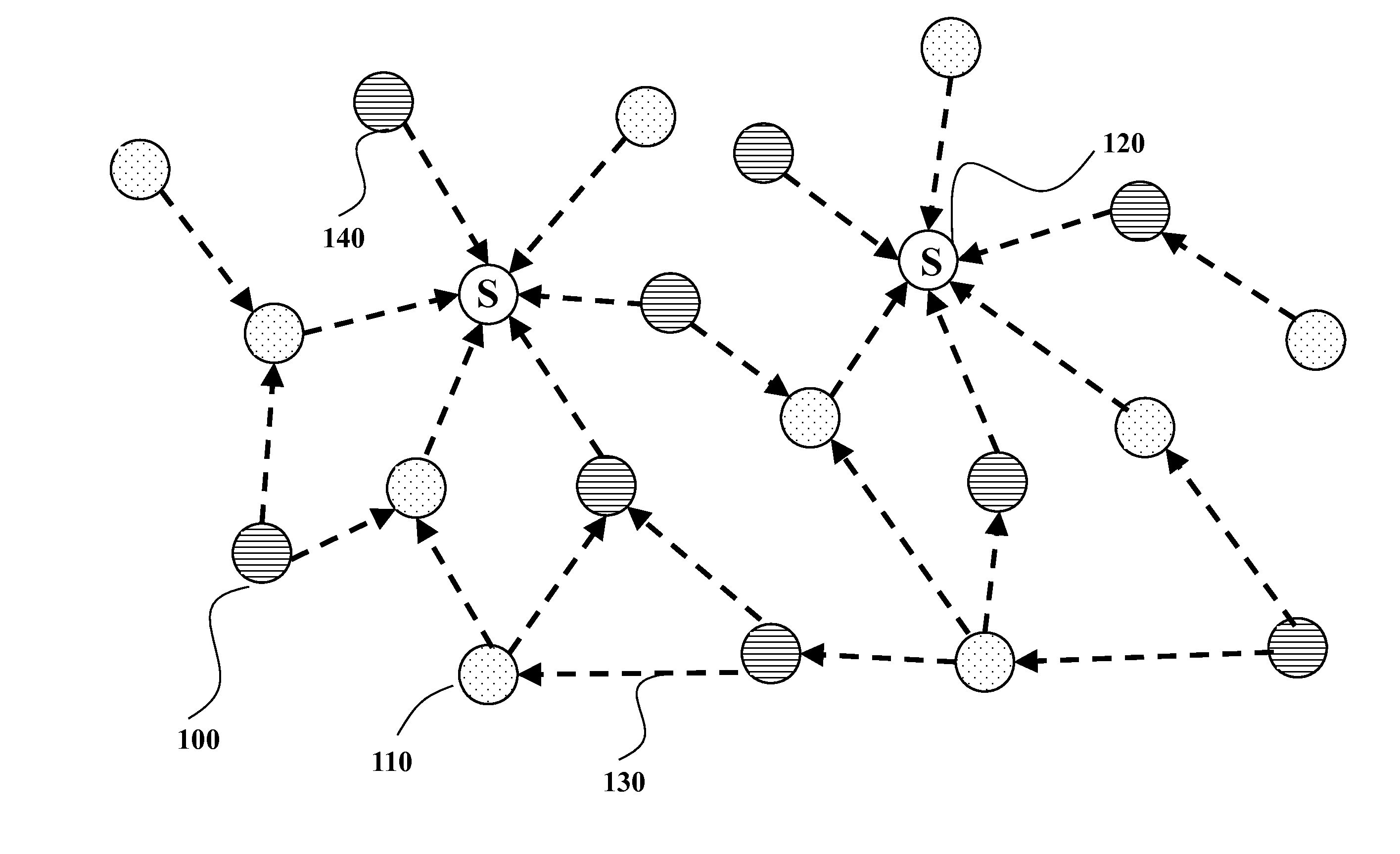

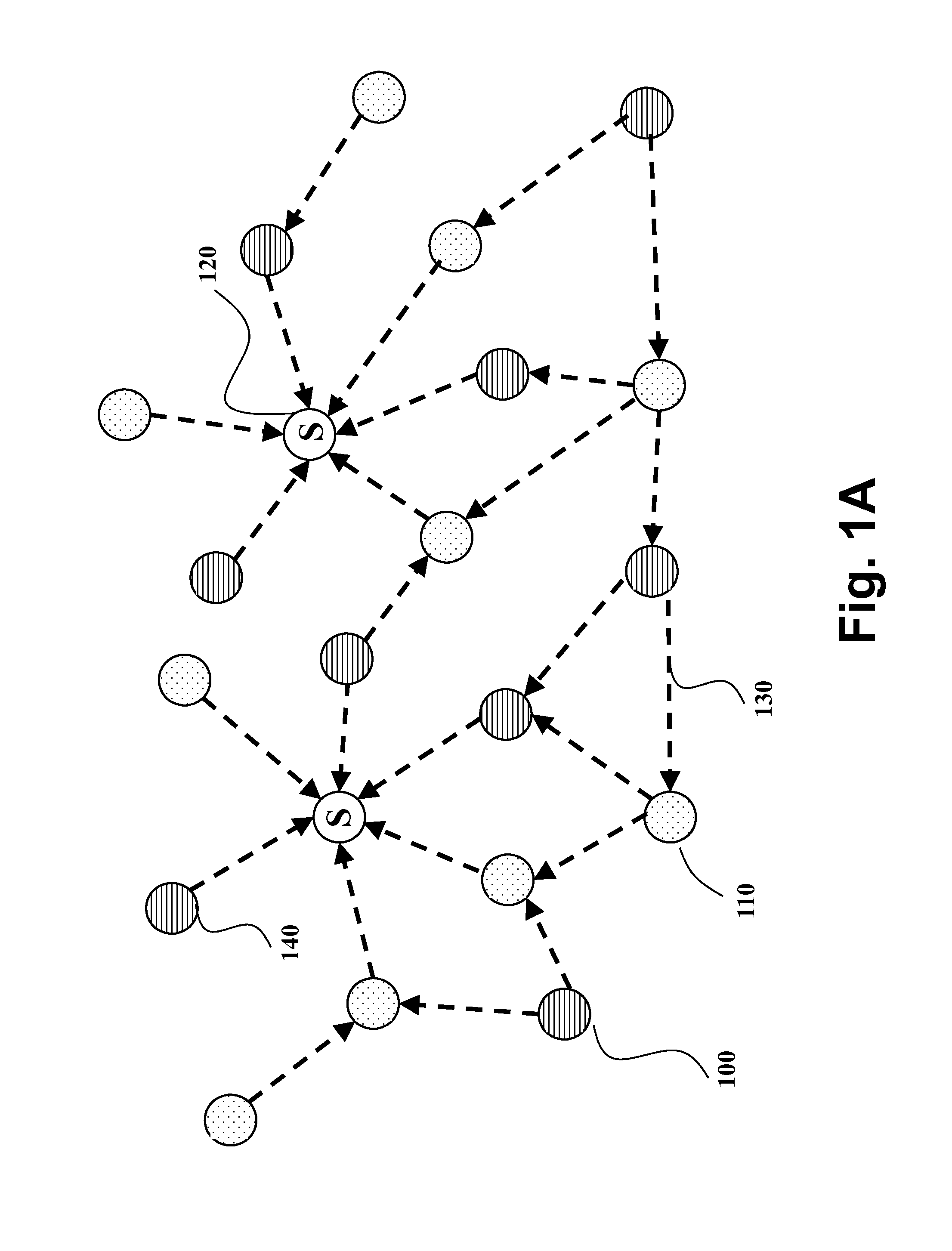

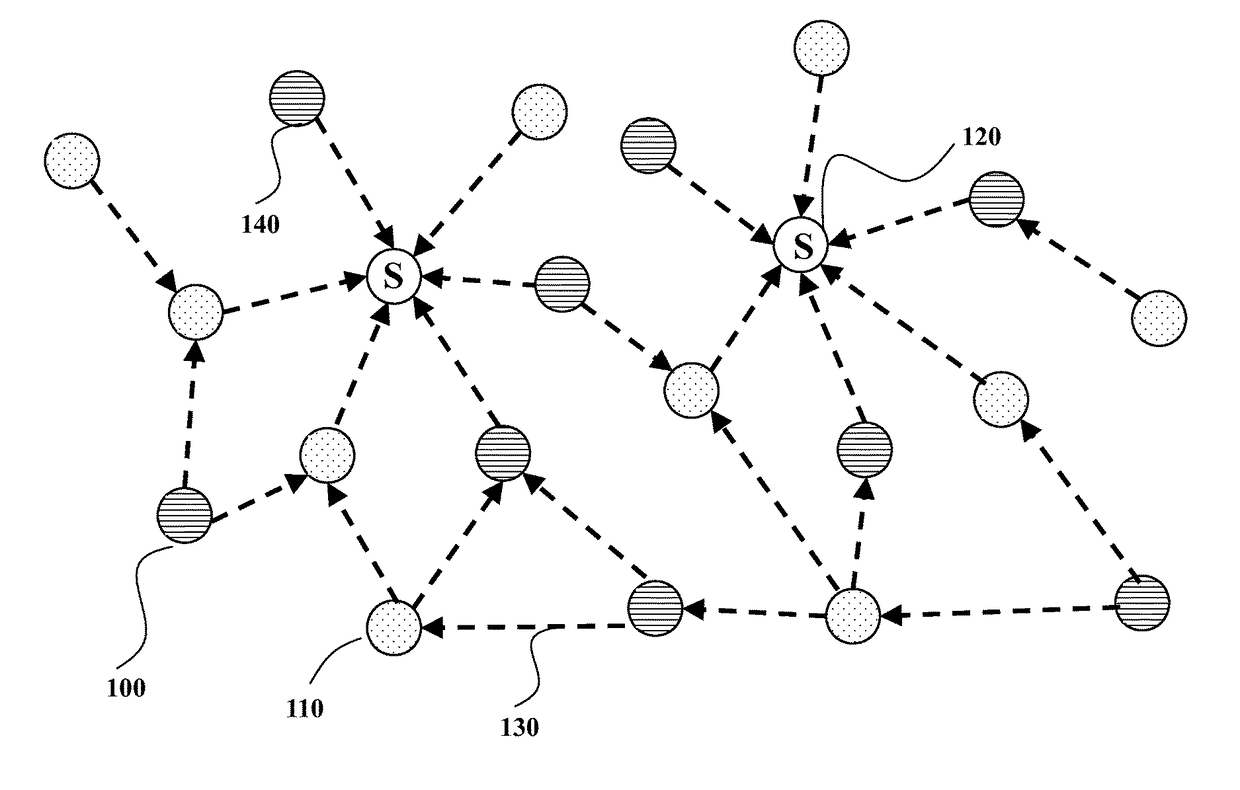

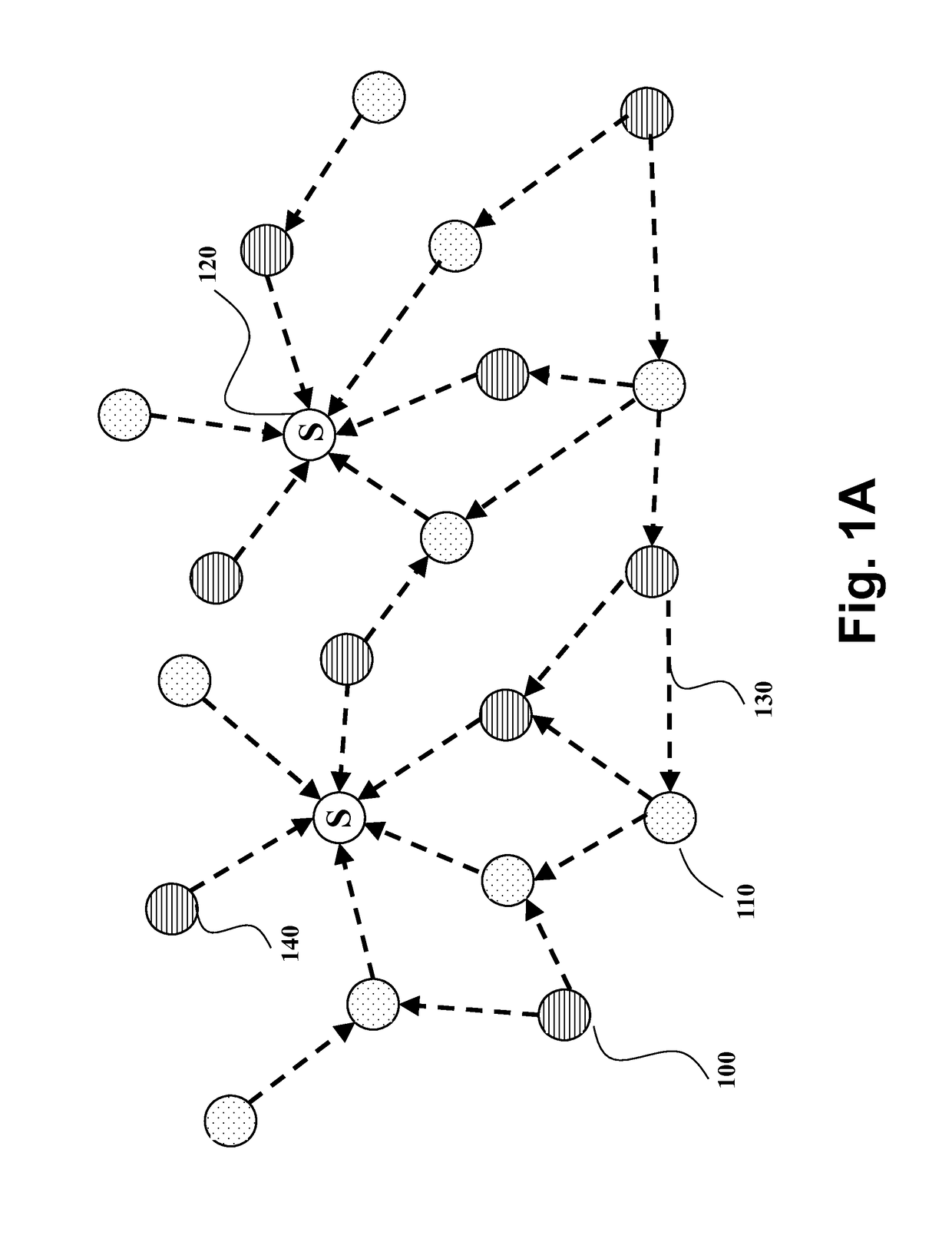

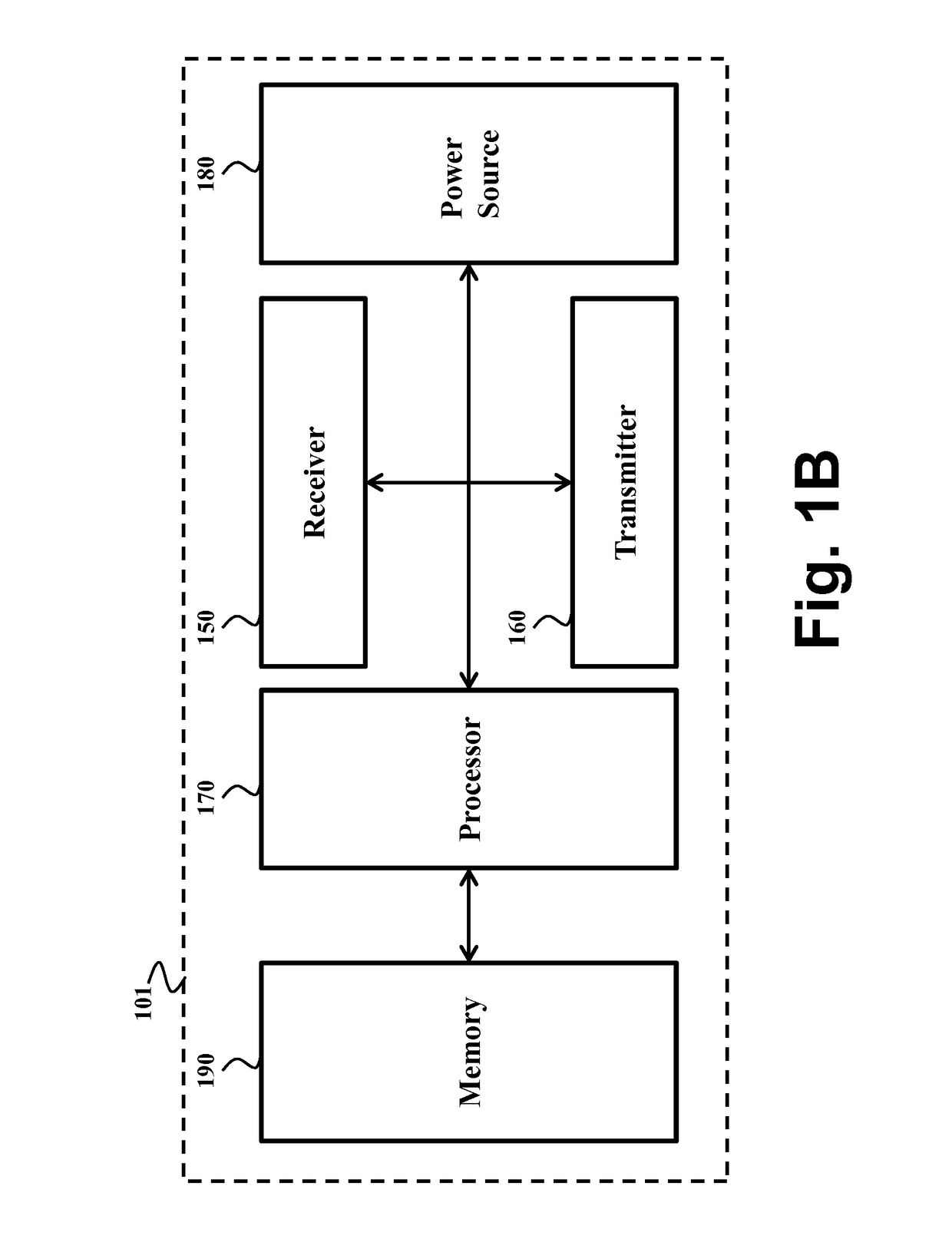

Energy Efficient Management of Heterogeneous Multi-Hop Wireless Networks

ActiveUS20160212698A1Reduce in quantityReduce collisionPower managementTransmission systemsTime scheduleTransceiver

A wireless multi-hope network of nodes including data nodes and at least one sink node. The data nodes include battery-powered nodes (BPNs) having active and sleep periods and mains-powered nodes (MPNs) having only active periods, wherein each data node transmits the packets only within corresponding active periods. A BPN includes a transceiver for transmitting and receiving data packets and a processor for determining a schedule of active and sleep periods of the BPN independently from the active and sleep periods of other data nodes in the network and independently from commands transmitted by the sink node, and a battery for providing energy to the transceiver and the processor. The processor switches the transceiver ON and OFF according to the schedule.

