Low-fading-rate NAO friction material and preparation method thereof

A friction material and decay rate technology, which is applied in the field of low decay rate NAO friction materials and its preparation, can solve the problems of poor high temperature resistance of organic fibers, inability to effectively and quickly dissipate heat, and poor thermal conductivity. Solve the effect of thermal recession and moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method involved in the present invention comprises the following steps:

[0018] (1) Mixing: Weigh all the raw materials according to the weight of the formula, put all the raw materials into a high-speed mixer, and stir for 2 to 5 minutes to make a friction material mixture;

[0019] (2) Pre-compression molding: put the mixed material into the pre-forming mold, using 400-500kg / cm 2 Press forming into a cold billet, and then put the cold billet into the mold for pressing;

[0020] (3) Hot pressing: Put the mixture into the mold, the mold temperature is controlled at 150±5°C, the pressing pressure is 30±2MPa, and the heat preservation and pressure holding time is 30s / mm. One time of air, the residence time of each exhaust is 5s, after that, the mold is opened and exhausted 3 to 5 times every 10s;

[0021] (4) Heat treatment: From room temperature to 140°C, heat at a constant rate for 1 to 2 hours, keep warm for 2 to 4 hours, from 140°C to 160°C, heat at...

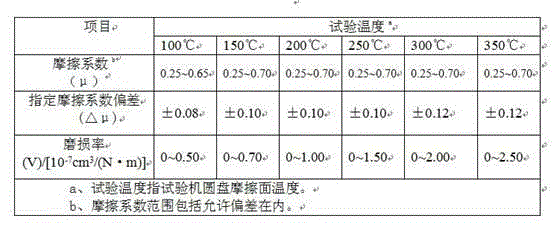

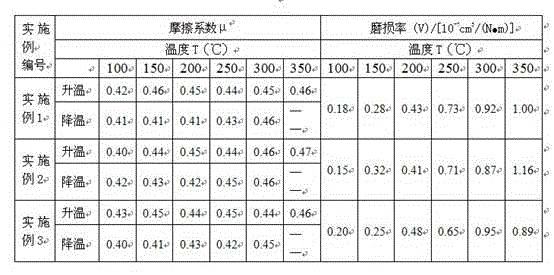

Embodiment 1

[0026] Example 1: 5 parts of resin, 4 parts of friction powder, 2 parts of nitrile rubber powder, 3 parts of tire powder, 1 part of aramid fiber, 14 parts of silicate mineral fiber, 7 parts of brass fiber, 27 parts of barite , 3 parts of zirconium silicate, 1 part of brown corundum, 6 parts of fluoride, 5 parts of red vermiculite, 1 part of sulfur, 1 part of calcium oxide, 10 parts of artificial graphite, 5 parts of natural flake graphite and 5 parts of calcined petroleum coke, according to The material prepared by the above preparation method by mixing, pressing and heat treatment was tested for friction and wear, and the test results are shown in Table 2.

Embodiment 2

[0027] Example 2: 3 parts of resin, 6 parts of friction powder, 1 part of nitrile rubber powder, 5 parts of tire powder, 1 part of aramid fiber, 13 parts of silicate mineral fiber, 6 parts of brass fiber, 28 parts of barite , 2 parts of zirconium silicate, 2 parts of brown corundum, 5 parts of fluoride, 4 parts of red vermiculite, 1 part of sulfur, 2 parts of calcium oxide, 9 parts of artificial graphite, 4 parts of natural flake graphite and 6 parts of calcined petroleum coke, according to The material prepared by the above preparation method by mixing, pressing and heat treatment was tested for friction and wear, and the test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com