Patents

Literature

59 results about "Passive testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Passive testing is a software testing technique that observes the system without interaction. On the other hand, active testing involves interaction with the system.

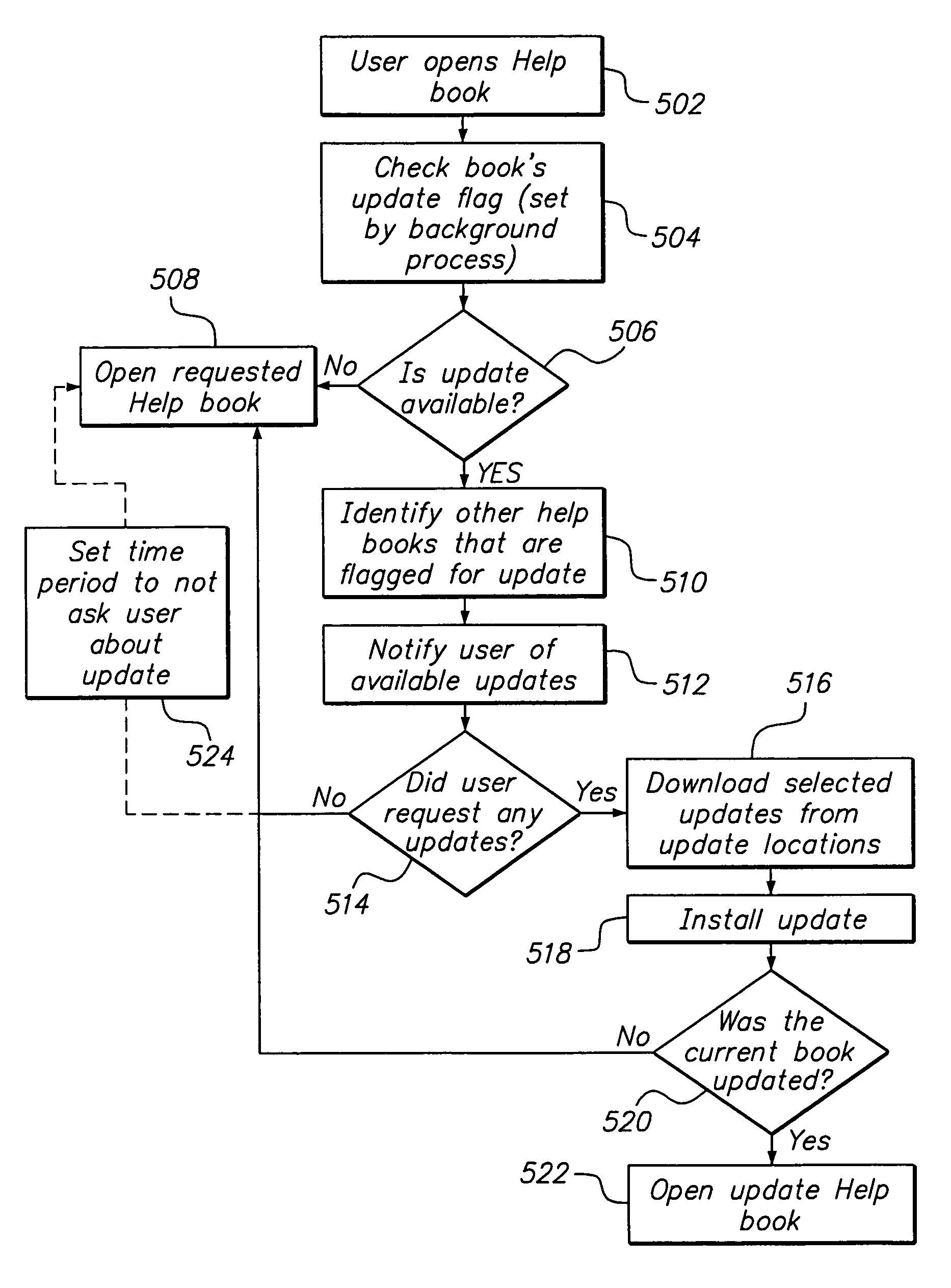

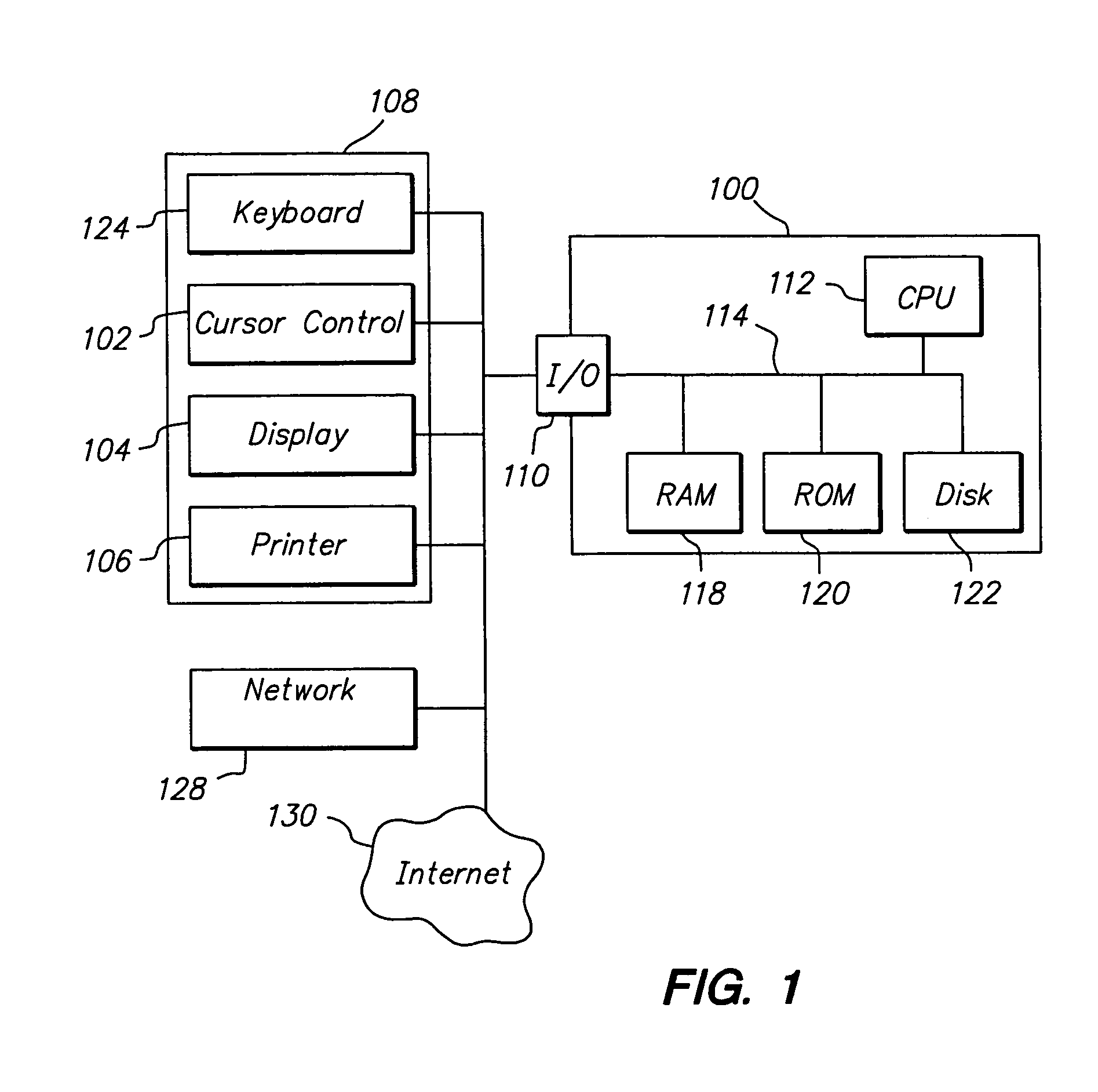

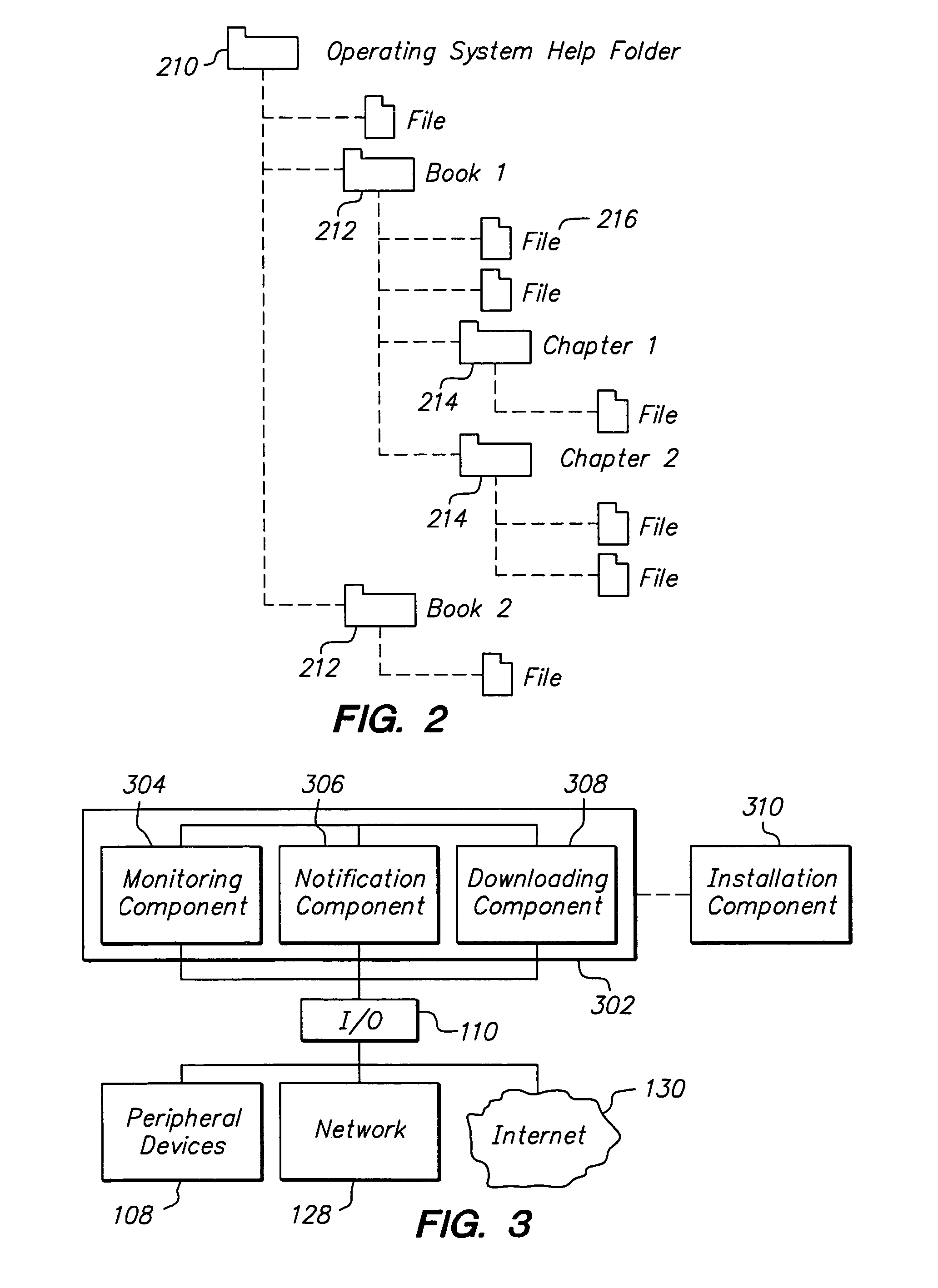

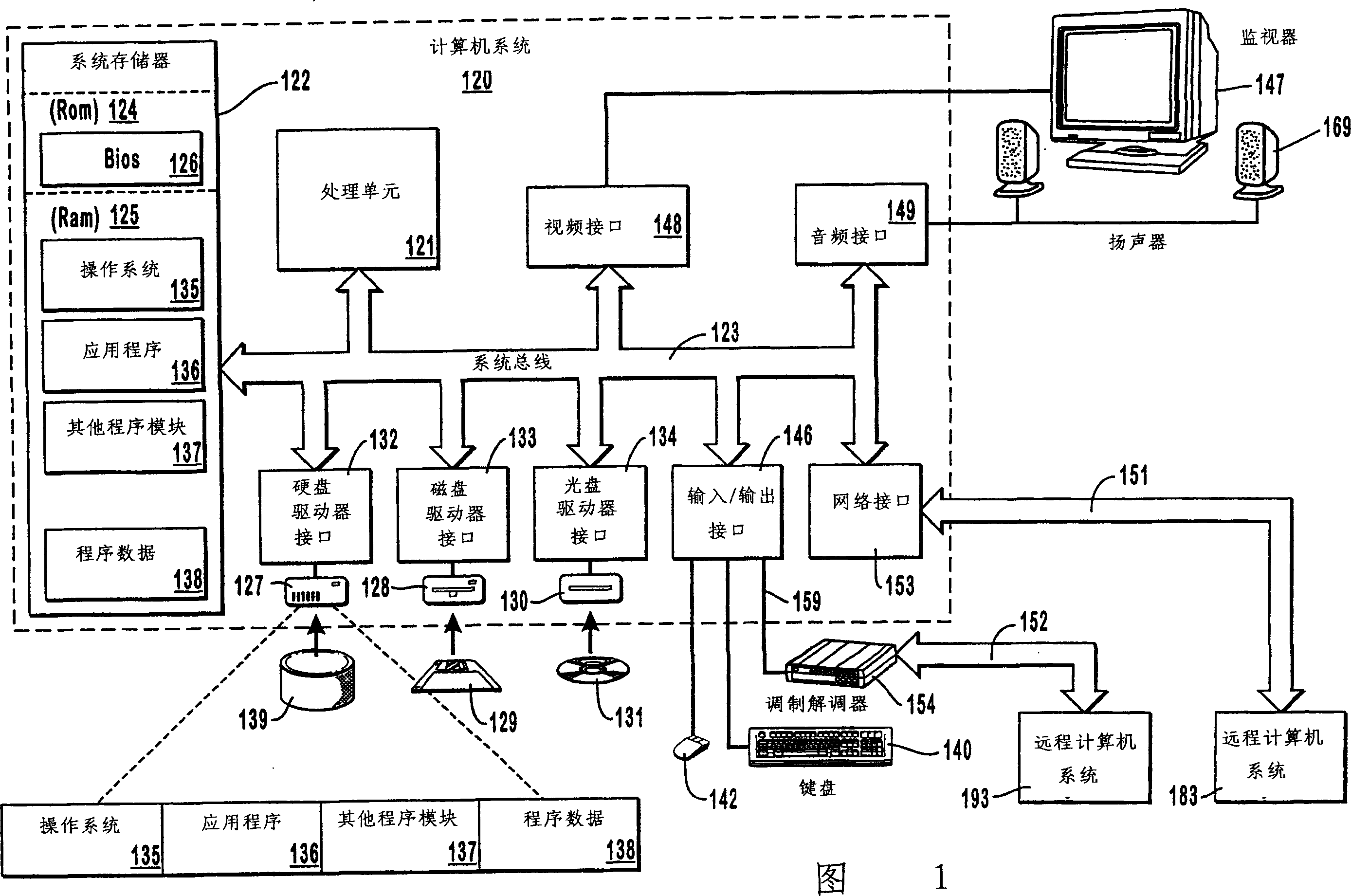

System and method for passive detection and context sensitive notification of upgrade availability for computer information

InactiveUS7016944B1Problem convenienceProblem costMultiple digital computer combinationsProgram loading/initiatingPassive testingPassive detection

The present invention is a system and method that monitors upgrade availability for computer information on a user's computer and allows the user to determine which of the available upgrades will be downloaded to the user's computer and installed. The upgrade availability for computer information on the user's computer is monitored in the background, without user-intervention when the user connects to a network, such as the Internet. If any such upgrades are available, a flag is set to notify the user of such upgrades. The user is notified of any available upgrades when computer information is accessed for which an upgrade is available, and given a choice of whether or not to download the available upgrade(s). The downloaded upgrade(s) may then be installed by an installation means. In this manner, the present invention allows for the user to download only those upgrades desired by the user.

