A Method for Realizing Controllable Gap Connection of Hard Materials in Atmospheric Environment

A hard material, atmospheric environment technology, applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of high vacuum environment requirements, large damage to the material matrix, complex process equipment, etc., to reduce production costs and reduce overheating problems. , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

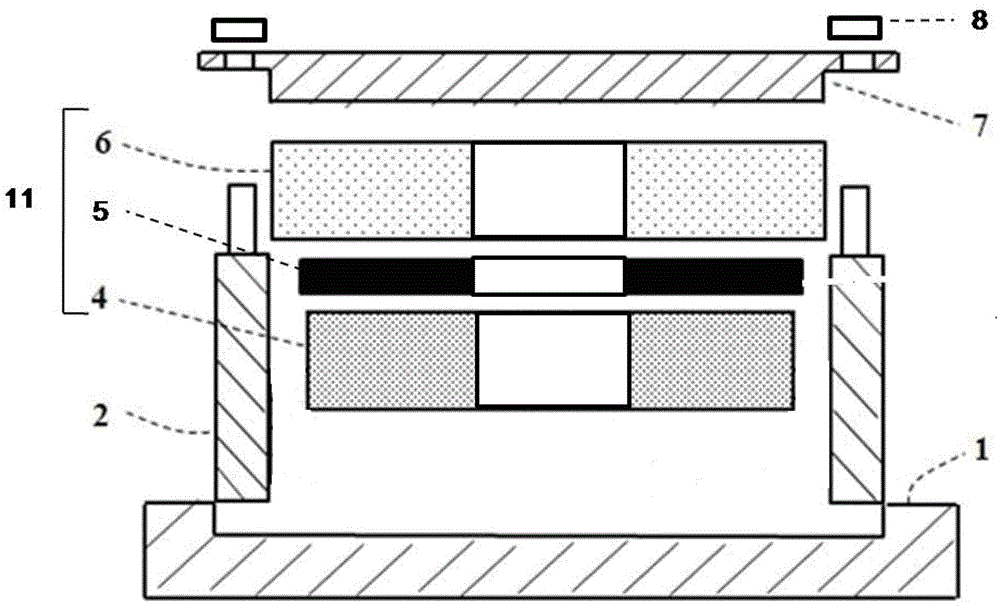

[0066] Embodiment one: see attached figure 1 As shown, a mold, the mold can make the hard material realize the heating and cooling connection with the mold with controllable gap in the atmospheric environment, which includes the mold bottom plate 1, the vertical baffle plate 2, the pressing part 7, and the matching nut part 8. The surrounding vertical baffles 2 are connected to the mold bottom plate 1; the connected workpiece 11 is located on the mold bottom 1 and in the cavity surrounded by the surrounding vertical baffles 2; the pressing member 7 and the vertical baffle 2 For connection, the matching nut piece 8 is used to adjust the pressure of the pressing piece 7 on the workpiece 11 to be connected. Connected workpiece 11: refers to the workpieces that need to be connected together.

[0067] The material of the mold is carbon steel.

[0068] The workpieces 11 to be connected are the same hard material ceramics, which are divided into a base material 4 and a base materia...

