Bidirectional intelligent automobile clutch driven disc with composite sleeve core

A composite sleeve and clutch technology, applied to clutches, friction clutches, mechanically driven clutches, etc., can solve the problems of vehicle damage, reduce the stiffness and strength of brake components, and increase the burden of the brake system, and achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

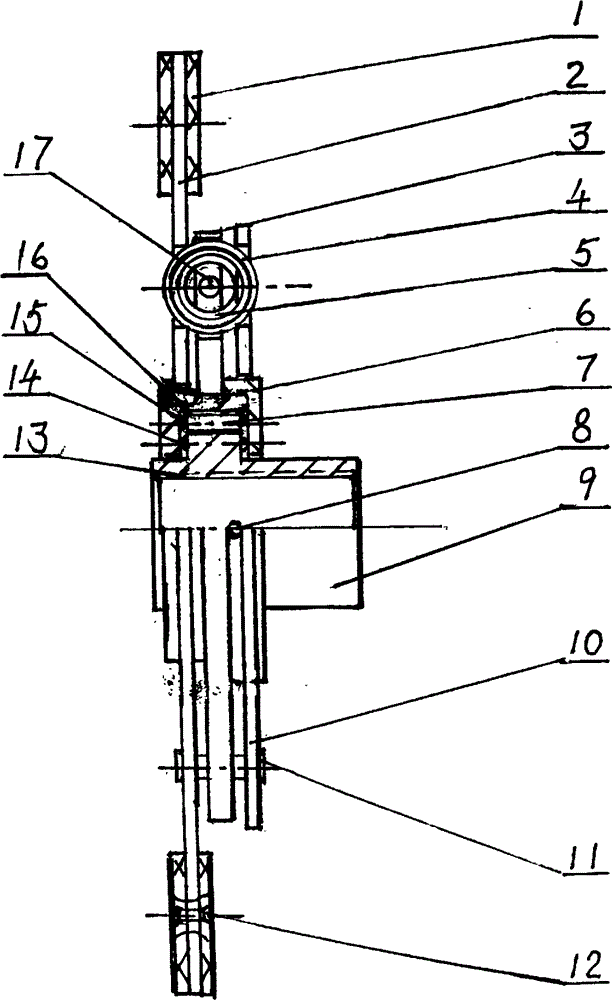

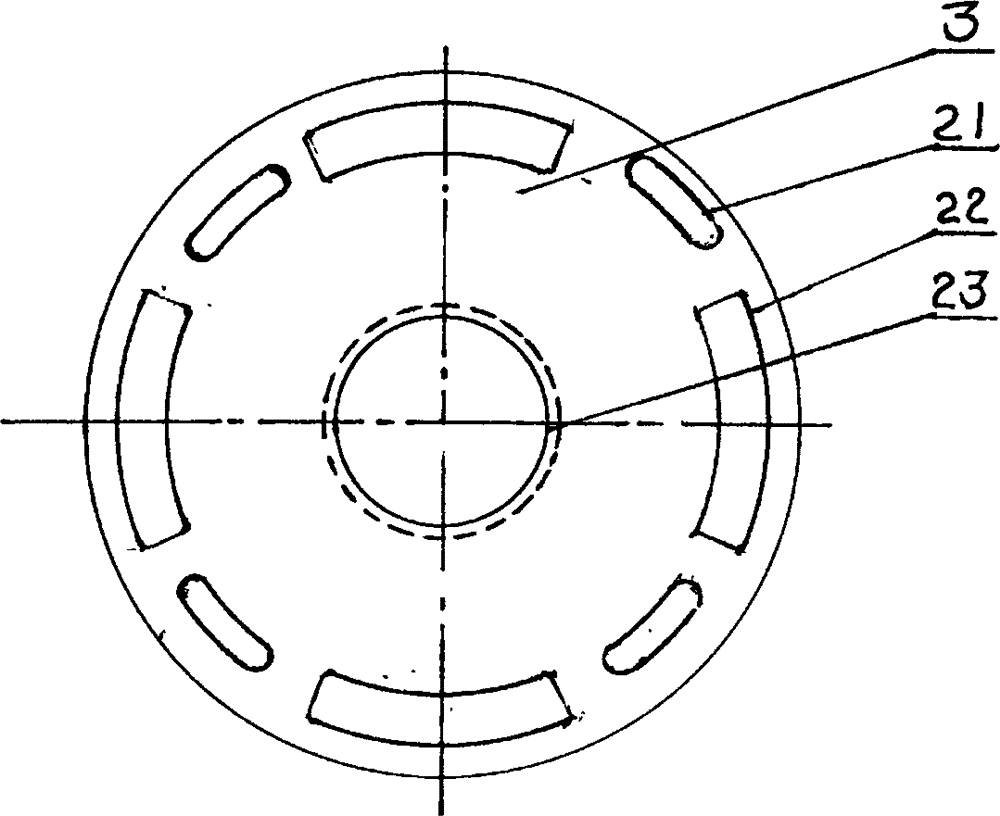

[0091] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only schematically illustrate the basic structure of the present invention, and only show the structures related to the present invention.

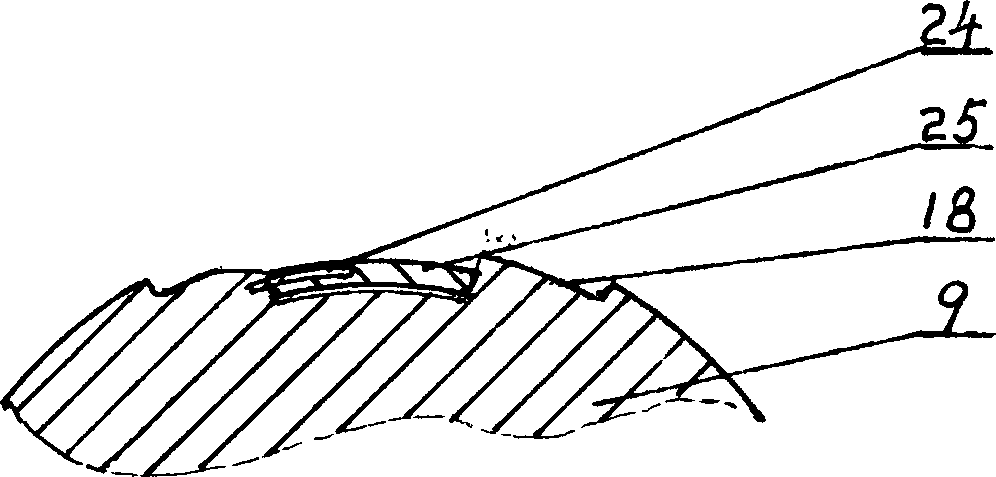

[0092] Example 1 of the working condition of the driven disc of the two-way intelligent composite sleeve core automobile clutch, the structural principle is as attached Figure 1-5 As shown in the figure, a driven plate of a two-way intelligent composite core automobile clutch, the structure includes: friction ring 1, left flower plate 2, force transmission frame 3, main spring 4, auxiliary spring 5, rotary shell cover 6, roller 7, tight Set screw 8, cavity core 9, right faceplate 10, pin post 11, rivet 12, spline sleeve 13, ceramic ball 14, ceramic ball 15, spiral shell 16, positioning core post 17, variable diameter curved surface 18, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com