Hydraulic design method for running down model impeller of nuclear main pump

A technology of hydraulic design and nuclear main pump, which is applied in the components, pumps, and pump elements of pumping devices for elastic fluids, and can solve problems such as little impact research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

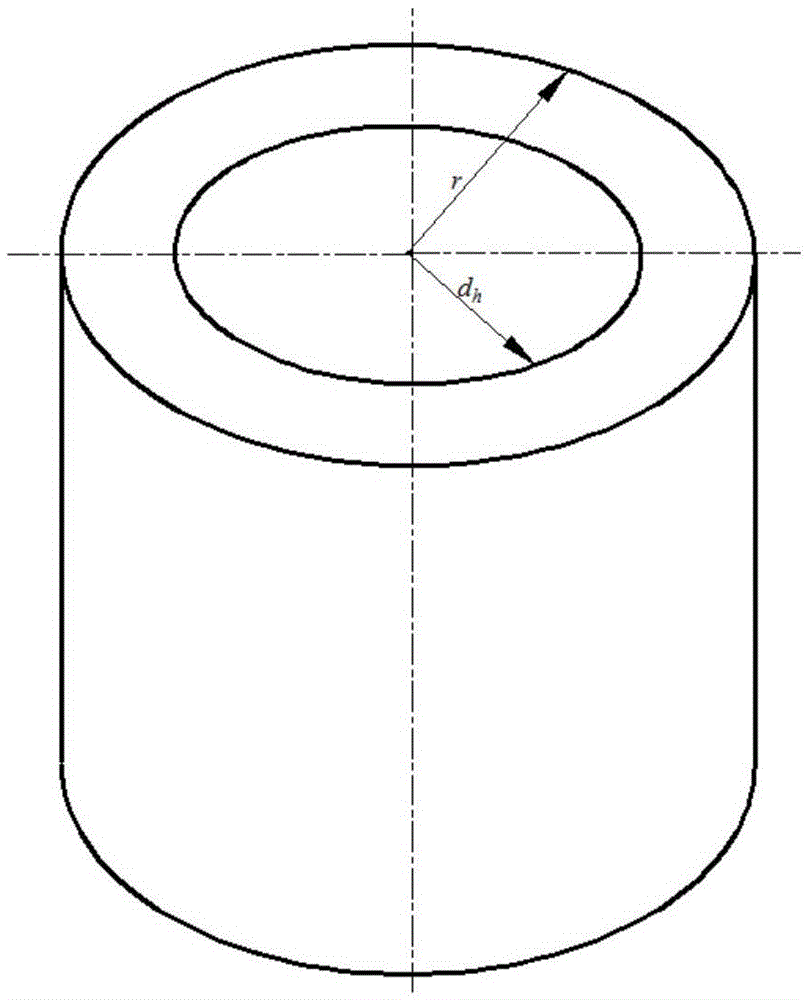

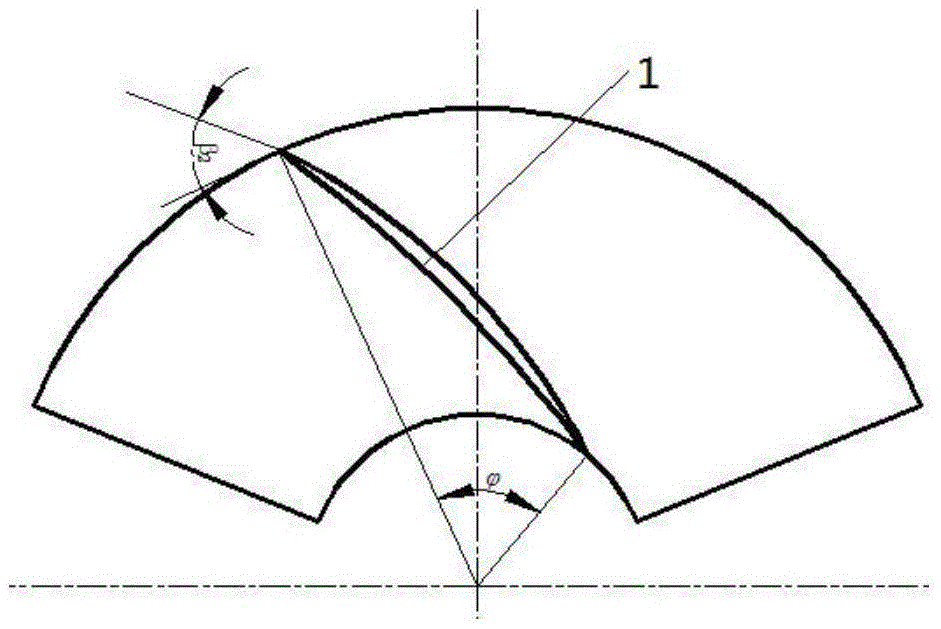

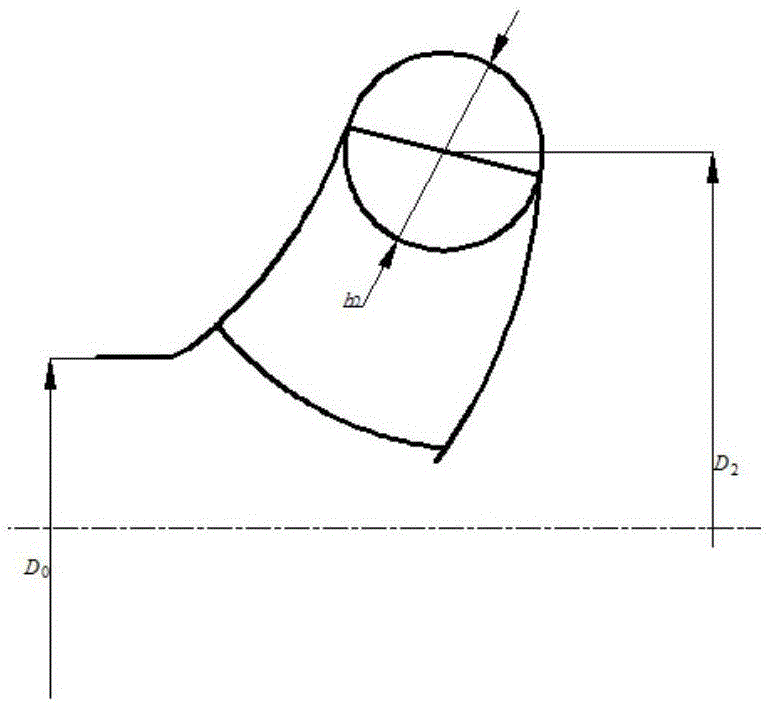

[0083] Design requirements: the design flow rate is 17886m 3 / h, the design head is 111.3m, the speed is 1485rev / s, g is 10kg / m 2 , the number of blades is 7 pieces, the weight of the flywheel is 8t, the radius of the flywheel is 450mm, the shaft diameter of the flywheel is 140mm, and the density of the impeller material is 7.85g / cm 3 ; Obtainable: moment of inertia I of flywheel 0 : 888.4N﹒ m; Moment of inertia I of the whole nuclear main pump: 973.1N. m; diameter of the impeller inlet of the nuclear main pump D 0 : 660mm; nuclear main pump impeller outlet diameter D 2 : 710mm; nuclear main pump impeller outlet width b 2 : 160mm; blade outlet placement angle β 2 : 37°; blade wrap angle 120°.

[0084] The above is a specific description of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com