Thermochromatic vanadium dioxide-based composite film with adjustable contact angles and preparation method thereof

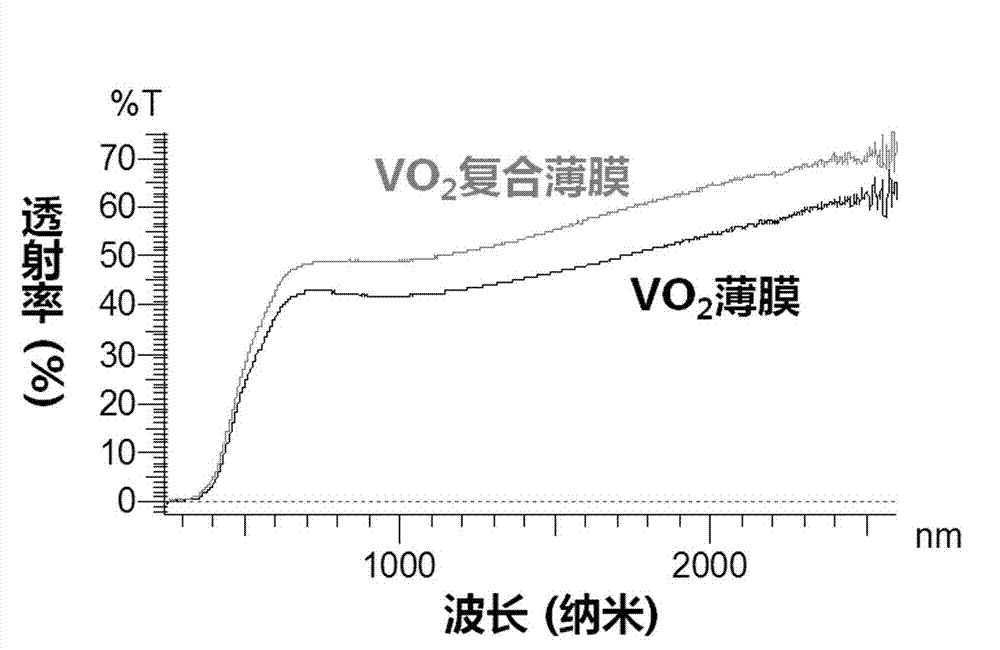

A technology of vanadium dioxide and composite film, which is applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems that do not involve the hydrophobicity of the film, the incompatibility of preparation conditions, the limitation of applicability, etc., and achieves a simple structure. , the effect of reducing the degree of refractive index adaptation and reducing the reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

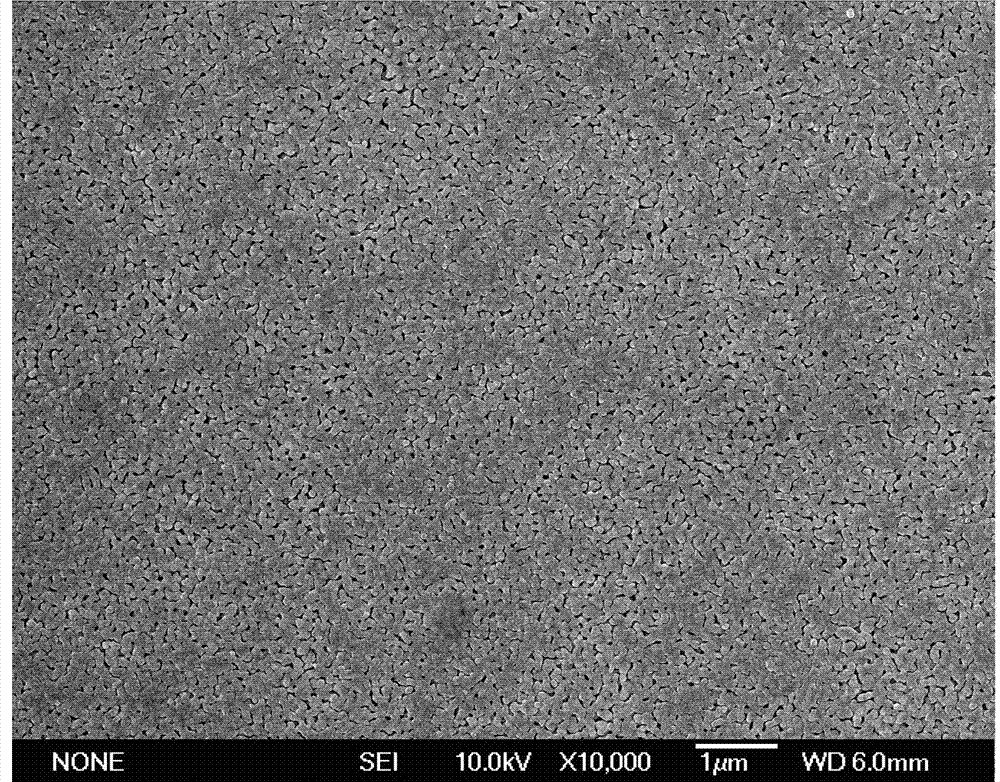

[0024] Preparation steps: (1) Deposit vanadium dioxide film on a transparent substrate: deposit vanadium dioxide (VO 2 )film.

