Layered Modular Ozone Generator

An ozone generator and modular technology, which is applied in the direction of ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., can solve the large difference in cooling effect of the electrode plate and the uneven flow velocity of the airflow plate surface , the cooling effect of the electrode plate is reduced, etc., to achieve good sealing, rapid cooling, and prevent the local temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

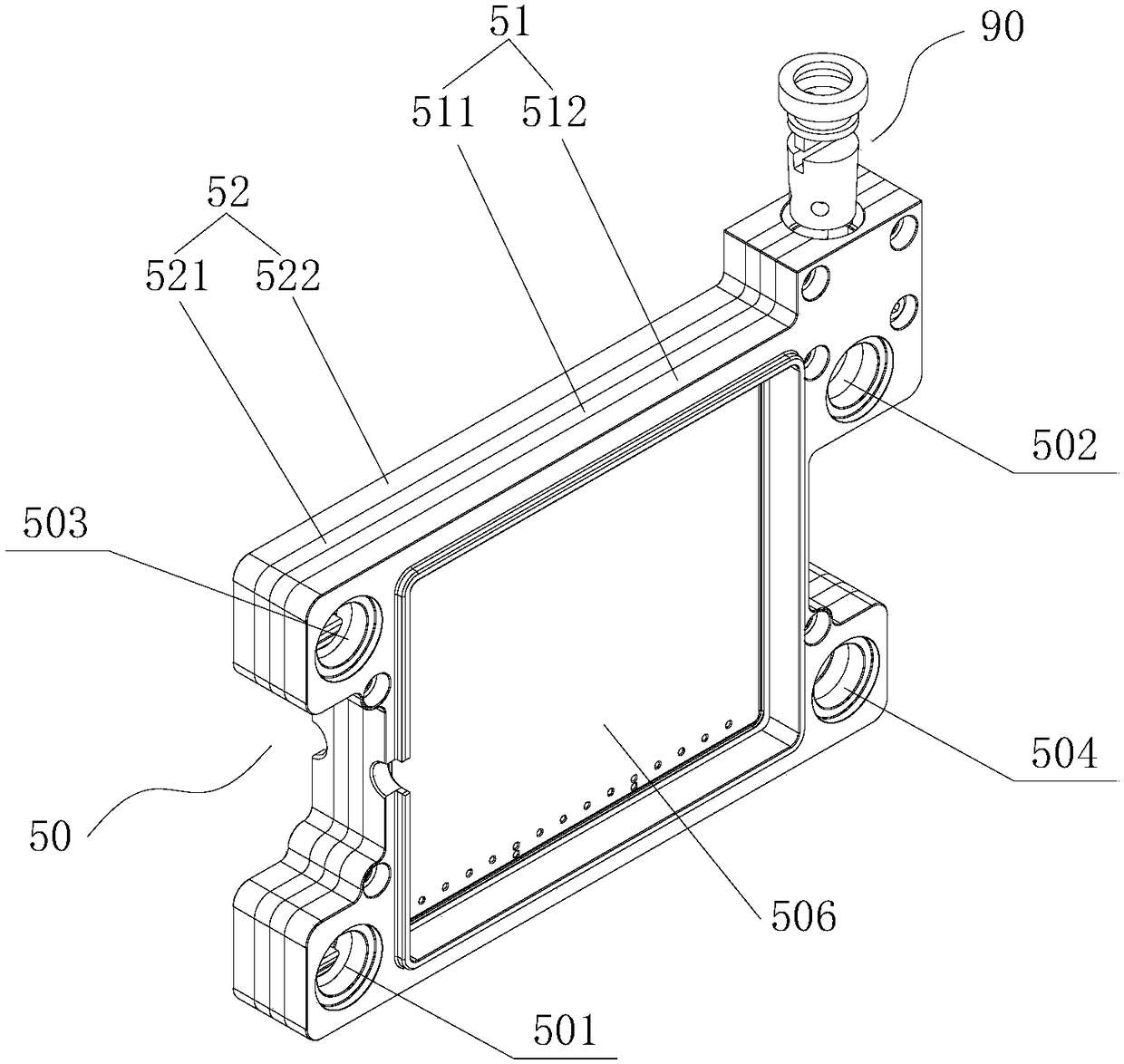

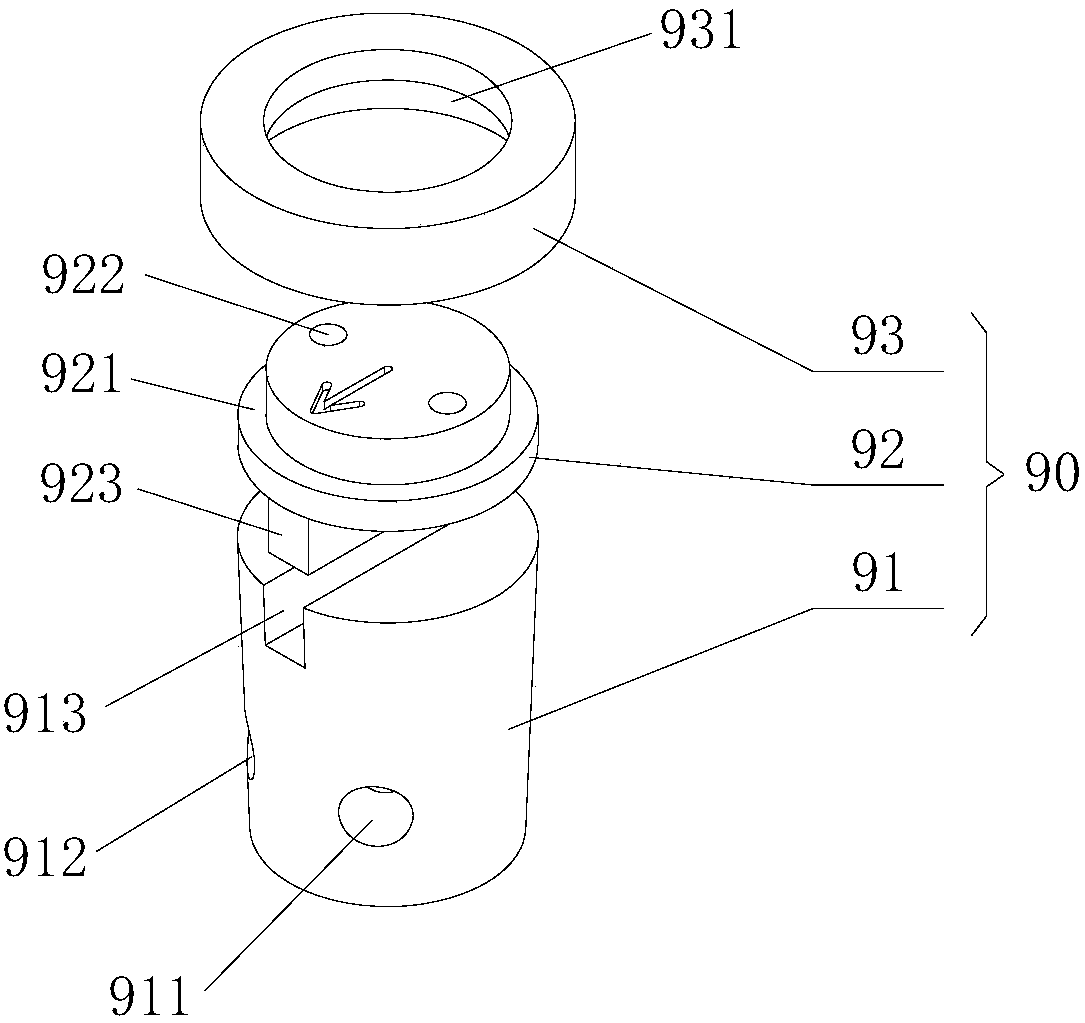

[0042] Such as Figure 1-12 As shown, Embodiment 1 of the present invention provides a layered modular ozone generator 100, including several ground electrode plate assemblies 50 and high voltage electrode plate assemblies 60,

[0043]The ground plate assembly, which has an air inlet 501, an air outlet 502, a water inlet 503 and a water outlet 504, includes a first ground electrode plate 51 and a second ground electrode plate 52, the first ground electrode plate and The back of the second ground electrode plate is docked and a water channel groove 505 is provided on the docking surface. The water channel groove communicates with the water inlet 503 and the water outlet 504. The front sides of the first ground electrode plate and the second ground electrode plate A ground electrode groove 506 is provided; preferably, an inner rib structure is provided on the inner wall of the water channel groove, and the ground electrode plate assembly adopts a plate structure design, so that ...

