LED dimming and color adjusting circuit

A circuit and dimming technology, which is applied in the field of LED lighting, can solve the problems of large voltage difference of the step-down drive circuit, difficulty in realizing constant voltage power supply, abnormal operation, etc., and achieve constant voltage, good effect of dimming and color adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

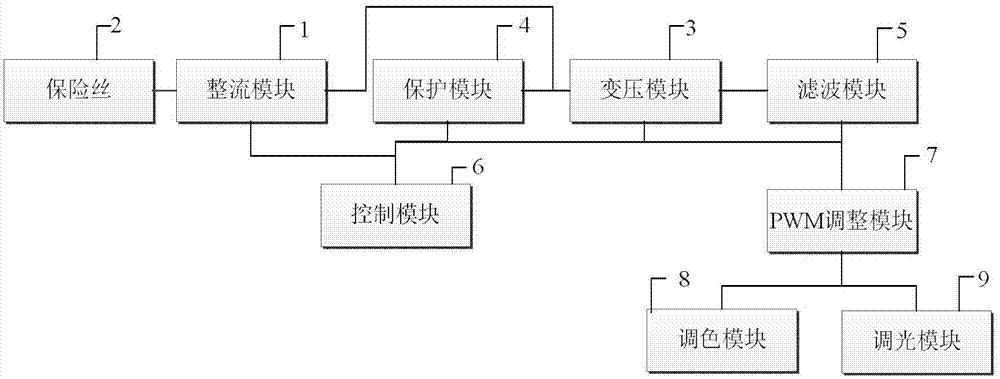

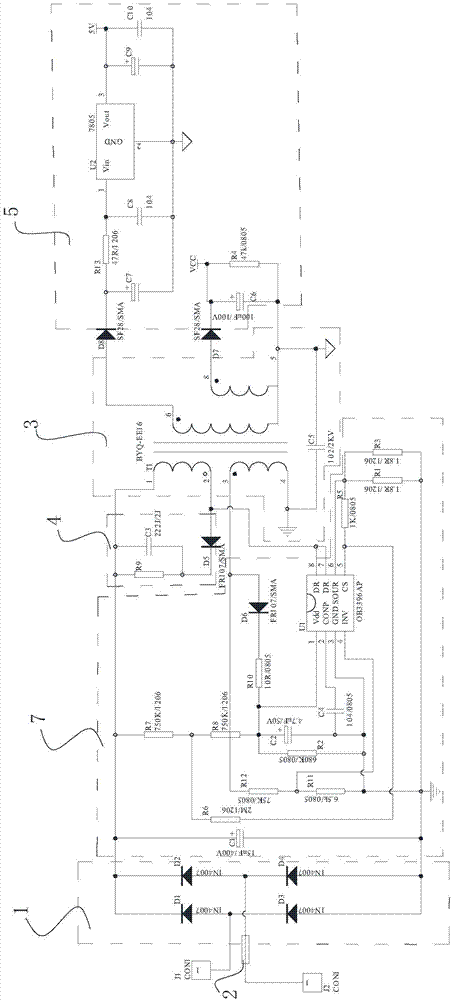

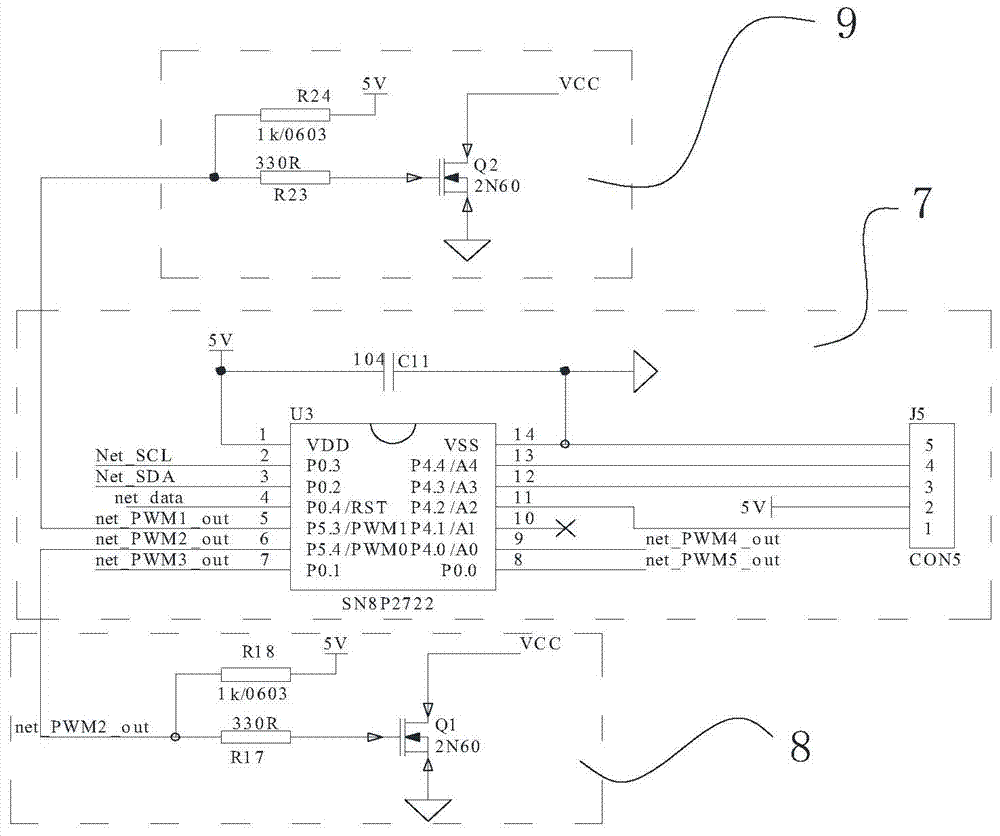

[0027] refer to Figure 1 to Figure 3 , an LED dimming and coloring circuit described in this embodiment, including a rectification module 1, a fuse 2, a transformer module 3, a protection module 4, a filtering module 5, a control module 6, a PWM adjustment module 7, and a coloring module 8 And dimming module 9. The rectification module 1 is used to convert alternating current into direct current. The fuse 2 is connected between the rectifier module 1 and the AC power supply. The transformer module 3 is connected to the output end of the rectifier module 2, and is used for transforming the direct current output by the rectifier module 2, for example, from high voltage to low voltage. The protection module 4 is connected to the input of the transformer module 3 . The protection module 4 is used to protect the color adjustment module 8 and the light a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com