Owner:APPLE INC

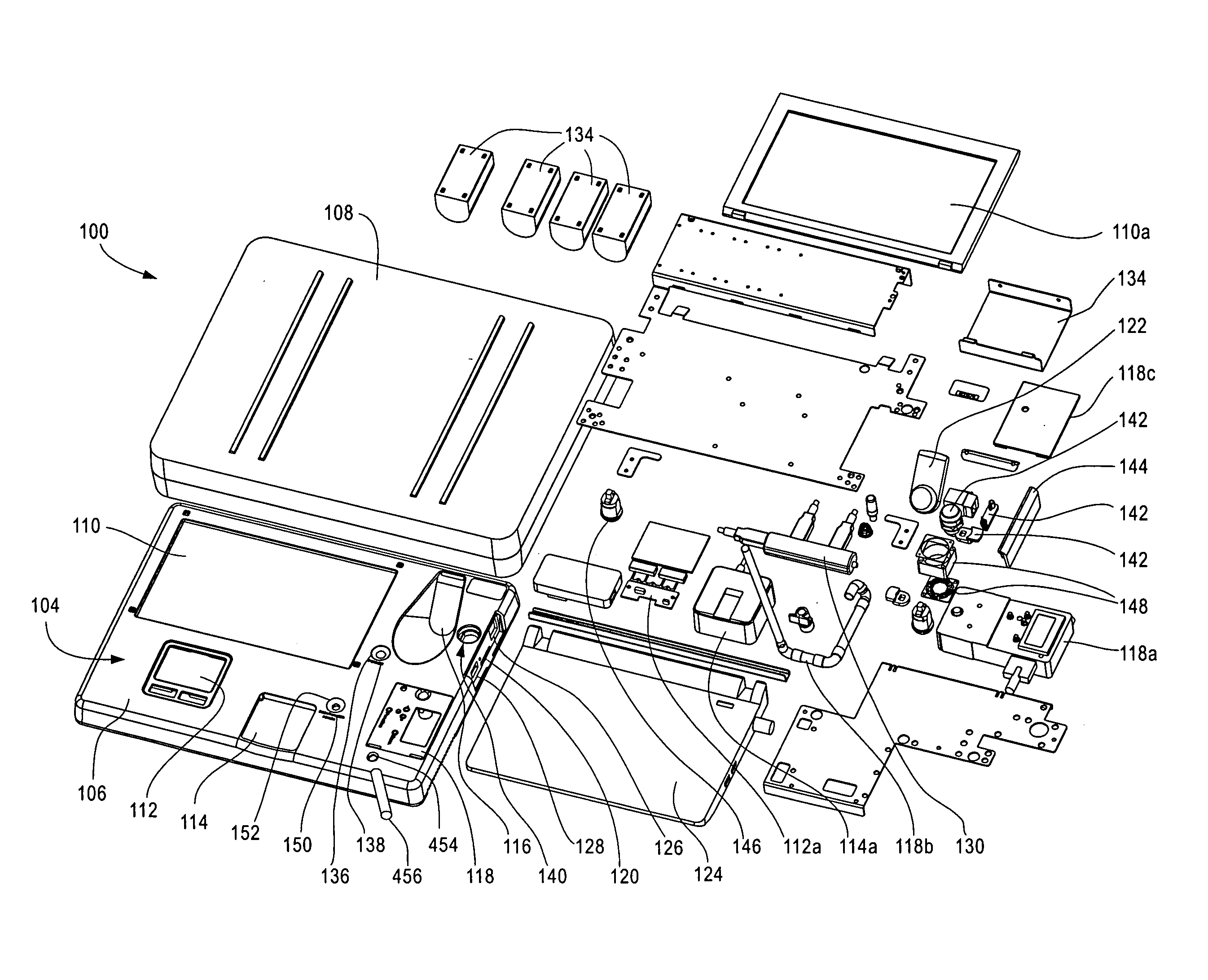

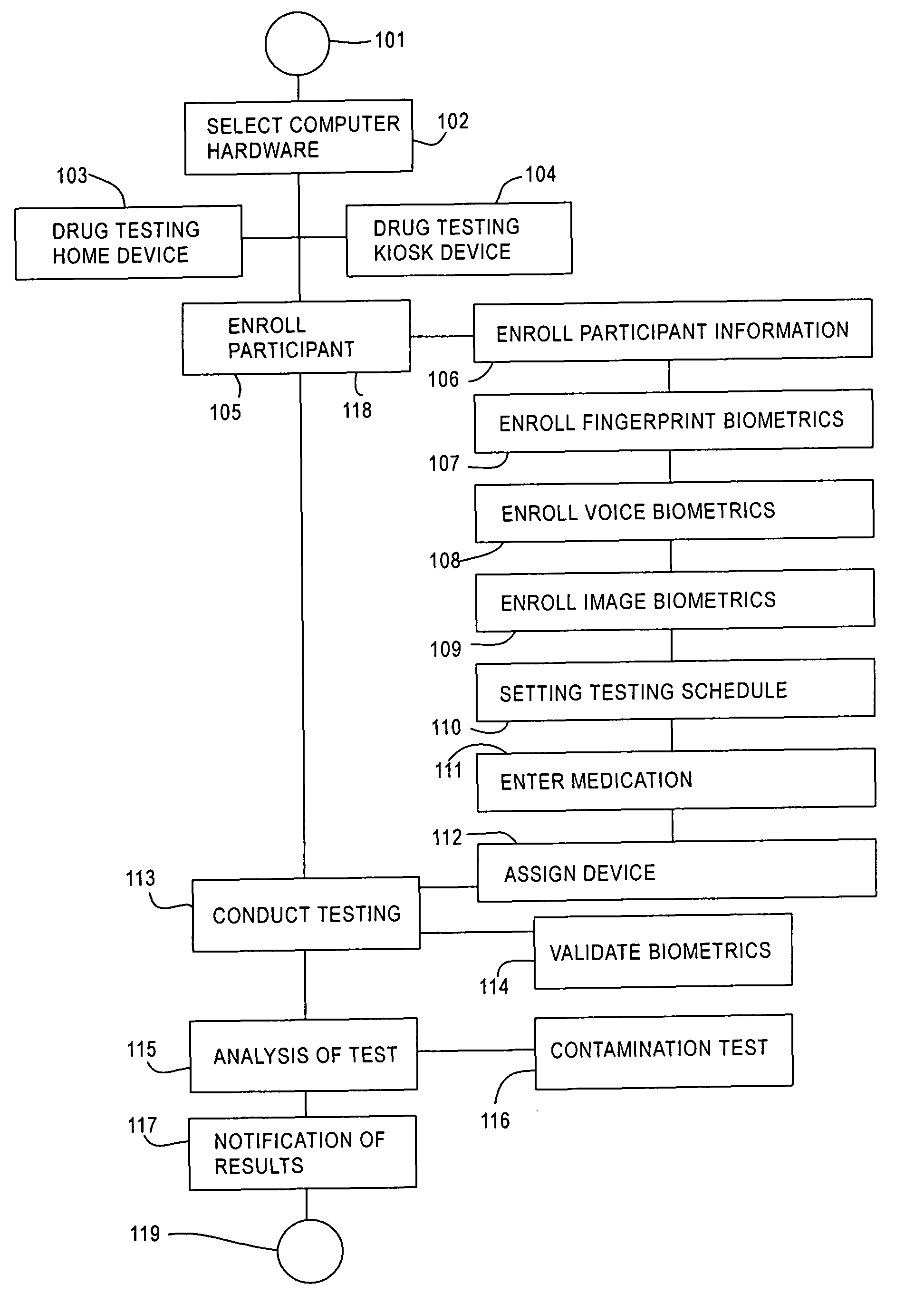

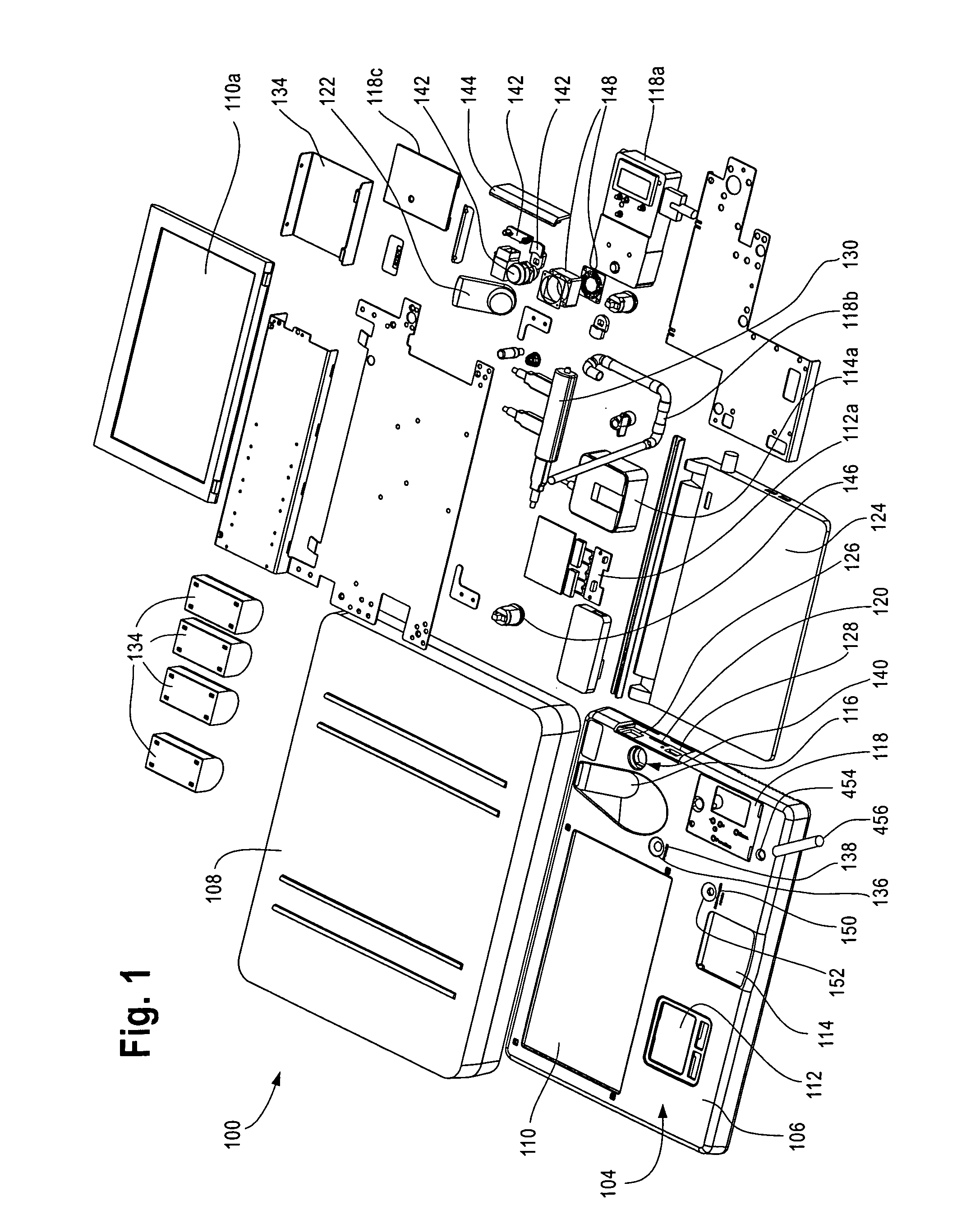

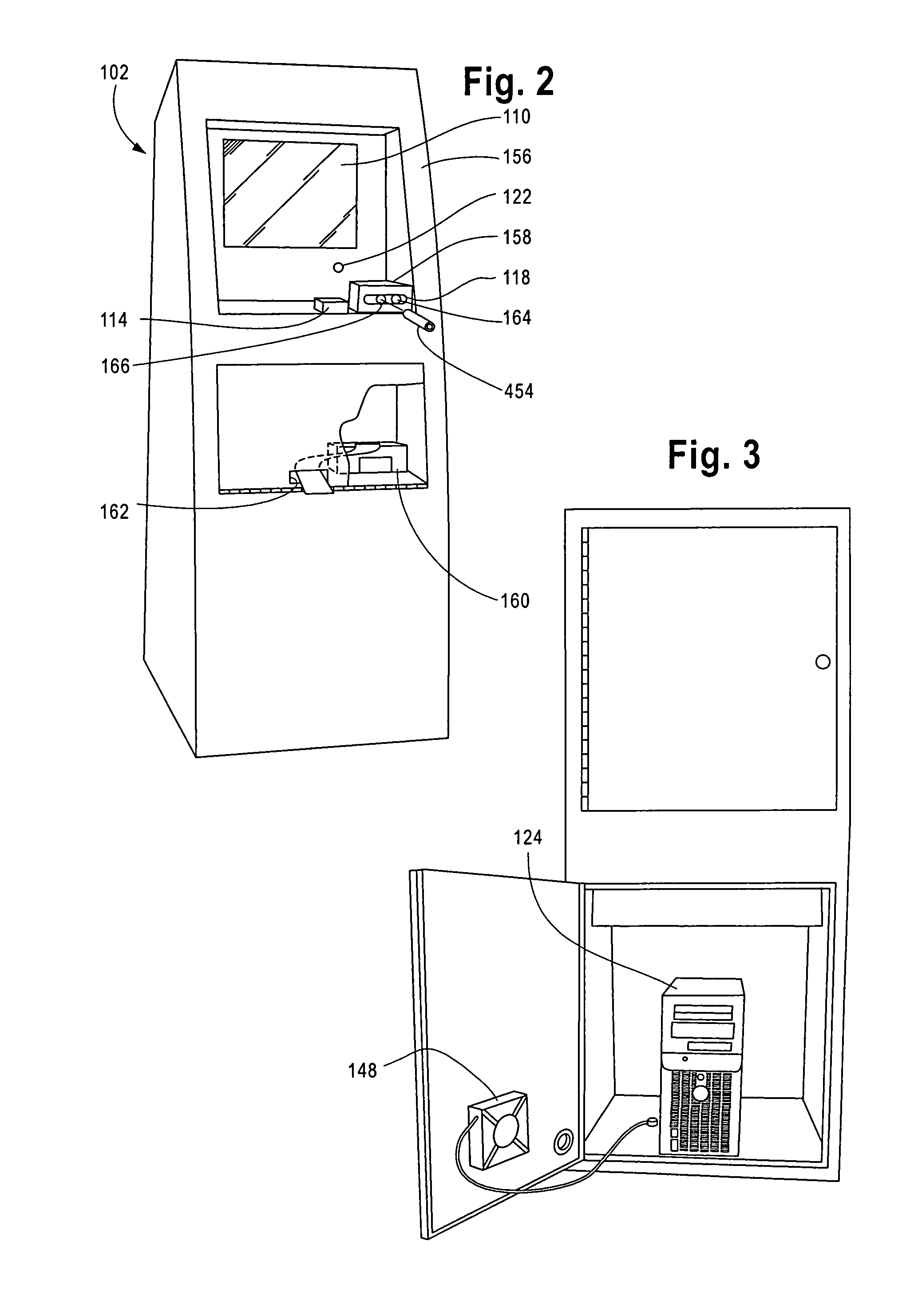

Apparatus and method for passive testing of alcohol and drug abuse

InactiveUS20100204600A1Digital data processing detailsPerson identificationCompound organicAlcohol and drug

An automated system and method for passive testing of alcohol and drug abuse. The system enters a participant or subject into the system who is to be monitored during a probationary or other program for alcohol or drug abuse offenders. The system provides a drug testing home device or a drug testing kiosk device for use by the participant. The system enrolls the biometrics information of the participant into the computer system (e.g., finger print, voice, image, volatile compound organic gas level, and pH level). When the participant is to be tested in accordance with a testing schedule, the system validates these same biometrics of the participant, conducts the test, and then analyzes the test information for determining if the participant has been using alcohol or other drugs and should be subjected to a confirming urinalysis exam.