Embodiment 2

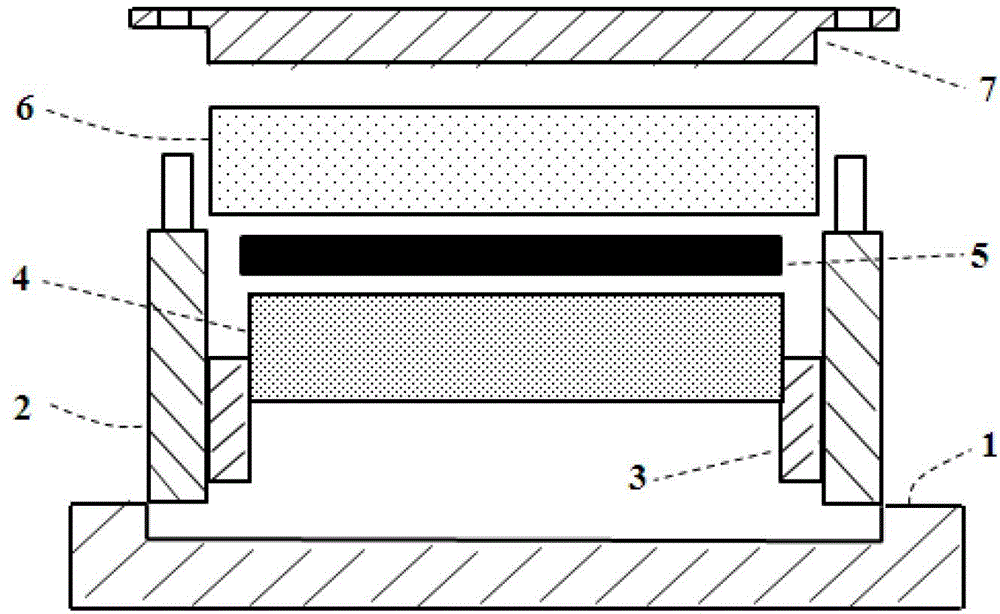

[0075] Embodiment two: see attached figure 2 As shown, a mold, the mold can make the hard material realize the controllable gap heating and cooling connection with the mold in the atmospheric environment, which includes the mold bottom plate 1, the vertical baffle plate 2, the gap control 3, and the pressing part 7 Cooperate with nuts 8, the surrounding vertical baffles 2 are connected around the mold bottom plate 1; the connected workpiece 11 is located on the mold bottom 1 and in the cavity surrounded by the surrounding vertical baffles 2; the gap control 3 is close to On the inner wall of the upright baffle 2, between the upright baffle 2 and the connected workpiece 11, the pressing piece 7 is connected to the upright baffle 2, and the nut 8 is used to adjust the pair of the pressing piece 7 to the connected workpiece 11 pressure sizes.

[0076] The material of the above mold is stainless steel (Cr series).

[0077] The workpiece 11 to be connected includes different har...

Embodiment 3

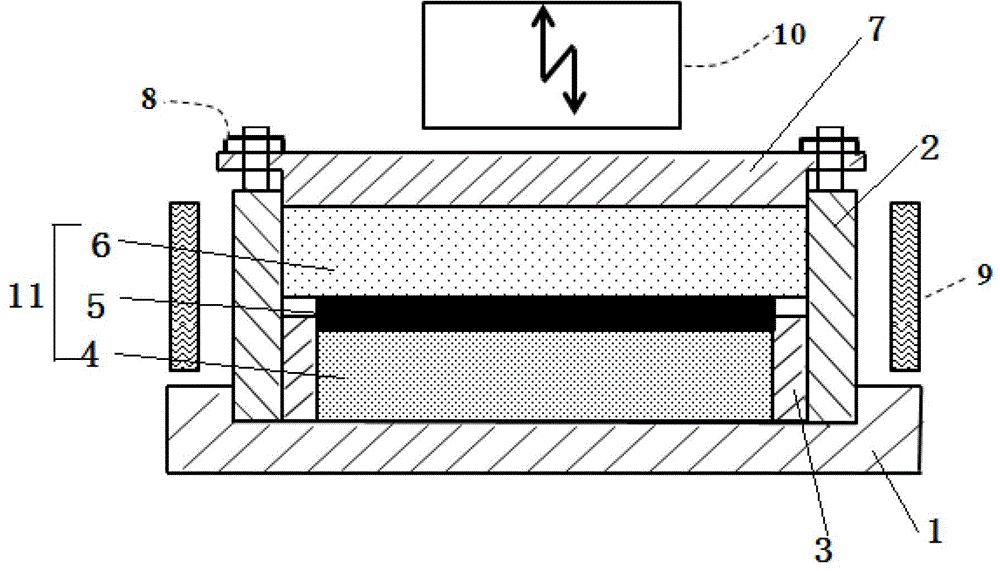

[0086] Embodiment three: see attached image 3 As shown, a mold can make hard materials realize controllable gap heating and cooling connection with the mold in the atmospheric environment, which includes a mold bottom plate 1, a vertical baffle 2, a gap control 3, and a pressing piece 7 , cooperate with the nut 8, the surrounding vertical baffles 2 are connected to the mold bottom plate 1, and the connected workpiece 11 is located on the mold bottom 1 and in the cavity surrounded by the surrounding vertical baffles 2; the gap control 3 is close to the vertical The inner wall of the baffle 2 is located between the upright baffle 2 and the connected workpiece 11, the pressing piece 7 is connected to the upright baffle 2, and the nut 8 is used to adjust the pressure of the pressing piece 7 to the connected workpiece 11. Pressure size.

[0087] The material of the above mold is two kinds of stainless steel (Mo series) or alloy steel.

[0088] The workpiece 11 to be connected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com