[0025] (2) Zinc oxide nanoarrays were prepared by chemical bath method; the quartz substrate deposited with a 110 nm thick vanadium dioxide film was completely immersed in 0.05 mol?L -1 Zinc acetate Zn(CH 3 COO) 2 with 0.05 mol?L -1 Herotropine C 6 h 12 N 4 Among the mixed solution, put the solution at 80 o C under reflux for 6 hours. After the reaction was completed, the samples were taken out, and washed twice with water and ethanol respectively.

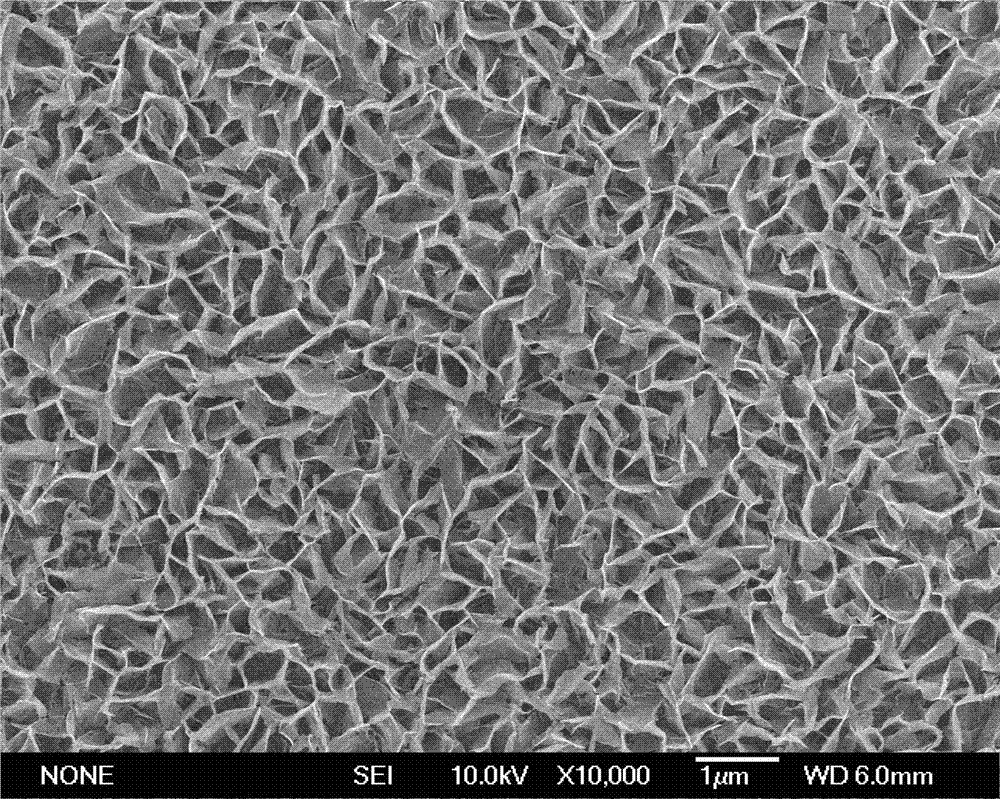

[0026] Product structure: The composite film obtained by the above preparation steps includes a vanadium dioxide film on a transparent substrate and a flaky zinc hydroxide (Zn(OH) 2) nano-array; the sheet-shaped zinc hydroxide nano-array is composed of sheet-shaped zinc hydroxide nanoparticles with a size of 300-700 nm and a thickness of 10-30 nm. The sheet-shaped zinc hydroxide is basically pe...

Embodiment 2

[0033] Preparation method: (1) Deposit vanadium dioxide film on transparent substrate: deposit 50 nm thick vanadium dioxide (VO2) on aluminum oxide (sapphire) transparent substrate 1.95 )film.

[0034] (2) Zinc oxide nanoarrays were prepared by chemical bath method; the quartz substrate deposited with a 50 nm thick vanadium dioxide film was completely immersed in 0.1 mol?L -1 Zinc oxalate ZnC 2 o 4 .2H 2 O and 0.1 mol?L -1 Herotropine C 6 h 12 N 4 Among the mixed solutions, the solution is at 60 o C under reflux for 5 hours. After the reaction was completed, the samples were taken out, and washed twice with water and ethanol respectively. After drying, a thermochromic vanadium dioxide-based composite film with adjustable contact angle can be obtained.

[0035] The composite thin film obtained by the above method includes a vanadium dioxide film on a transparent substrate and a rod-shaped zinc oxide (ZnO) nano-array on the vanadium dioxide film; the rod-shaped zinc ...

Embodiment 3

[0041] Preparation method: (1) Deposit vanadium dioxide film on a transparent substrate: deposit tungsten-doped vanadium dioxide (V 0.98 W 0.02 o 2 )film.

[0042] (2) Zinc oxide nanoarrays were prepared by chemical bath method; the sapphire substrate deposited with a 150 nm thick vanadium dioxide film was completely immersed in 0.1 mol?L -1 Aluminum nitrate Zn(NO 3 ) 2 ·6H 2 O and 0.1 mol?L -1 Herotropine C 6 h 12 N 4 Among the mixed solution, put the solution at 40 o C under reflux for 12 hours. After the reaction was completed, the samples were taken out, and washed twice with water and ethanol respectively. After drying, a thermochromic vanadium dioxide-based composite film with adjustable contact angle can be obtained.

[0043] The composite film obtained by the above method includes a vanadium dioxide film on a transparent substrate and an acicular sheet-like zinc oxide (ZnO) nanoarray on the vanadium dioxide film; the acicular ZnO nanoarray consists of a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com