Owner:JUSTICE EZ TRAC

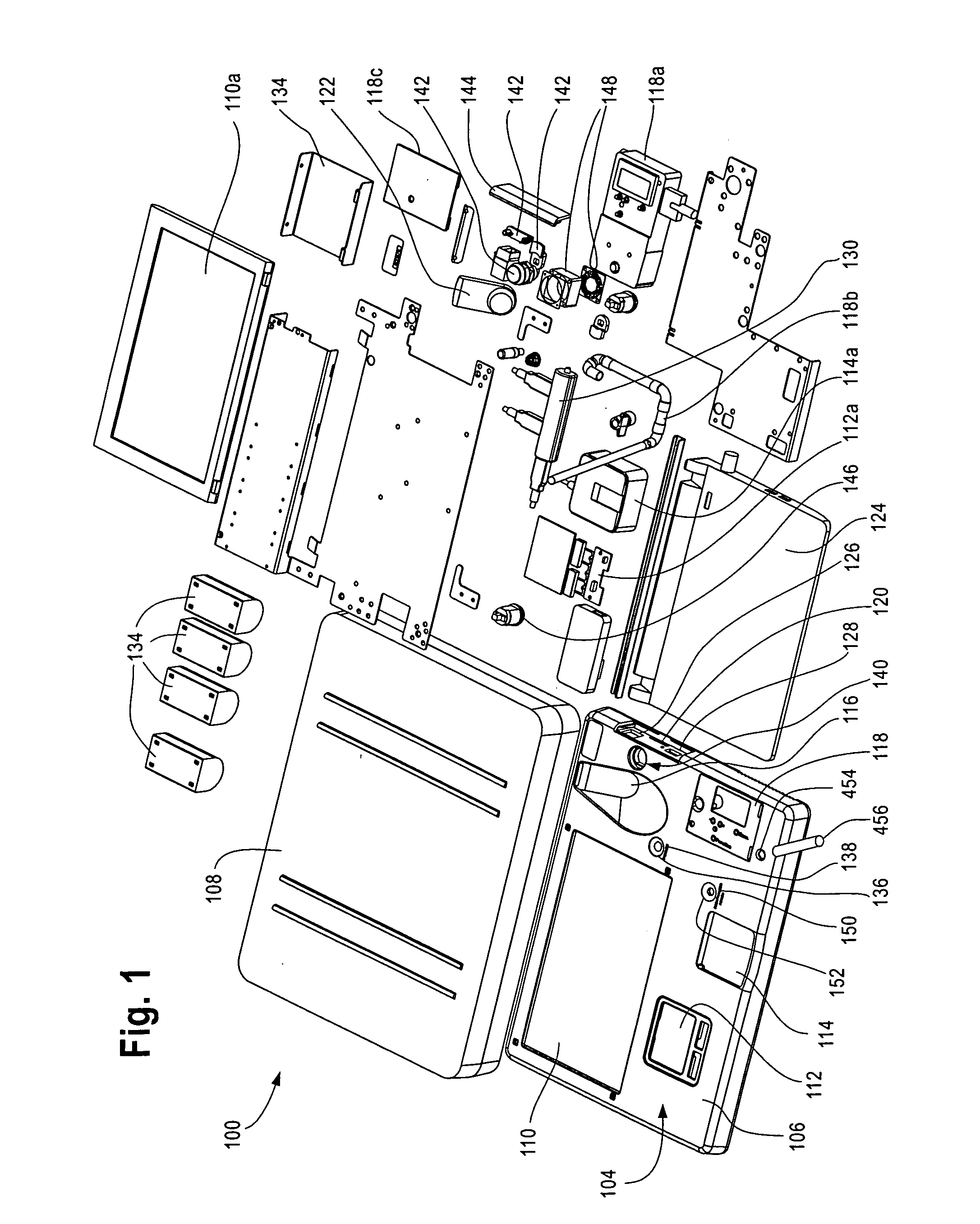

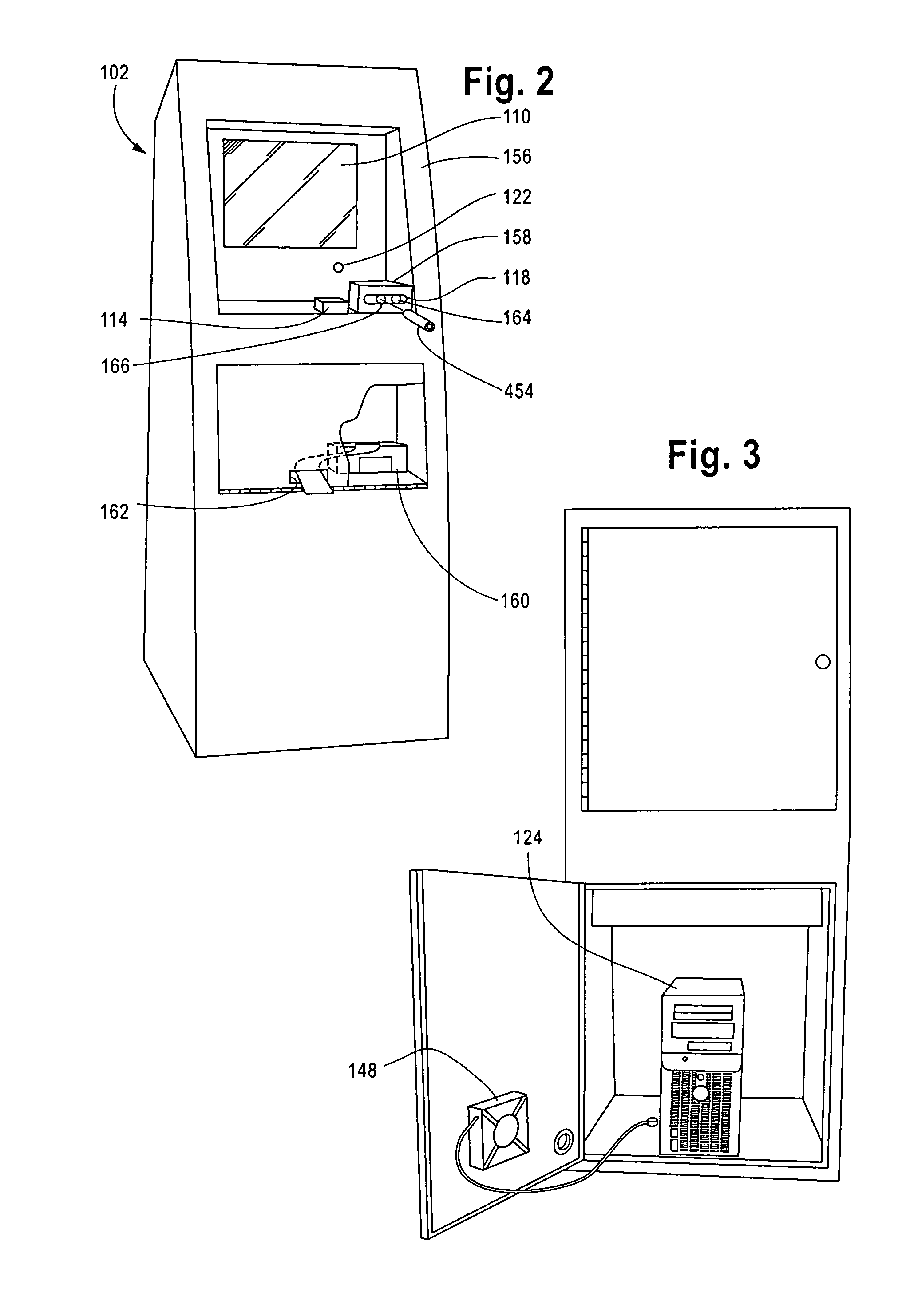

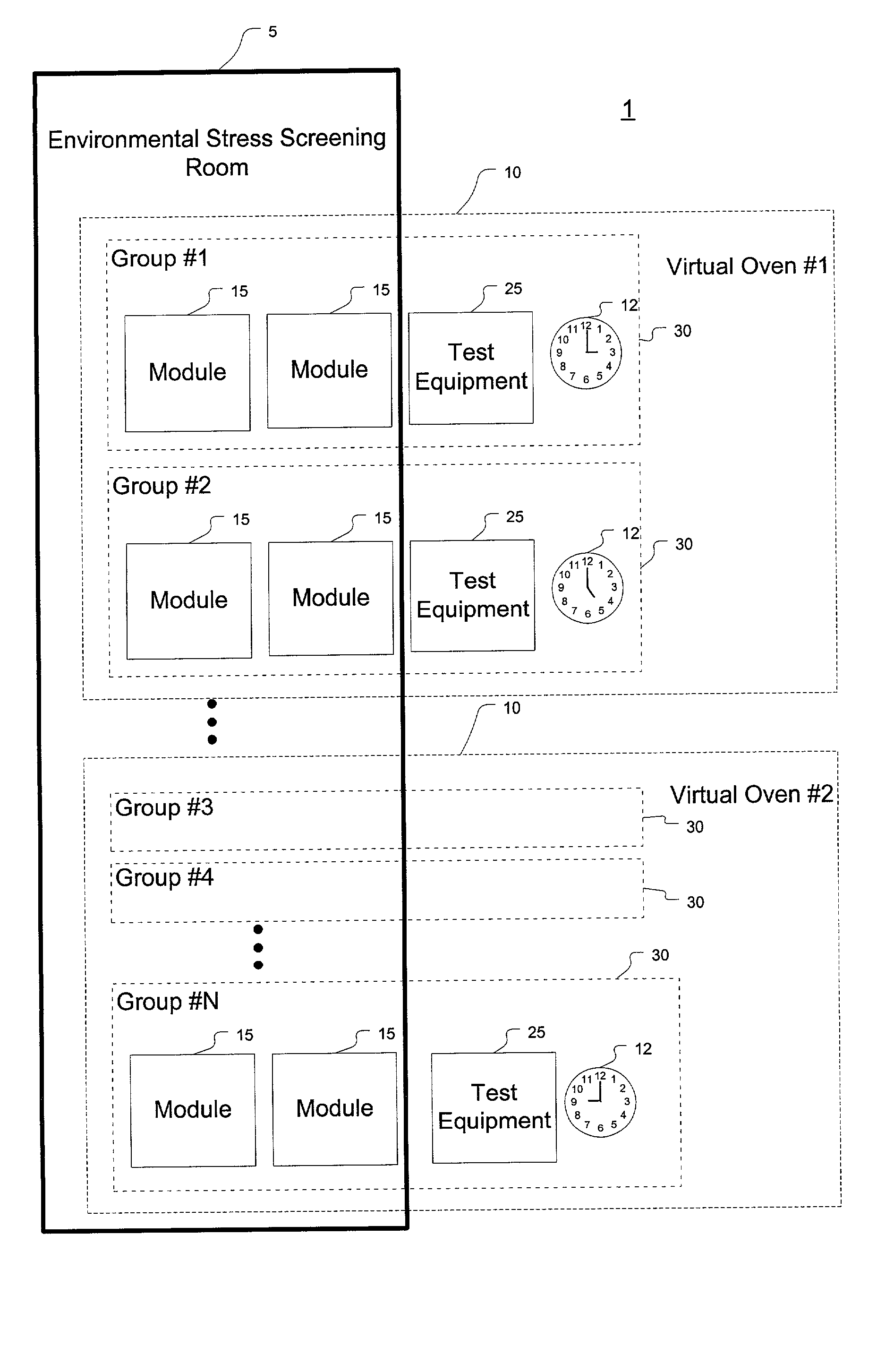

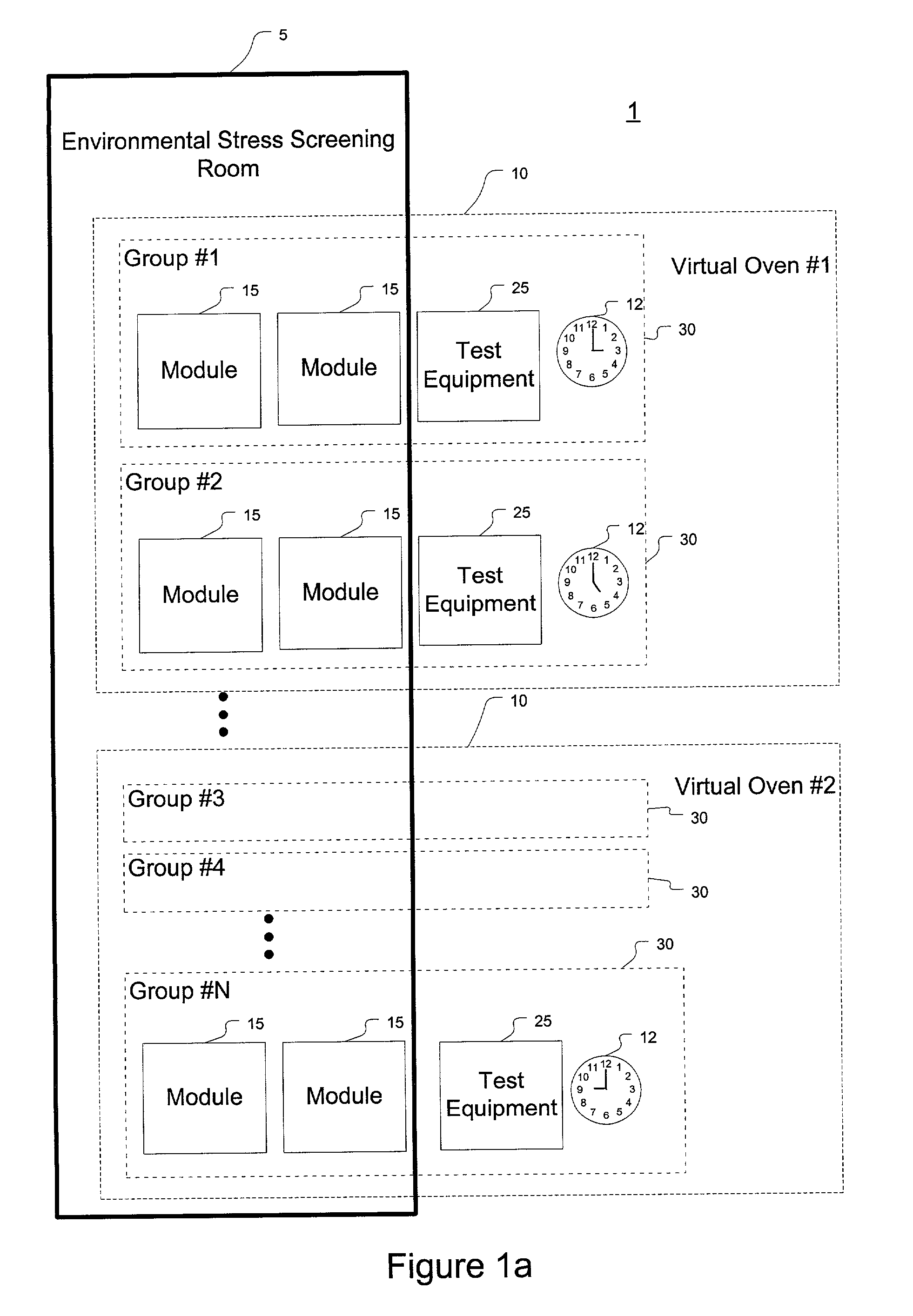

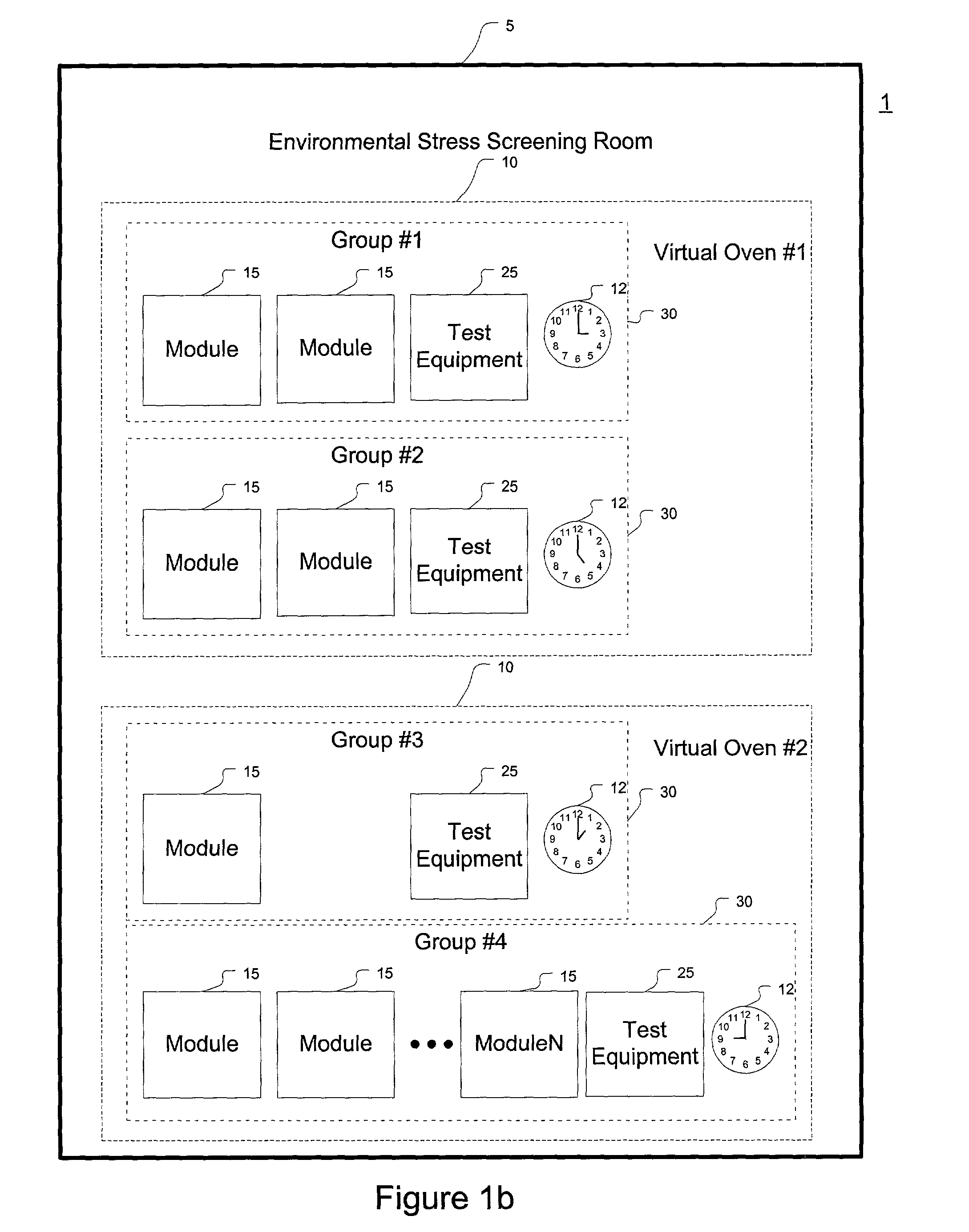

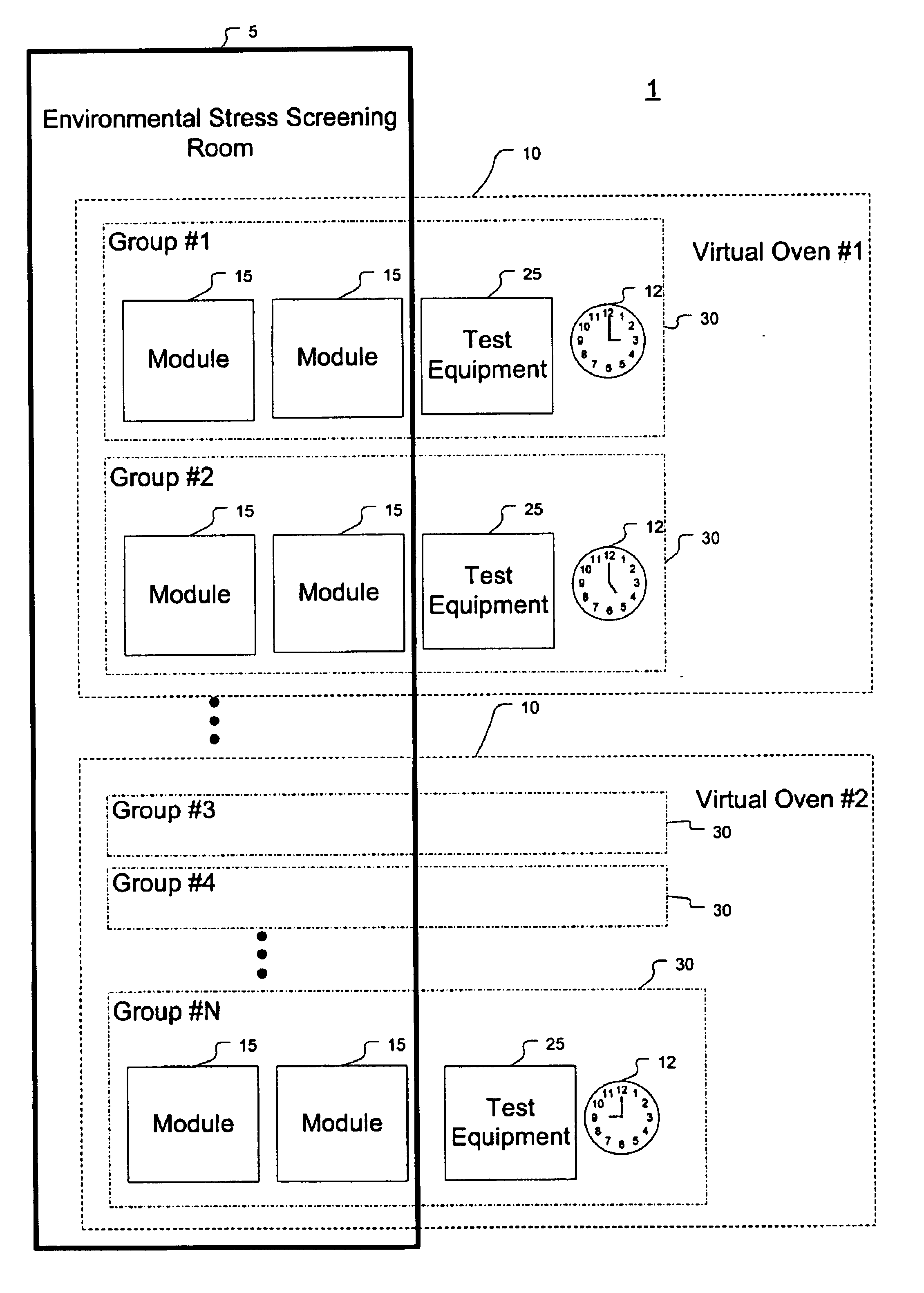

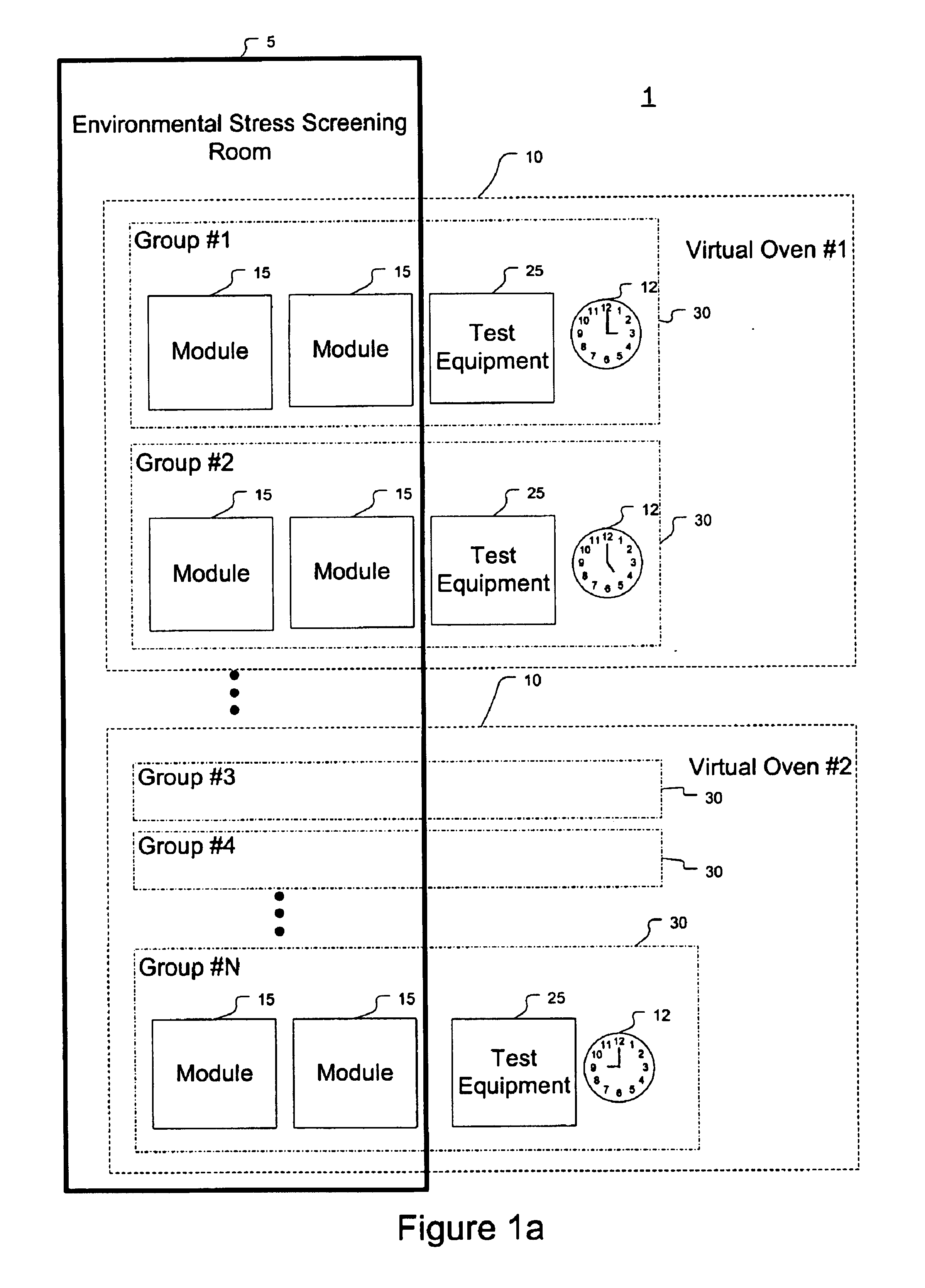

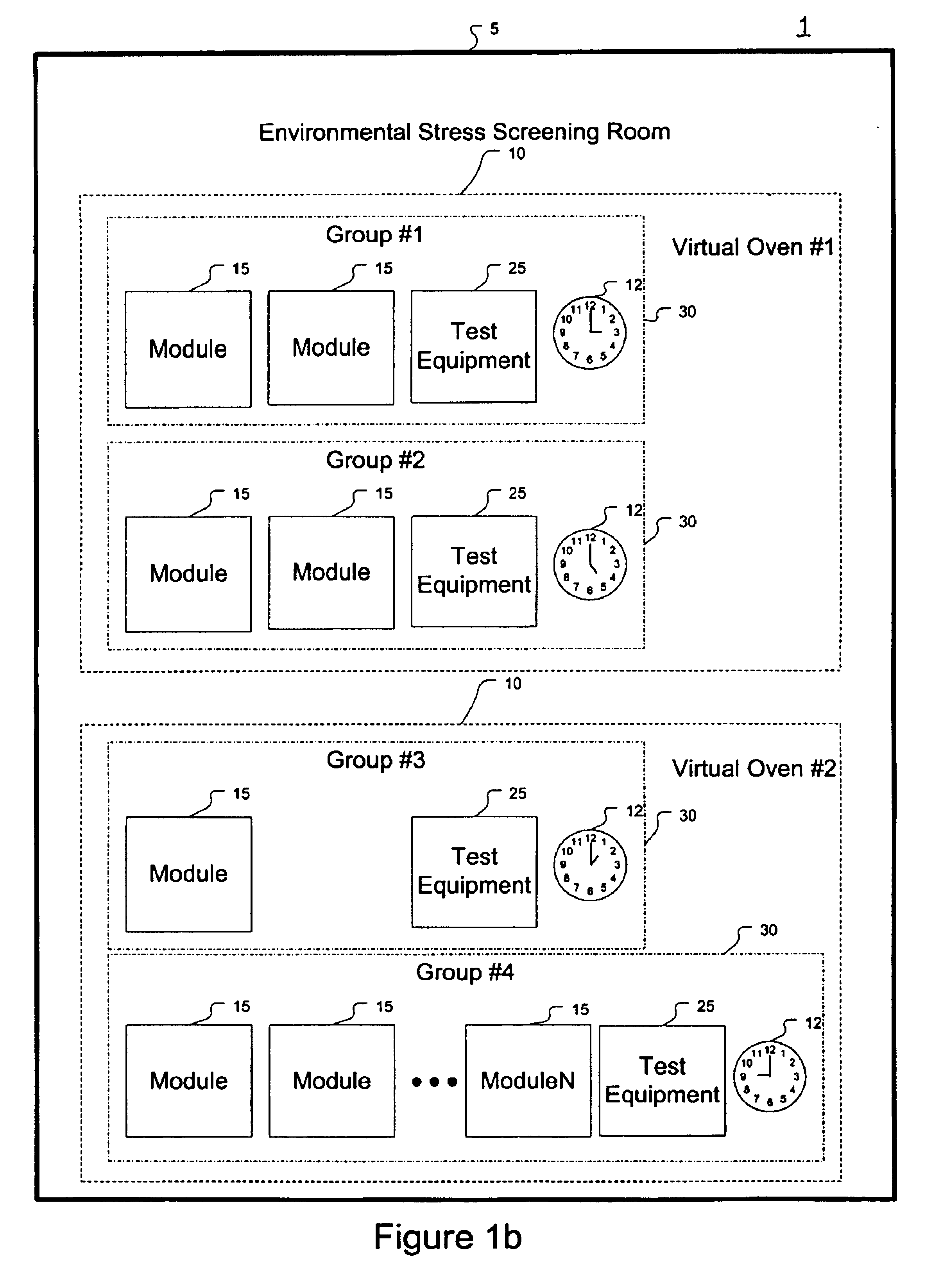

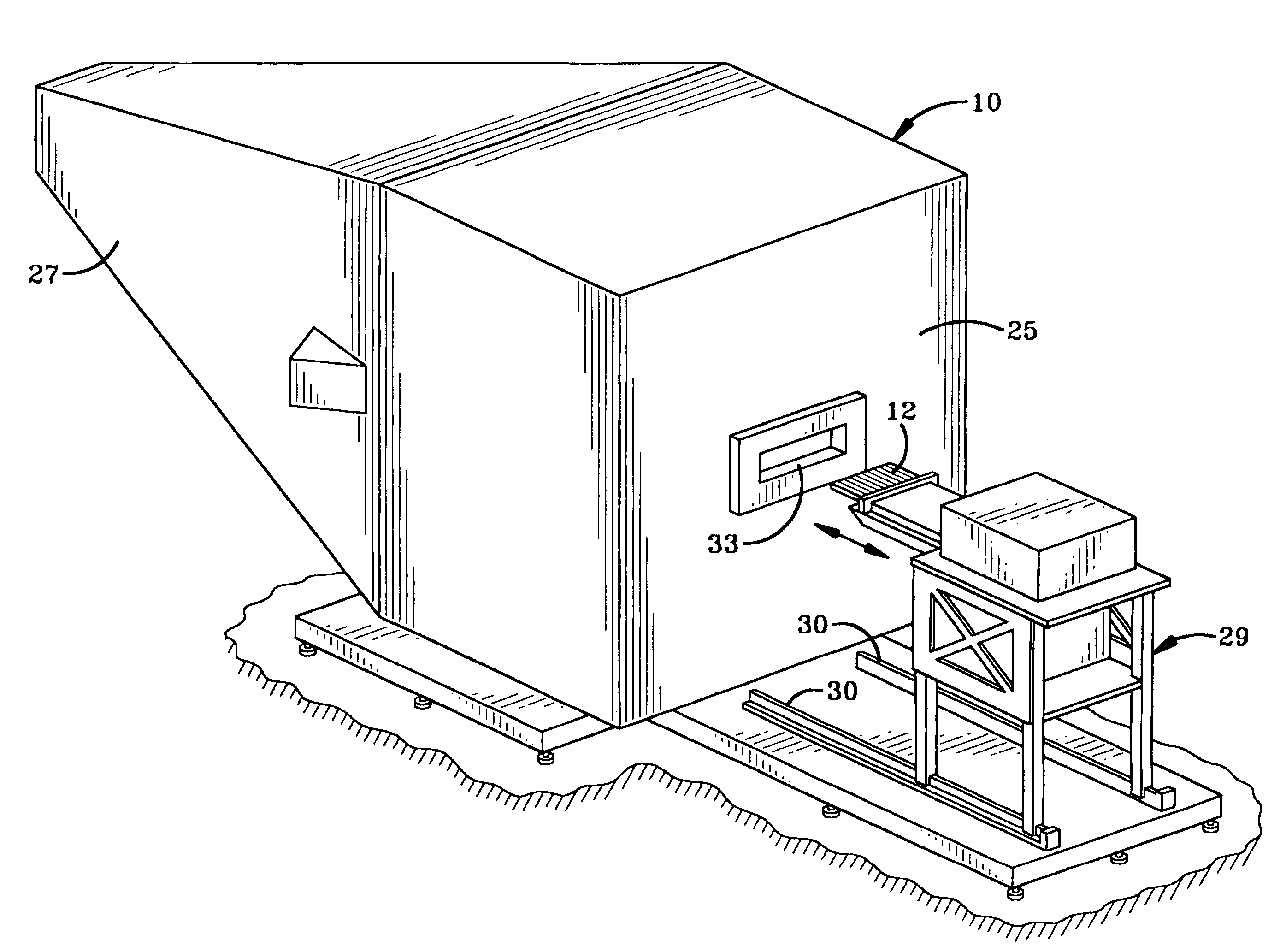

Automated monitoring system, virtual oven and method for stress testing logically grouped modules

InactiveUS20020105355A1Data processing applicationsResistance/reactance/impedenceComputer hardwareNetwork connection

A virtual oven efficiently conducts stress testing of large numbers of modules. The virtual oven includes a logical grouping of modules, a controller, test instruments and a database which are all connected via a network. The logical groupings of modules of several virtual ovens may be physically accommodated within a single environmental stress screening room. Switching between modules in a logical group permits a single test piece of test equipment to be time-shared