Owner:MITSUBISHI ELECTRIC RES LAB INC

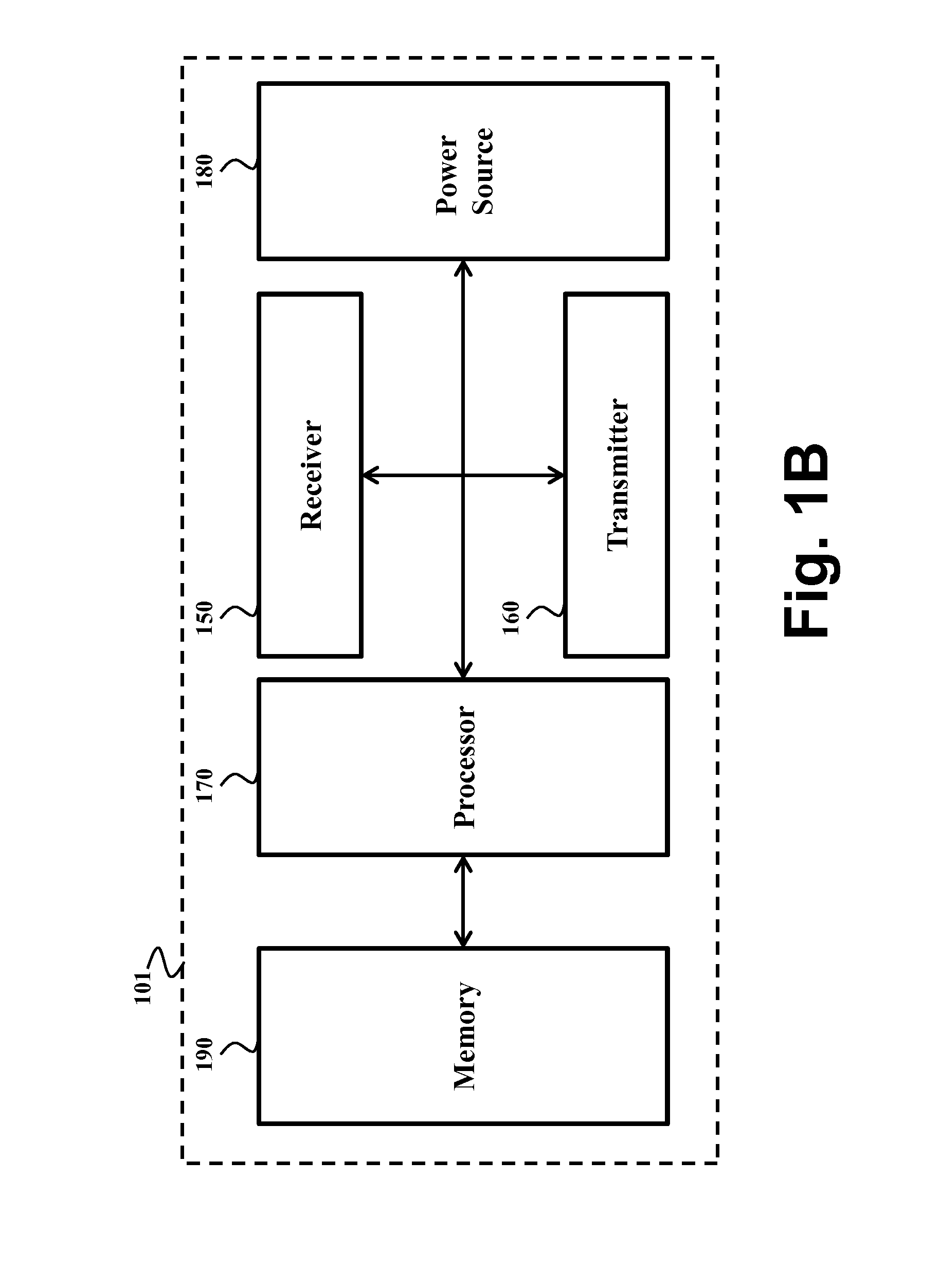

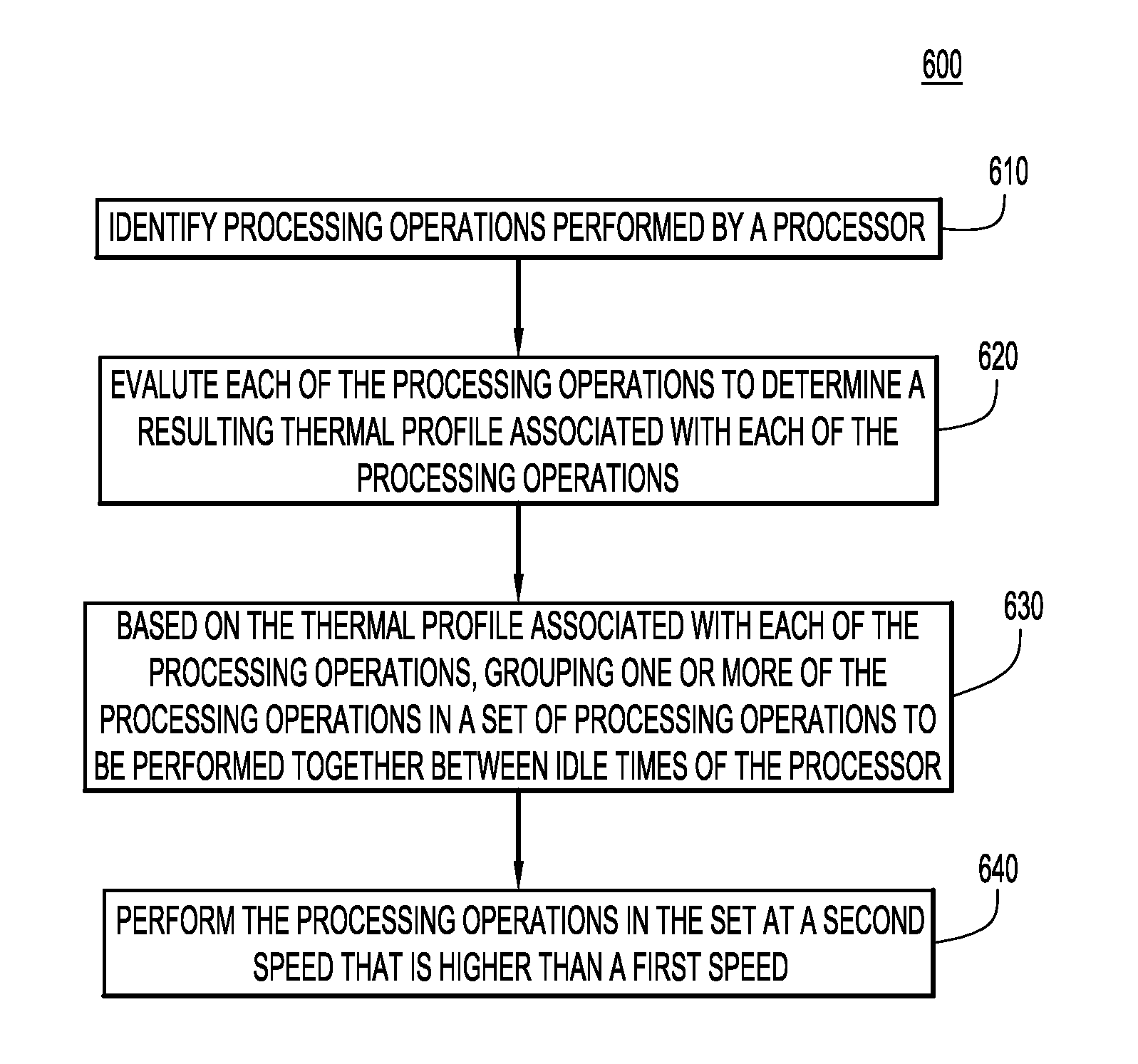

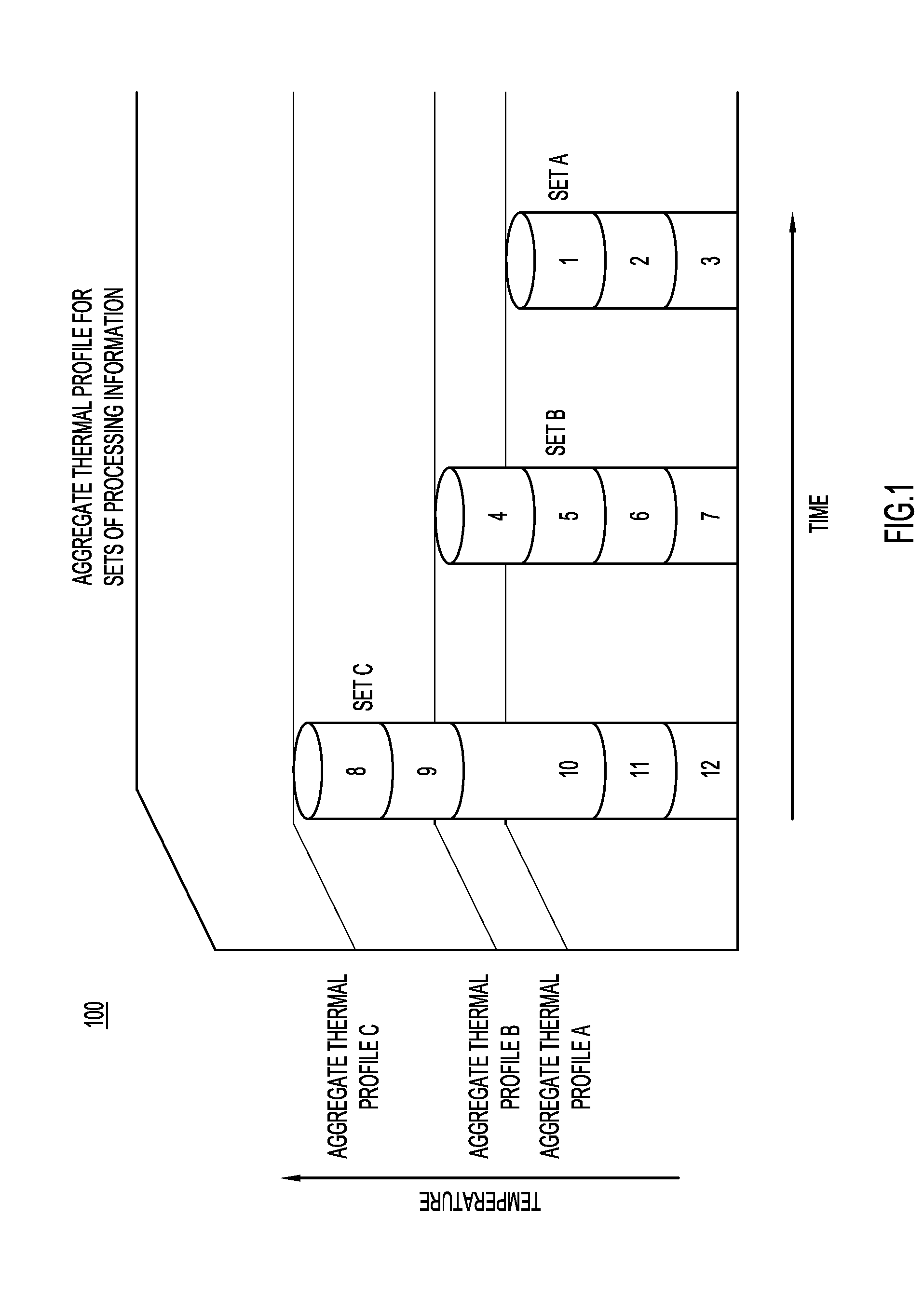

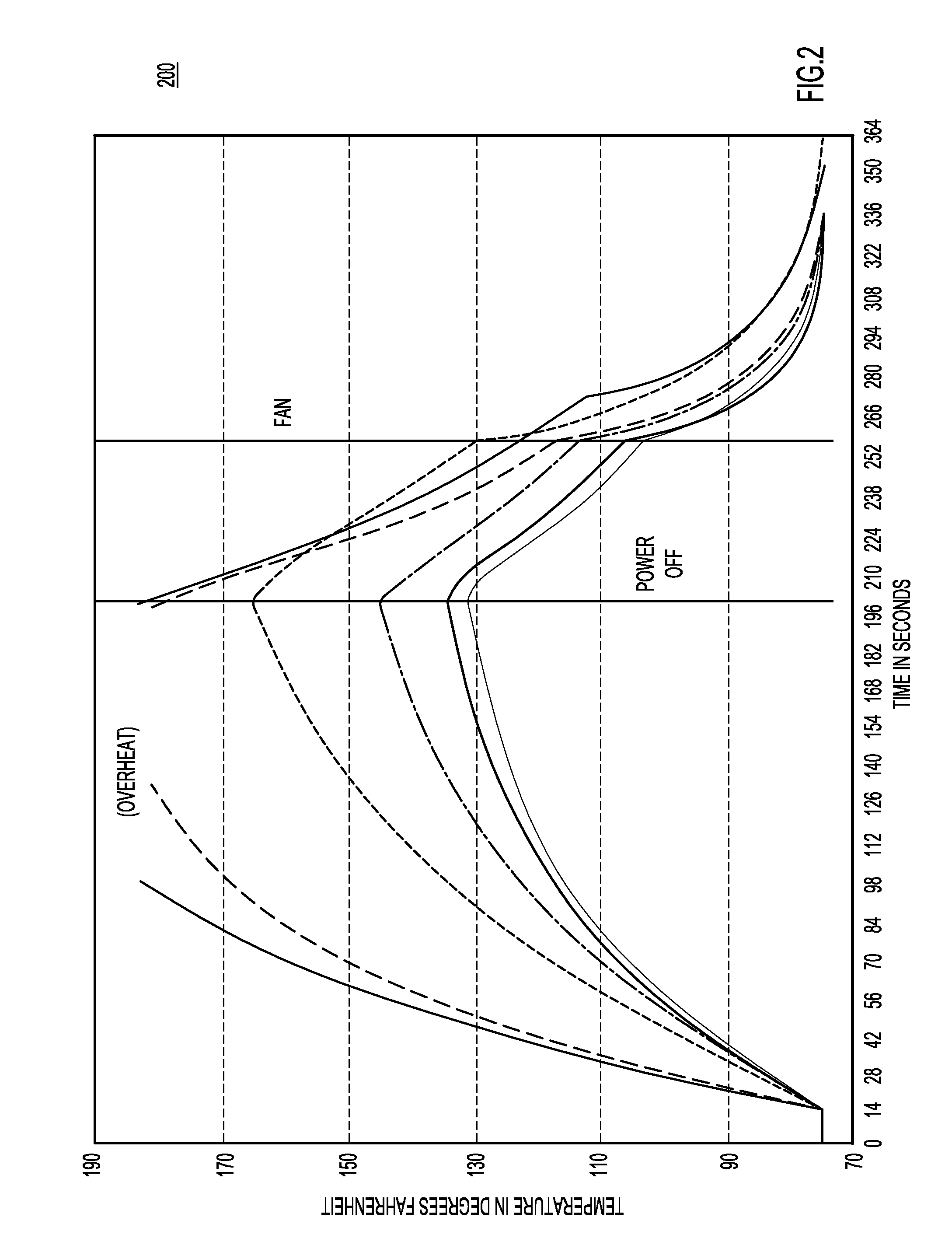

Thermal Profile Optimization Techniques

ActiveUS20140013098A1Improve performanceIncreased idle timeProgram control using stored programsError detection/correctionParallel computingElectronic equipment

Techniques are provided for optimizing performance of a processor. The techniques may be embodied as a method, an electronic device or a computer-readable storage media with instructions executable to perform the method. In summary, processing operations performed by a processor are identified. Each of the processing operations is evaluated to determine a resulting thermal profile associated with each of the processing operations. Based on the thermal profile associated with each of the processing operations, one or more of the processing operations are grouped in a set of processing operations to be performed together between idle times of the processor. The processing operations in the set are performed at a second speed that is higher than a first speed.

Owner:ACER INC

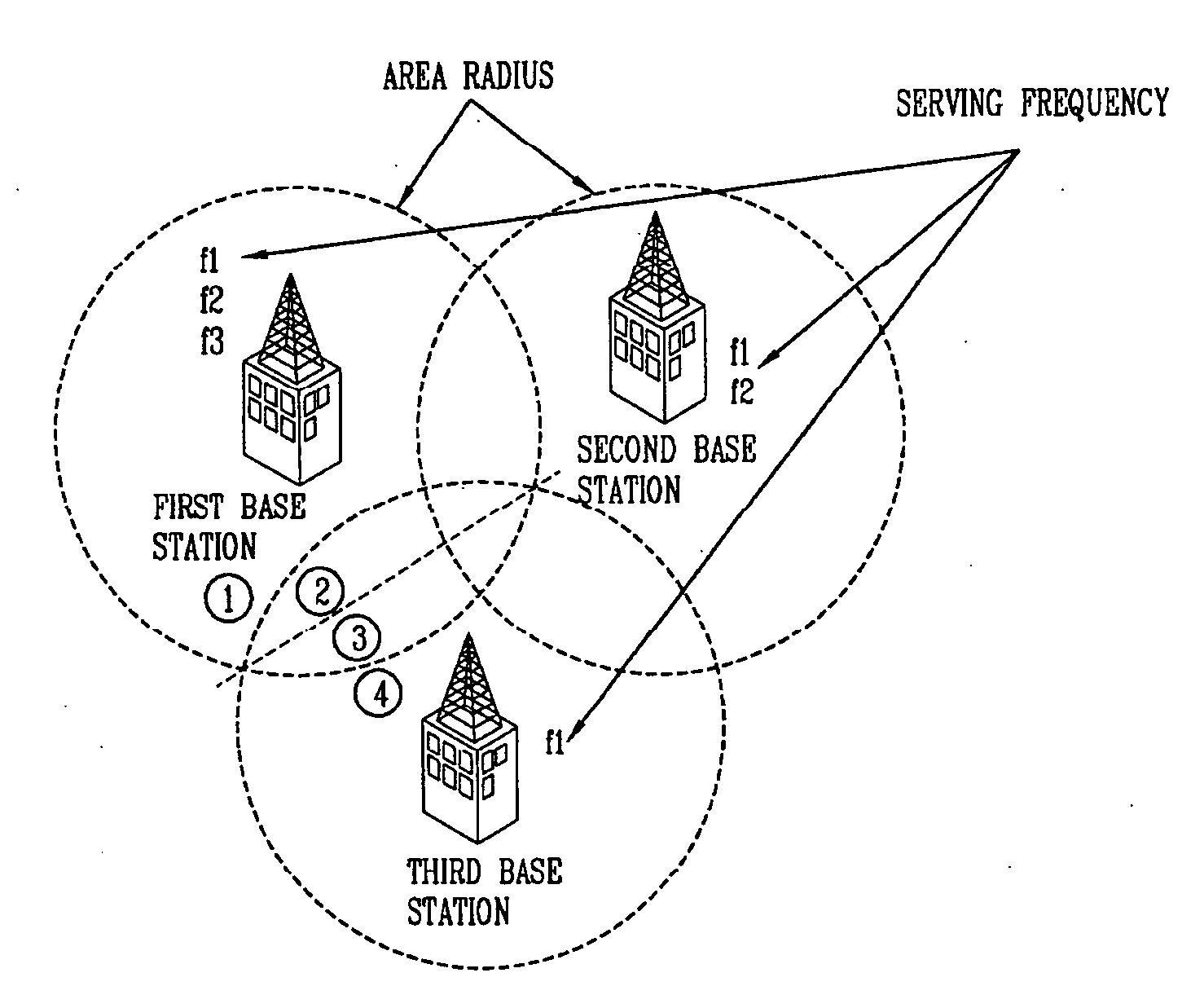

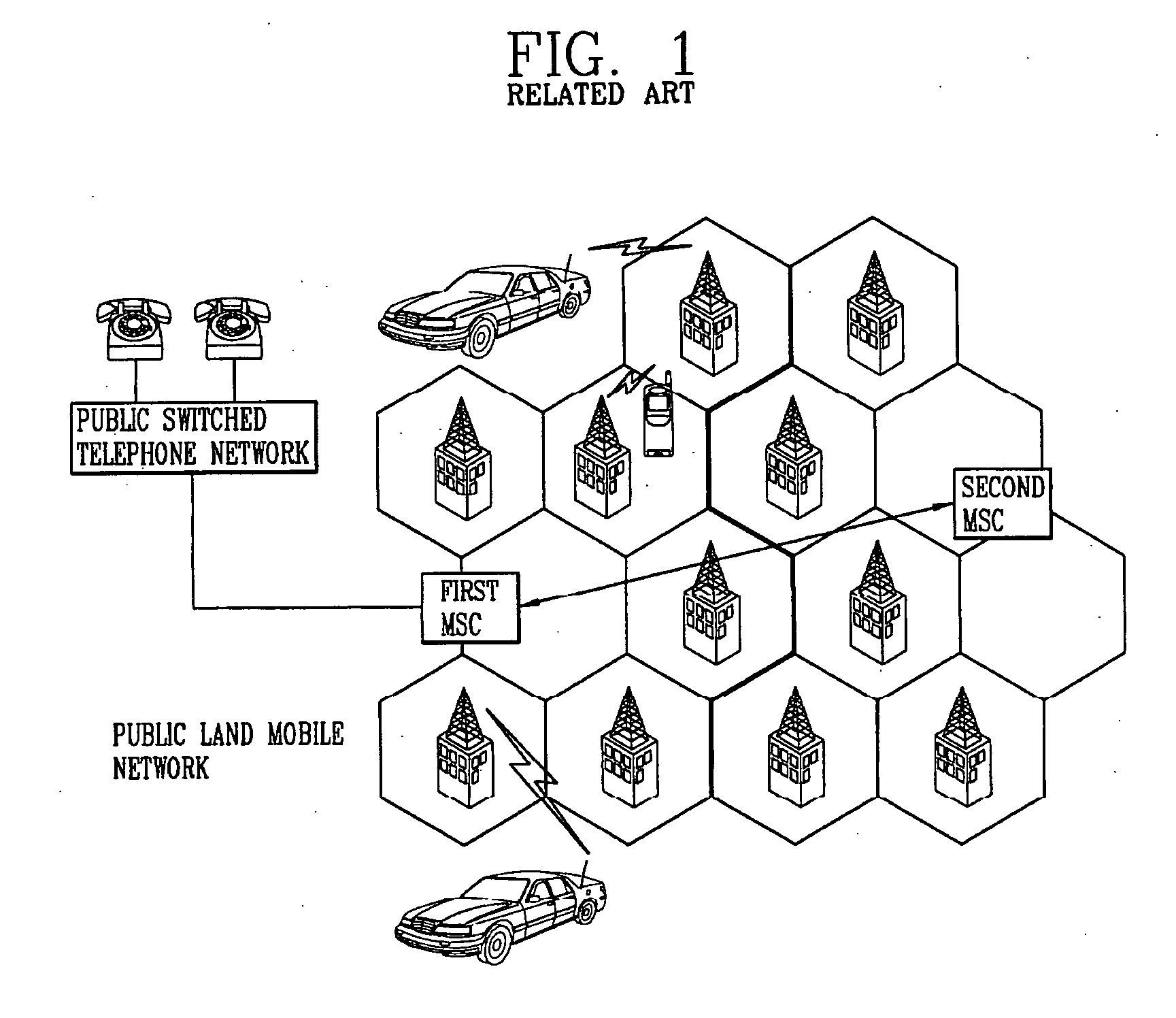

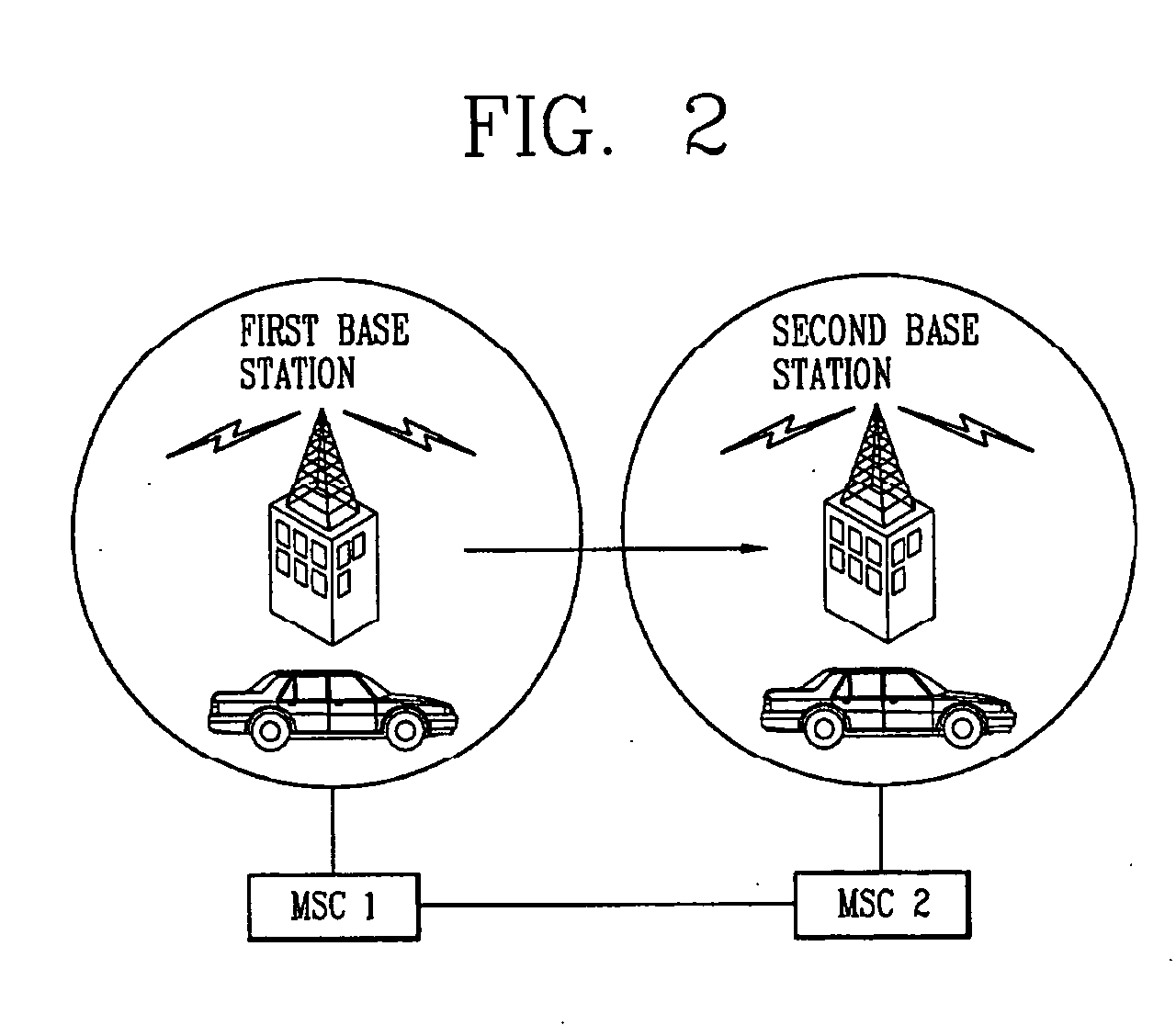

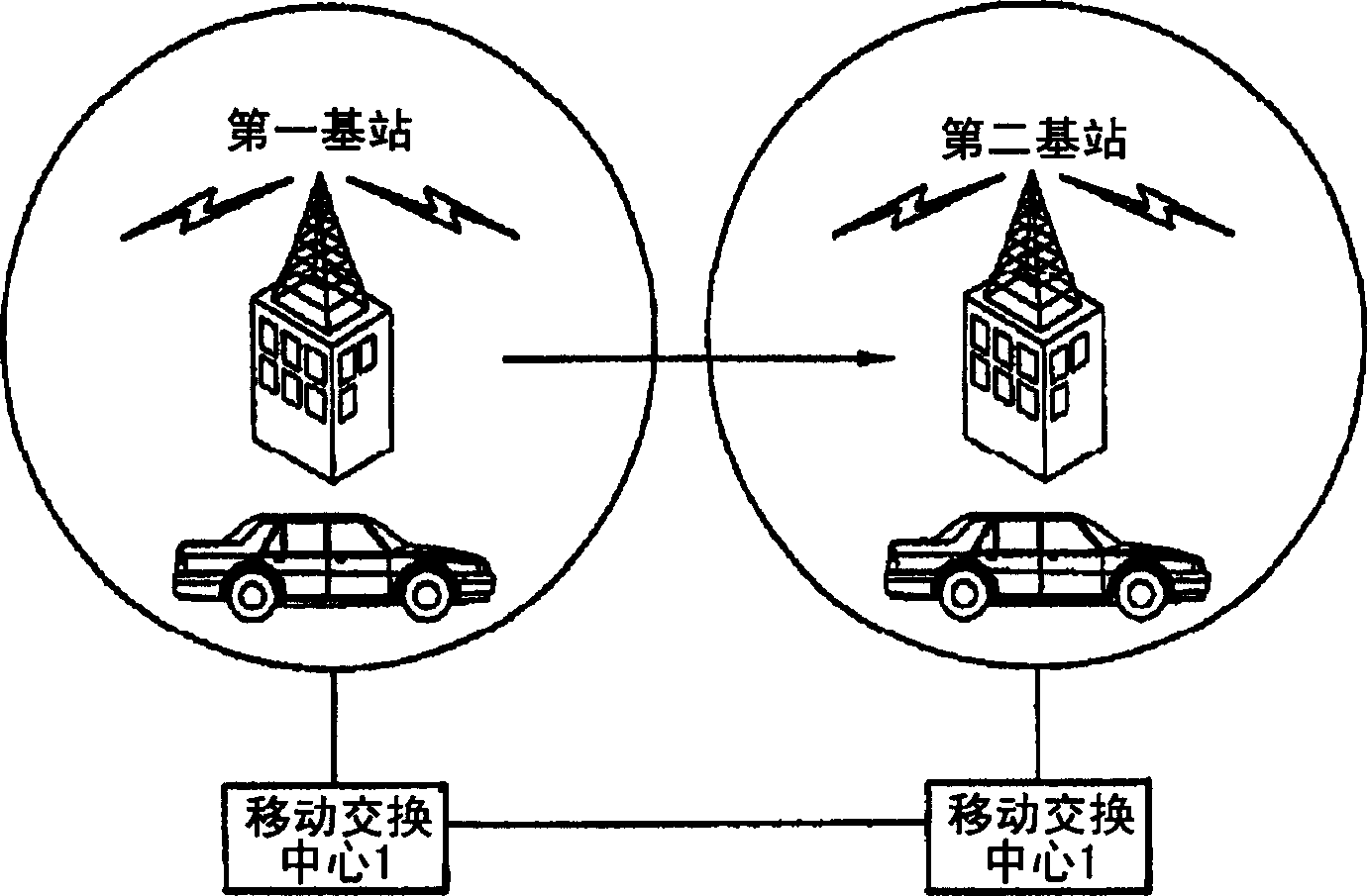

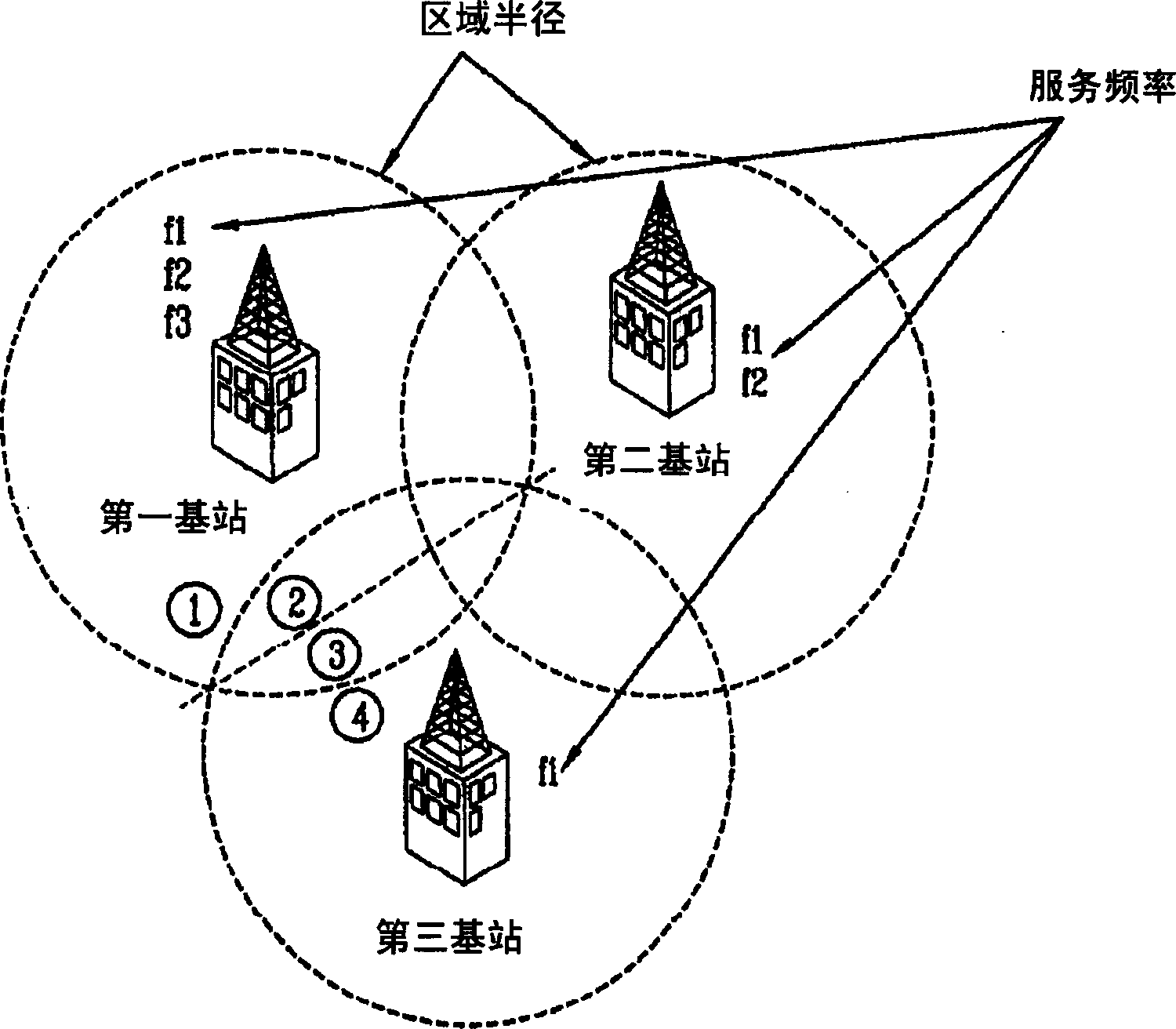

Idle mode handoff in a mobile communications system

InactiveUS20060233138A1Reduce paging message errorImprove signal reception rateEnergy efficient ICTAssess restrictionCommunications systemMobile station

A method and apparatus for idle mode handoff in an overlapping area of a multi-channel cell is provided. By monitoring different frequencies serviced by neighboring base stations, when a mobile station is located in an overlapping region between cells and the frequency channel being serviced in a multi-channel region is different from a channel being serviced in the neighboring base station, an idle mode handoff between cells may be smoothly performed.

