PWM dimming circuit used for high-power-factor primary-side-feedback LED driving power supply

A LED drive, high power factor technology, applied in the field of PWM dimming circuit, can solve the problems of poor dimming linearity, increase the operating frequency of LED drive power supply, limited range, etc., to achieve improved dimming linearity, superior PWM dimming light effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

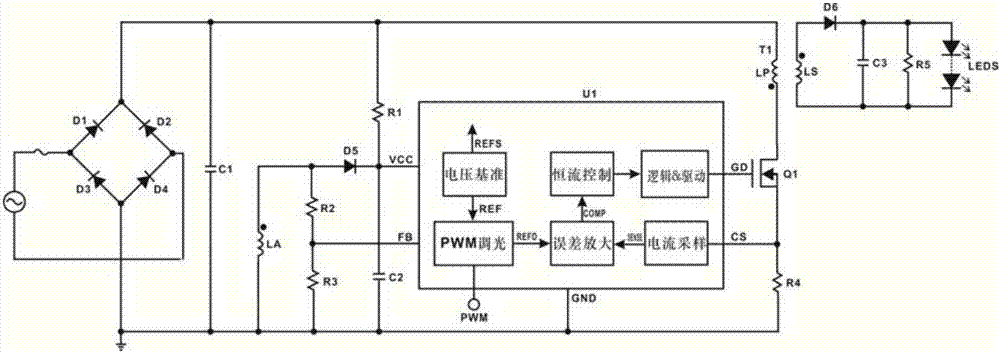

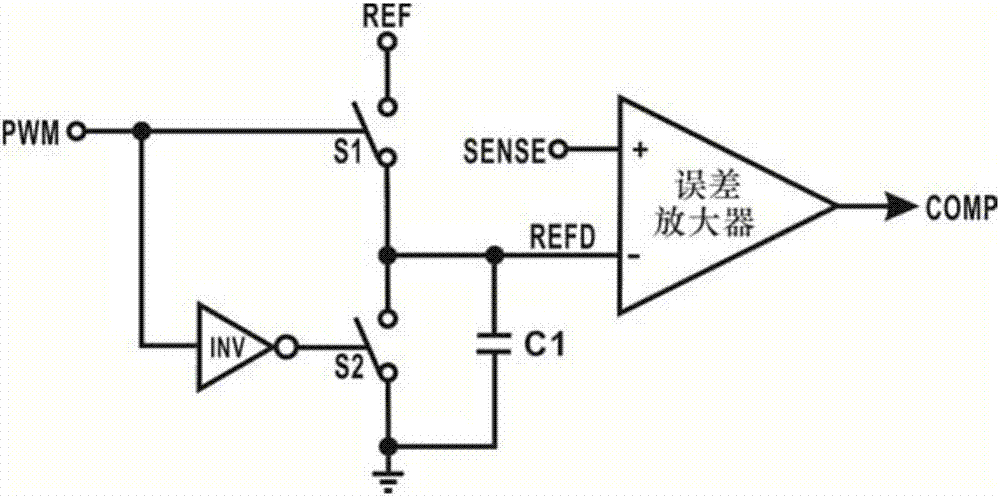

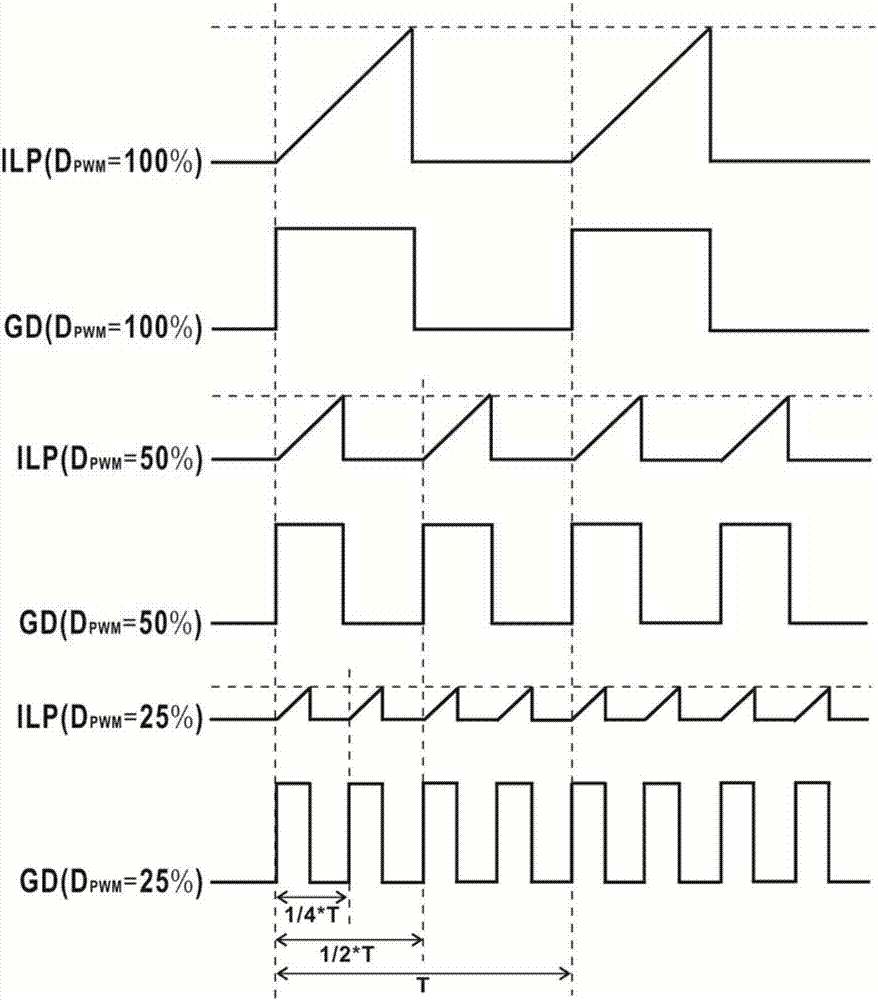

[0021]The invention solves the problem that the operating frequency of the LED drive power continuously increases with the decrease of the PWM dimming duty cycle in the traditional PWM dimming control technology used for high power factor primary side feedback LED drive power, and also solves the problem that The traditional PWM dimming control technology solves the problem that the output current dimming linearity effect is not ideal when the PWM signal is a low duty cycle, and provides a PWM dimming control circuit that solves the above problems. By reducing the reference voltage of the output current and increasing the idle time of the secondary winding of the transformer, the operating frequency of the LED drive power supply is controlled within an appropriate range, and at the same time the peak current of the primary winding of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com