among the modules in the logical group. The method of bum-in testing a logical group of modules rotates a test sequence, including passive and active test cycles, between the modules. A test signal is split and supplied to multiple modules. Passive testing may be performed by monitoring parameters of the module while the test signal is supplied to the module. Active testing may be a functional test of the module in which the test signal is supplied to, processed by, and output from the module. Such test signals output from the modules are switched to the test equipment on a time-share basis. In this way, the number or expensive test equipment set-ups may reduced. The controller for each virtual oven also generates displays so that a user can track the test progress of all modules within the virtual oven. The controller also builds a database of the active and passive tests for each module. A graphical user interface may be used to interact with the virtual oven, control the testing, and view the database.

Owner:CIENA

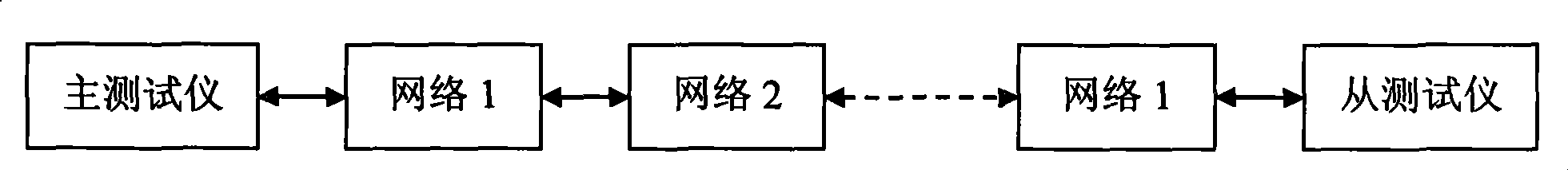