Embodiment 2

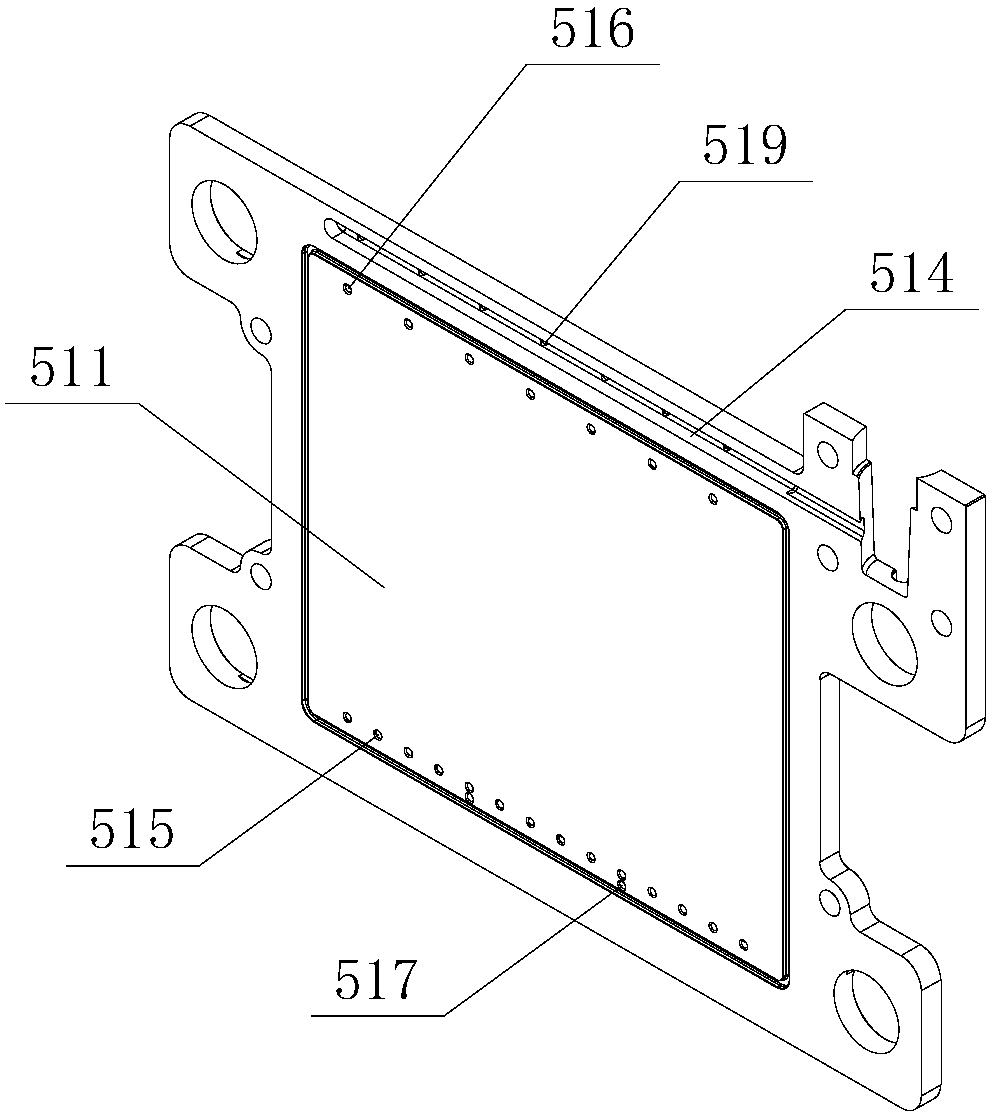

[0048] The layered modular ozone generator provided in this embodiment is further optimized on the basis of Embodiment 1: preferably, one end of the ground electrode tank 505 is provided with evenly arranged air inlets 515, and the air inlets 515 communicates with the air inlet 501 through the air inlet channel 513 , and the other end of the ground electrode groove 505 is provided with evenly arranged air outlet holes 516 , and the air outlet holes 516 communicate with the air outlet through the air outlet channel 514 .

[0049] Preferably, the air inlet holes 515 and the air outlet holes 516 are distributed in parallel to ensure that the distance between the air inlet holes 515 and the air outlet holes 516 is equal, so that the air flow can pass evenly along the surface of the ground electrode plate to ensure that the oxygen is fully reacted Ozone is generated, thereby avoiding local overheating caused by too slow flow velocity.

[0050] Preferably, the distance between the a...

Embodiment 3

[0053] The layered modular ozone generator that present embodiment provides, it optimizes design further on the basis of embodiment 1 and 2:

[0054] The high-voltage electrode plate assembly 60 includes a frame pressing block 61, a sealing partition 62 and a high-voltage electrode plate 63, the back of the high-voltage electrode plate 63 is connected to the sealing partition 62, and the sealing partition 62 is embedded Installed on the frame pressing block 61 ; two high-voltage electrode plates 63 and two sealing partitions 62 are installed on both sides of the surrounding frame pressing block 61 .

[0055] Between the distribution area of the air inlet hole 515 and the frame of the ground electrode groove 506, there is a balanced air passage hole 517 communicating with the air inlet passage 513, and the balanced air passage hole 517 passes through the sealing partition 62 and The space on the back of the high voltage electrode plate 63 is connected. The balanced air chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com