Owner:LG ELECTRONICS INC

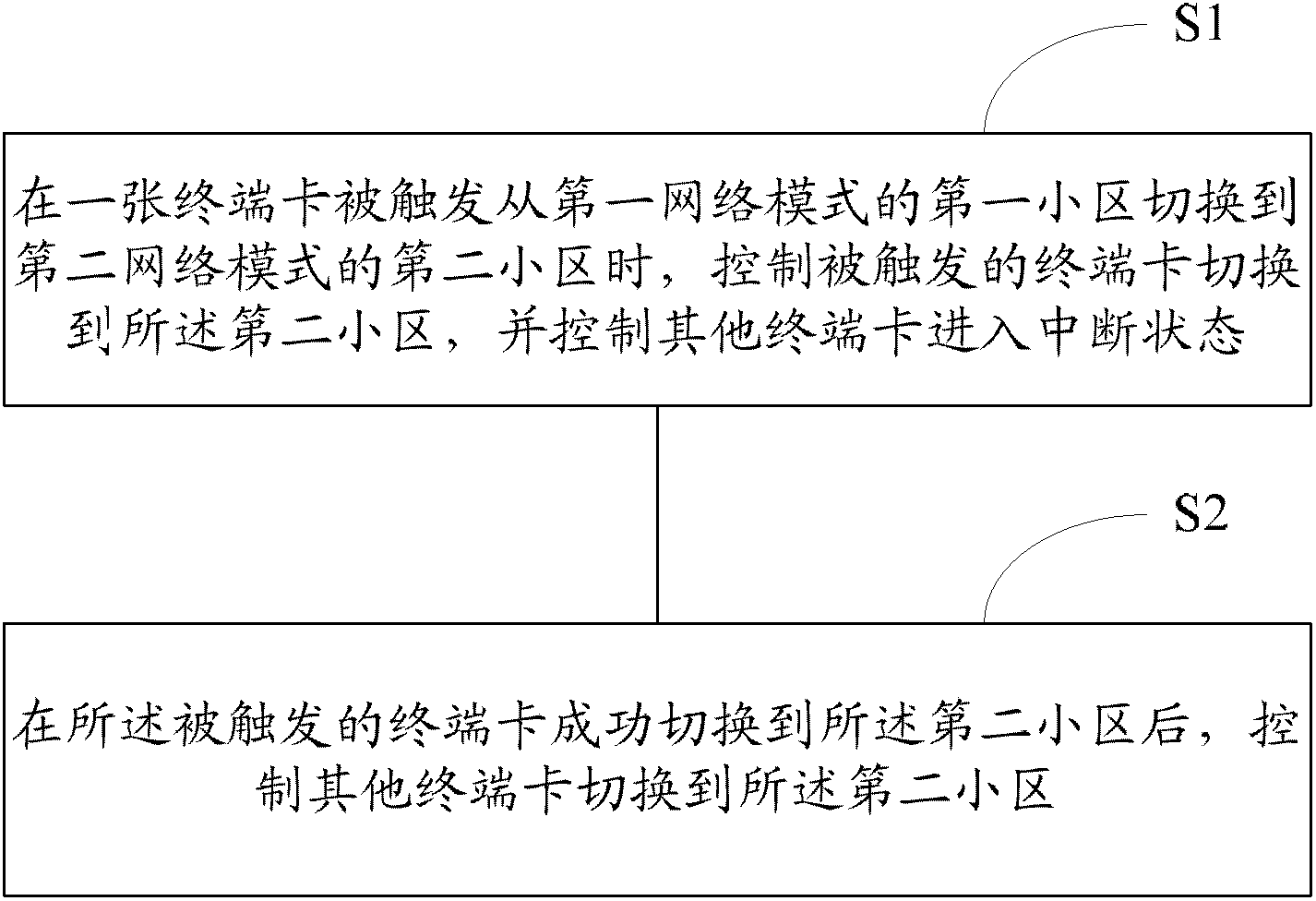

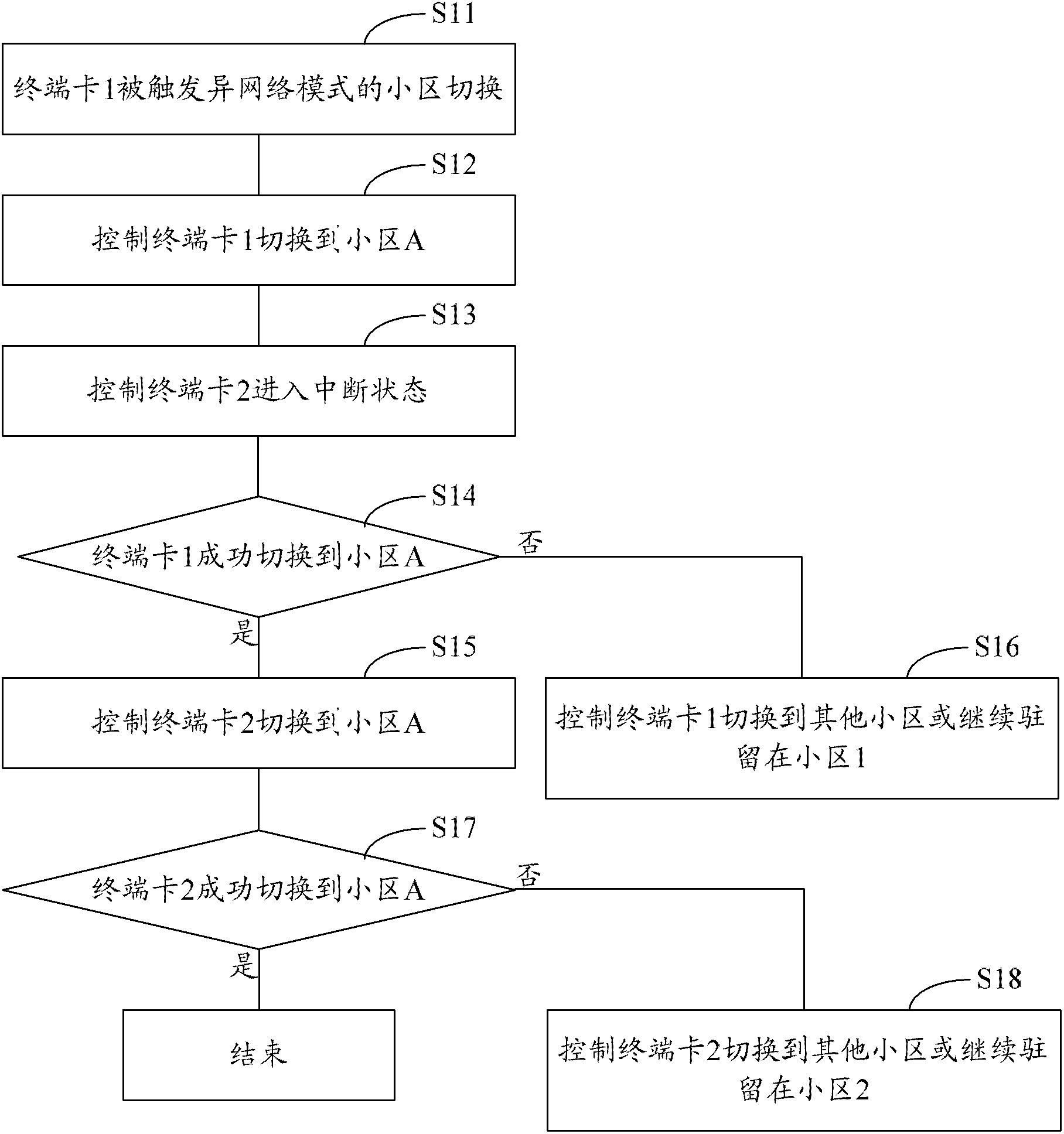

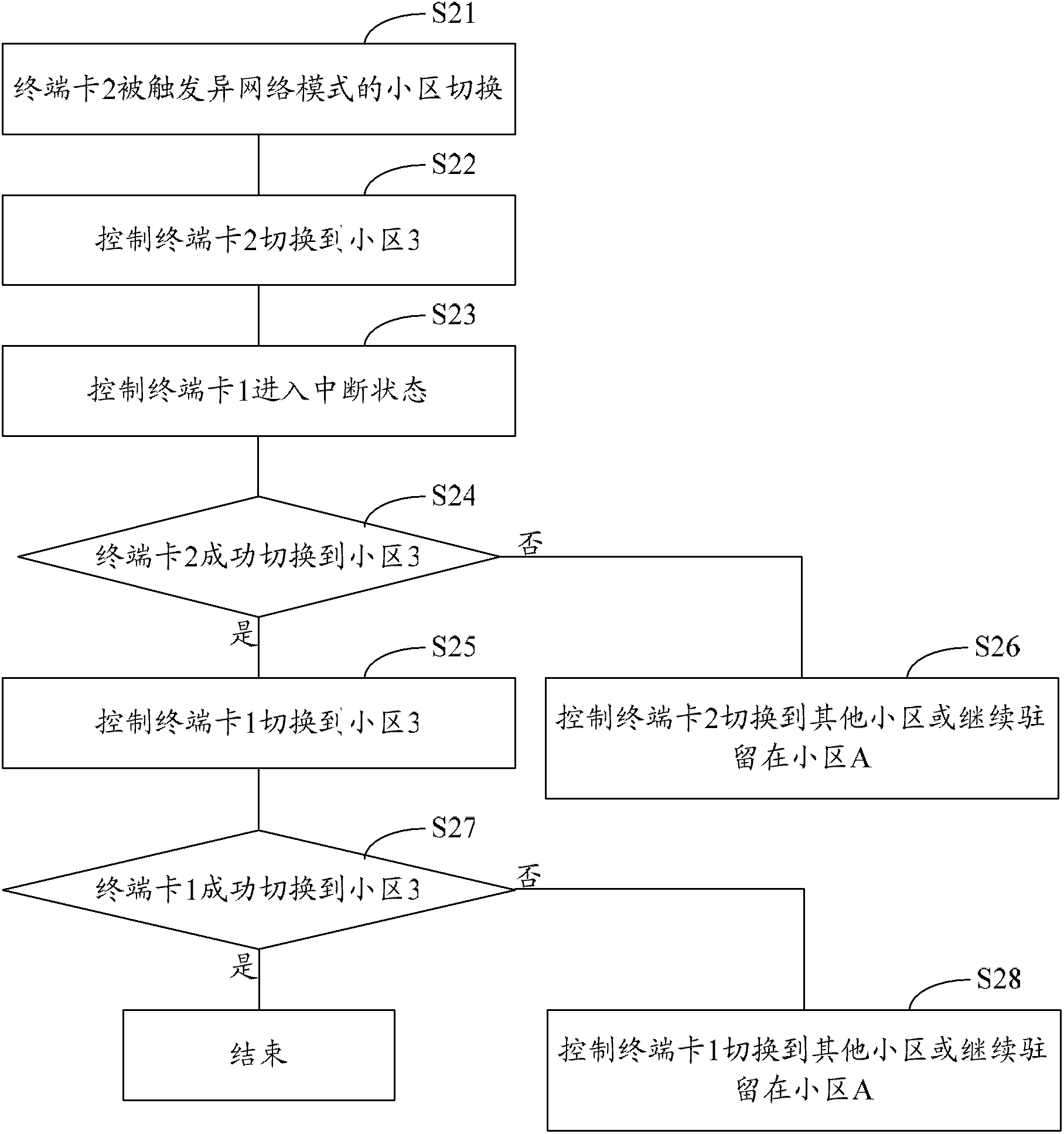

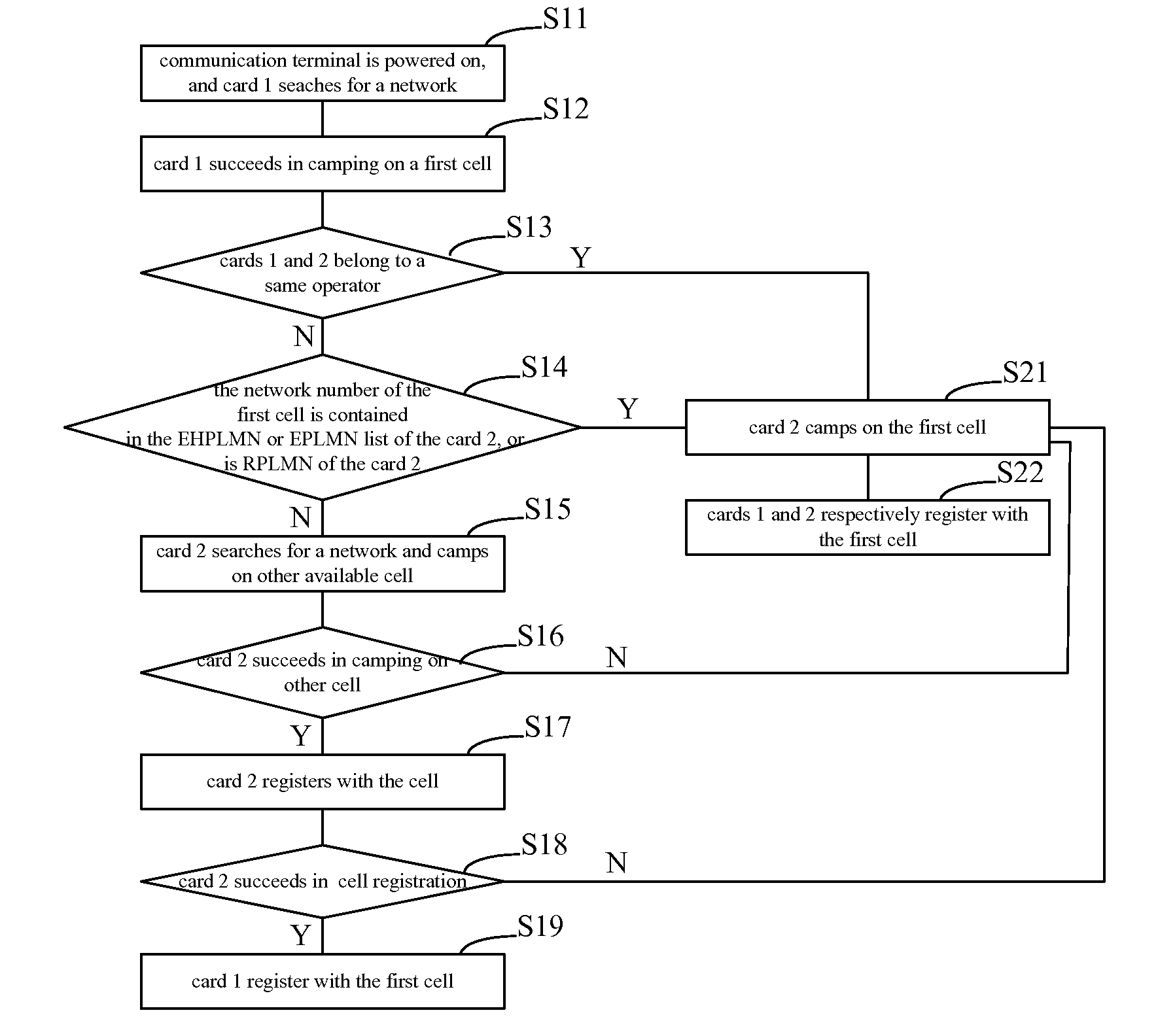

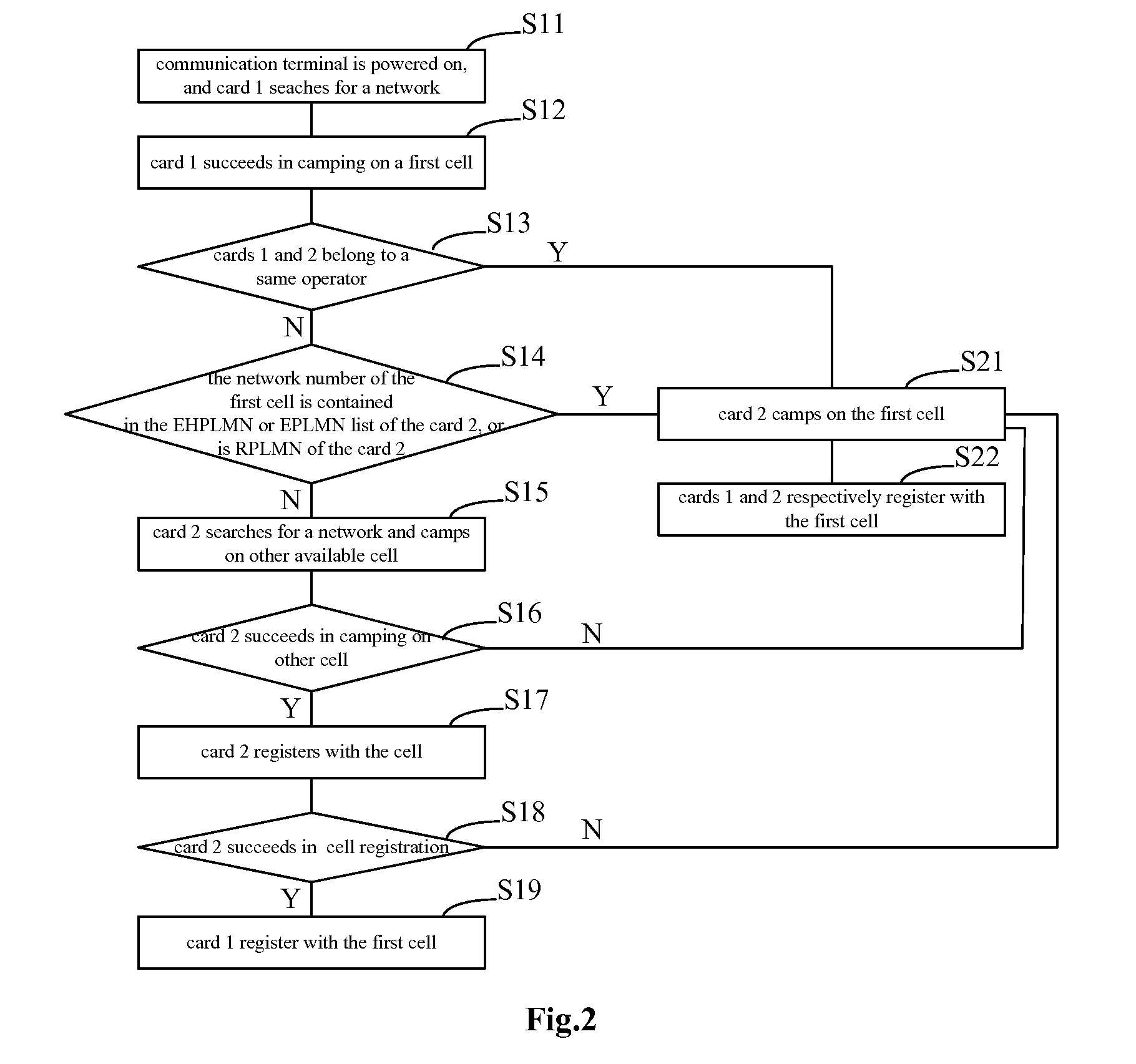

Multi-card and multi-mode terminal, method and device for synchronizing access modes thereof

ActiveCN102202363AAccess Mode SynchronizationRealize free mode switchingWireless communicationComputer hardwareAccess technology

The invention discloses a multi-card and multi-mode terminal, a method and device for synchronizing access modes thereof. The method for synchronizing the access modes of the multi-card and multi-mode terminal comprises the following steps of: when a terminal card is triggered to be switched from a first cell in a first network mode to a second cell in a second network mode, controlling the triggered terminal card to be switched to the second cell and controlling other terminal cards to be in an interrupt state; and, after the triggered terminal card is successfully switched to the second cell, controlling other terminal cards to be switched to the second cell. According to the technical scheme of the invention, in the event of not increasing hardware equipment of the multi-card and multi-mode terminal, the multi-card and multi-mode terminal can be synchronously switched to the same access technology. A plurality of terminal cards can work in a network mode simultaneously, therefore, the investment of user equipment is saved; and modes of the multi-card and multi-mode terminal can be freely switched.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