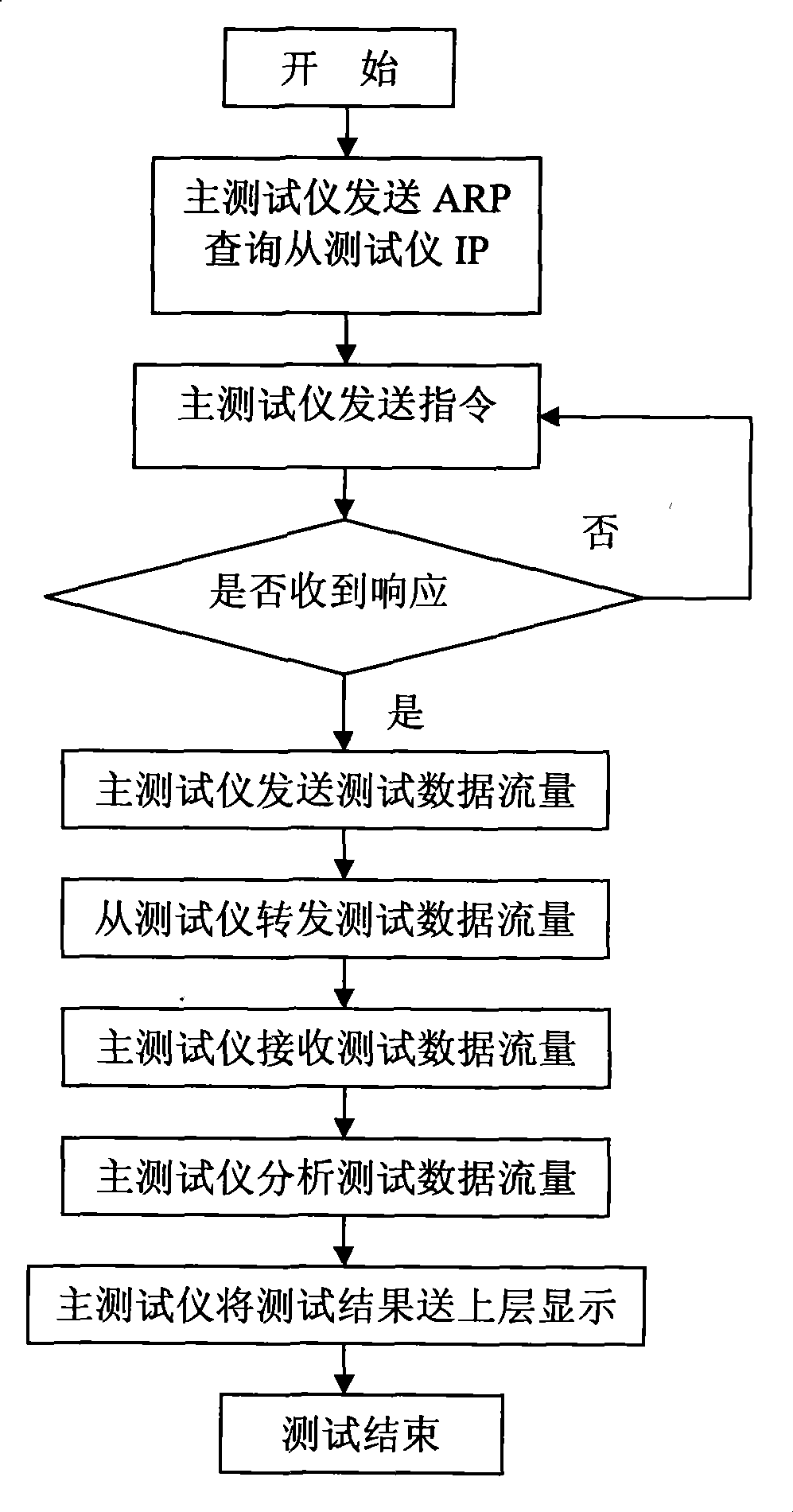

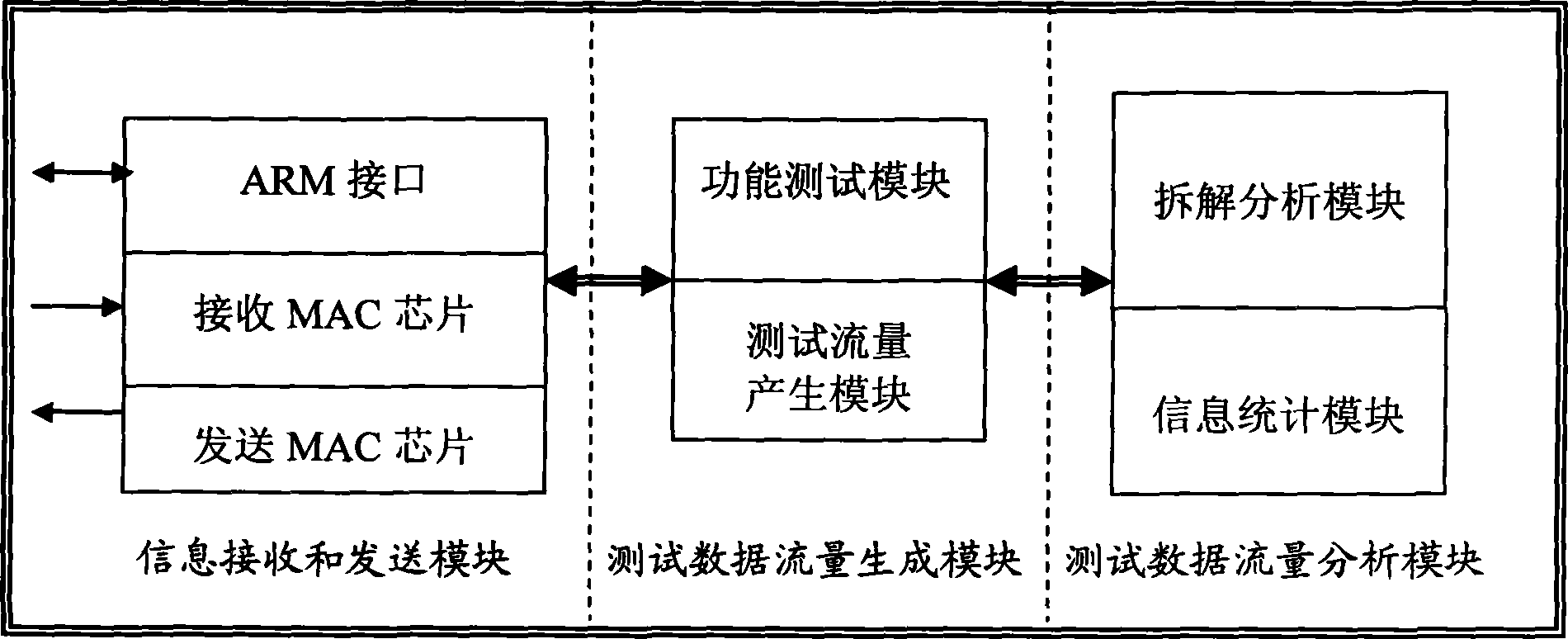

Method and device for testing Ethernet network performance

InactiveCN101521607AGet network performance metricsImprove versatilityData switching networksTraffic capacityPassive testing

The invention relates to a method and a device for testing the Ethernet network performance. In order to overcome the defects that the network performance can not be tested by actively transmitting testing data flux, special performance indexes of some networks can not be tested, and the like in the network performance testing method in the prior art, the invention provides a method and a device which can test the Ethernet network performance by transmitting and receiving the testing data flux. The method and the device for testing the Ethernet network performance overcome the shortage of a passive testing method, effectively obtain Ethernet network performance indexes, and achieve good universality and expandability because connection among FPGA technique and peripheral devices uses a universal MAC chip and an ARM interface.

