Impeller optimized design method capable of prolonging running down time of reactor coolant pump

A technology of idle time and optimal design, applied in multi-objective optimization, computer-aided design, components of pumping devices for elastic fluids, etc., can solve problems such as result deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

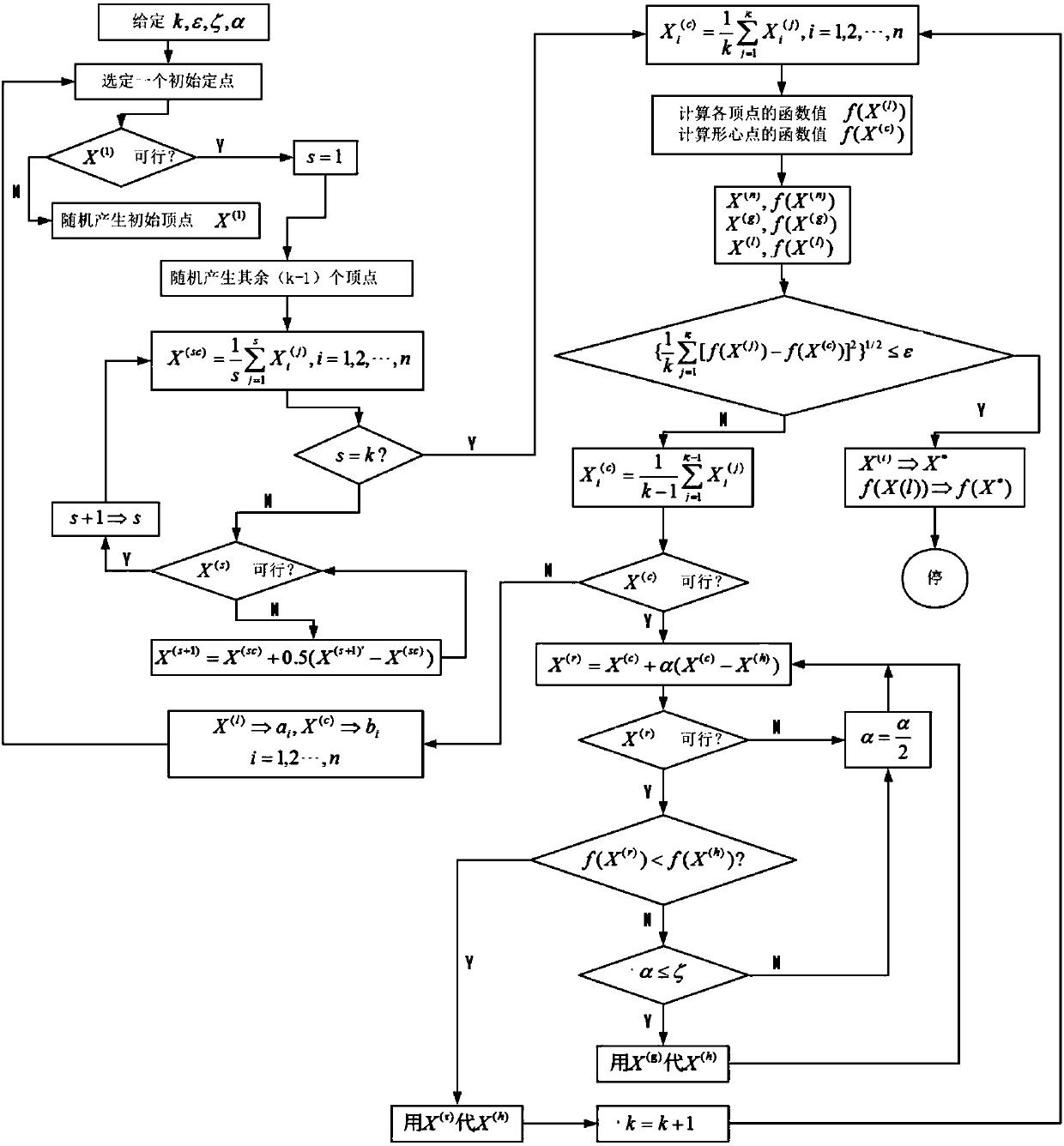

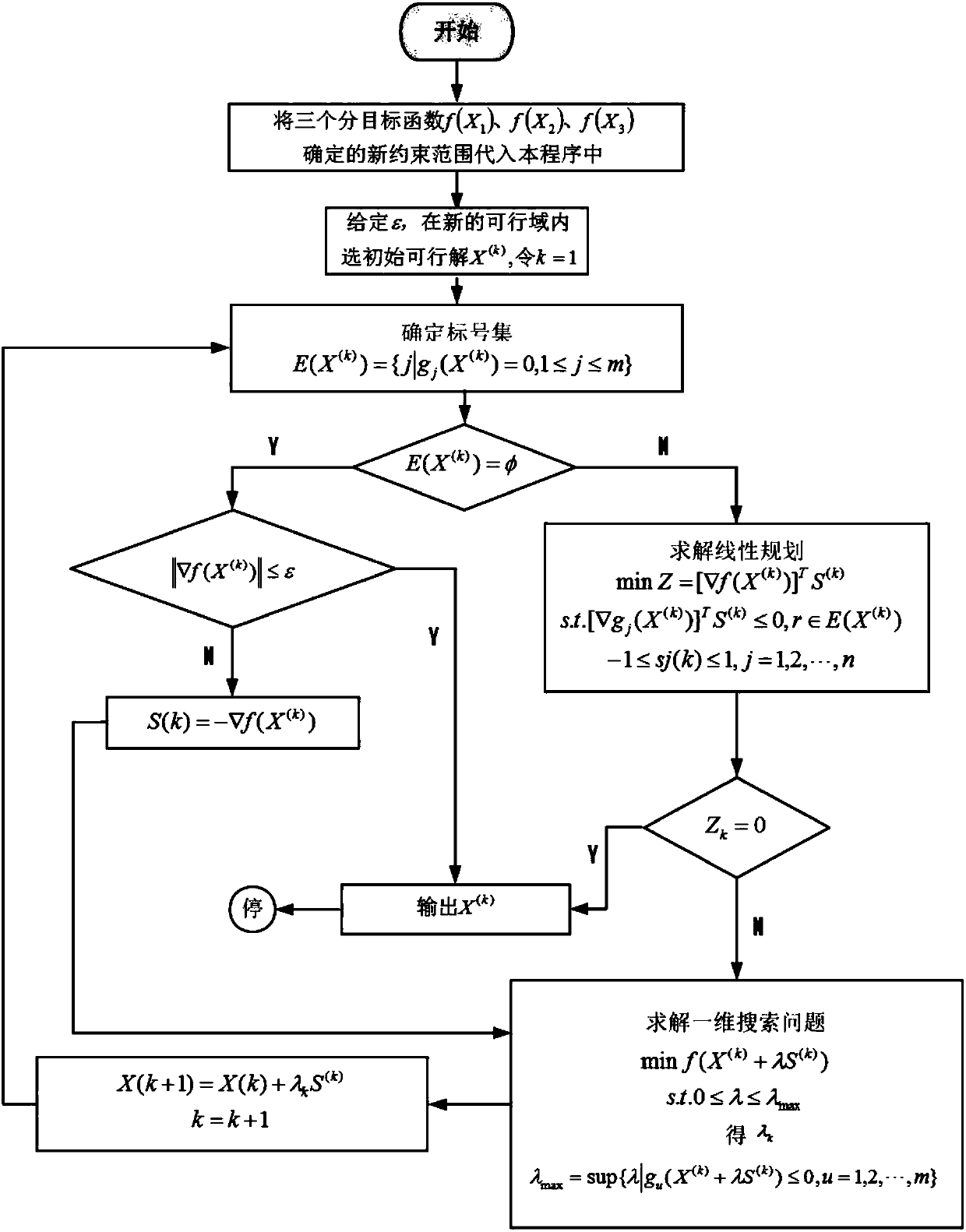

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with the accompanying drawings and specific technical solutions.

[0088] An impeller optimization design method that can improve the idling time of the nuclear main pump is established by optimizing the main parameters of the impeller (impeller inlet diameter D 0 , impeller outlet diameter D 2 , impeller outlet width b 2 , blade inlet angle β 1 , blade outlet placement angle β 2 , blade wrap angle The number of blades Z) to improve the main objective function of operating efficiency under idling conditions, the specific process is:

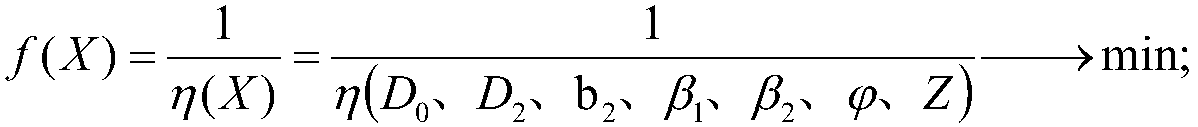

[0089] The design variables are: The main objective function is:

[0090]

[0091] In the formula, D 0 -Impeller inlet diameter, in meters;

[0092] D. 2 -Impeller outlet diameter, in meters;

[0093] b 2 -Impeller inlet width, in meters;

[0094] beta 1 - impeller inlet angle, unit degree;

[0095] beta 2 - The placement angle of the impeller outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com