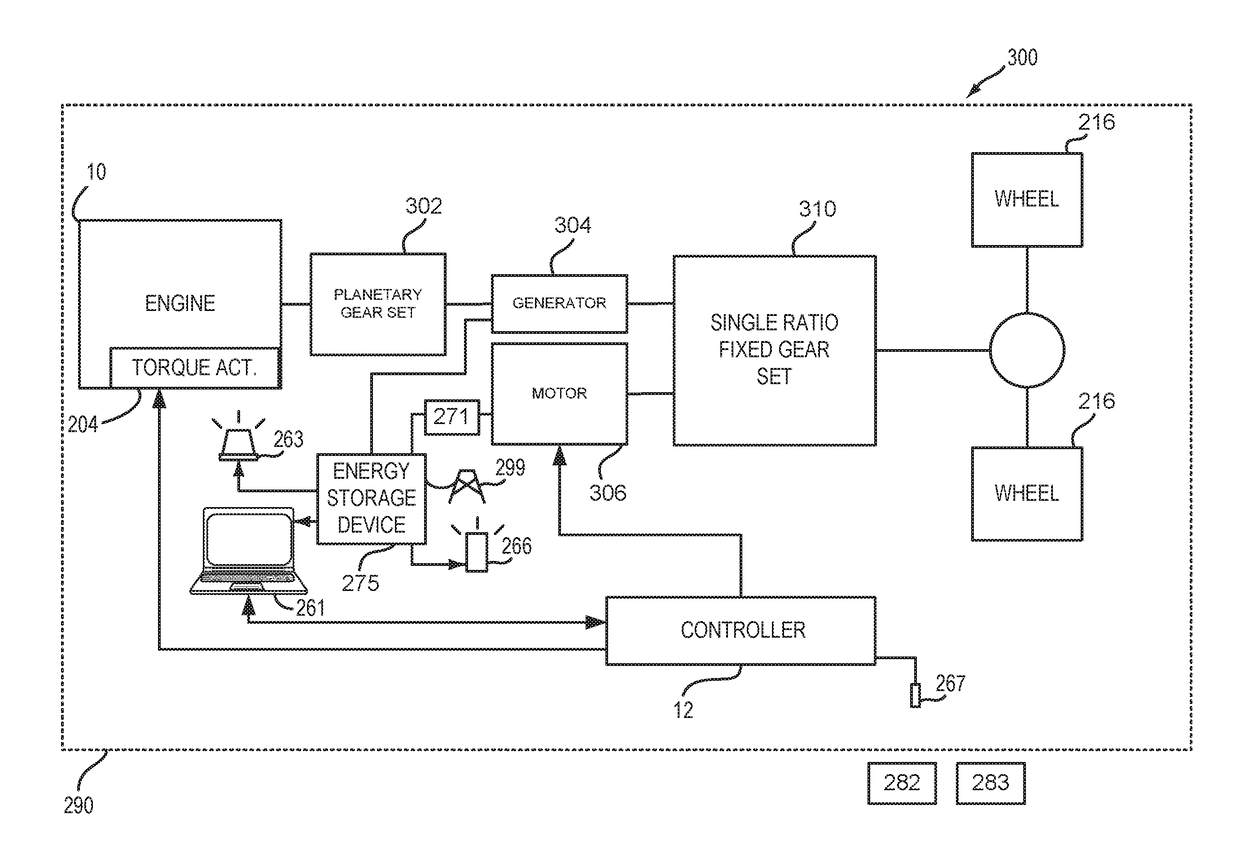

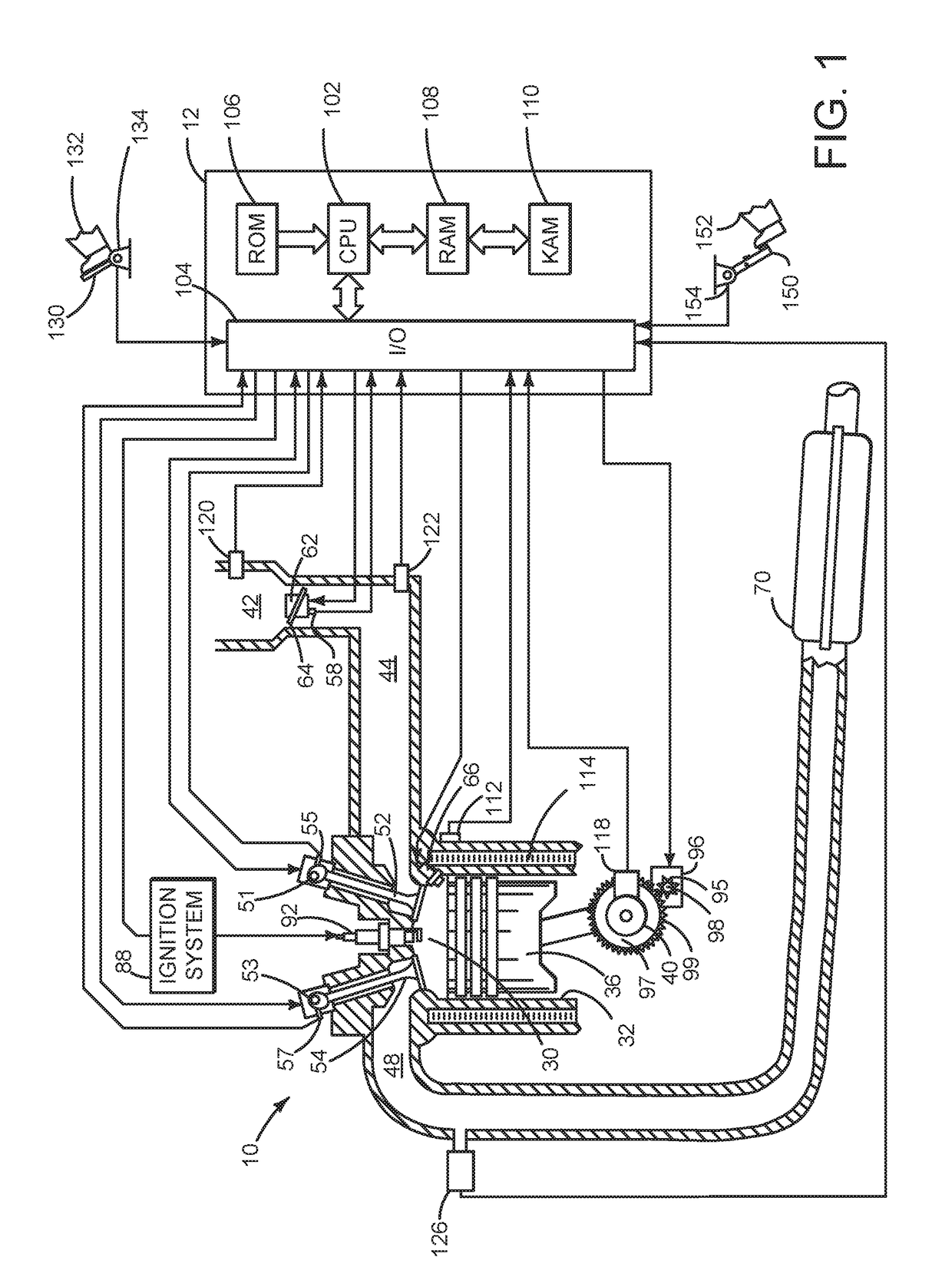

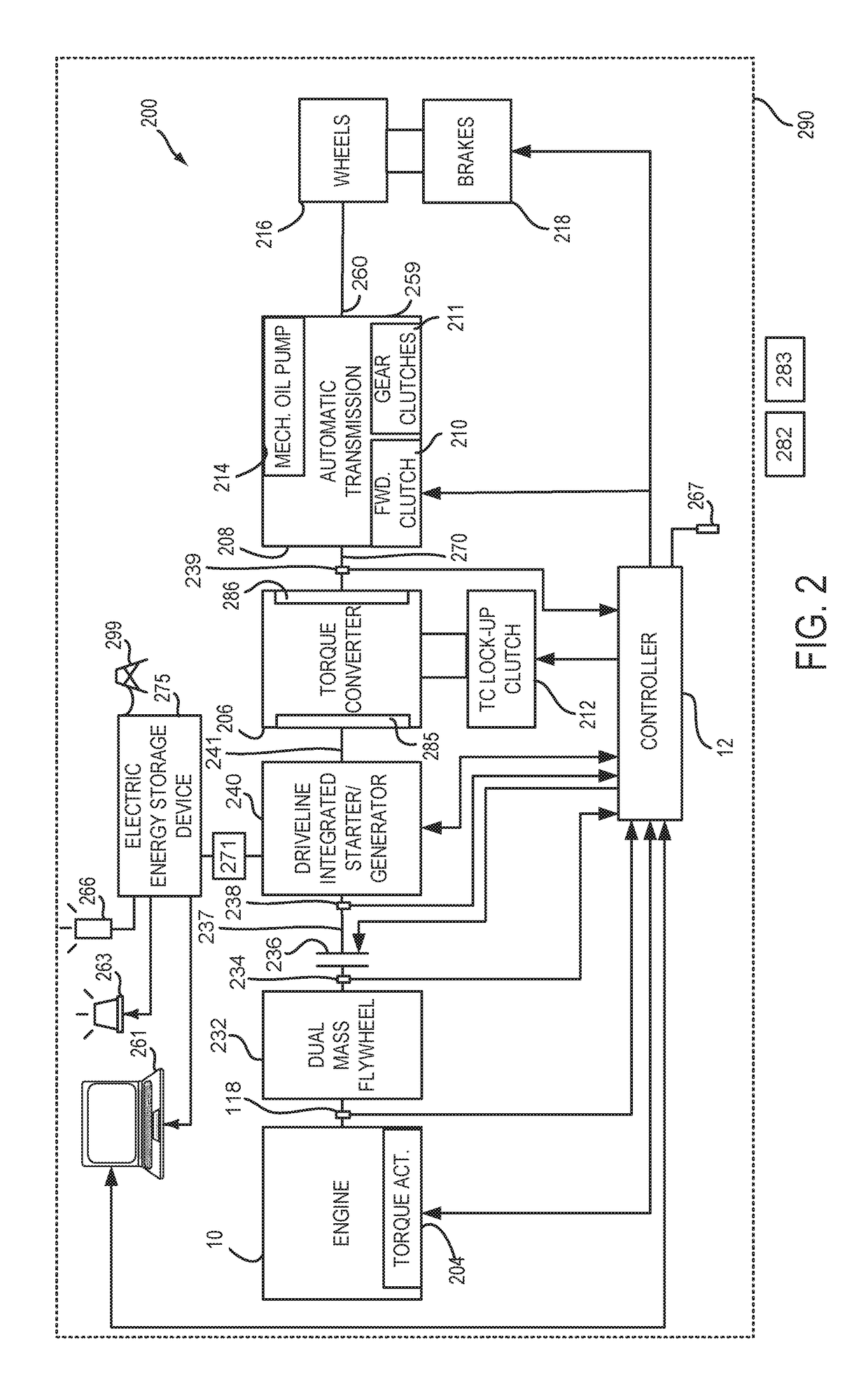

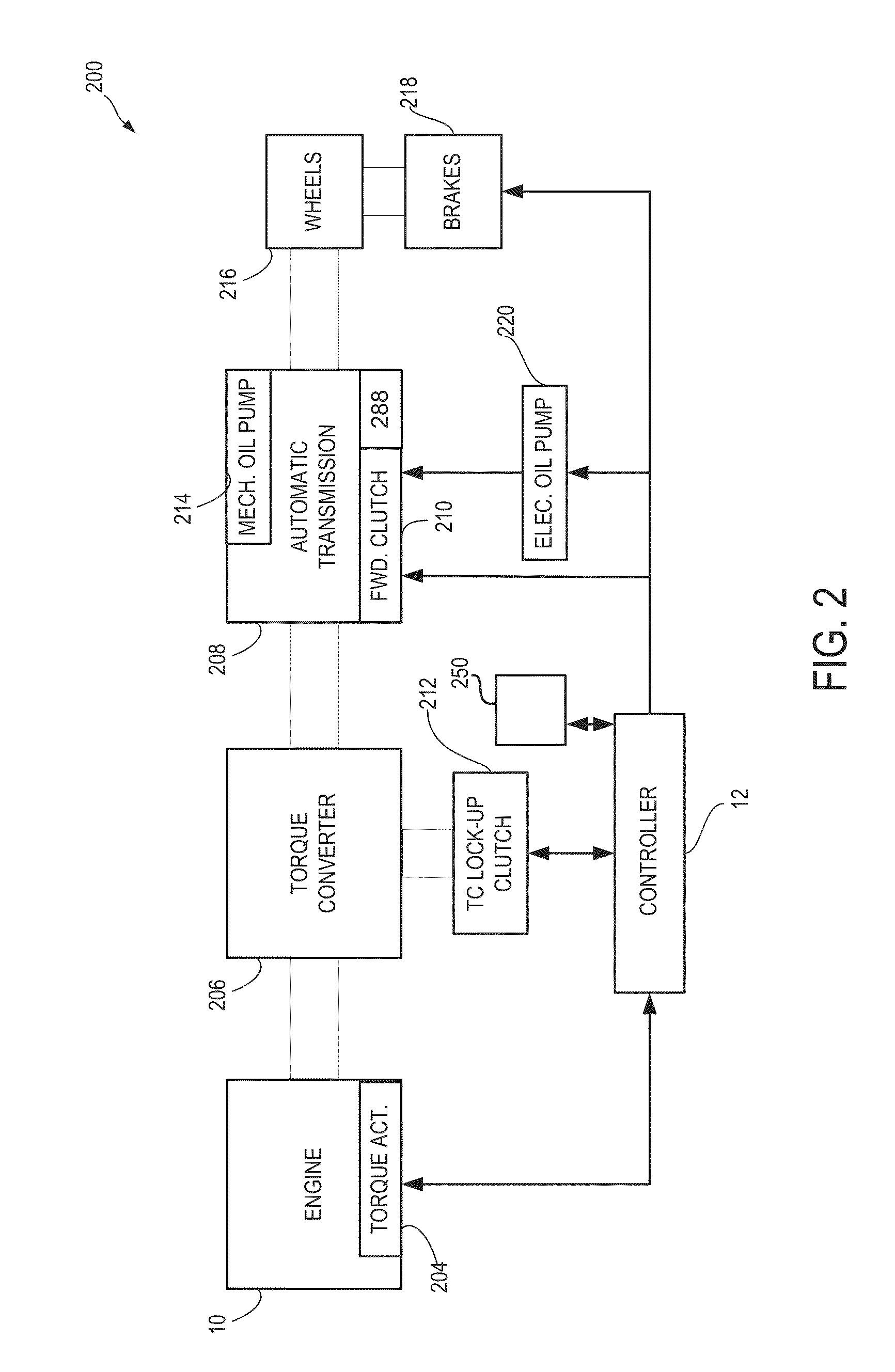

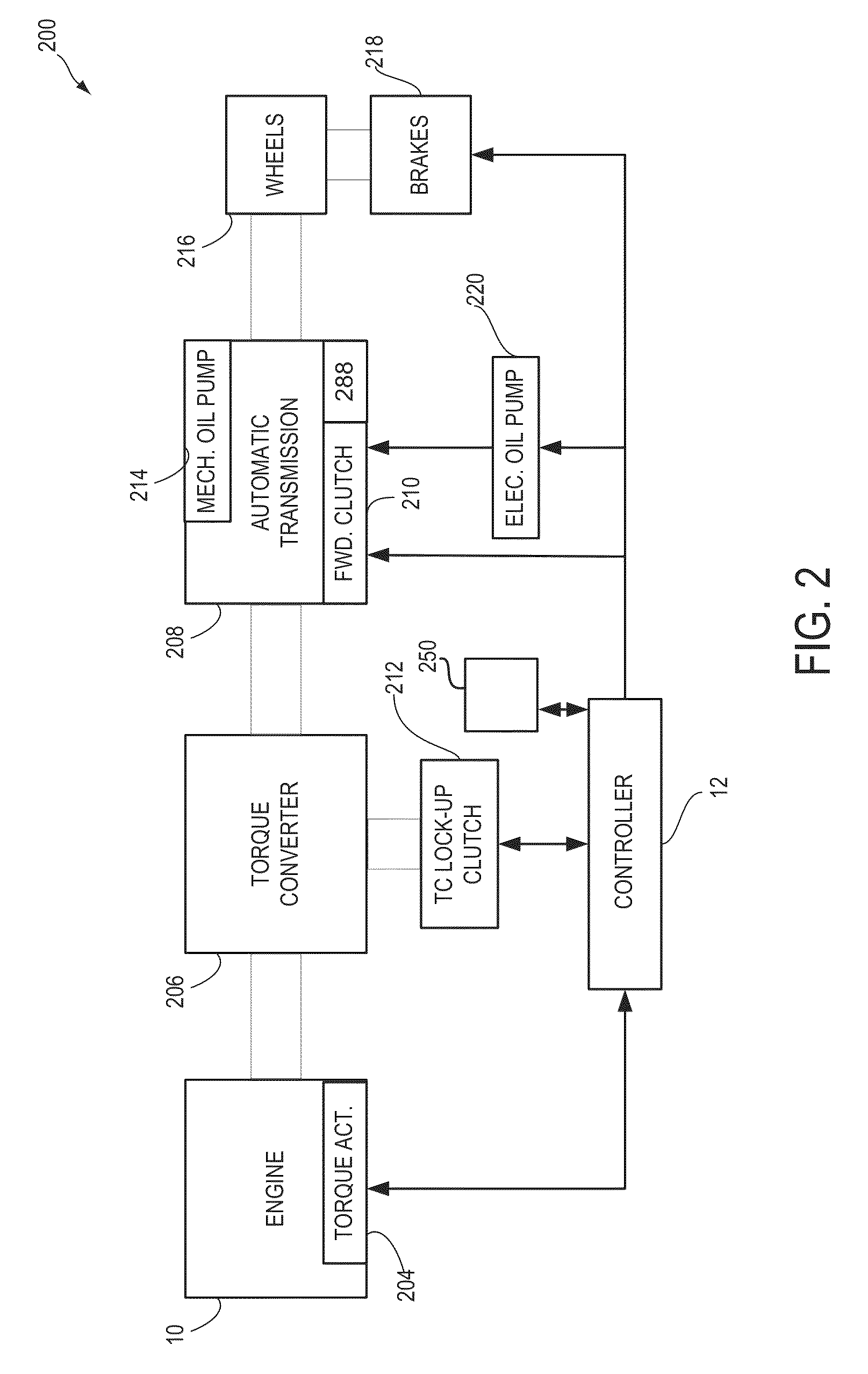

Methods and systems for extending electric idle

ActiveUS20170282737A1Extend electric idle durationReduce the number of timesHybrid vehiclesOperating modesElectric energyVariator

Systems and methods for operating a vehicle in an electric idle mode are presented. The vehicle electrical idle mode may be characterized as a mode where the vehicle's engine is off; the vehicle increases torque to vehicle wheels responsive to an application of an accelerator pedal, release of a brake pedal, or a vehicle occupant shifting a transmission; and the vehicle's battery supplies electrical energy to devices of the vehicle being operated by a vehicle occupant.

Owner:FORD GLOBAL TECH LLC

Pigmented inkjet ink

The present invention provides pigmented inks comprising self-dispersing pigment and an amino-containing compound. The addition of an amino-containing compound to the self-dispersing pigment can improve the reliability and performance of the ink in an inkjet printhead. The present invention also provides methods for making a surface modified pigment comprising associating a self-dispersing pigment with an amino-containing compound having no more than one primary amino group or one secondary amino group.

Owner:BRADY JOHN A +1

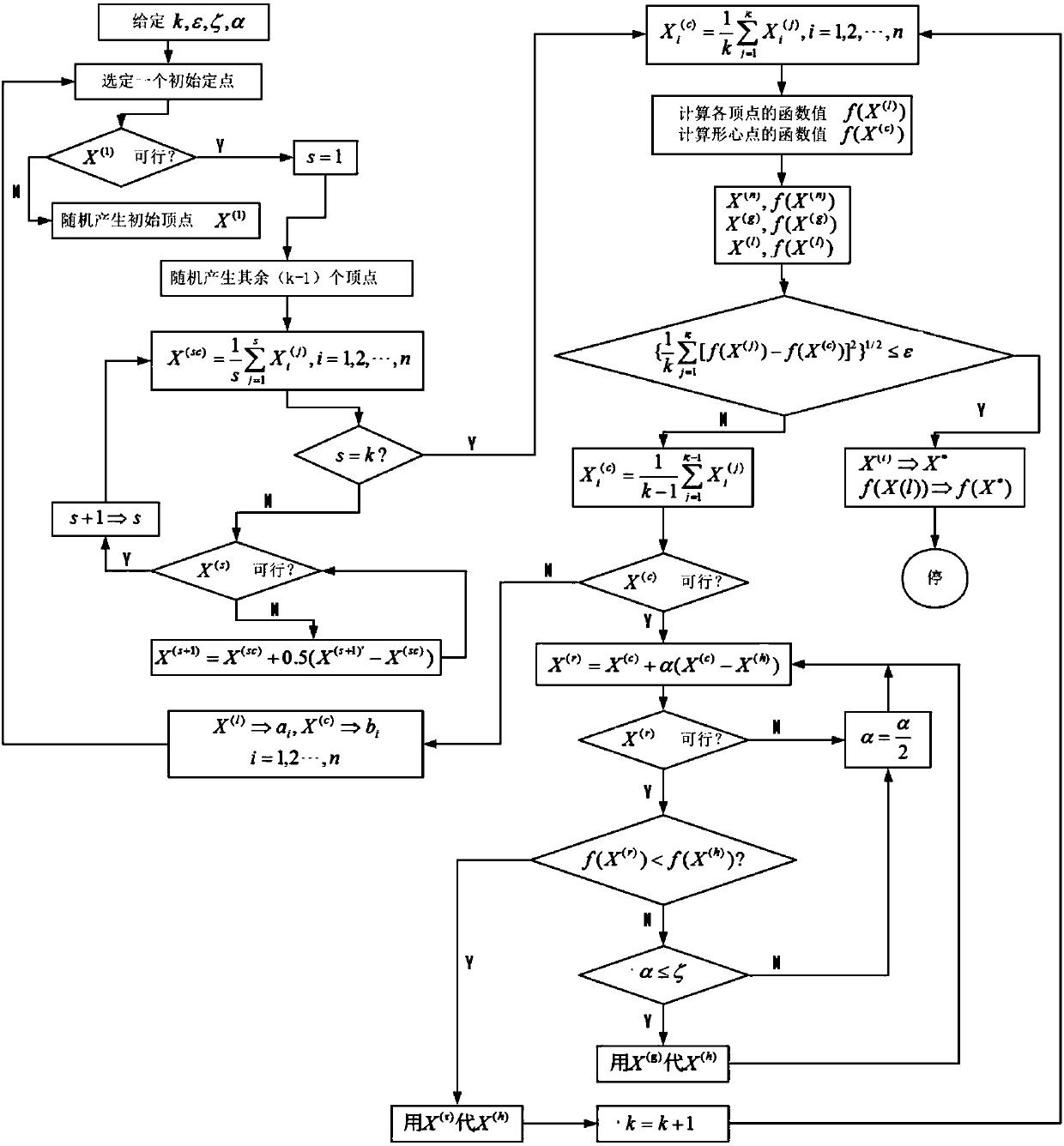

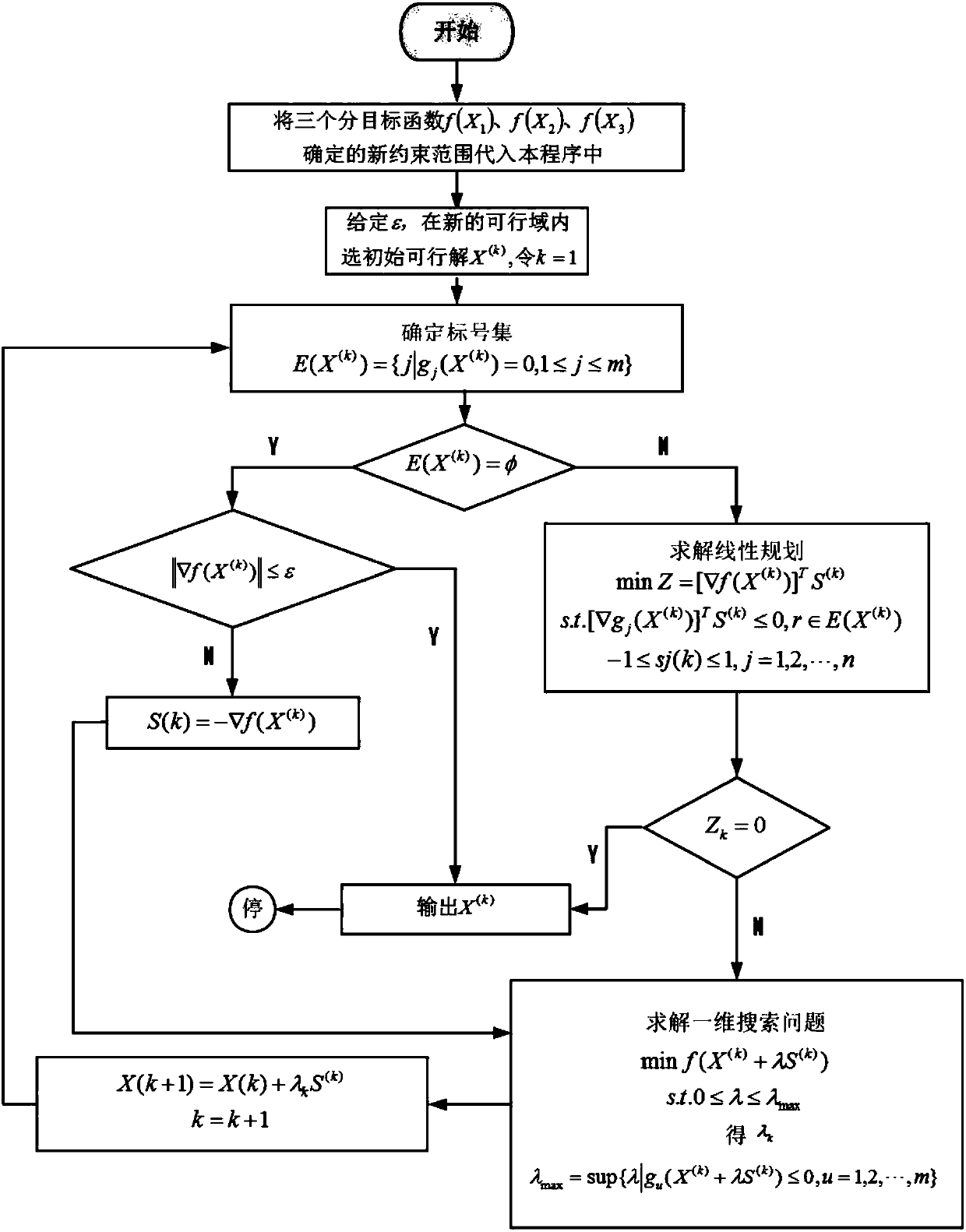

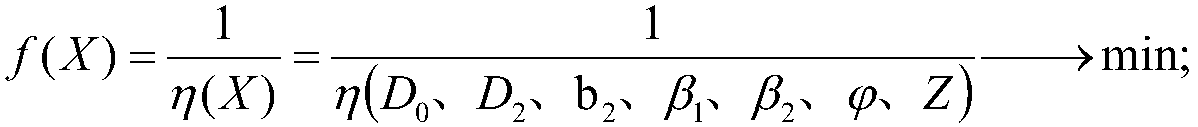

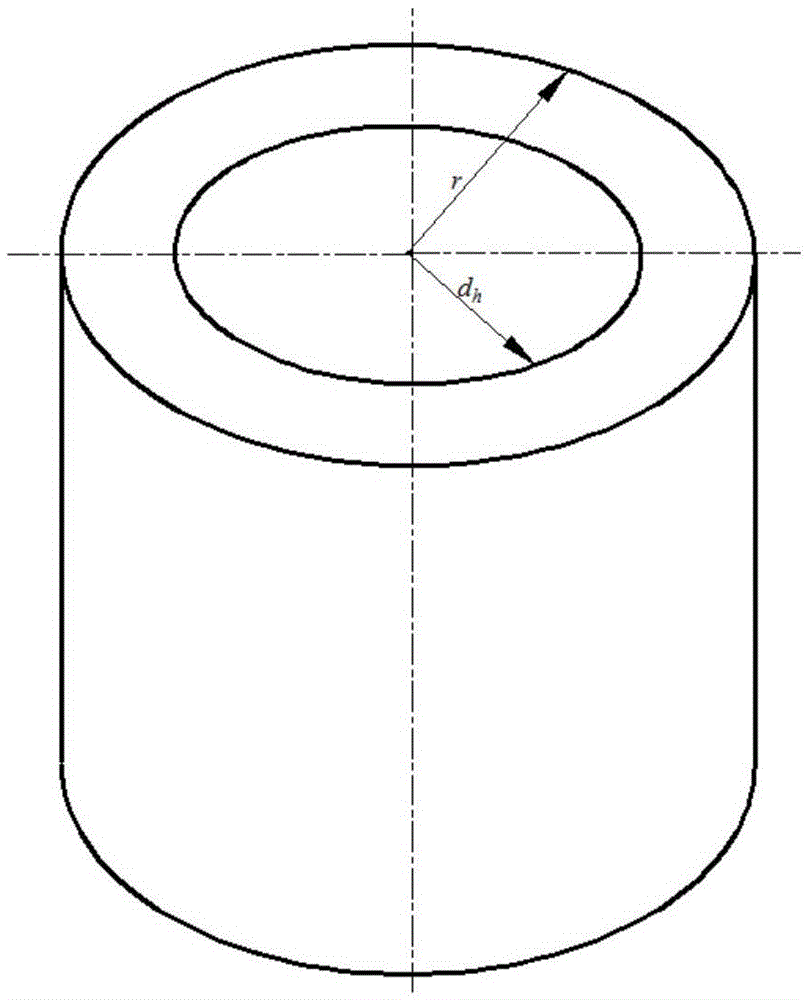

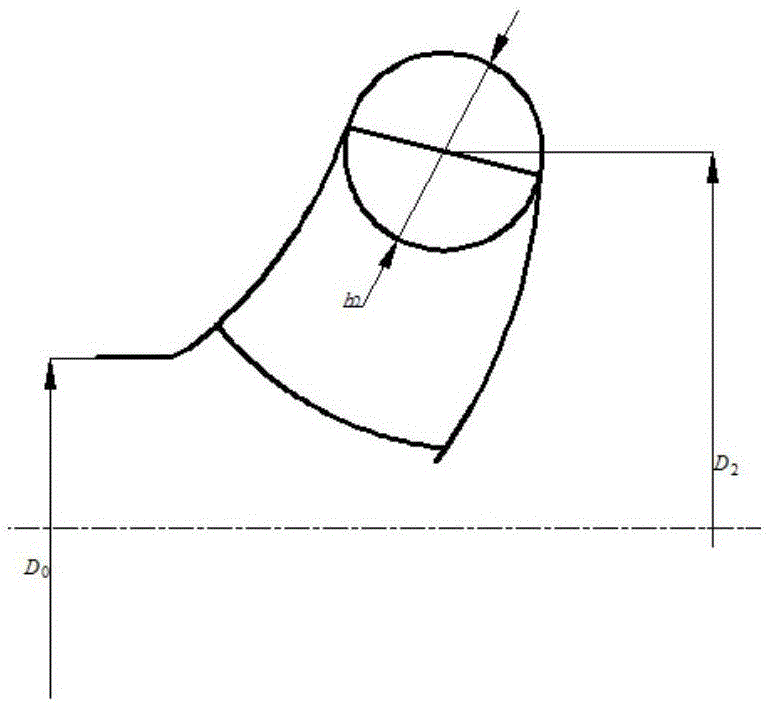

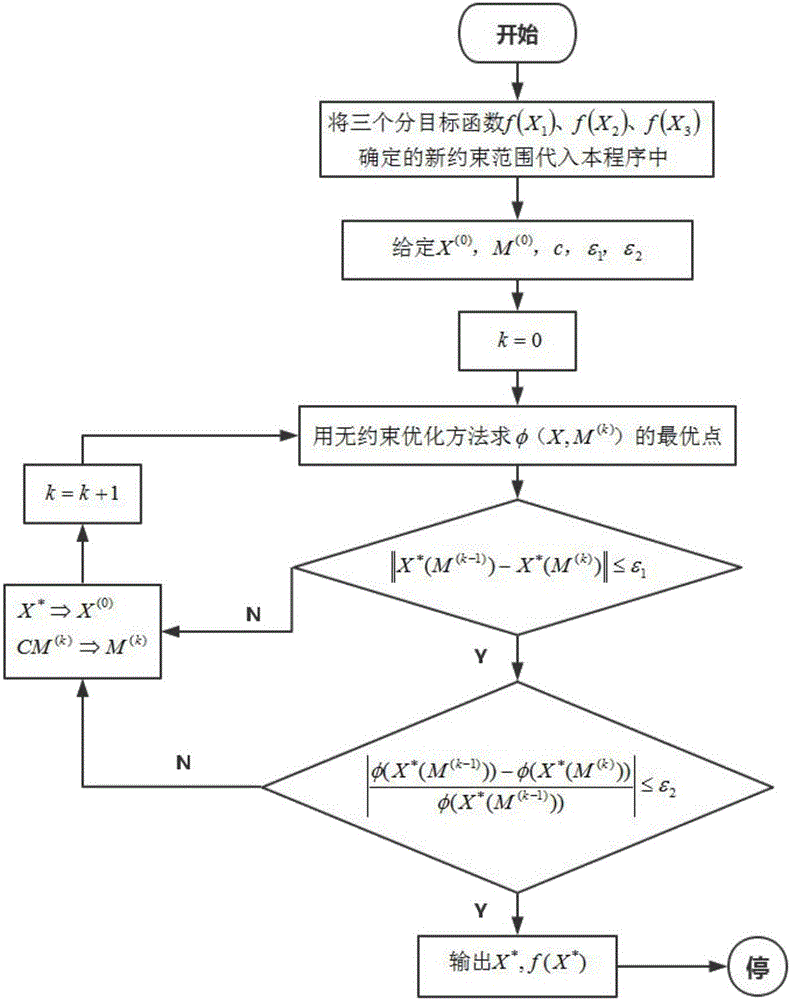

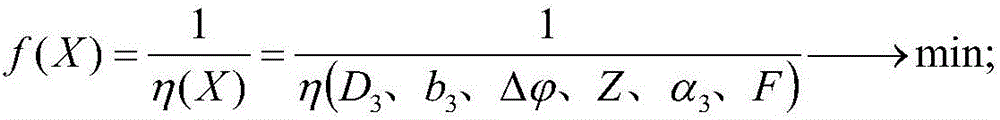

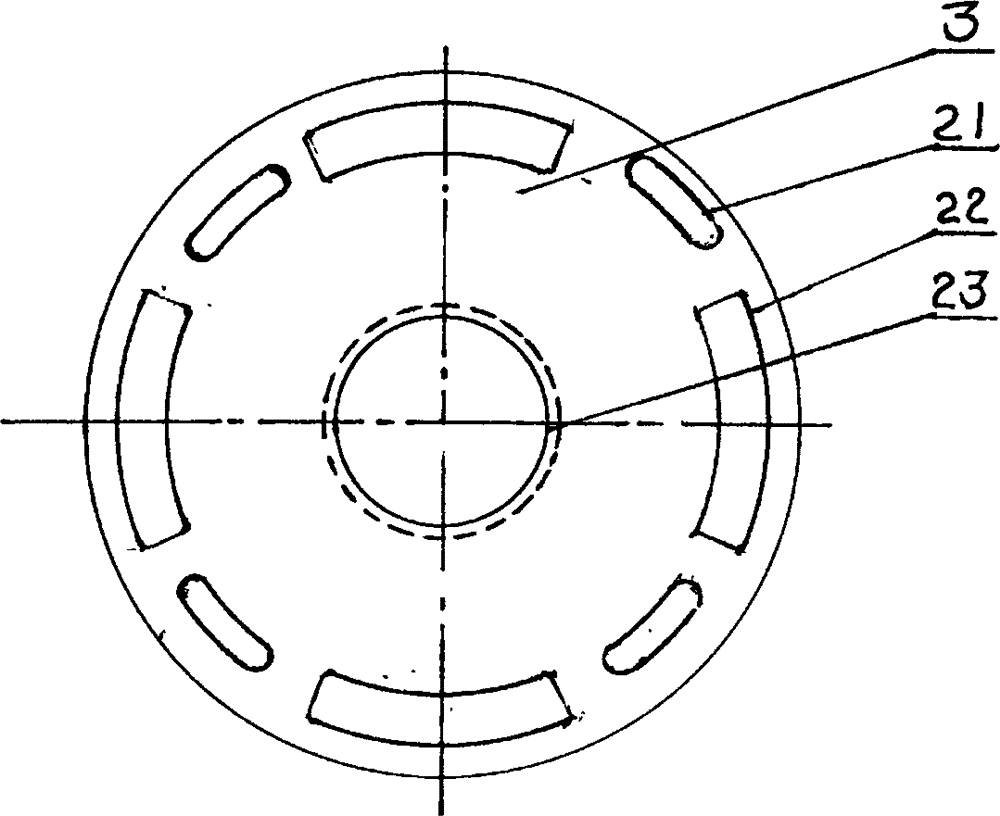

Impeller optimized design method capable of prolonging running down time of reactor coolant pump

InactiveCN106015082AImprove Nuclear Safety PerformanceIncreased idle timeGeometric CADPump componentsImpellerProcess engineering

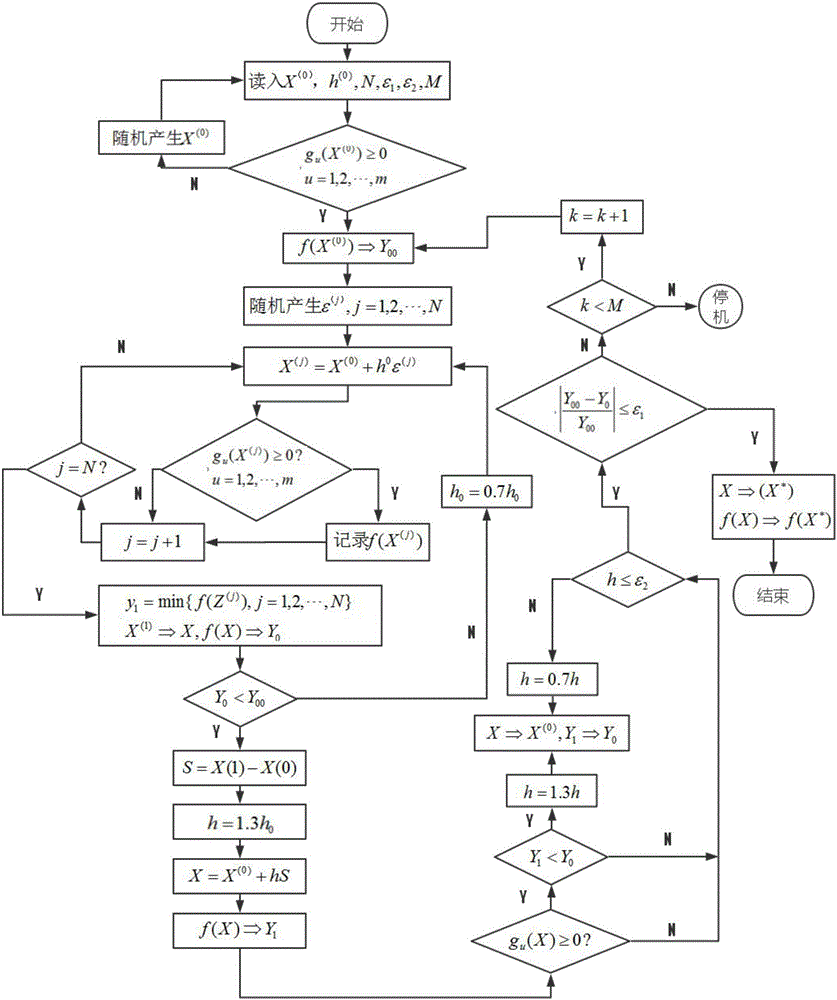

The invention relates to an impeller optimized design method capable of prolonging running down time of a reactor coolant pump. According to the impeller optimized design method, firstly, a main objective function for improving running efficiency under a running down working condition by optimizing main parameters of an impeller is established; then the main parameters are divided into three groups which are taken as design variables respectively, three subordinate objective functions are optimized respectively with a complex method for running down efficiency under initial constraint conditions, and the optimum points, guaranteeing the highest efficiency, of main geometric parameters of the impeller are obtained respectively; and a new constraint is determined in a small range nearby the optimum points, optimized solution is performed on the main objective function under the reduced new constraint with a feasible direction method, and the final optimized result is obtained. By means of design of the impeller of the reactor coolant pump, the problem of lower running down efficiency of the impeller can be improved, the running down time is prolonged, and the nuclear safety is improved. Meanwhile, with innovative application of the step-by-step optimization design method adopting constraint range reduction for subordinate objectives and optimum point searching for the main objective, the optimization speed is increased, and the effectiveness of the optimized result is guaranteed.