Owner:重庆重邮汇测通信技术有限公司

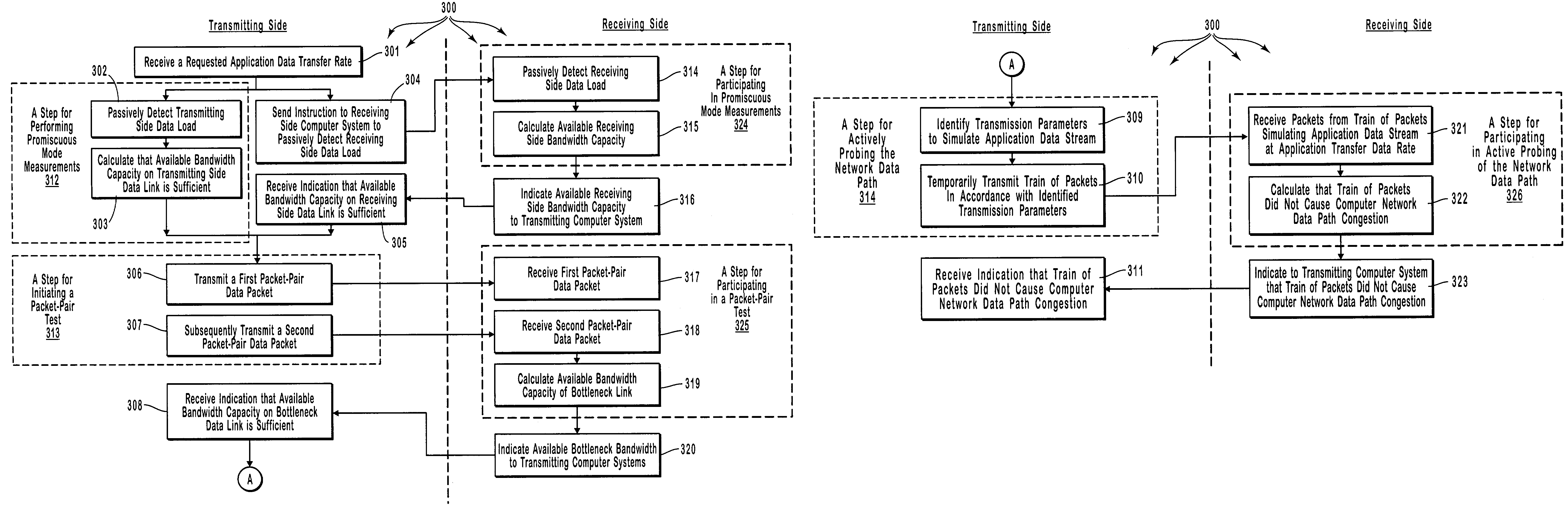

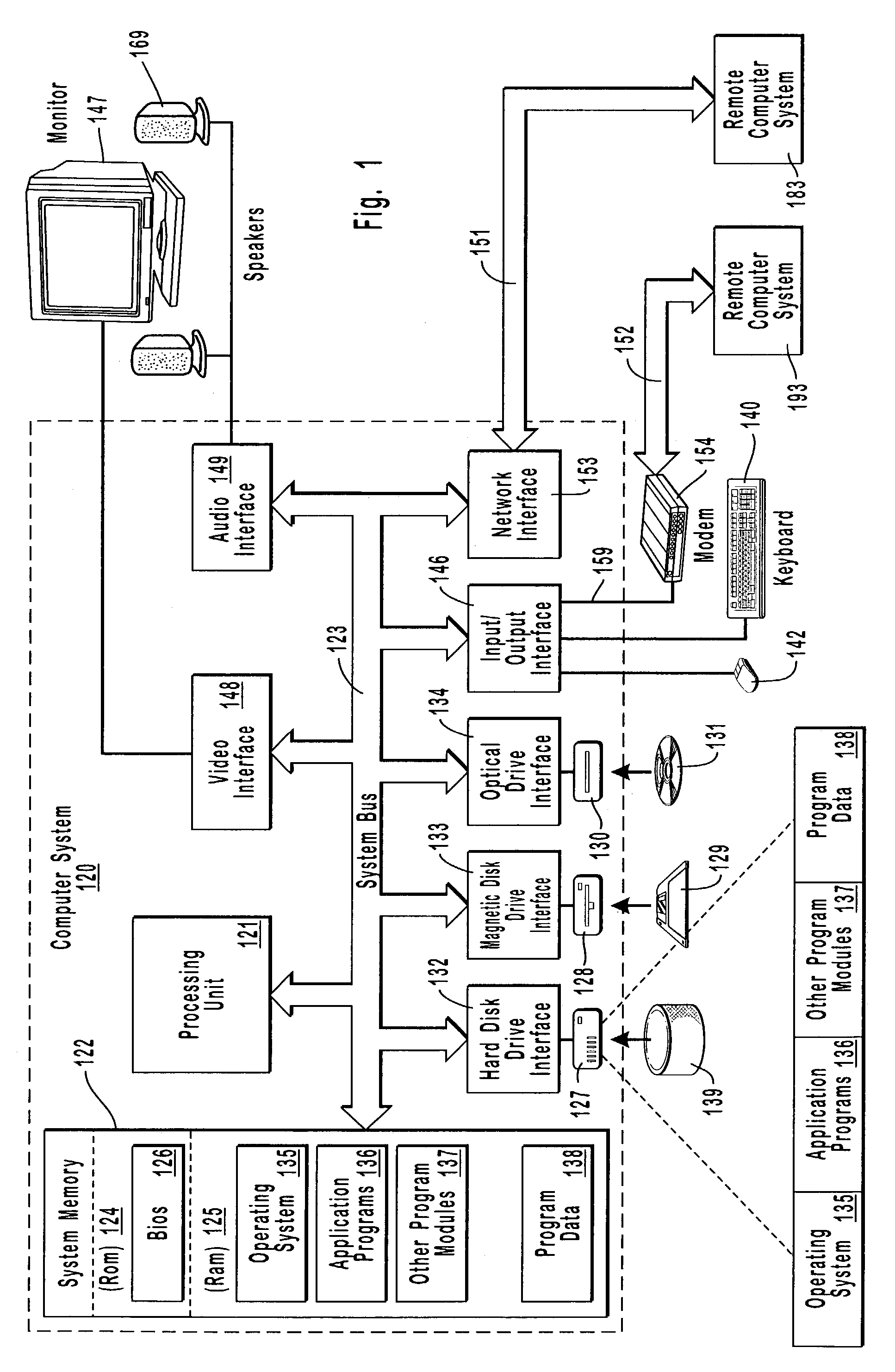

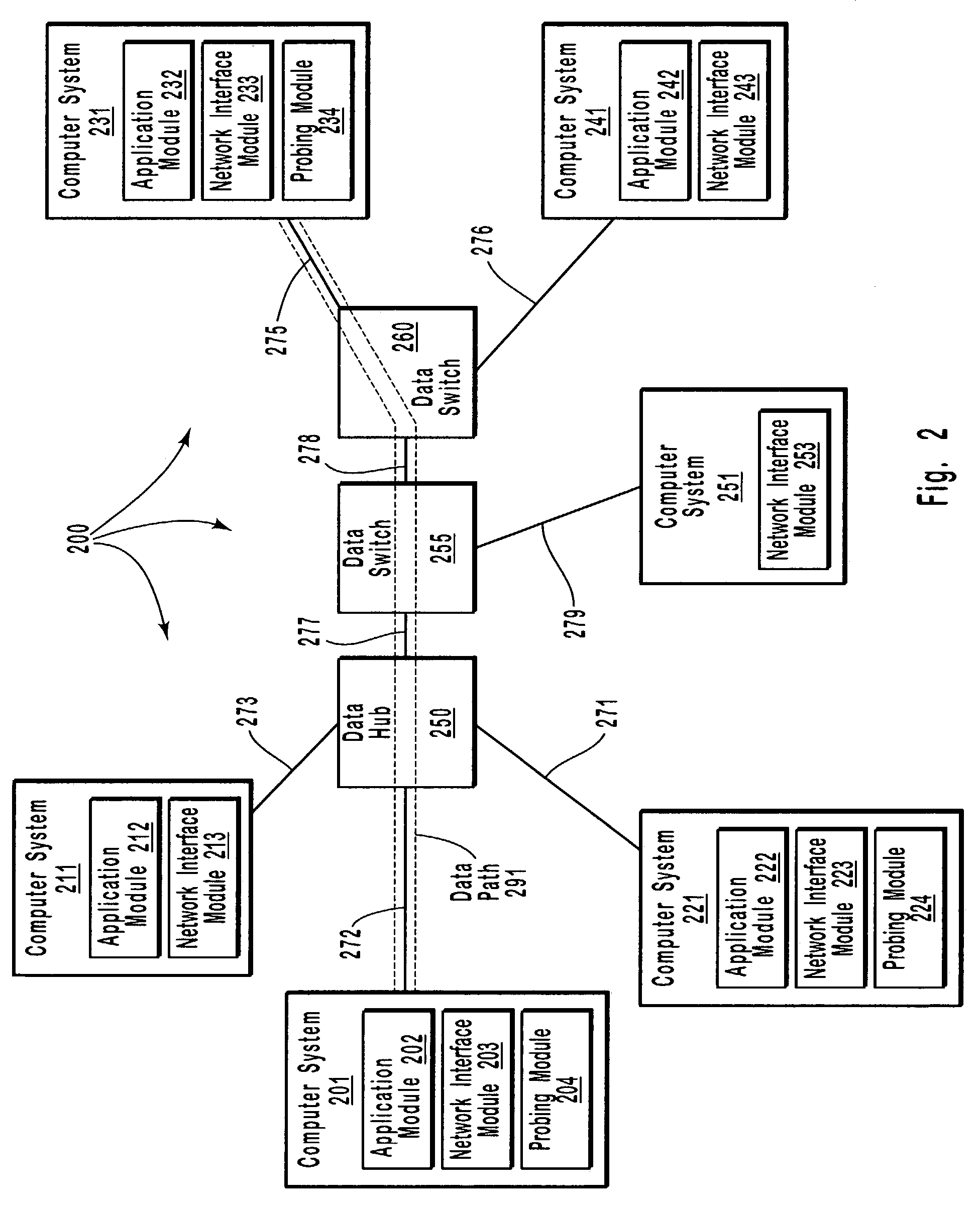

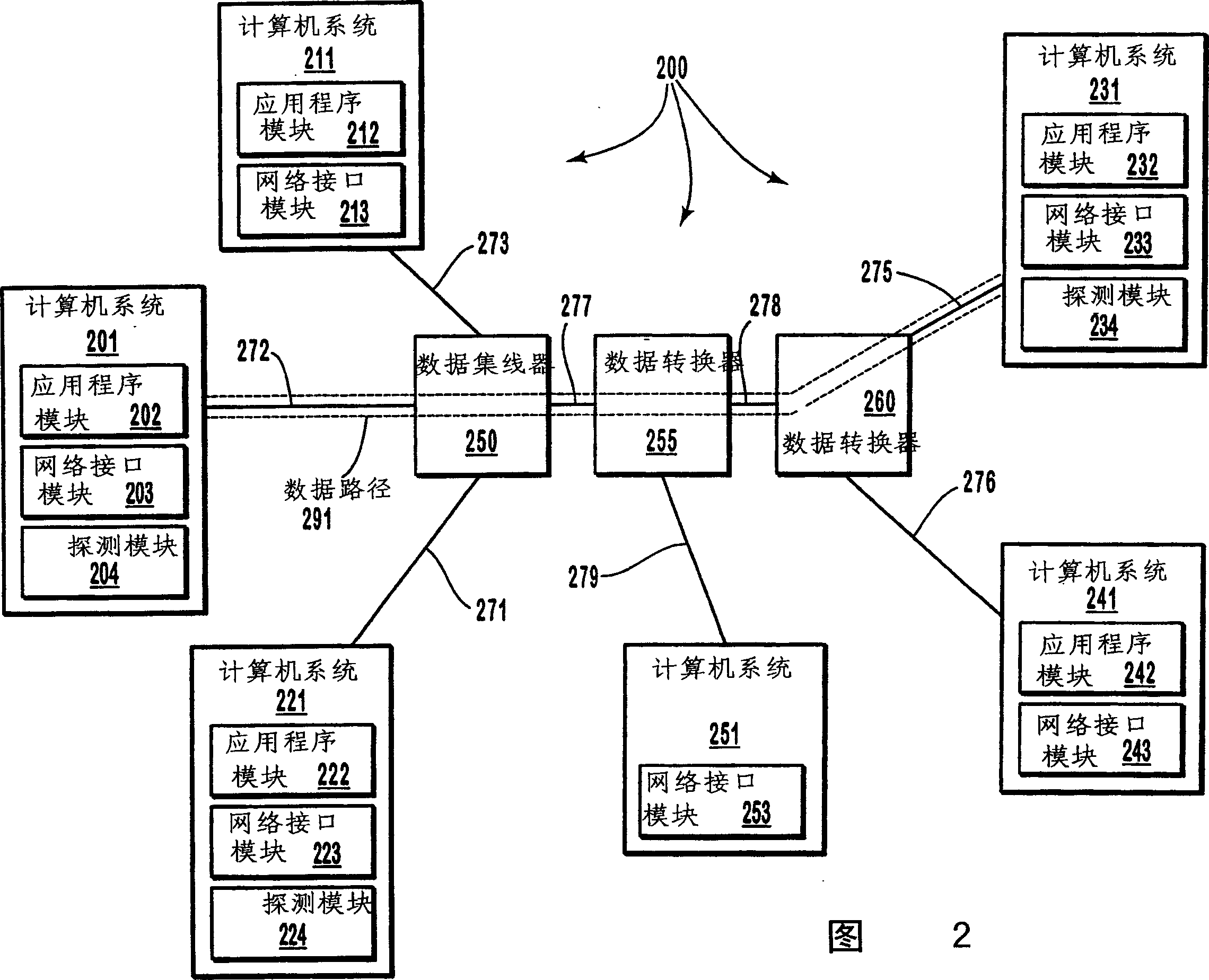

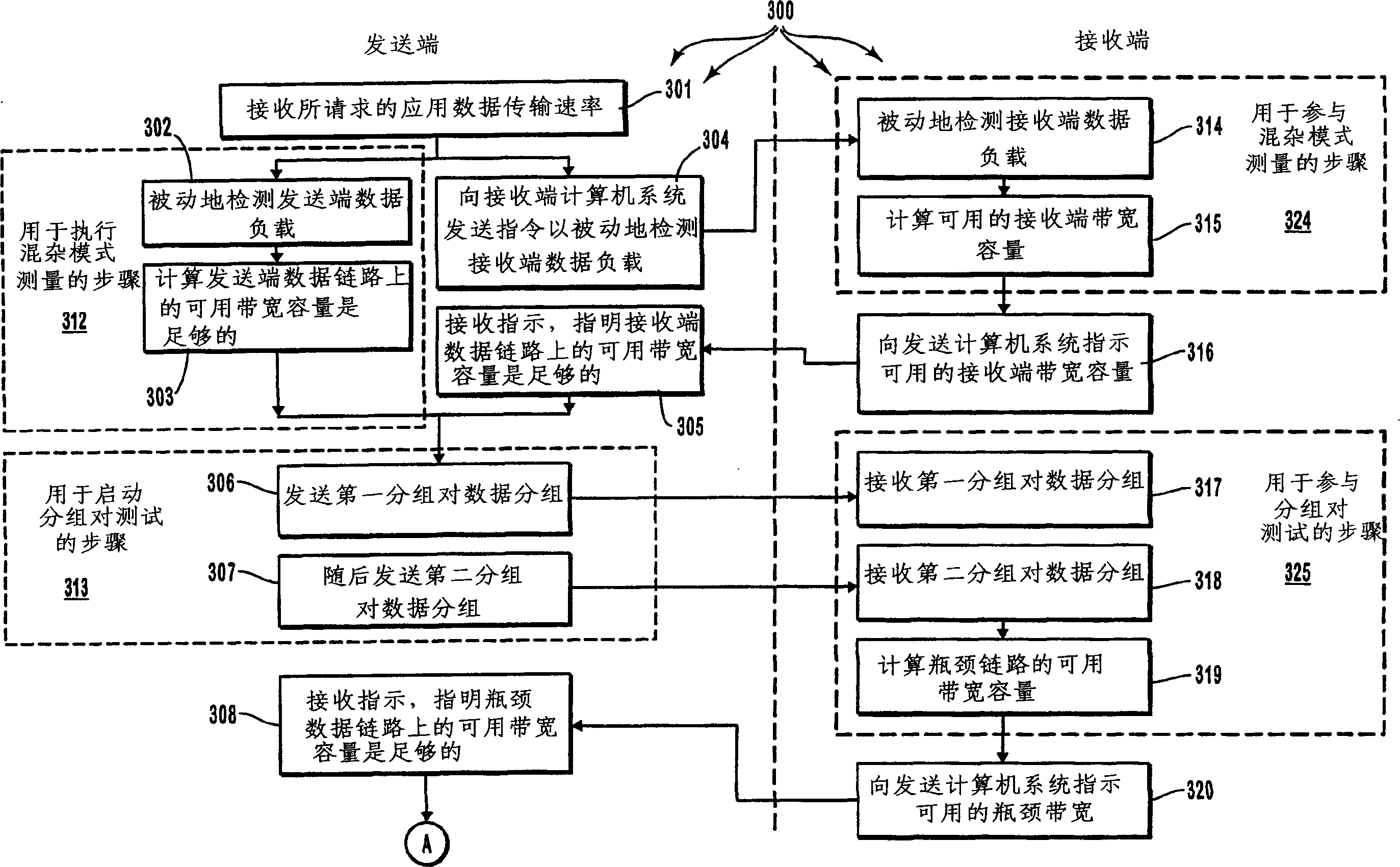

Controlling admission of data streams onto a network based on end-to-end measurements

Appropriate determinations in a series of tests, which transition from more passive tests to more active tests, control the admission of data streams onto a network data path. More passive tests can include promiscuous mode and packet-pair tests. When the results of more passive tests indicate a reduce likelihood of a data stream causing a network data path to transition into a congested state, the network data path can be actively probed to make a more precise determination on the likelihood of congestion. A train of diagnostic data packets is transmitted at a diagnostic data transfer rate having a significantly reduced chance of causing congestion. A train of target data packets is transmitted at a requested application transfer data rate. The number of target data packets received within a specified delay threshold is compared to the number of diagnostic data packets receive with the delay threshold.