Owner:JIANGSU UNIV

Hydraulic design method for running down model impeller of nuclear main pump

InactiveCN105545799AIncrease the moment of inertiaIncreased idle timePump componentsPumpsImpellerMoment of inertia

The invention belongs to the field of fluid machinery and particularly discloses a hydraulic design method for a running down model impeller of a nuclear main pump. Specific to the condition that a nuclear main pump running down model neglects the influence of impeller rotational inertia on the running down process, the impact of geometric parameters of an impeller of the nuclear main pump on the operating performance and the impeller rotational inertia is considered simultaneously in the design process of the nuclear main pump impeller, and thus the key parameters of the designed impeller can well meet the requirement of performance during normal operation and the impeller can have large rotational inertia so that the running down time can be prolonged.

Owner:JIANGSU UNIV

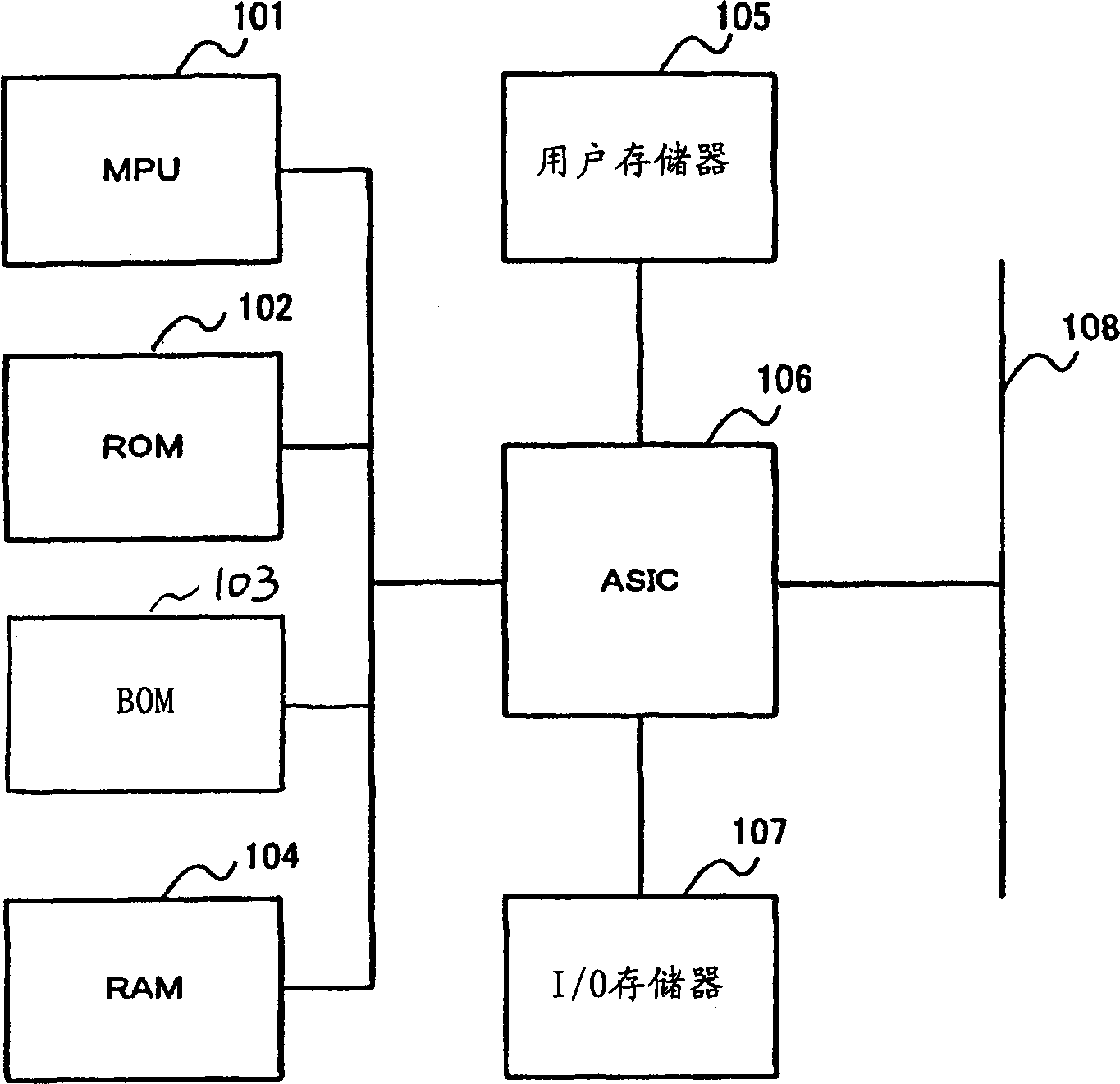

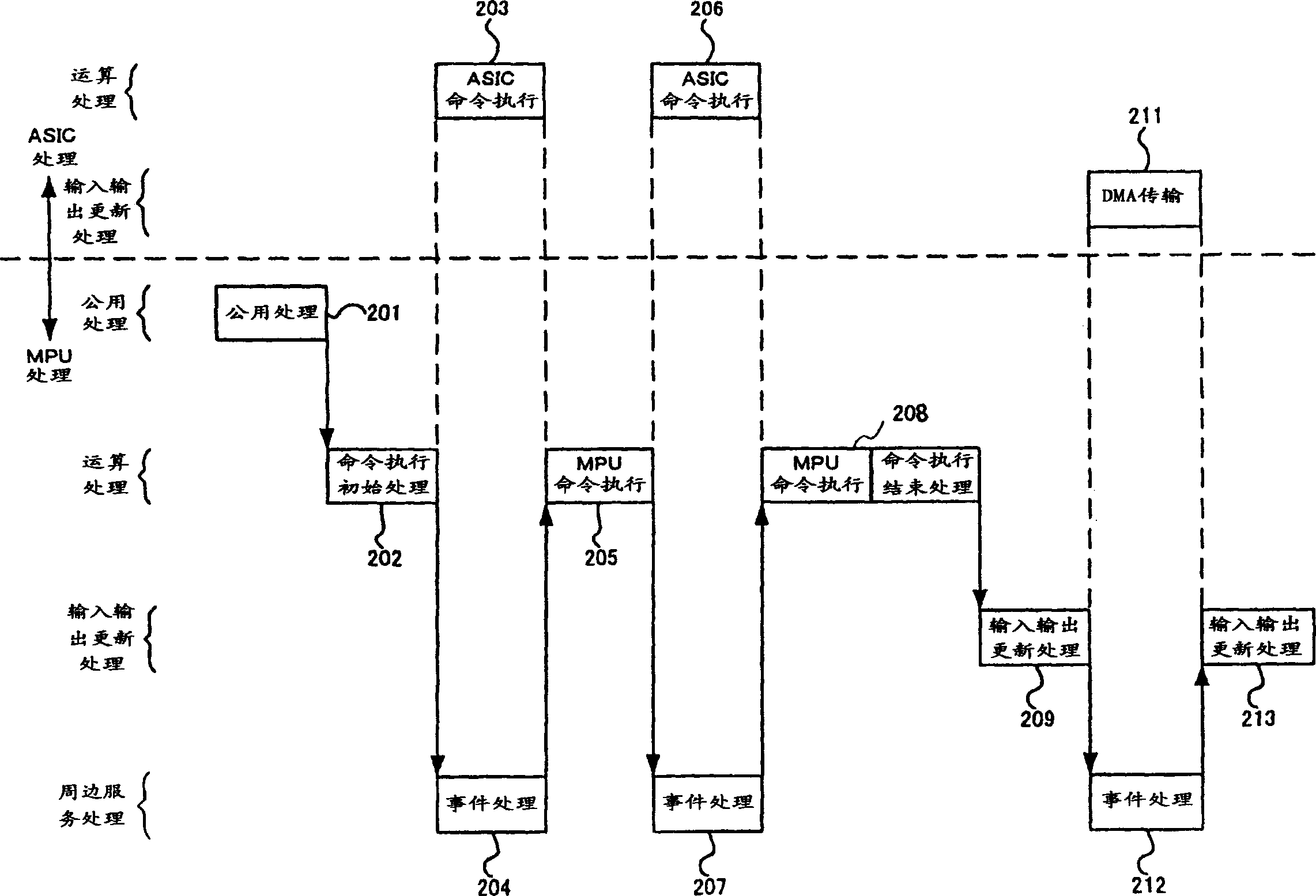

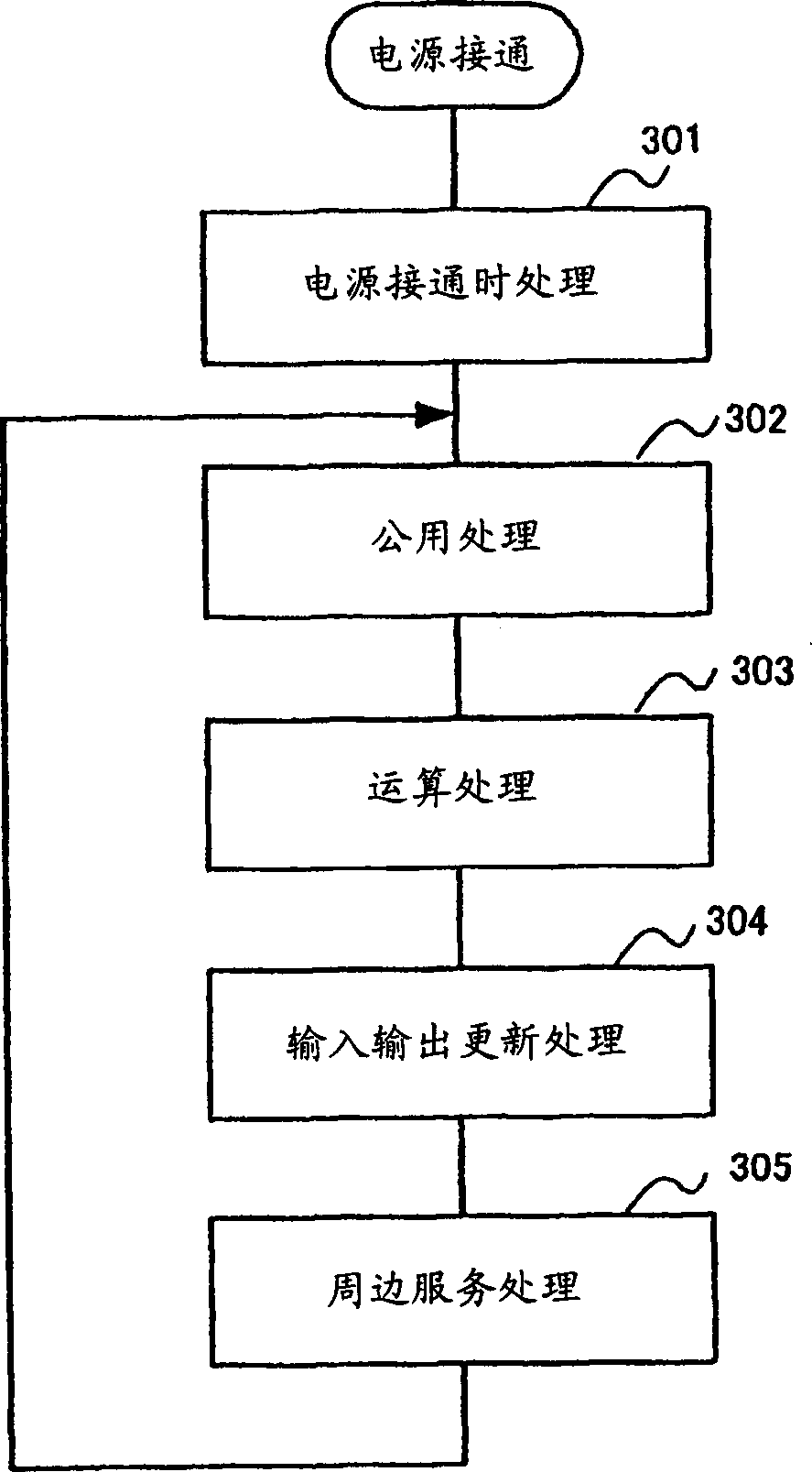

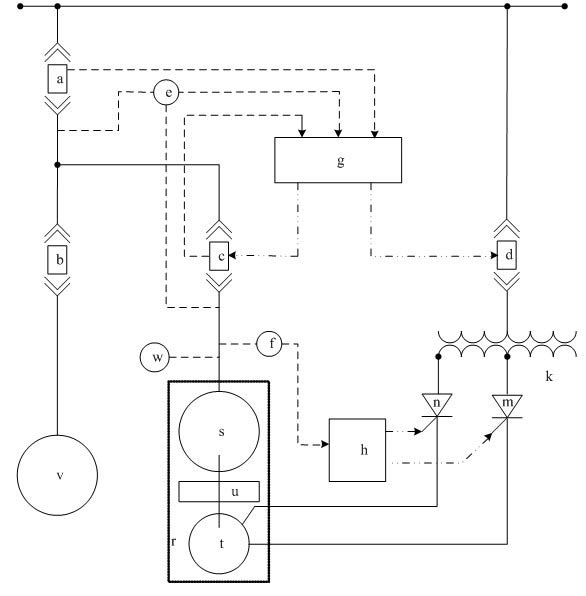

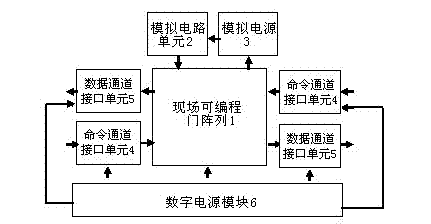

Programmable controller

InactiveCN1384410AGuaranteed timeIncreased idle timeComputer controlSimulator controlGeneral purposeArithmetic processing unit

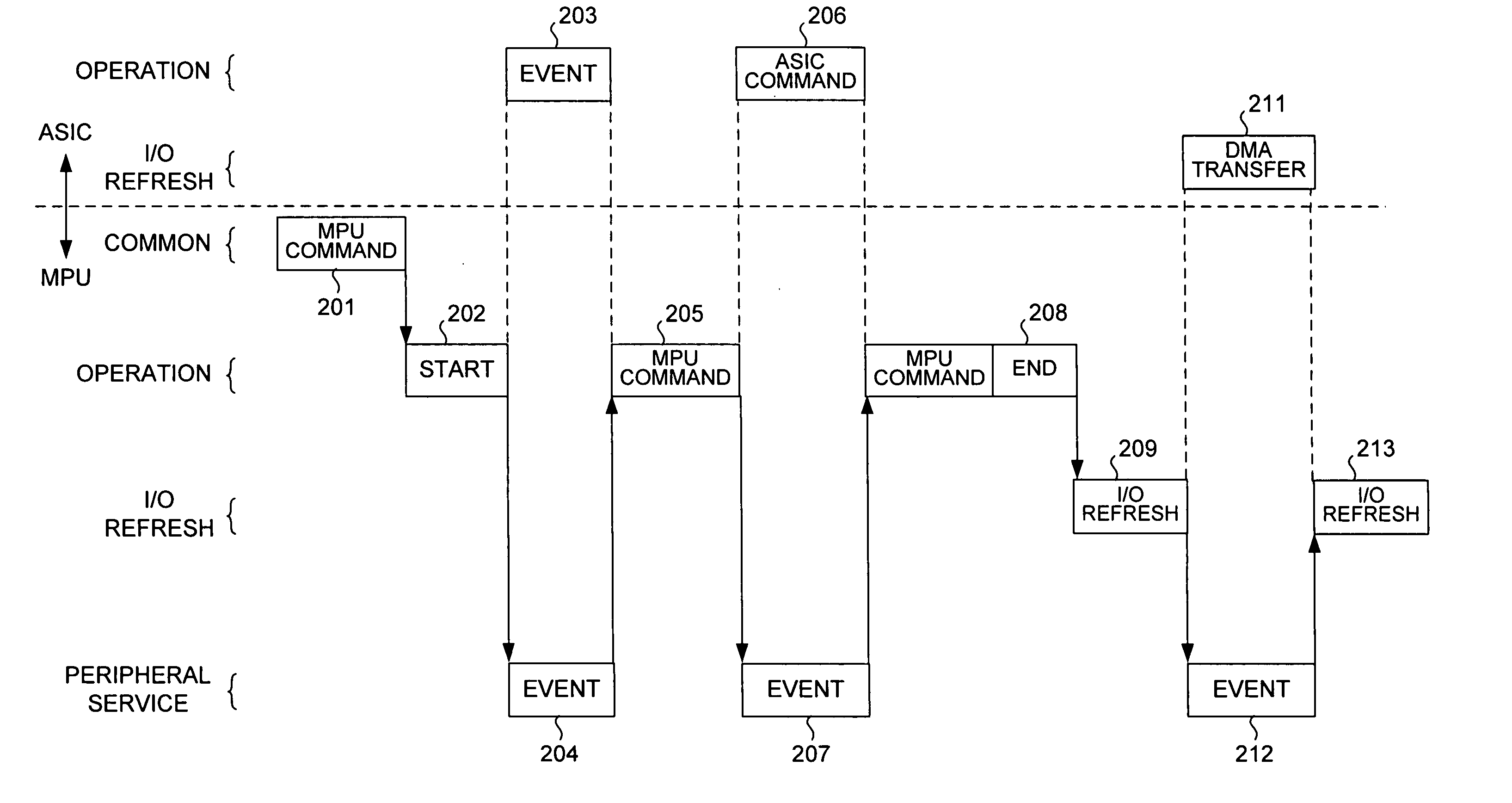

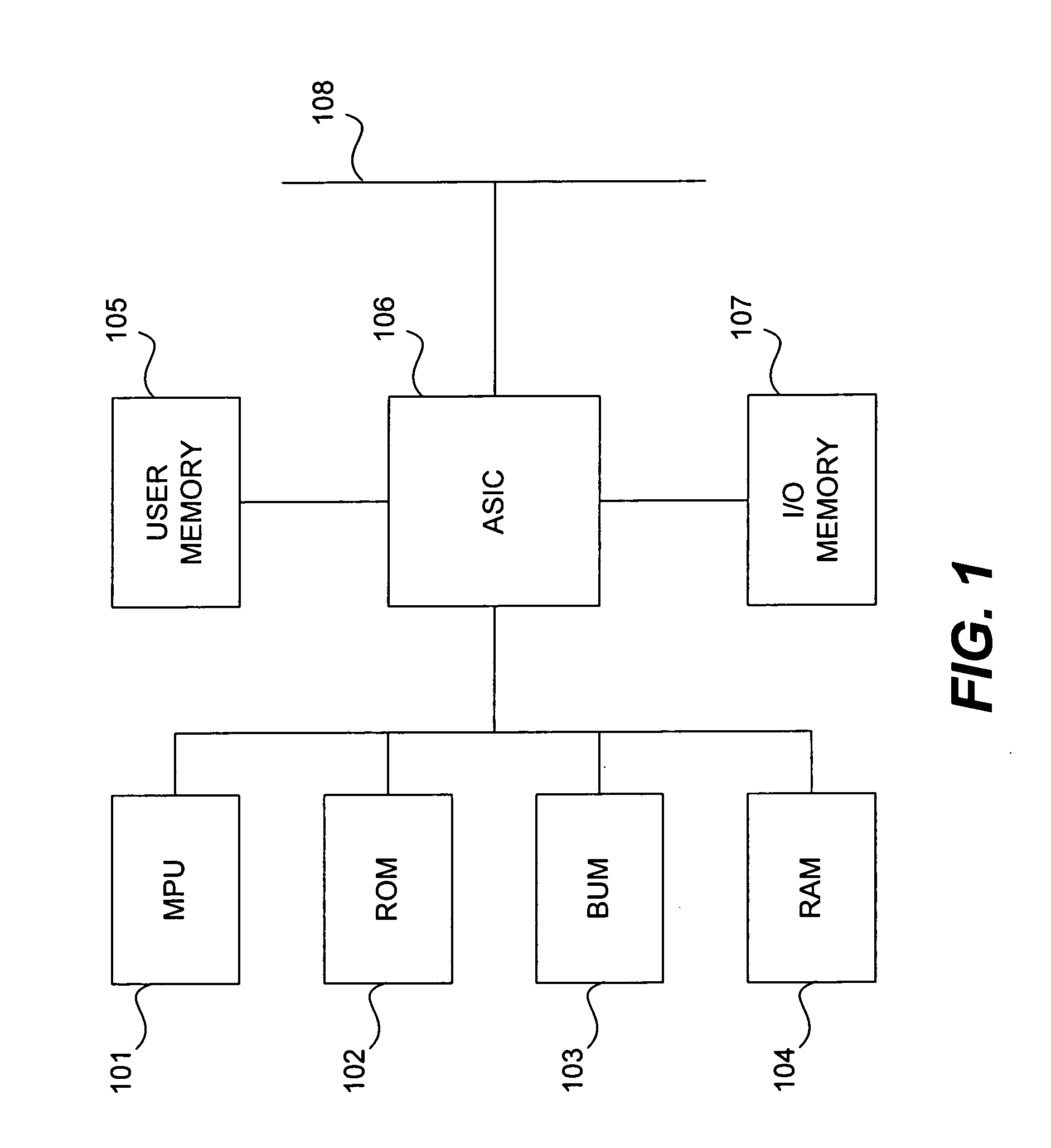

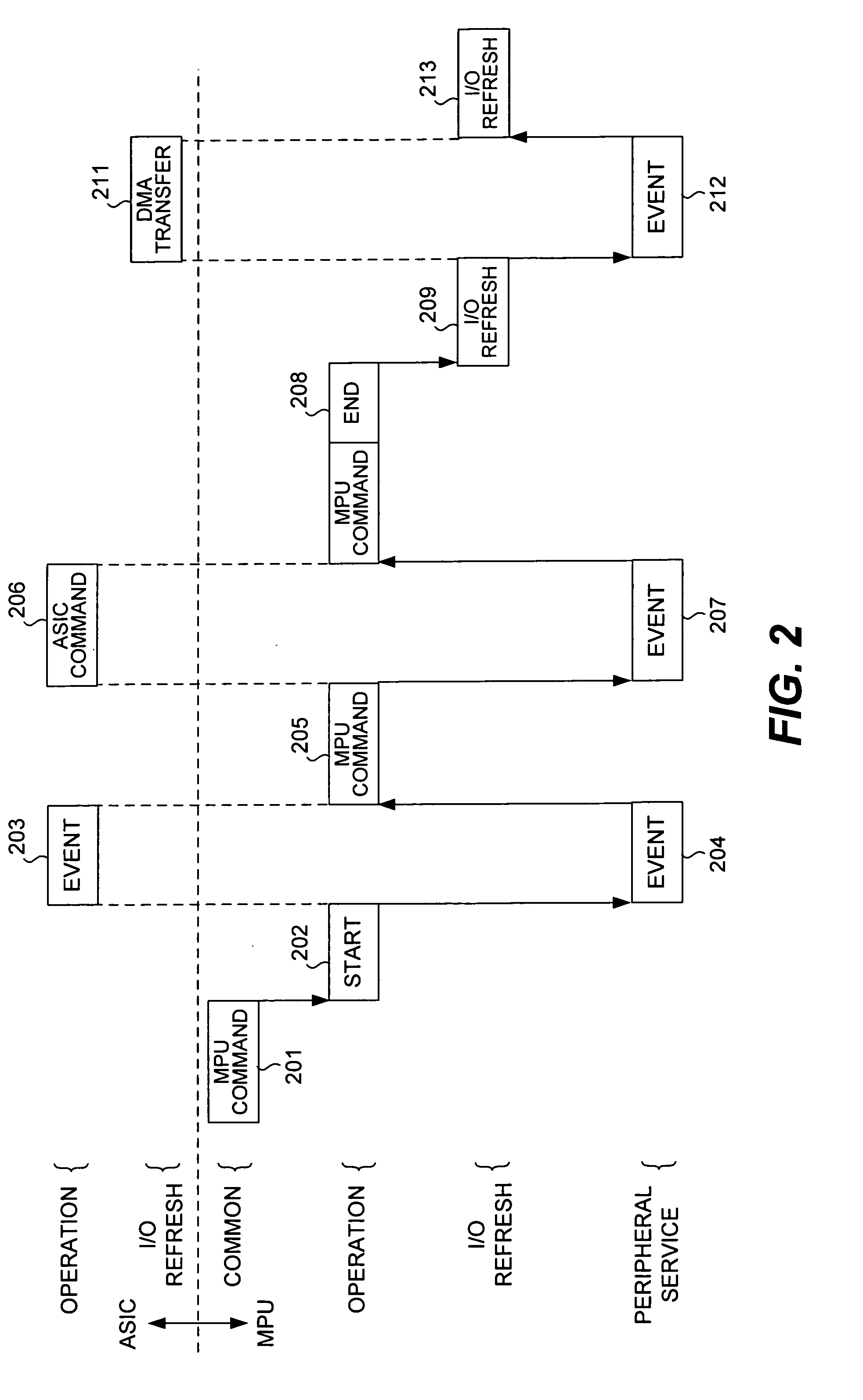

Shorten cycle time and improve responsiveness in programmable controllers equipped with general-purpose arithmetic processing units and special-purpose control units. After the MPU (101) entrusts the ASIC (106) to execute the user program or the I / O update process, it starts to execute the event processing, and terminates the above-mentioned event process according to the processing end notification of the above-mentioned user program or the I / O update process from the ASIC (106). , and performs so-called internal processing that returns to normal processing, thereby realizing parallel execution of user program execution processing, input / output update processing, and event processing.

Owner:OMRON CORP

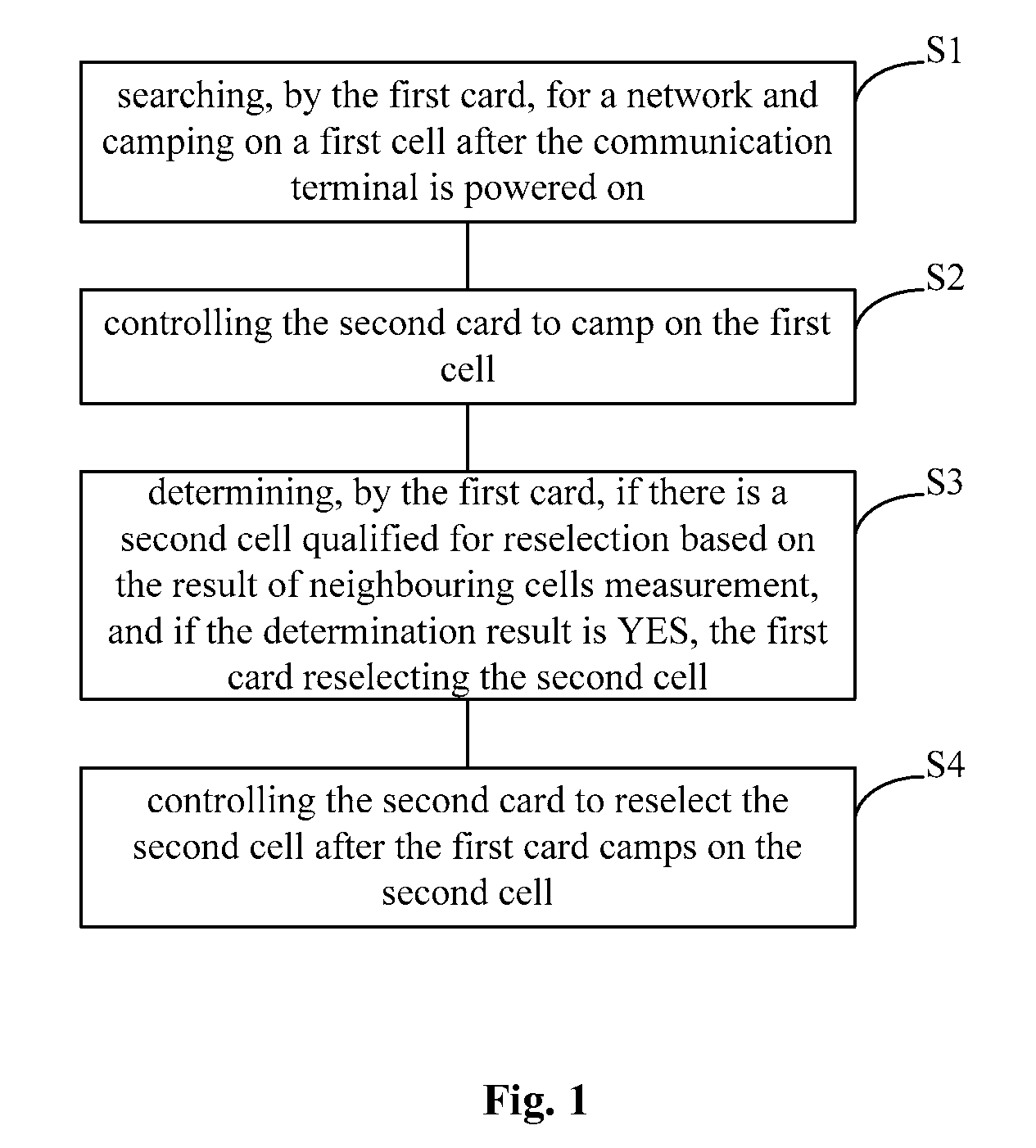

Multi-sim multi-standby communication terminal, and synchronization device and method thereof

ActiveUS8805444B2Effective informationIncrease power consumptionEnergy efficient ICTPower managementElectricityPhysical layer

A multi-SIM multi-standby communication terminal, and a synchronization device and method thereof are provided. The synchronization method includes: searching, by the first card, for a network and camping on a first cell after the communication terminal is powered on; controlling the second card to camp on the first cell; determining, by the first card, if there is a second cell qualified for reselection based on the result of neighboring cells measurement, and if the determination result is YES, the first card reselecting the second cell; and controlling the second card to reselect the second cell after the first card camps on the second cell. This disclosure has the following advantages: the efficiency of paging information reception and neighboring cells measurement is increased, power consumption is reduced, the time for camping on and cell reselection is reduced, and the implementation of the physical layer is simplified.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

Idle mode handoff in a mobile communications system

InactiveCN1856168AAvoid enteringReduce errorsAssess restrictionLocation information based serviceCommunications systemMobile communication systems

A method and apparatus for idle mode handoff in an overlapping area of a multi-channel cell is provided. By monitoring different frequencies serviced by neighboring base stations, when a mobile station is located in an overlapping region between cells and the frequency channel being serviced in a multi-channel region is different from a channel being serviced in the neighboring base station, an idle mode handoff between cells may be smoothly performed.

Owner:LG ELECTRONICS INC

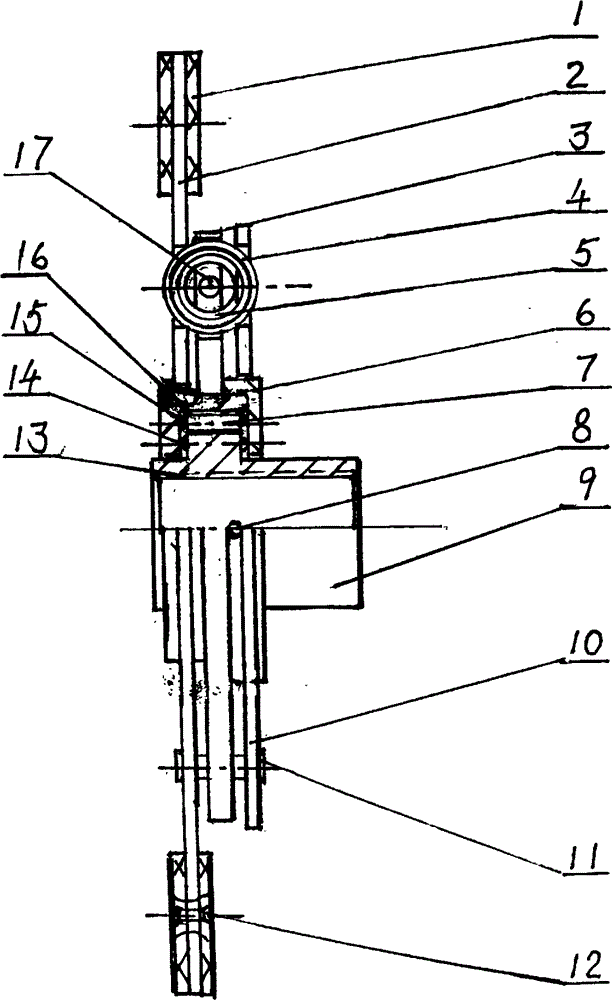

Main pump electromagnetic flywheel of PWR (Pressurized Water Reactor) nuclear power station

ActiveCN102104291AIncreased idle timeImprove securityEnergy storageMechanical energy handlingStart timeSynchronous motor

The invention discloses a main pump electromagnetic flywheel of a PWR (Pressurized Water Reactor) nuclear power station, aiming to provide a main pump electromagnetic flywheel of the PWR nuclear power station, substituting the coupling of an electromagnetic field for the mechanical connection between a flywheel and a main pump shafting, greatly improving the main pump running down time by separating a main pump shaft from a flywheel shaft, lowering the manufacture requirements on the main pump shafting, reducing the vibration energy of the main pump shafting, shortening the start time of a main pump and lessening the influence of the main pump start process on peripheral equipment. The main pump electromagnetic flywheel of the PWR nuclear power station comprises a mechanical flywheel, a synchronous motor, a DC start motor, a start control unit and a synchronous control unit, wherein the mechanical flywheel and the synchronous motor are mechanically connected with the rotating shaft ofthe DC start motor, the synchronous motor is connected in parallel with the main pump motor through a switch and a lead, the DC start motor is controlled by the start control unit, the electromagnetic flywheel is started by the DC motor, the synchronous motor keeps synchronous rotation, and the mechanical flywheel, the synchronous motor and the main pump motor jointly provide the main pump with running down energy. The invention is suitable for all PWR nuclear power stations.

Owner:WEIHAI CREDITFAN VENTILATOR

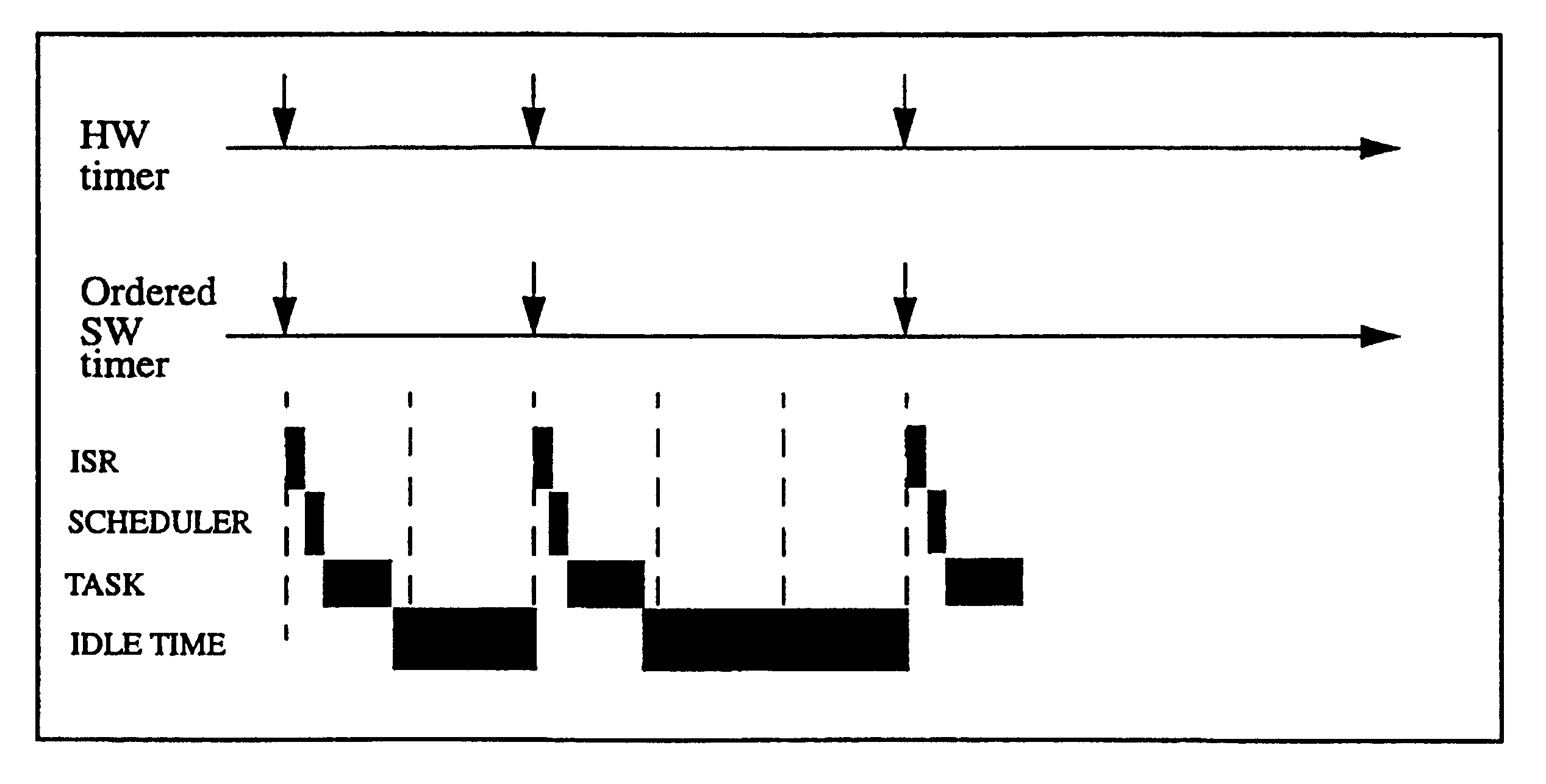

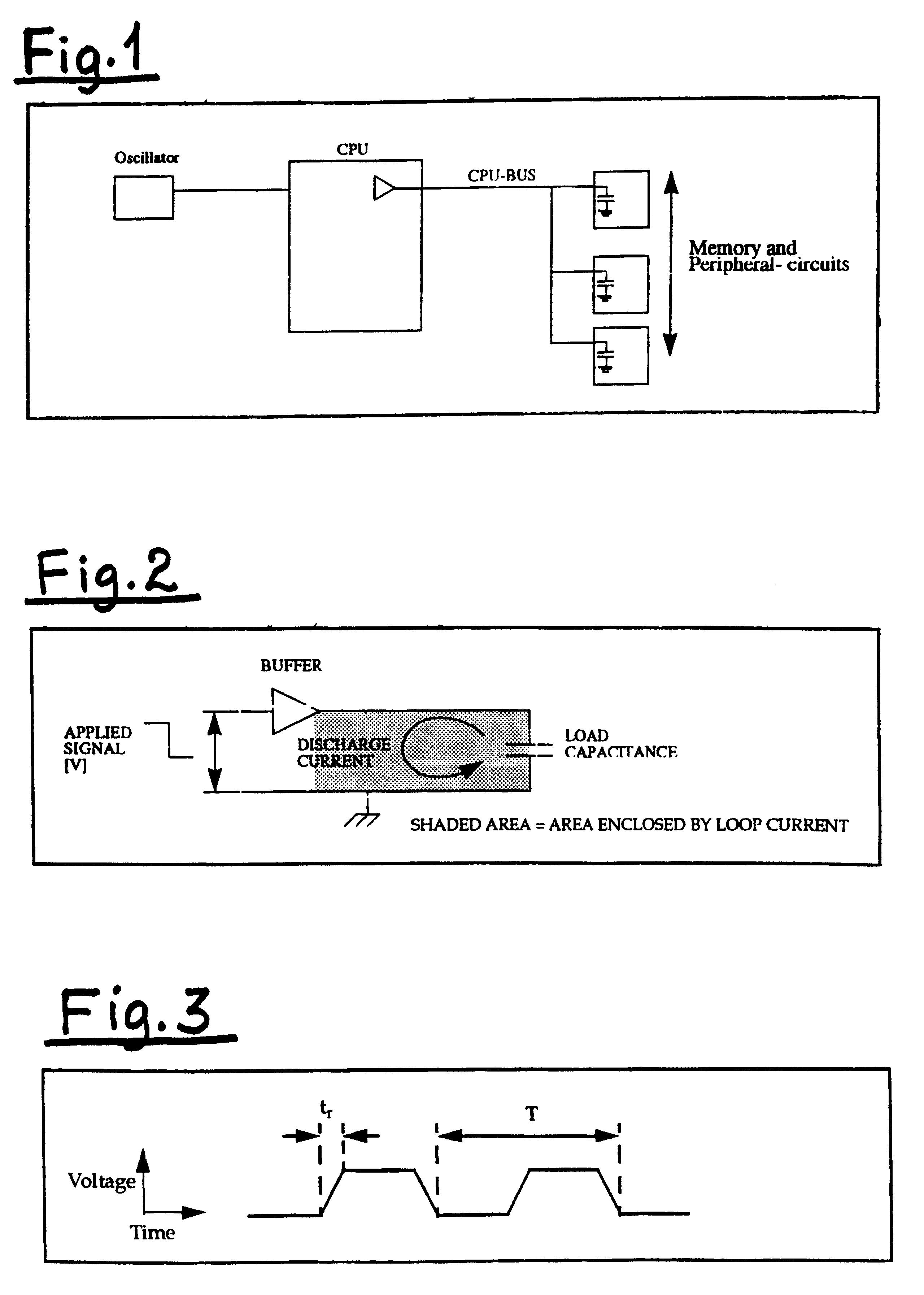

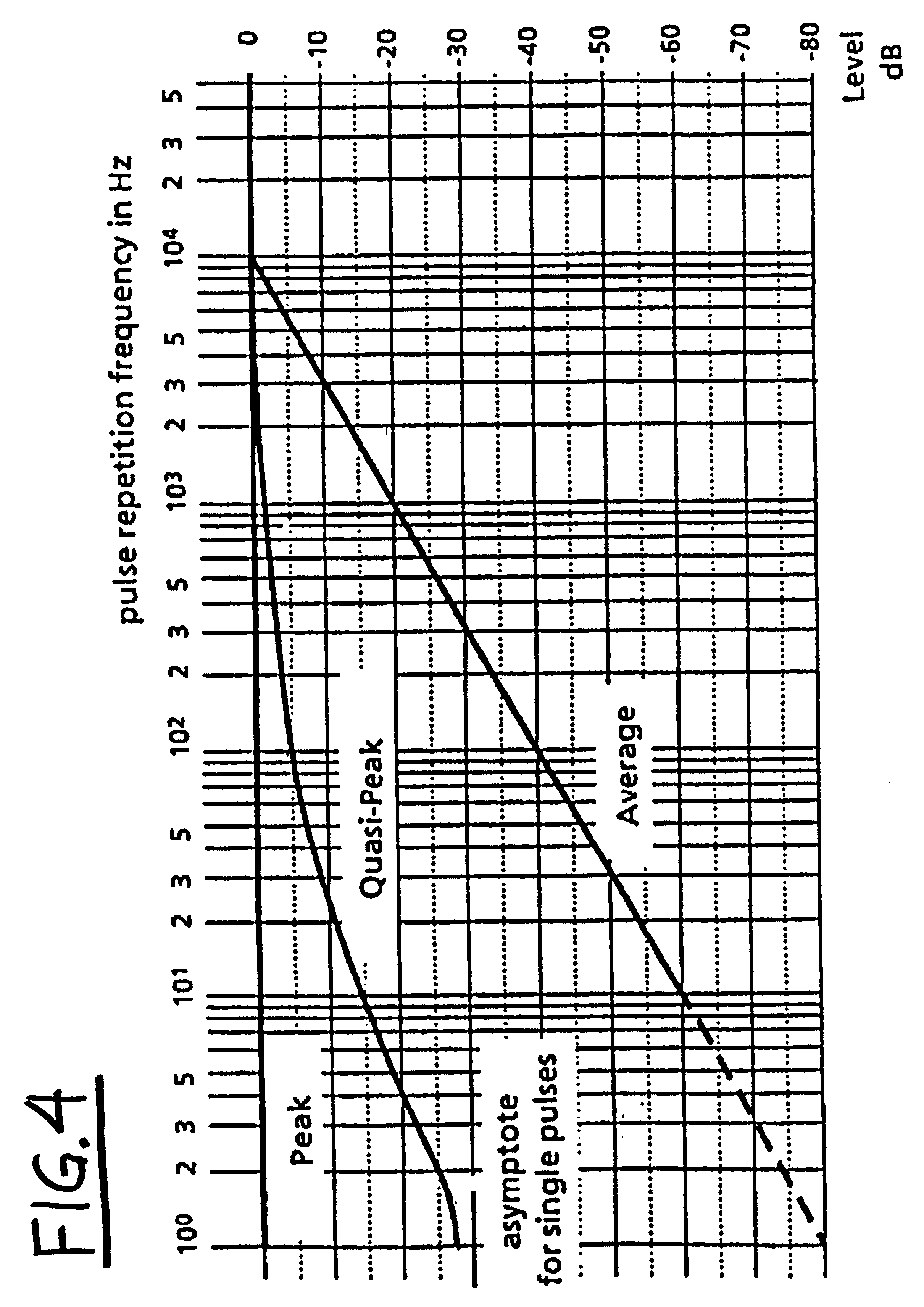

Reduction of electromagnetic emission

InactiveUS6438698B1Extra extra consumptionExtra cost extraVolume/mass flow measurementPower supply for data processingElectromagnetic radiationEmbedded system

The present invention relates to a method for reducing electromagneic emission, especially in connection with high-performance real-time systems, and more specifically for complying with the EMC (ElectroMagnetic Compatibility) thereof, and in order to acheive a reduced electromagnetic emission, it is according to the invention suggested to control the access to the CPU (Central Processing Unit) bus for thereby through power-down to reduce said bus-activity and thereby reduce the electromagnetic emission therefrom.

Owner:TELEFON AB LM ERICSSON (PUBL)

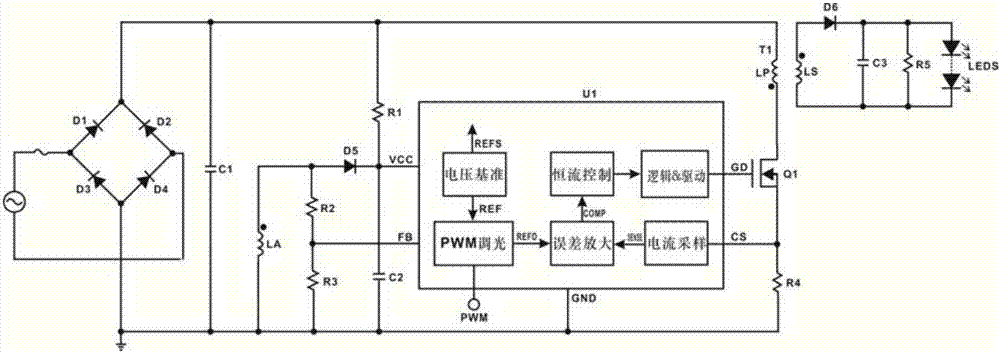

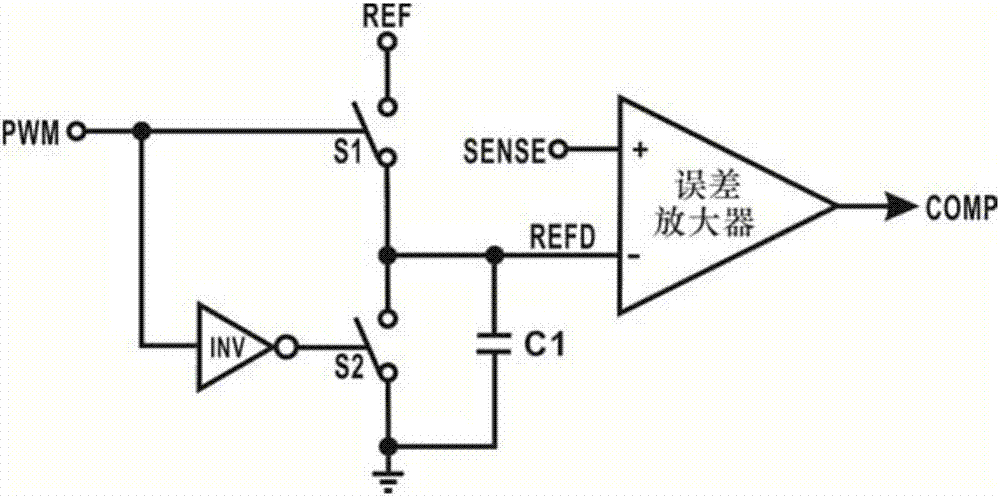

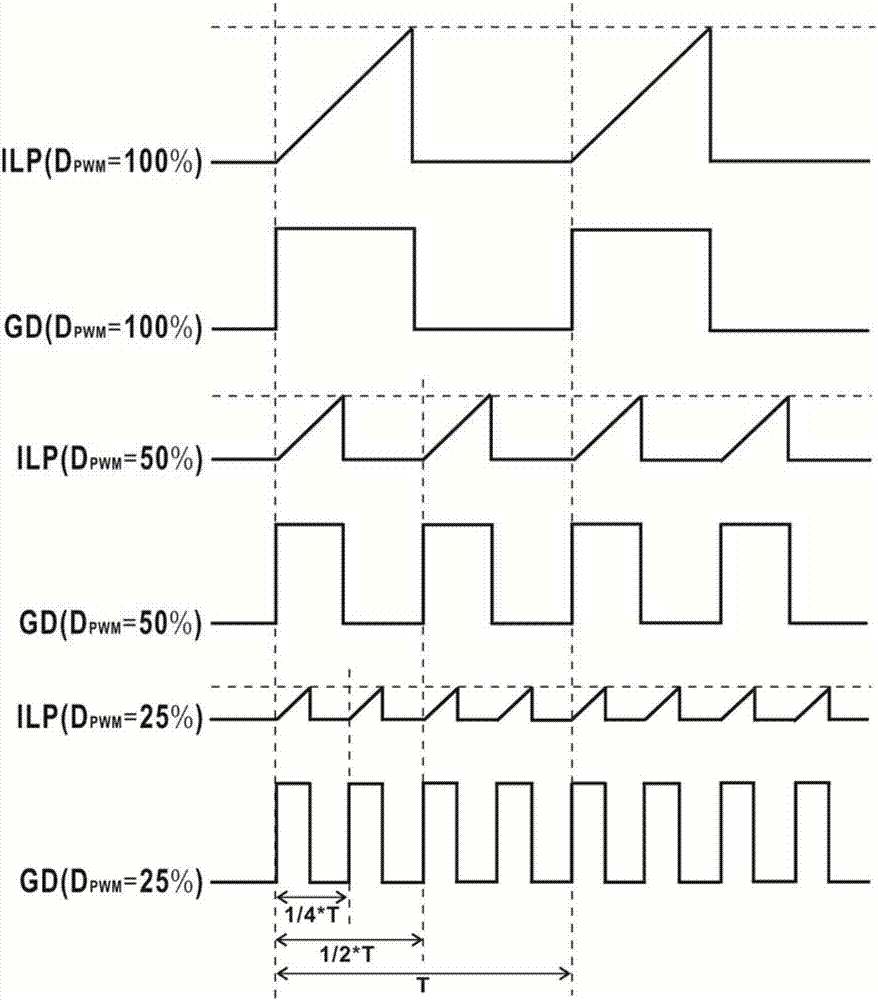

PWM dimming circuit used for high-power-factor primary-side-feedback LED driving power supply

ActiveCN106954307AGood dimming effectIncreased idle timeElectrical apparatusElectroluminescent light sourcesIdle timePower factor

The invention discloses a PWM dimming control circuit used for a high-power-factor primary-side-feedback LED driving power supply. The PWM dimming control circuit comprises a voltage reference generation unit, a PWM processing unit, a current sampling unit, an error amplification unit, a constant current control unit, a zero-crossing detection unit, a transformer secondary winding idle time control unit and a logical and driving unit, wherein the transformer secondary winding idle time control unit is used for controlling the duration of the transformer secondary winding idle time in PWM dimming to output a signal for controlling conduction of a power switch tube; and the logical and driving unit is used for performing logical control on the constant current control unit and the output signal of the transformer secondary winding idle time control unit, so as to further drive the power switch tube and control the transformer secondary winding idle time control unit.

Owner:深圳天源中芯半导体有限公司

Robot vision system and detection method

InactiveUS8331617B2Less consumedIncreased idle timeImage enhancementImage analysisParallaxVideo bitstream

Owner:ELECTRONICS & TELECOMM RES INST

Energy efficient management of heterogeneous multi-hop wireless networks

ActiveUS9736771B2Reduce collisionIncreased idle timeEnergy efficient ICTPower managementTransceiverComputer science

A wireless multi-hope network of nodes including data nodes and at least one sink node. The data nodes include battery-powered nodes (BPNs) having active and sleep periods and mains-powered nodes (MPNs) having only active periods, wherein each data node transmits the packets only within corresponding active periods. A BPN includes a transceiver for transmitting and receiving data packets and a processor for determining a schedule of active and sleep periods of the BPN independently from the active and sleep periods of other data nodes in the network and independently from commands transmitted by the sink node, and a battery for providing energy to the transceiver and the processor. The processor switches the transceiver ON and OFF according to the schedule.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Programmable controller

InactiveUS20060155960A1Short response timeSecure sufficient timeProgramme controlComputer controlApplication specificApplication-specific integrated circuit

A programmable controller has a multi-purpose processor such as an MPU and an application specific control device such as an ASIC (application specific integrated circuit). When the MPU requests the ASIC to execute a user program and the ASIC is activated, the MPU executes an event process while the ASIC executes the requested user program. When the MPU requests the ASIC to execute a DMA transfer process in an input / output refresh process and the ASIC is activated, the MPU executes an event process while the ASIC executes the requested DMA transfer process.