Owner:MICROSOFT TECH LICENSING LLC

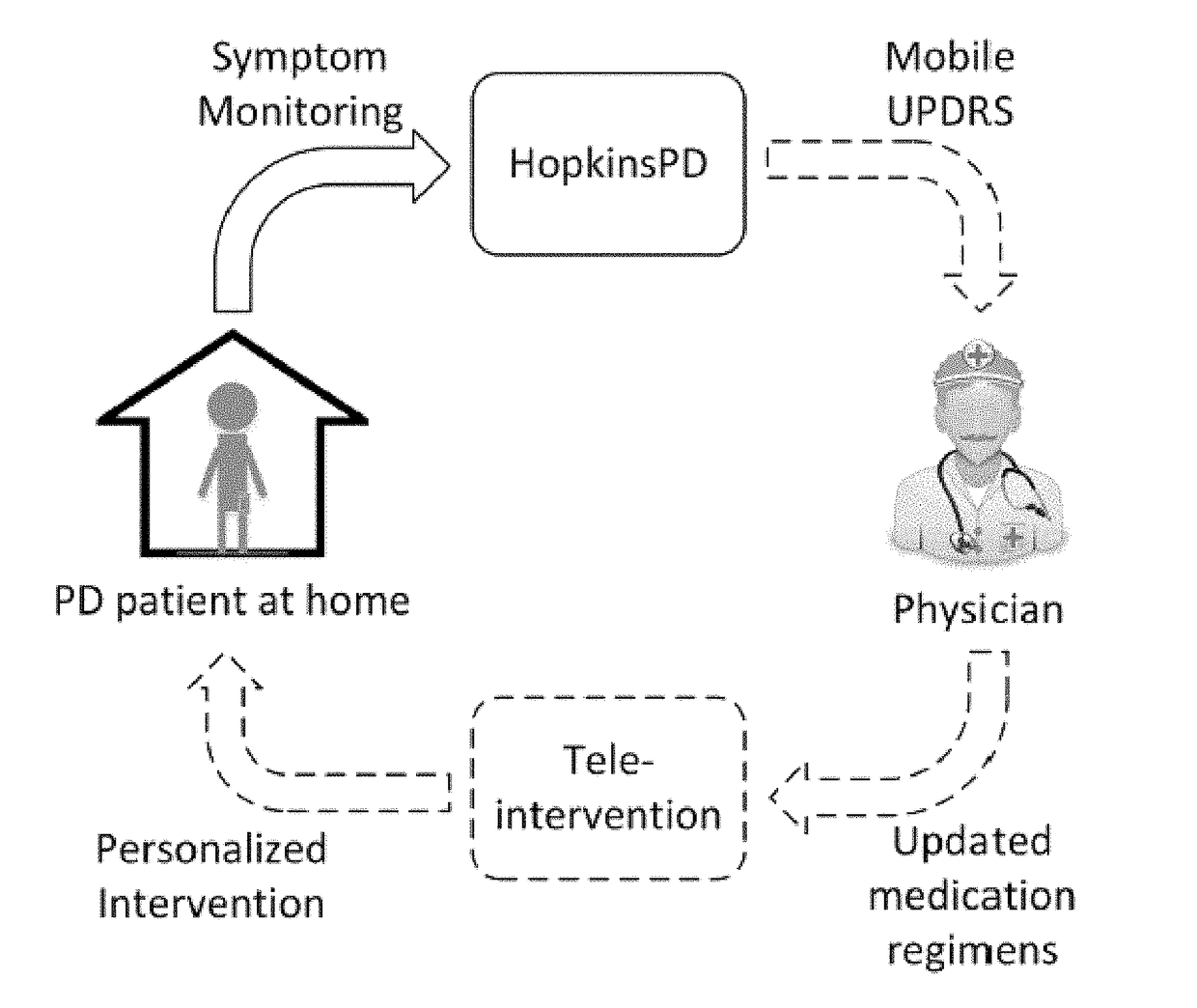

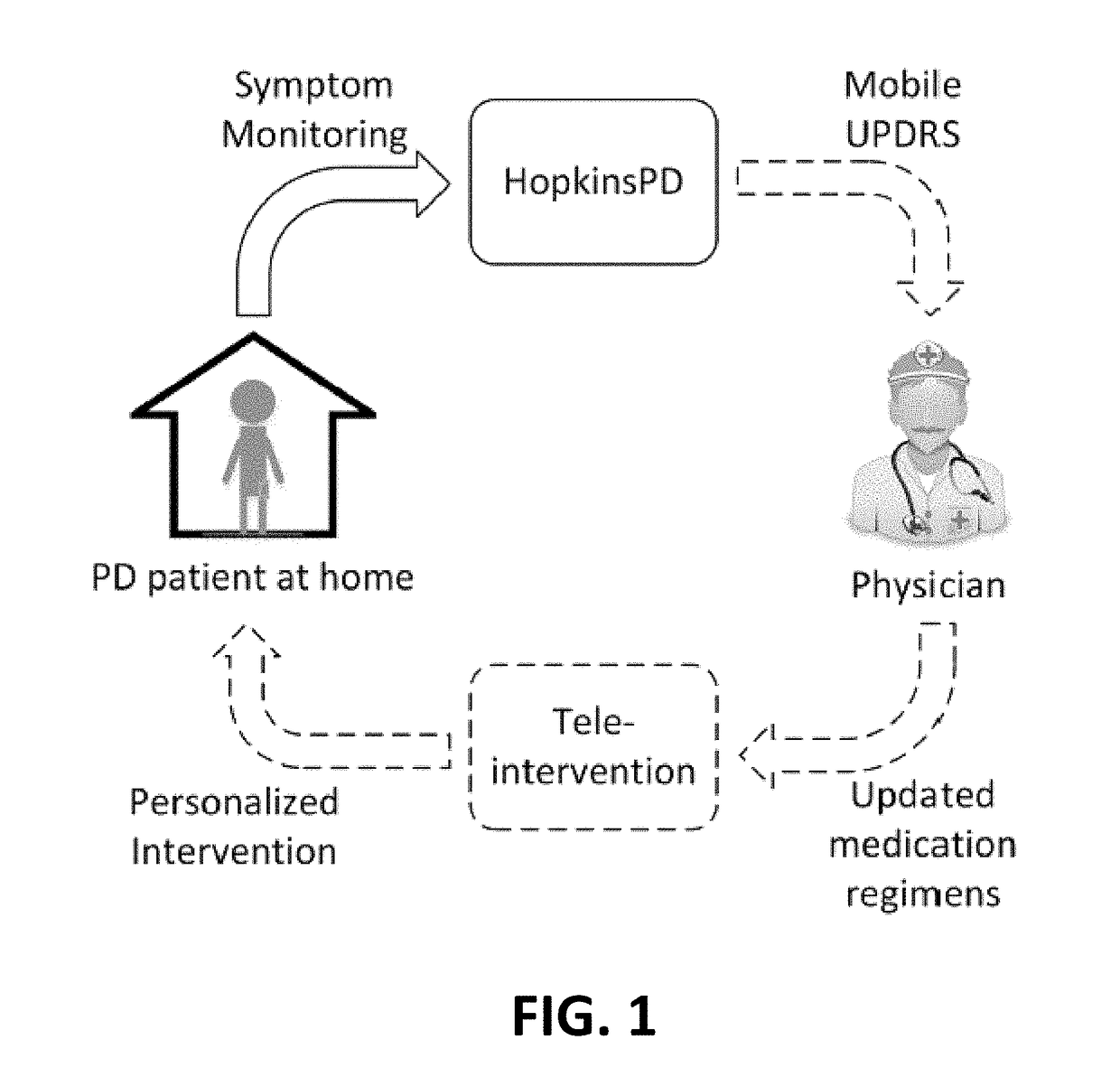

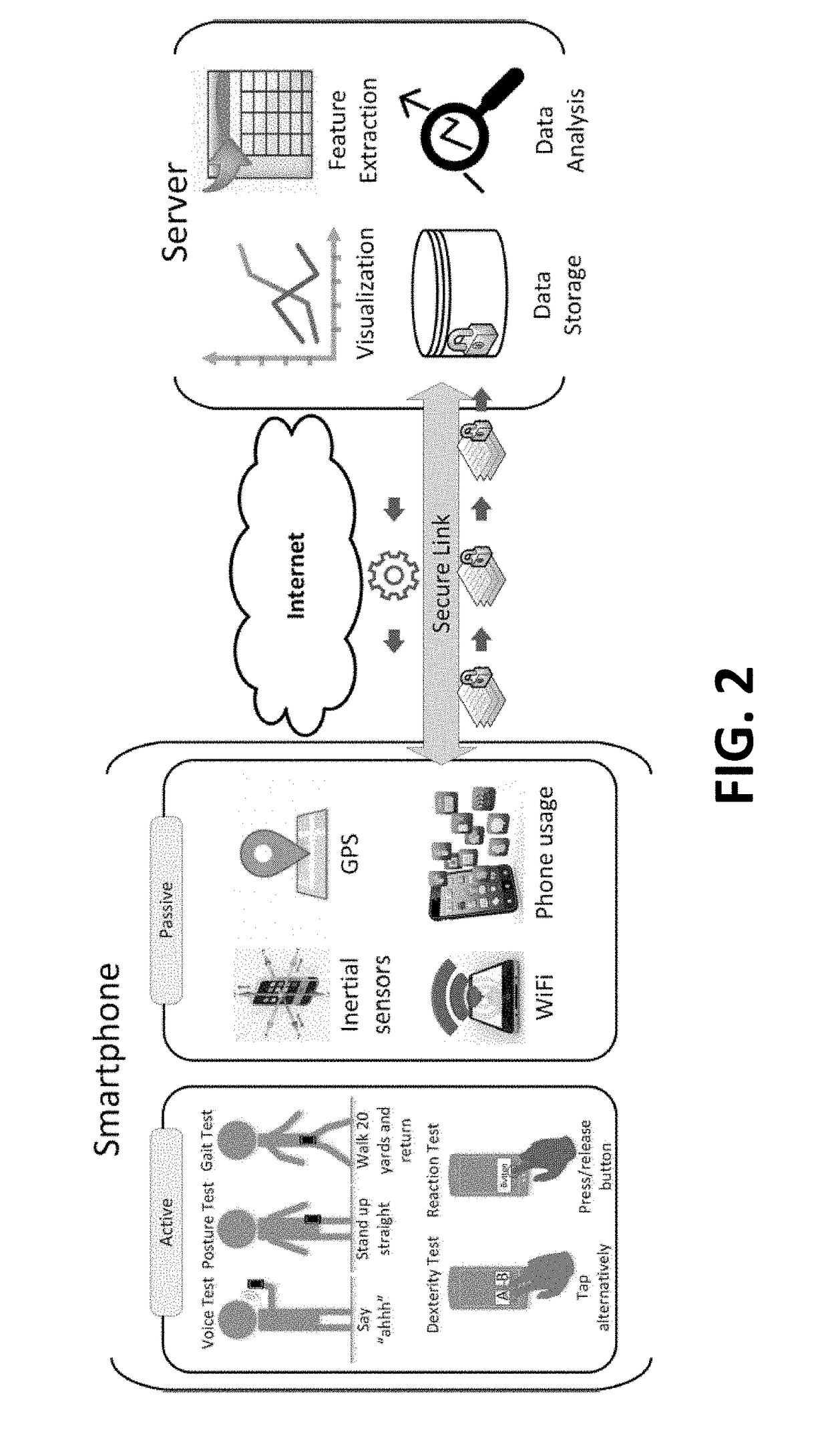

Measuring medication response using wearables for parkinson's disease

An embodiment in accordance with the present invention includes a smartphone based platform that can be used to objectively and remotely measure aspects related to PD (e.g., voice, balance, dexterity, gait, and reaction time), activities of daily living, and PD medicine response. The present invention includes a unified PD-specific remote monitoring platform that incorporates both active and passive tests to provide high frequency monitoring of symptoms and activities of daily living related to PD and medicine response. The platform of the present invention does not require specialized medical hardware.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