Owner:OKADA KAZUNORI

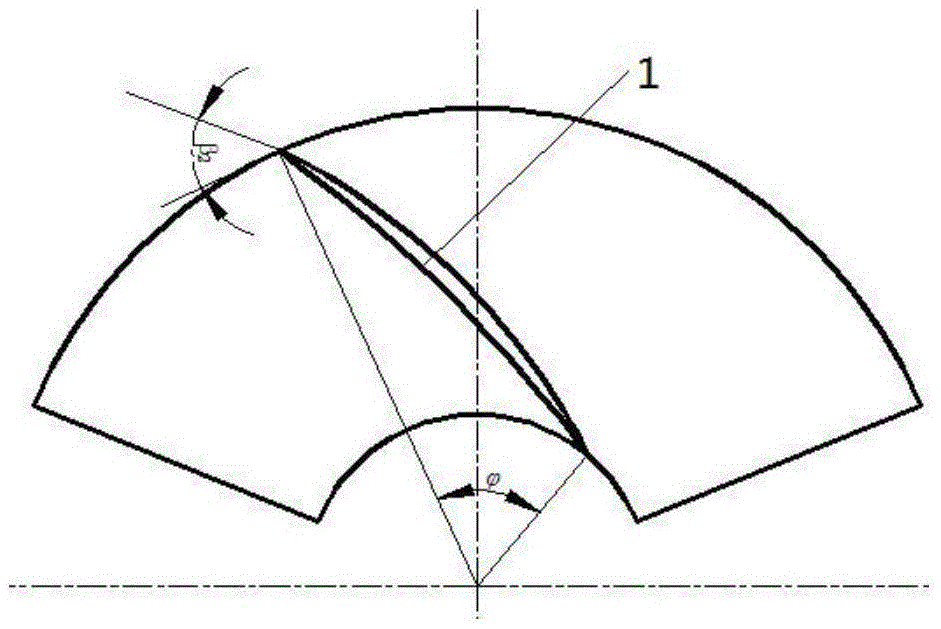

Guide vane optimized design method capable of prolonging running down time of reactor coolant pump

InactiveCN106015102AIncreased idle timeImprove Nuclear Safety PerformancePump componentsPumpsProcess engineeringEngineering

The invention relates to a guide vane optimized design method capable of prolonging running down time of a reactor coolant pump. According to the guide vane optimized design method, firstly, a main objective function for improving running efficiency under running down by optimizing main parameters of a radial guide vane is established; then the main parameters are divided into three groups of subordinate design variables, subordinate objective functions are optimized respectively with running down efficiency, optimized solution is performed under initial constraint conditions, and the optimum points of the performance of the parameters are obtained; and the optimum points serve as centers for determination of new constraint conditions, optimized solution is performed on the main objective function under the new constraint conditions, and the final optimized result is obtained. By means of the design of the radial guide vane of the reactor coolant pump, the problems of lower efficiency and production of secondary backflow in a running down process can be improved, the running down time is prolonged, sufficient flow passes through to cool a reactor core, and the nuclear safety is enhanced. With application of step-by-step optimization design method adopting a subordinate objective constraint random direction searching method for reduction of a constraint range and a main objective exterior penalty function method for search of the optimum points, the effectiveness of the optimized result is guaranteed, and the optimization speed is increased.

Owner:JIANGSU UNIV

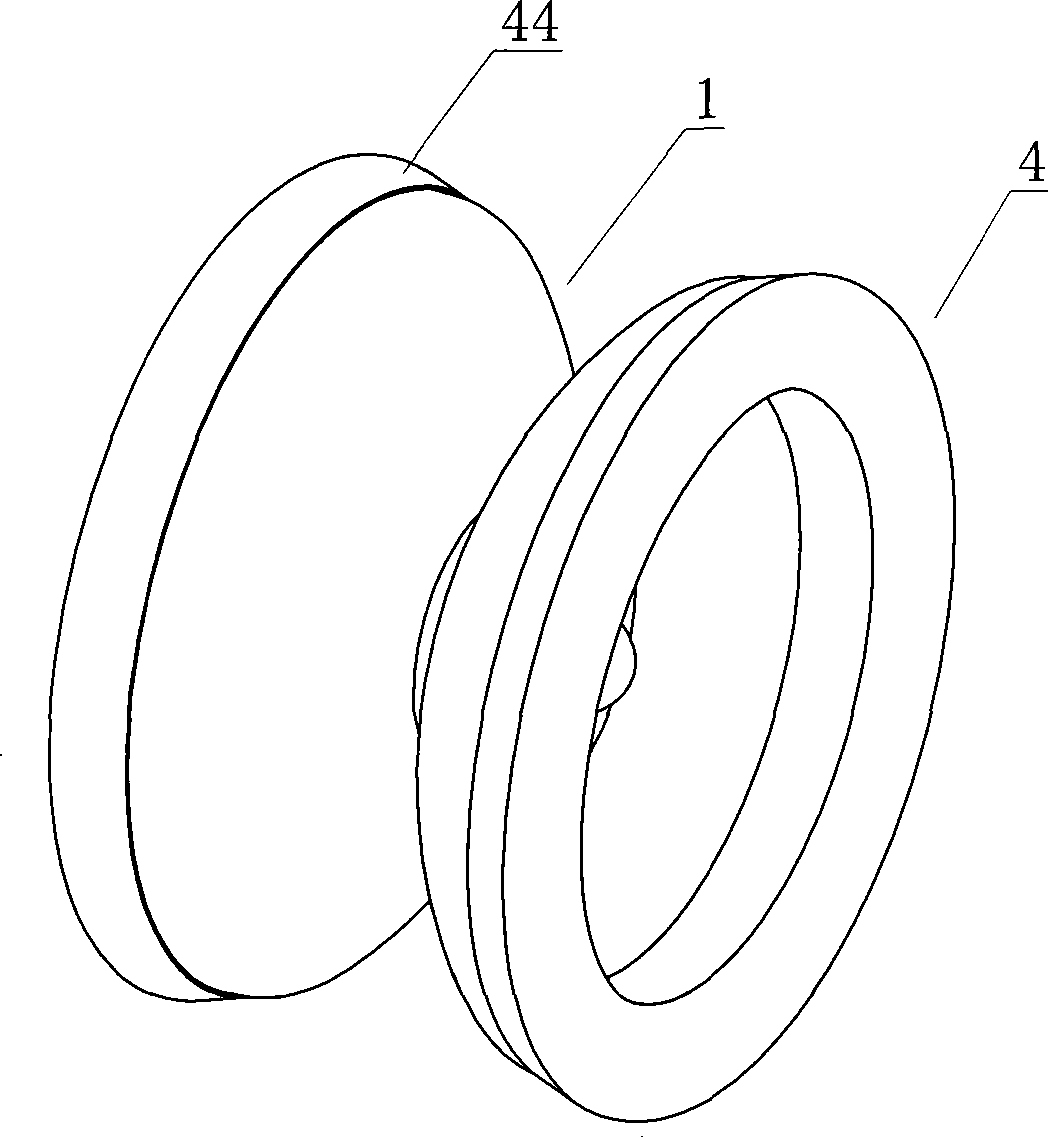

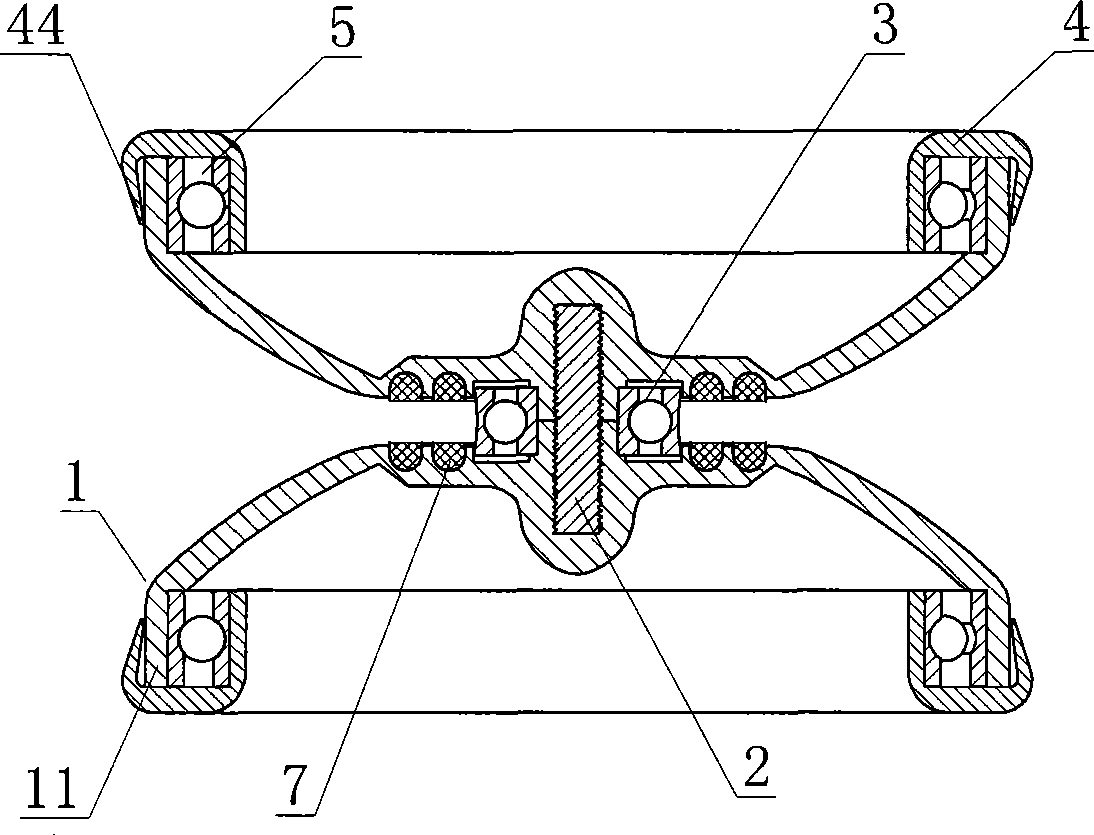

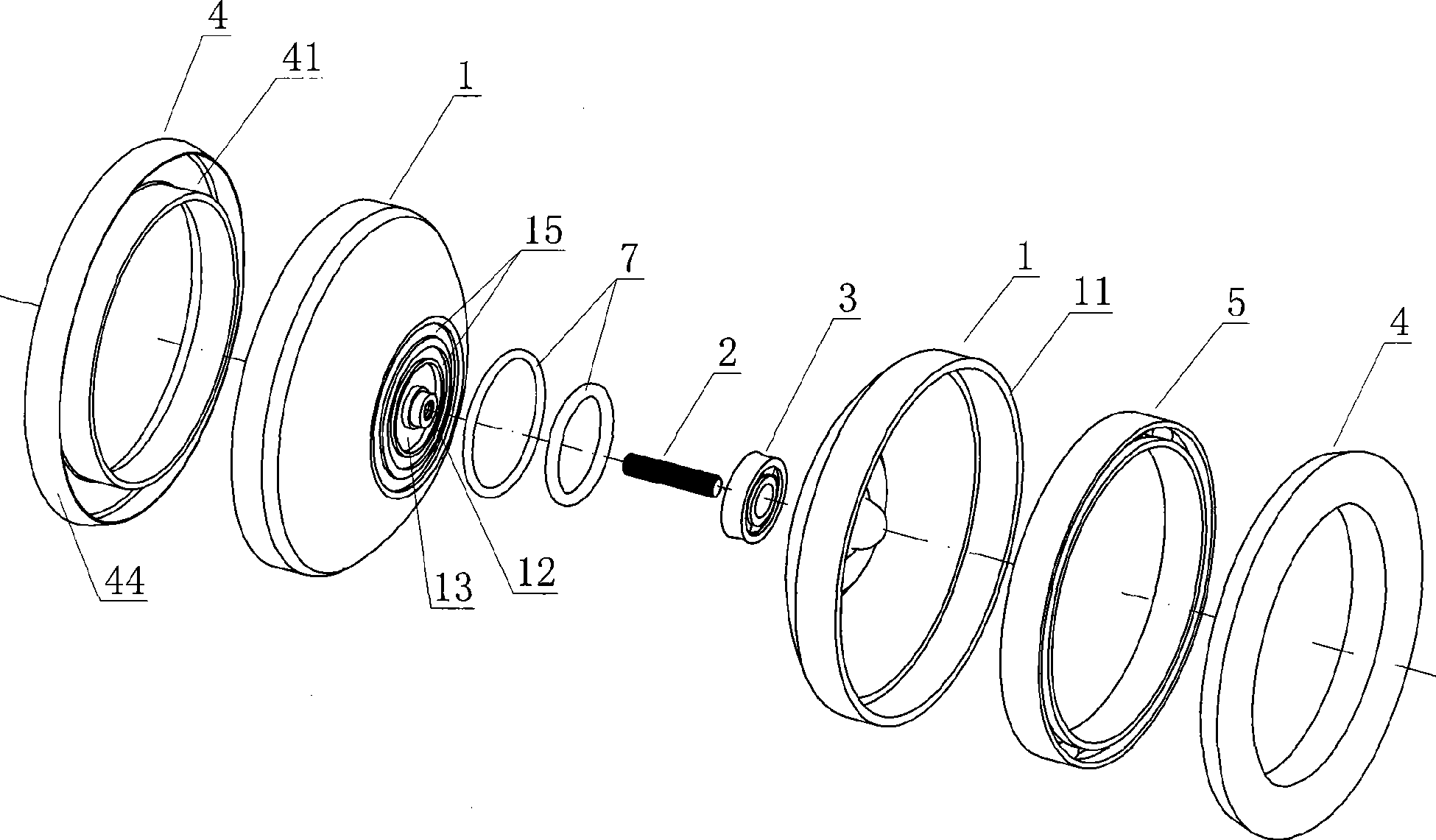

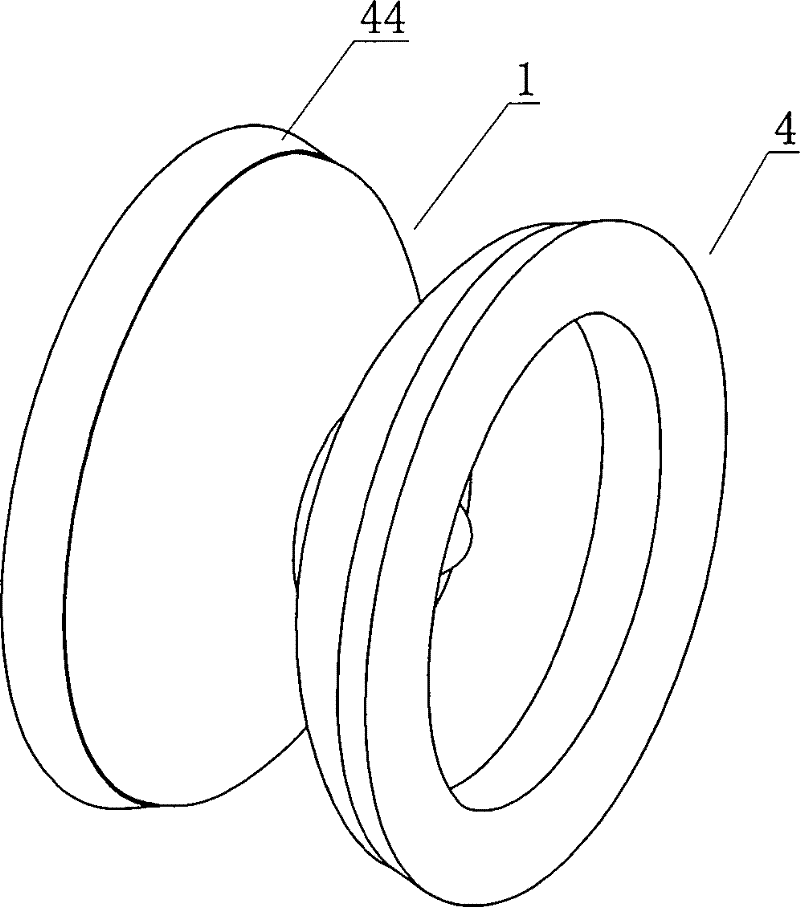

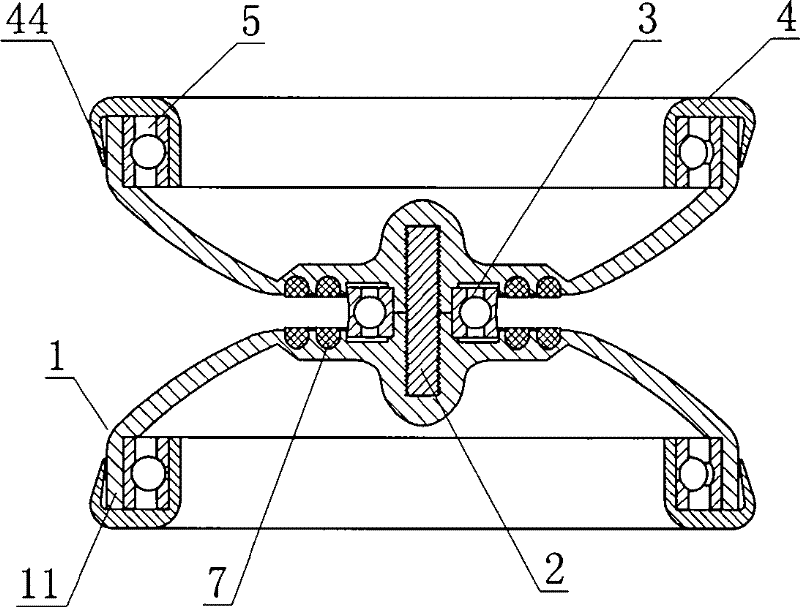

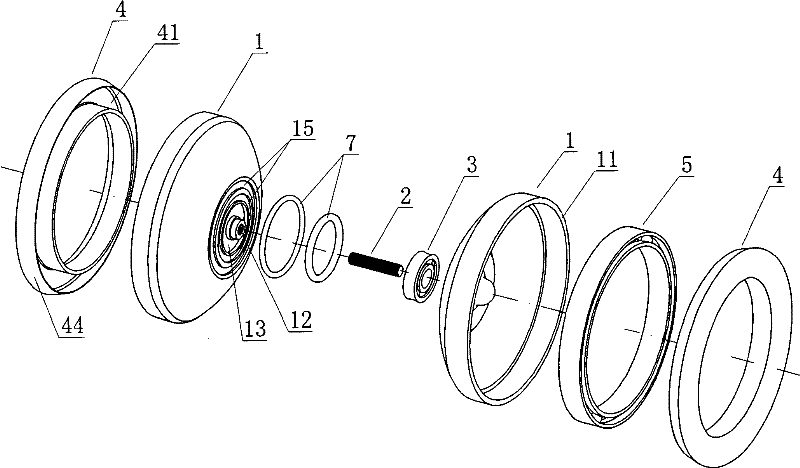

Interesting yoyo ball played in hand-held mode

An interesting yoyo ball played in a hand-held mode comprises two rotating bodies with inside surfaces oppositely arranged and a connecting shaft which connects the two rotating bodies, wherein, an external rotating body which can rotate in relative to the rotating bodies is arranged at an outer edge of the rotating bodies. As the external rotating body which can rotate in relative to the rotating bodies is arranged at the outer edge of the rotating bodies, and a buckling edge which is buckled at an edge of the rotating bodies is arranged at the outer edge of the external rotating body, the external rotating body of the yoyo ball can be held by hands without touching the rotating bodies which are rotating to slow down rotation of the rotating bodies during play; a bearing is arranged between the rotating bodies and the external rotating body, thus achieving smoother rotation effect by the bearing; and the external rotating body with the bearing also has balancing weight effect. Therefore, the yoyo ball composed of the external rotating body has the advantages of more stable directivity, easier operation and better control performance, thus leaving a player space to develop creative playing methods so that yoyo toys can attract the player for longer time.

Owner:ALPHA GRP CO LTD +1

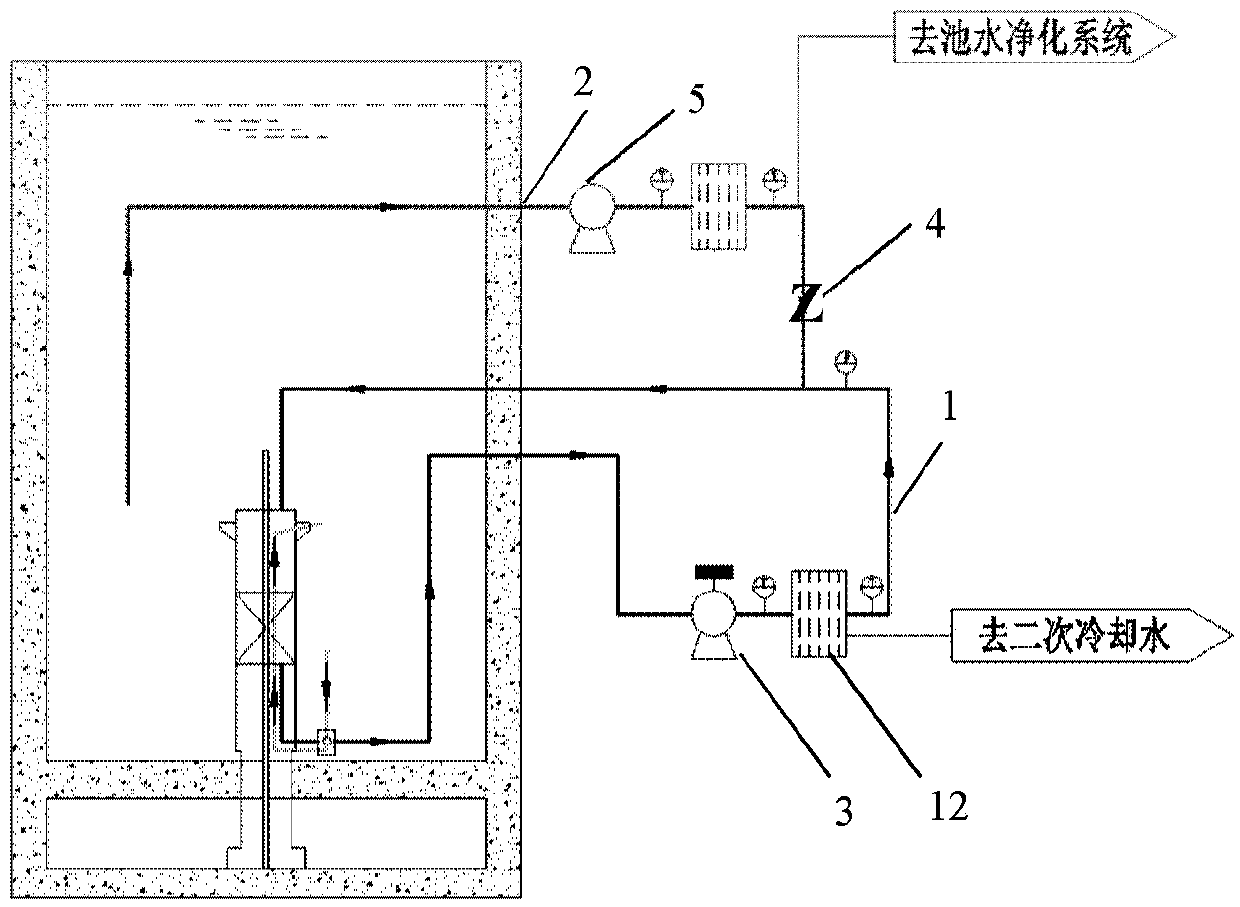

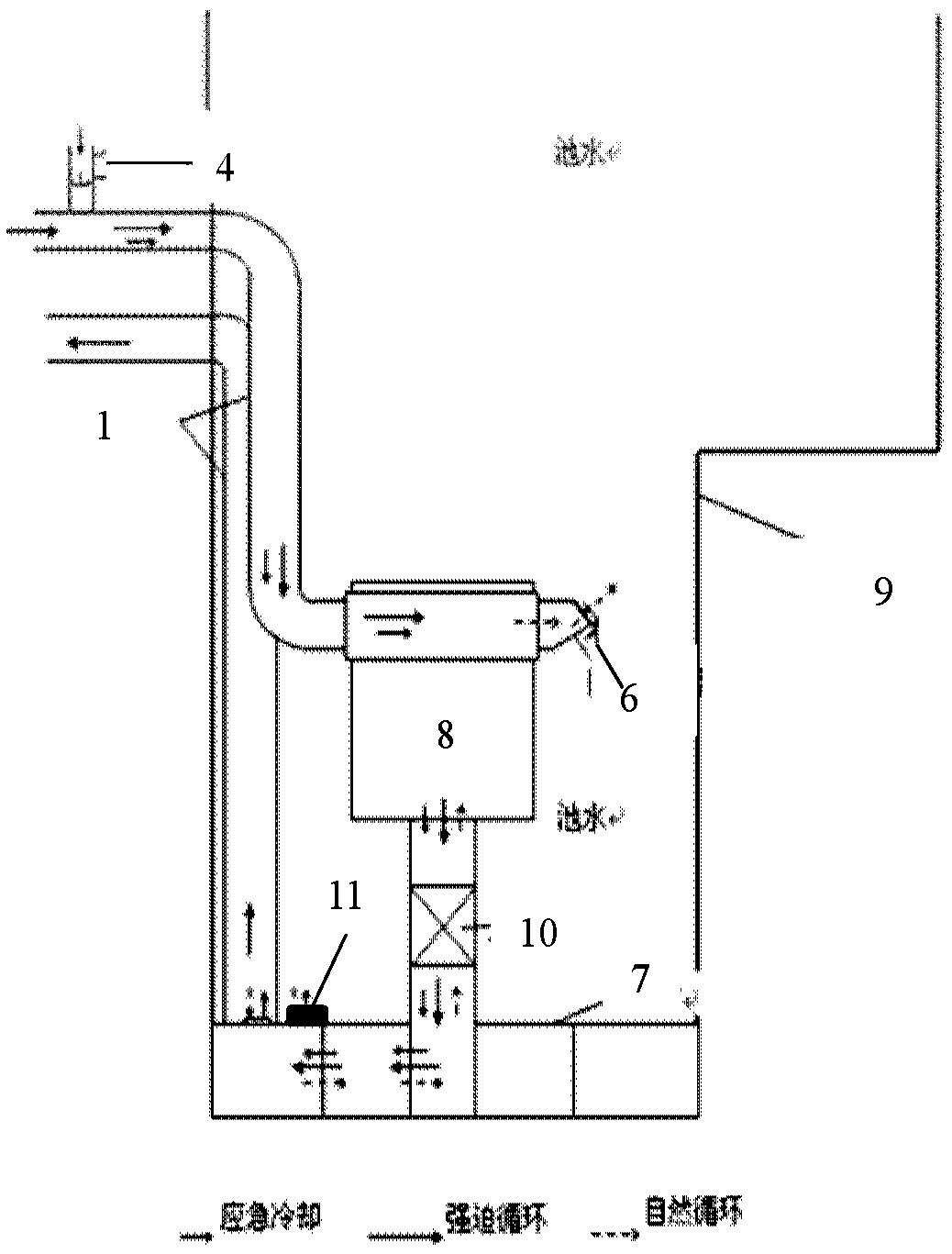

Coupled reactor residual-heat removal system

PendingCN109659046AIncreased idle timeCoolant Flow GuaranteeNuclear energy generationCooling arrangementWater flowCheck valve

The invention discloses a coupled reactor residual-heat removal system which comprises a main cooling circuit for driving the liquid in the circuit to flow through a main pump so as to take away the heat of a reactor, an emergency reactor core cooling system configured to operate simultaneously with the reactor and configured with an uninterruptible power supply, a pipeline connected between the main cooling circuit and the emergency reactor core cooling system. An emergency cooling pipeline check valve is arranged on the pipeline to be turned on after the main pump of the main cooling circuitstops power supply. In the coupled residual-heat removal system, the pipeline is arranged between the main cooling circuit and the emergency reactor core cooling system and is provided with the emergency cooling pipeline check valve which is turned on after the main pump of the main cooling circuit stops power supply so that new water flow circulation can still be achieved after the main coolingloop is powered off, and residual heat in a reactor core can be led out.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

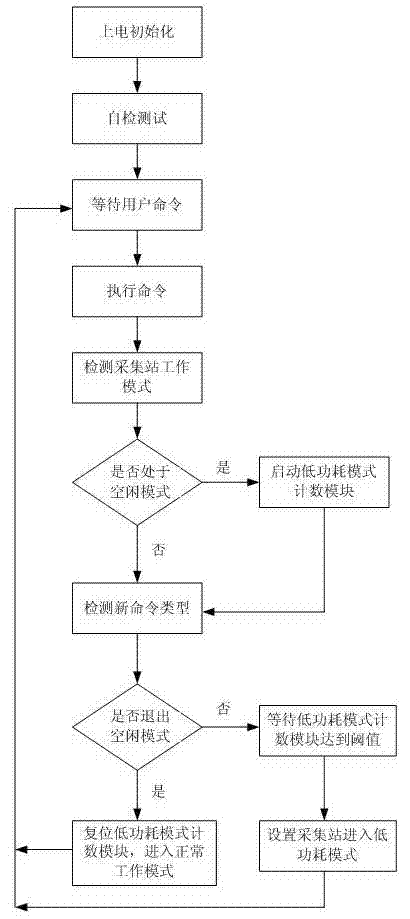

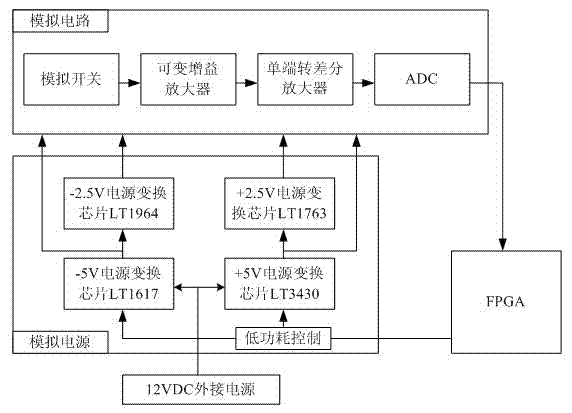

Self-adaptive low-power consumption method suitable for overland geophysical exploration data acquisition station

InactiveCN102809760ALong collection intervalReduce power consumptionSeismic signal transmissionSelf adaptiveEngineering

The invention discloses a self-adaptive low-power consumption method suitable for an overland geophysical exploration data acquisition station. When the acquisition station is in an idle mode, an analog power supply is controlled to stop supplying power to an analog circuit, and the analog circuit stops working, so that the acquisition station enters a low-energy consumption working mode to reduce the power consumption of the acquisition station; and therefore, the power consumption of an overall seismic prospecting instrument is reduced, the service life of a system power supply and the system standby time are prolonged, batteries are prevented from being replaced frequently, and the efficiency of field construction is improved.

Owner:HEFEI GUOWEI ELECTRONICS

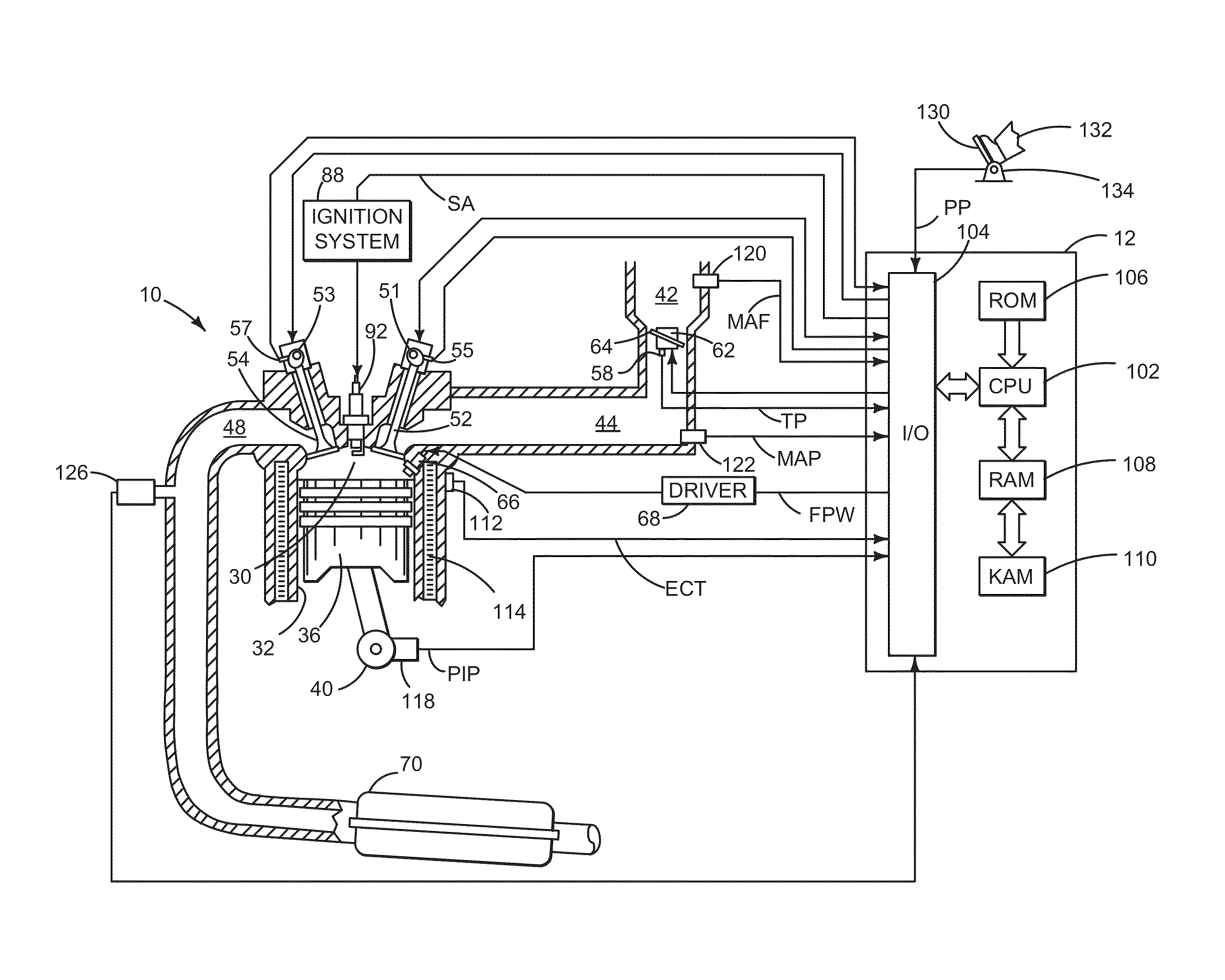

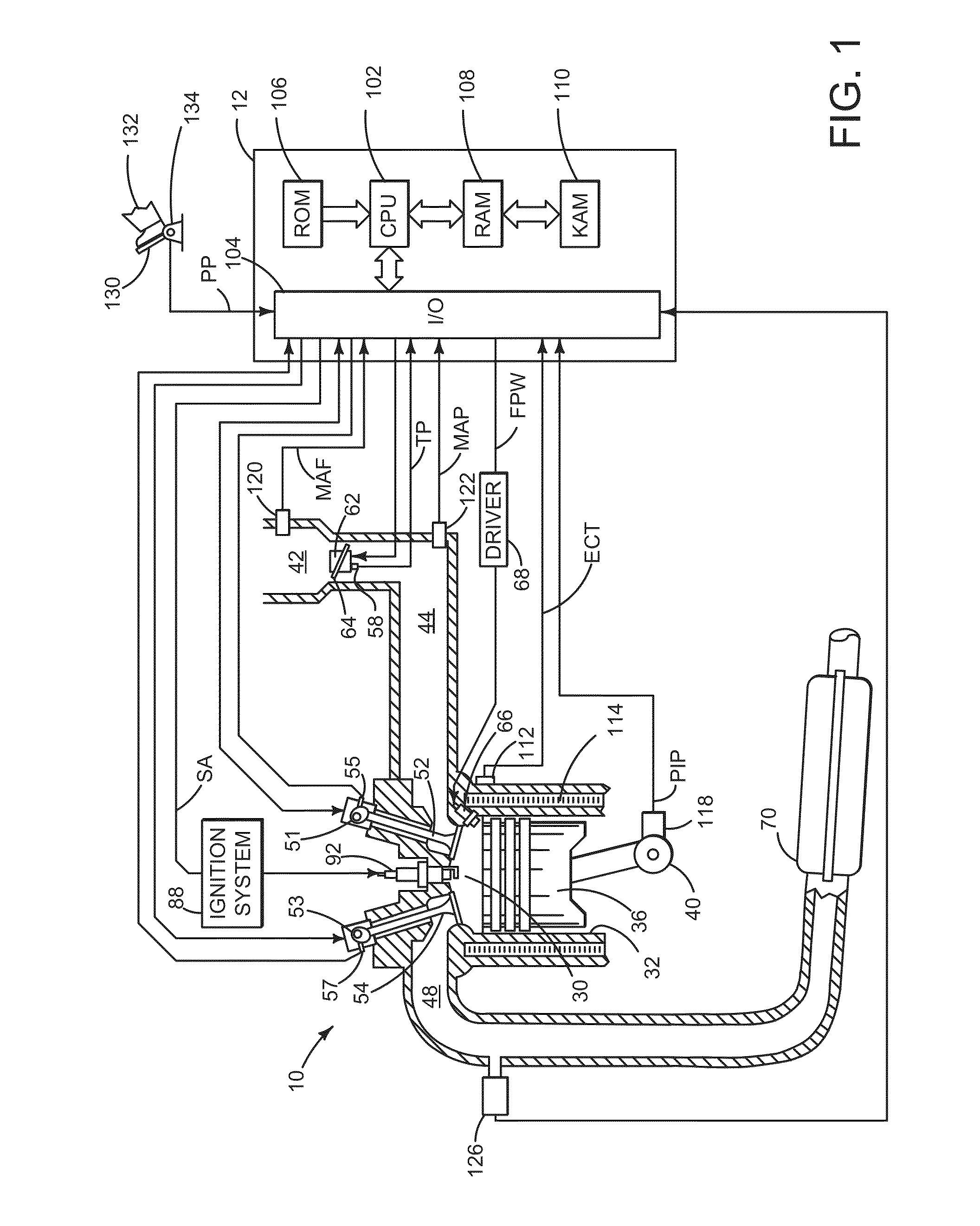

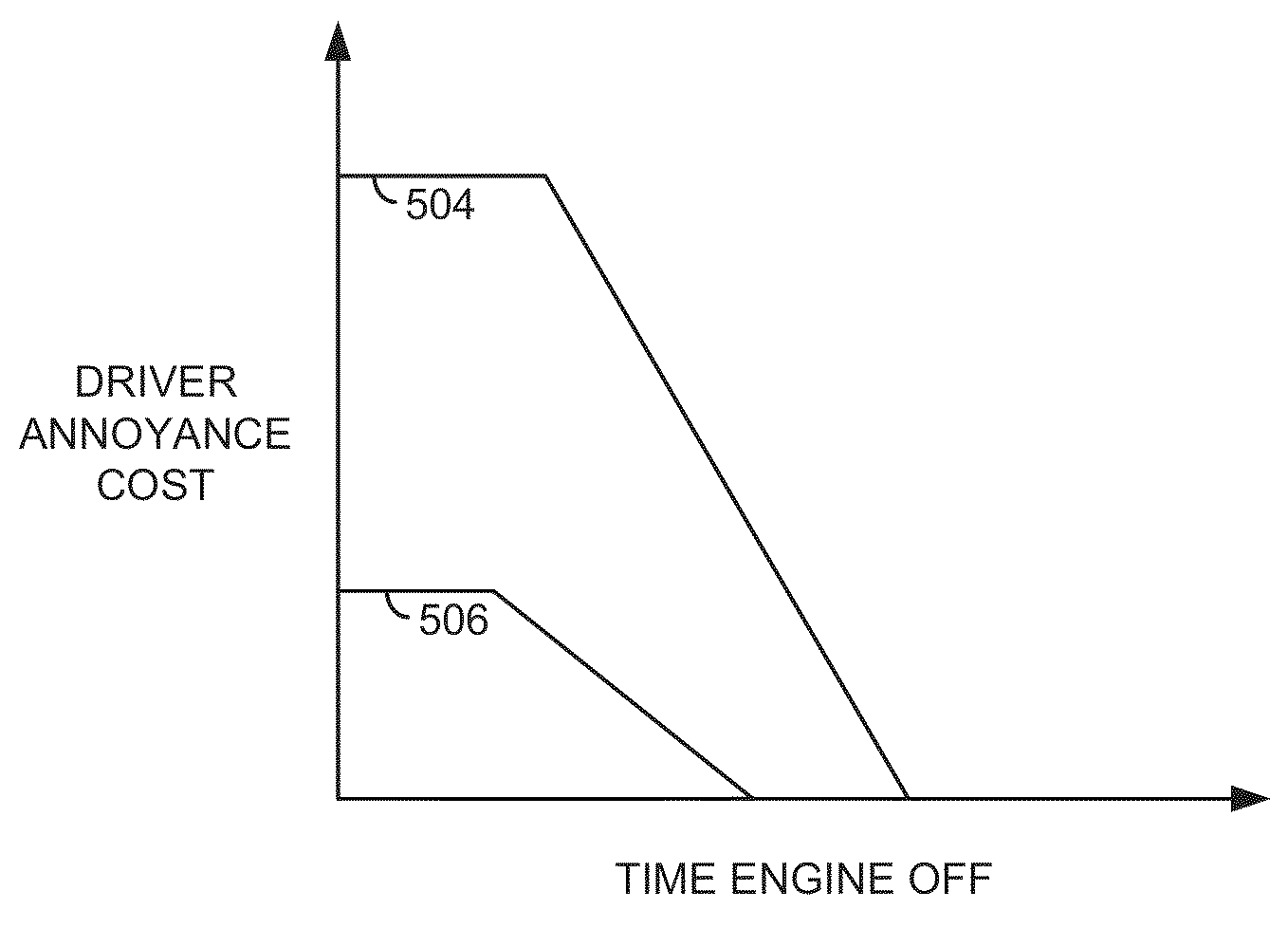

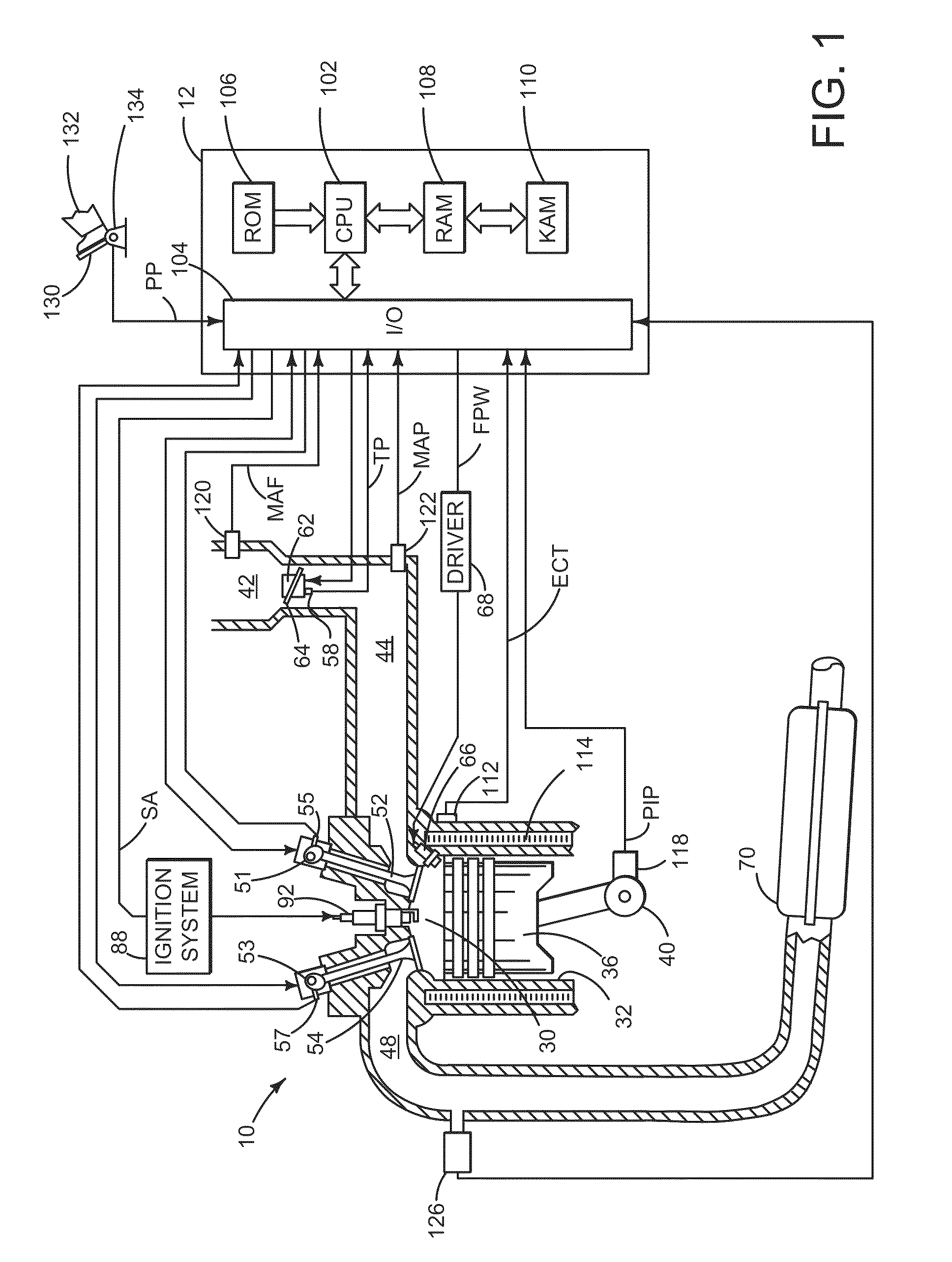

Method and system for improving automatic engine stopping

ActiveUS20140067239A1Improve vehicle fuel efficiencyLimiting driver annoyanceAnalogue computers for vehiclesElectrical controlOperant conditioningAutomotive engineering

A method and system for improving automatic engine stopping and starting is presented. In one example, the method adjusts conditions for engine stopping in response to operating conditions that are evaluated according to one or more cost functions. The method may improve vehicle fuel economy and limit driver annoyances.

Owner:FORD GLOBAL TECH LLC

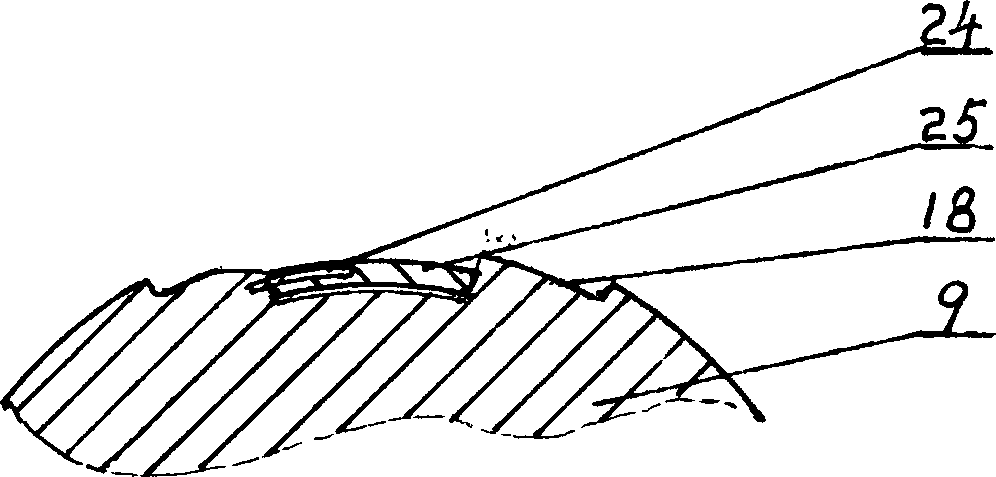

Bidirectional intelligent automobile clutch driven disc with composite sleeve core

ActiveCN105257724AOvercome technical shortcomingsReduce usageFriction clutchesLathe faceplateThrust bearing

A bidirectional intelligent automobile clutch driven disc with a composite sleeve core comprises a rotating shell made of bearing steel and a force transmission frame formed by punching an alloy steel plate. The spline face of the rotating shell is connected with a spline hole of the force transmission frame. The diameter of each auxiliary spring steel wire is larger than the diameter of each main spring steel wire. Each auxiliary spring is mounted in an inner hole of a corresponding main spring, and locating core columns are mounted in holes of the auxiliary springs. The two ends of each locating core column are riveted to the edges of a corresponding fan-shaped hole of the force transmission frame. The main springs are placed in clamping grooves of a right disc chuck and a left disc chuck. A cavity core is arranged in the rotating shell and an inner cavity of a rotating shell cover, and the surface of the cavity core is provided with multiple sections of reducing curved surfaces. Two pairs of thrust bearings are composed of ball grooves of the rotating shell, ball grooves of the rotating shell cover, ball grooves in the two end faces of the cavity core, a plurality of ceramic balls and separation columns with the same number with the ceramic balls, and the metal separation columns are hollow cylinders and are filled with lubricating grease. The right disc chuck and the left disc chuck are connected through pins. According to the bidirectional intelligent automobile clutch driven disc, gear shifting operation is simplified, when an automobile goes down a slope, good braking performance is achieved, and the service life of an engine and the service life of a gearbox can be prolonged.

Owner:帅晓华

Method and system for improving automatic engine stopping

ActiveUS9243600B2Reduce the possibilityImprove fuel efficiencyElectrical controlInternal combustion piston enginesOperant conditioningAutomotive engineering

A method and system for improving automatic engine stopping and starting is presented. In one example, the method adjusts conditions for engine stopping in response to operating conditions that are evaluated according to one or more cost functions. The method may improve vehicle fuel economy and limit driver annoyances.

Owner:FORD GLOBAL TECH LLC

Interesting yoyo ball played in hand-held mode

An interesting yoyo ball played in a hand-held mode comprises two rotating bodies with inside surfaces oppositely arranged and a connecting shaft which connects the two rotating bodies, wherein, an external rotating body which can rotate in relative to the rotating bodies is arranged at an outer edge of the rotating bodies. As the external rotating body which can rotate in relative to the rotating bodies is arranged at the outer edge of the rotating bodies, and a buckling edge which is buckled at an edge of the rotating bodies is arranged at the outer edge of the external rotating body, the external rotating body of the yoyo ball can be held by hands without touching the rotating bodies which are rotating to slow down rotation of the rotating bodies during play; a bearing is arranged between the rotating bodies and the external rotating body, thus achieving smoother rotation effect by the bearing; and the external rotating body with the bearing also has balancing weight effect. Therefore, the yoyo ball composed of the external rotating body has the advantages of more stable directivity, easier operation and better control performance, thus leaving a player space to develop creative playing methods so that yoyo toys can attract the player for longer time.

Owner:ALPHA GRP CO LTD +1

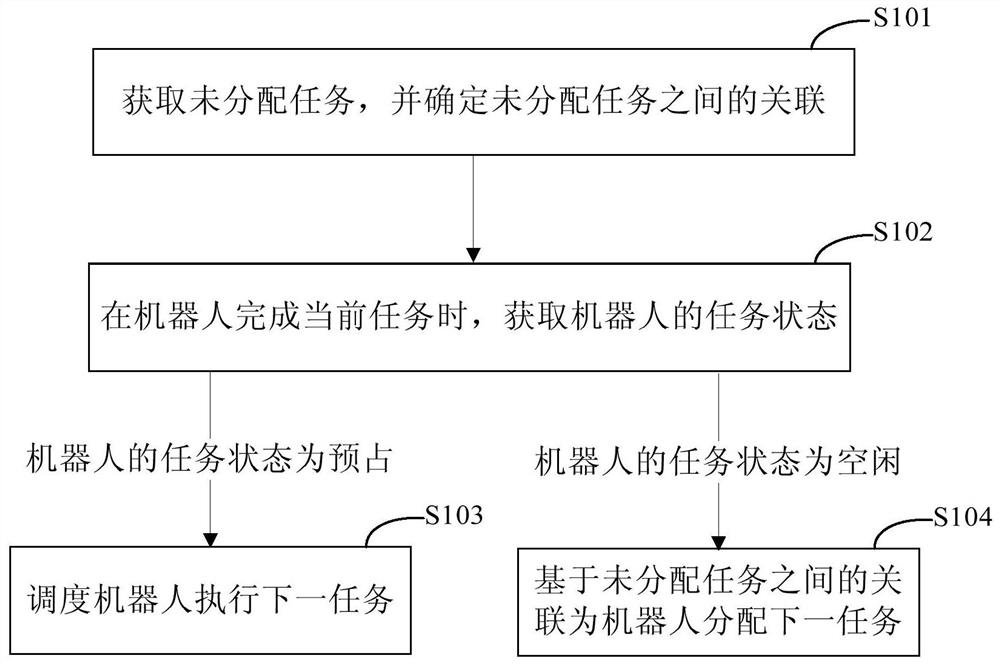

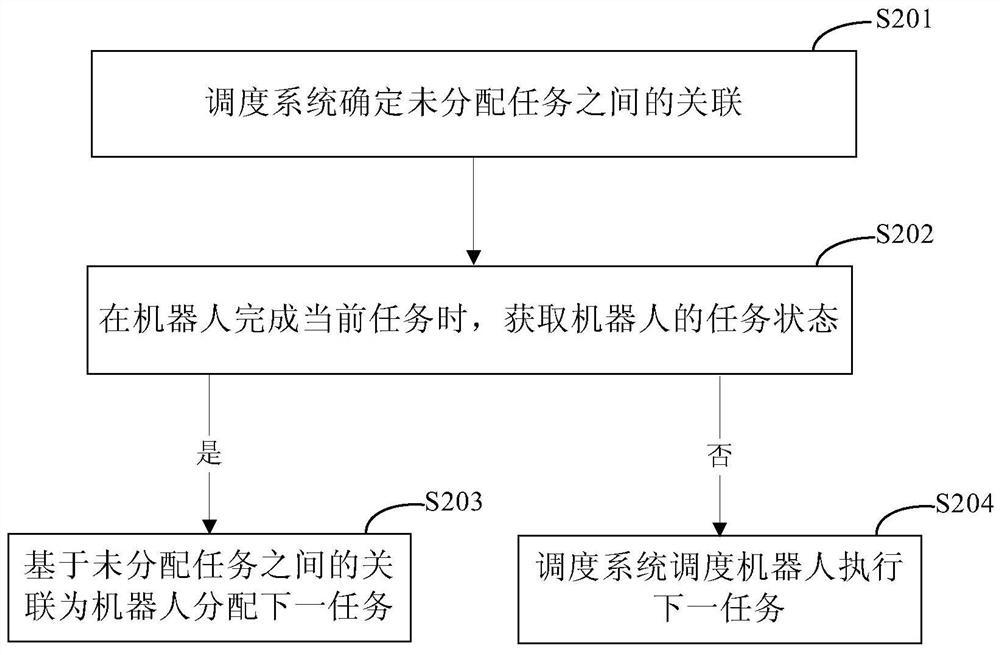

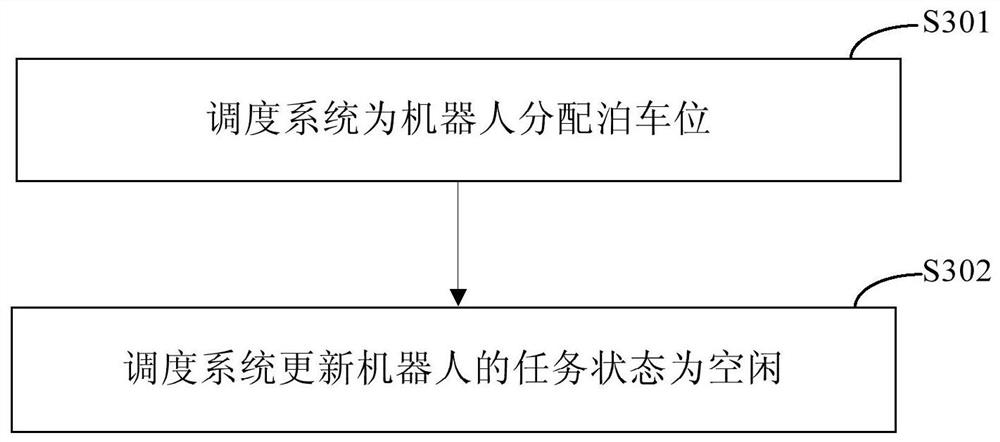

Method and device for scheduling robots

PendingCN112631268AIncreased idle timeDecrease productivityResourcesLogisticsDistributed computingReal-time computing

The invention discloses a method and device for scheduling robots, and relates to the technical field of computers. A specific embodiment of the method comprises the steps of obtaining unallocated tasks, and determining association between the unallocated tasks; when the robot completes the current task, obtaining the task state of the robot, wherein the task state is determined based on the current task; if the task state of the robot is pre-occupation, scheduling the robot to execute the next task; and if the task state of the robot is idle, allocating a next task to the robot based on the association between the unallocated tasks. According to the embodiment, the scheduling order can be optimized, and the storage work continuity of the robot is ensured, so that the work efficiency of the robot is improved, and the work efficiency in storage is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com