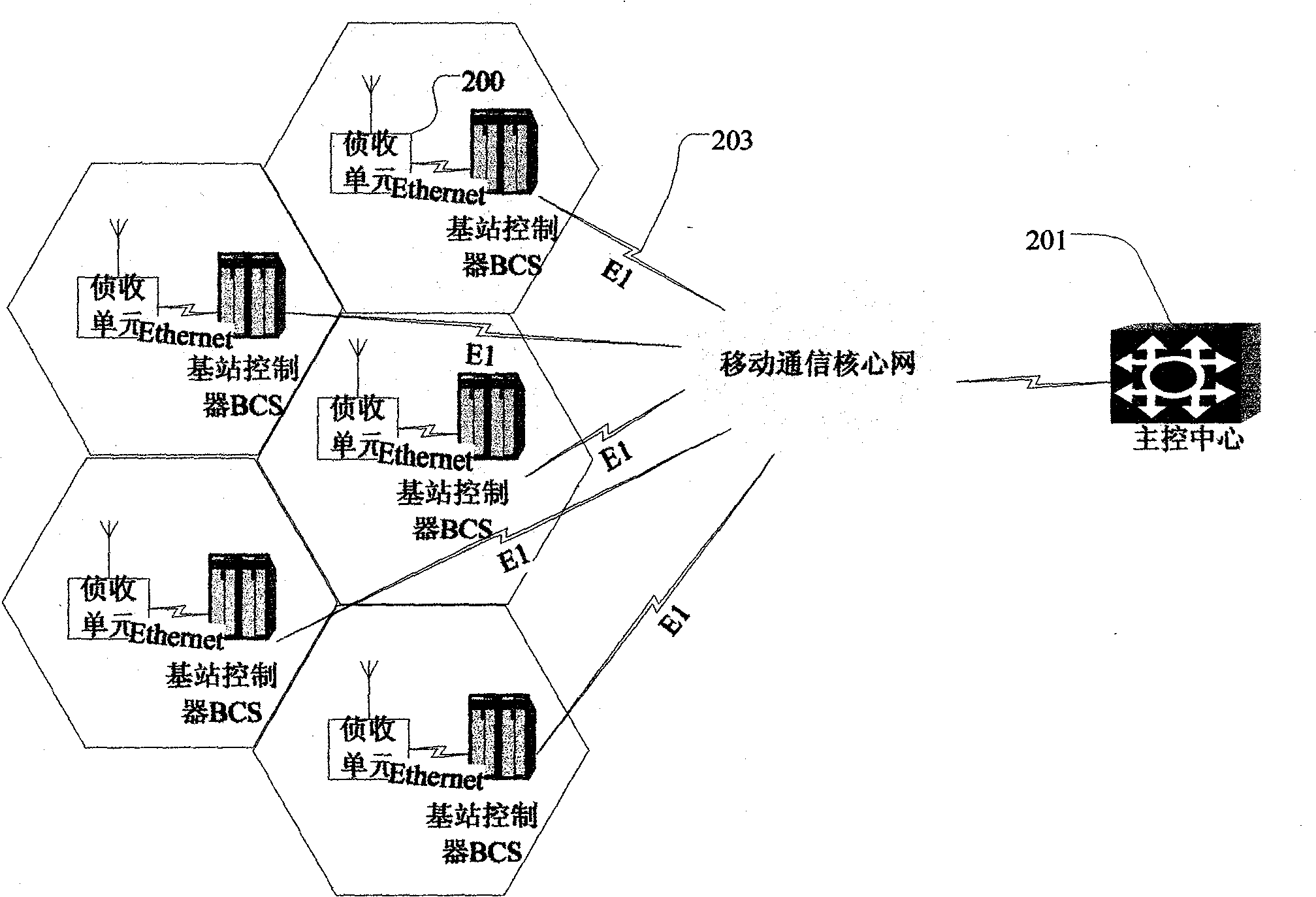

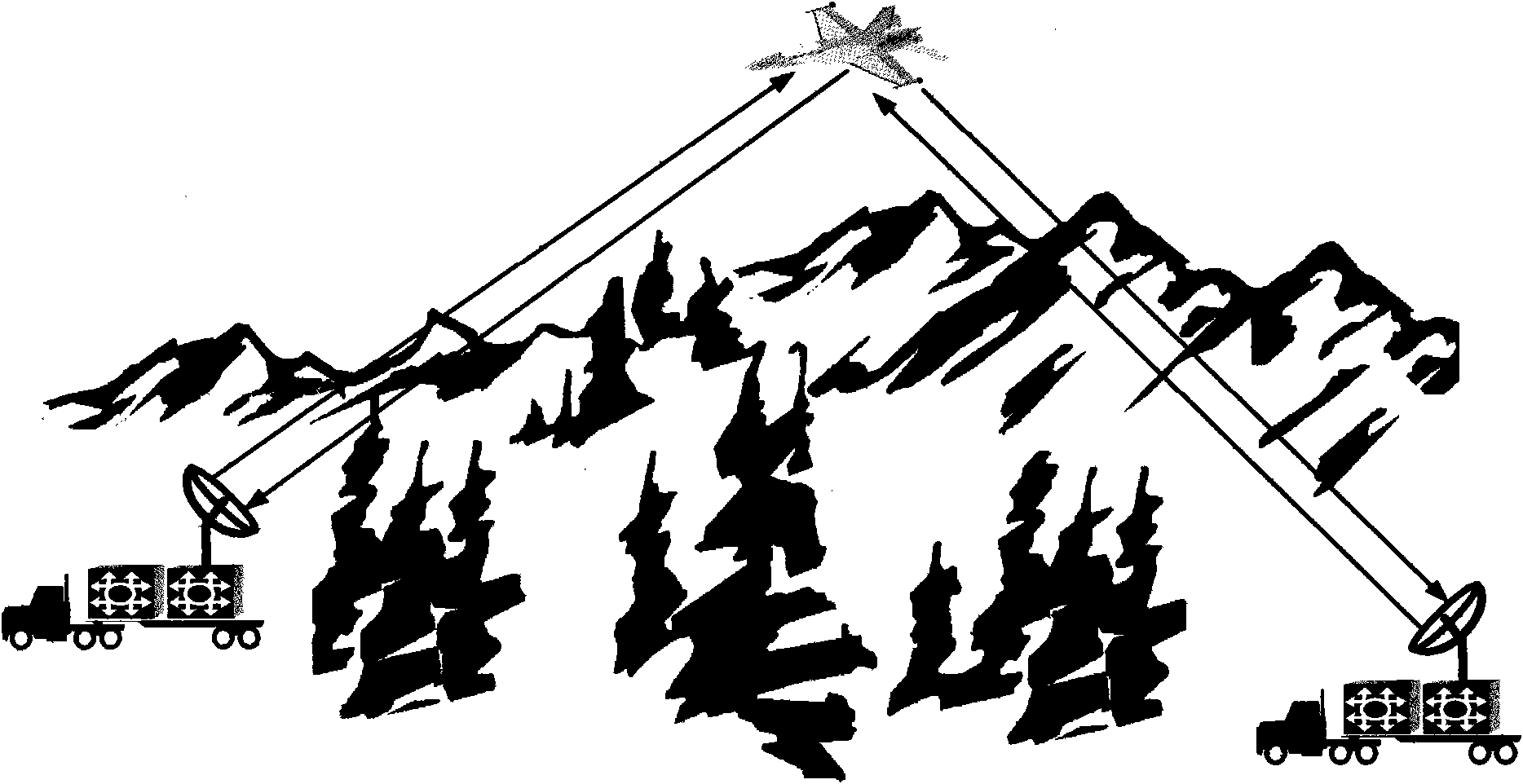

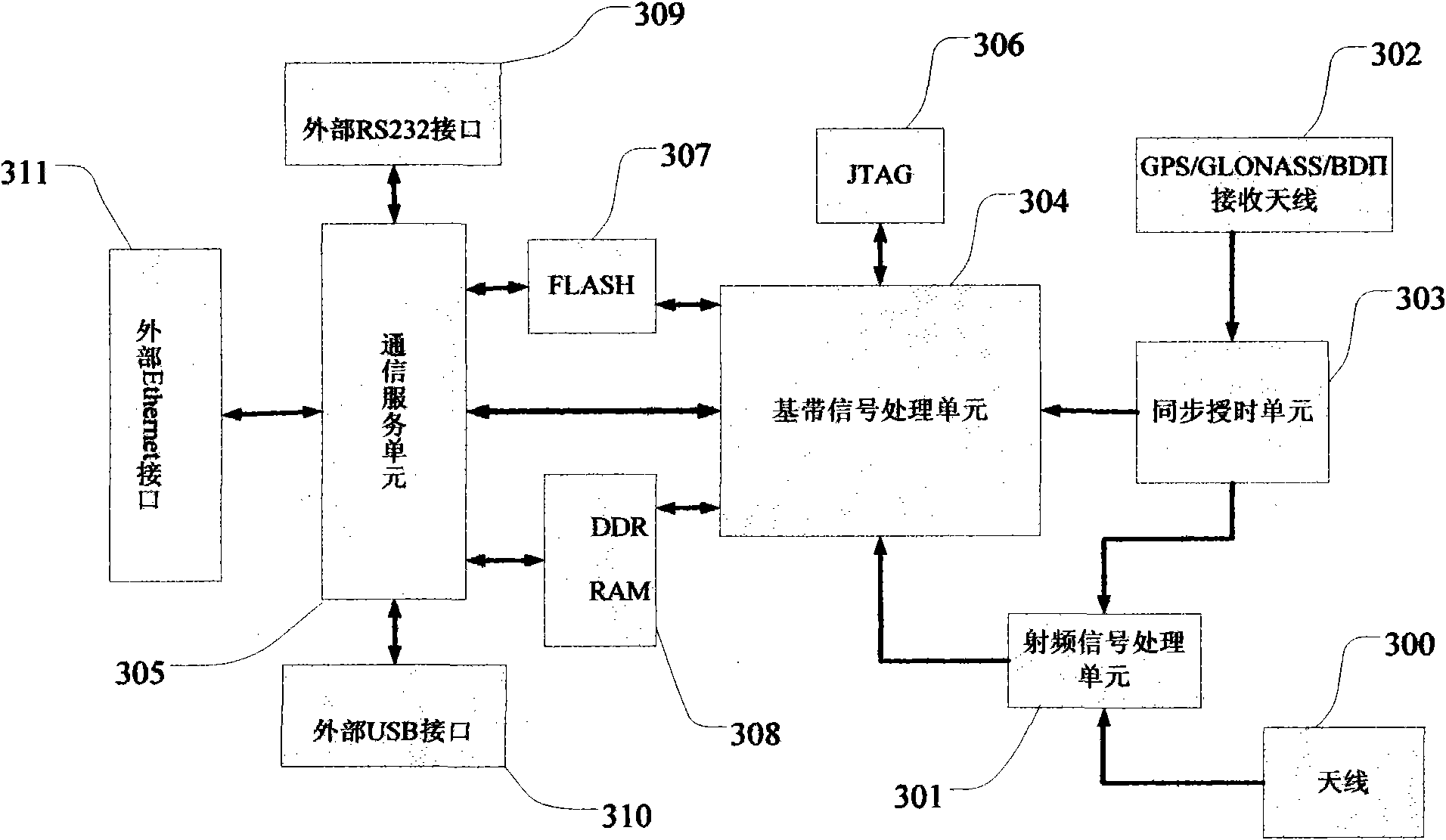

Distributed passive detection system based on cellular mobile communication base station and network thereof

ActiveCN101986169AOptimize layoutWide coverage areaSatellite radio beaconingWireless communicationTelecommunications linkManagement unit

The invention provides a distributed passive detection system based on a cellular mobile communication base station and a network thereof. The system comprises an intercept receiving unit, a communication link and a master control center, wherein the intercept receiving unit comprises an antenna unit, a radio frequency signal processing unit, a baseband signal processing unit, a synchronous time service unit and a communication service unit; and the master control unit comprises a communication service unit, a data fusion unit, a target positioning / tracking unit, a target identifying unit, an integrated display control unit, a binary search decision unit and an intercept receiving equipment managing unit. The distributed passive detection system based on the cellular mobile communication base station and the network thereof provided by the invention is easy for wide arrangement, and has wide coverage range and good destruction resistance and elusive.

Owner:重庆九洲星熠导航设备有限公司

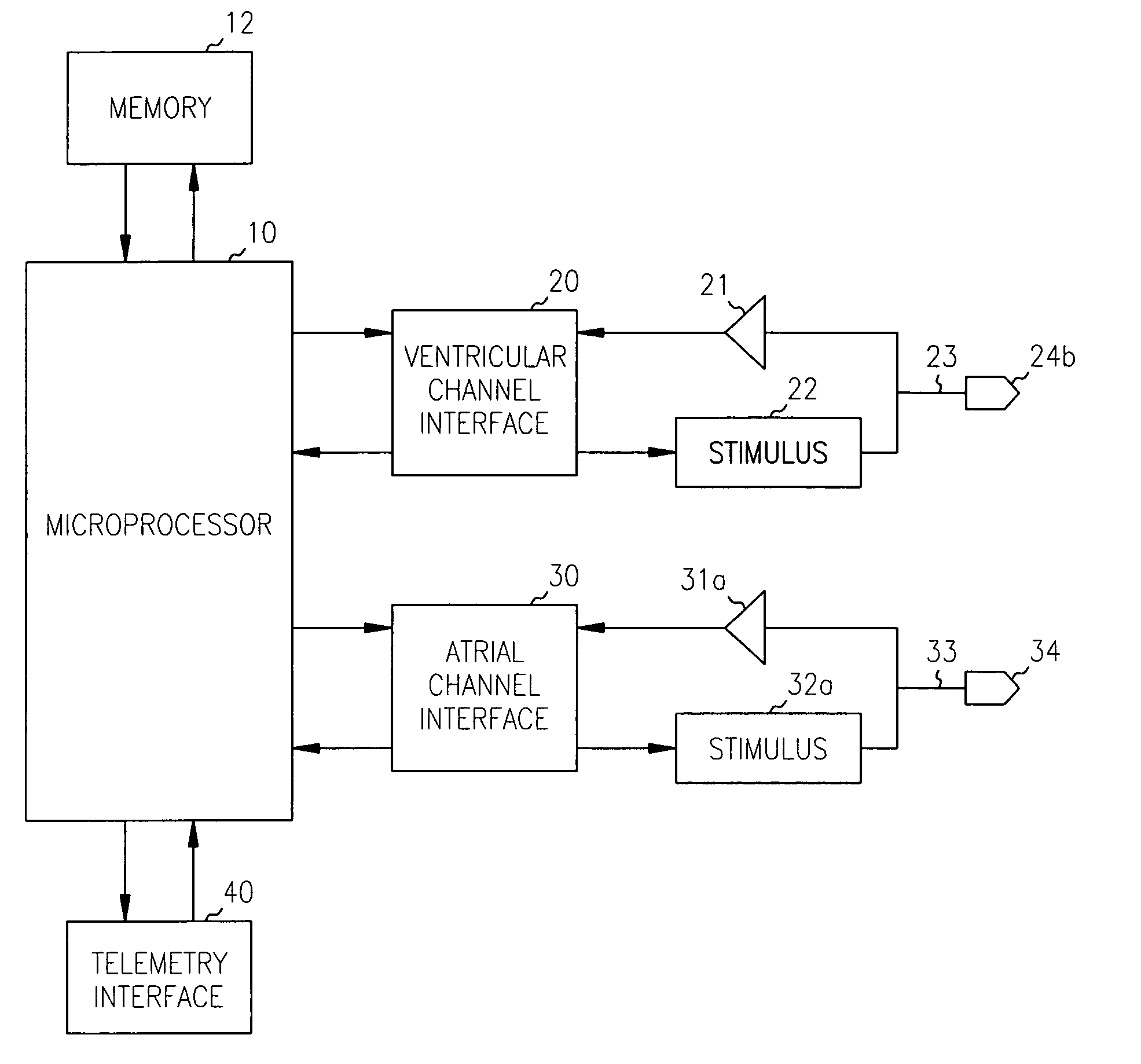

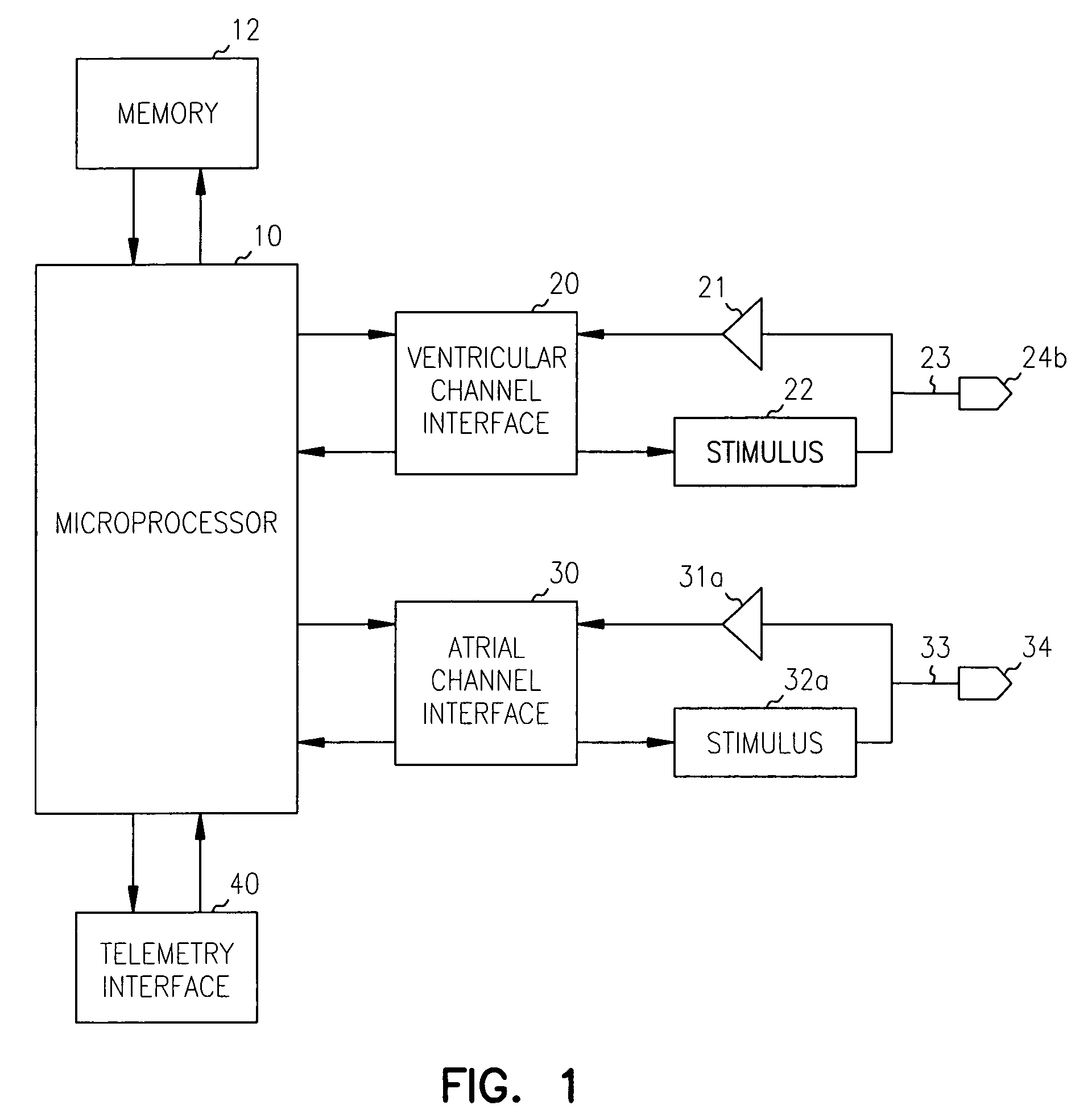

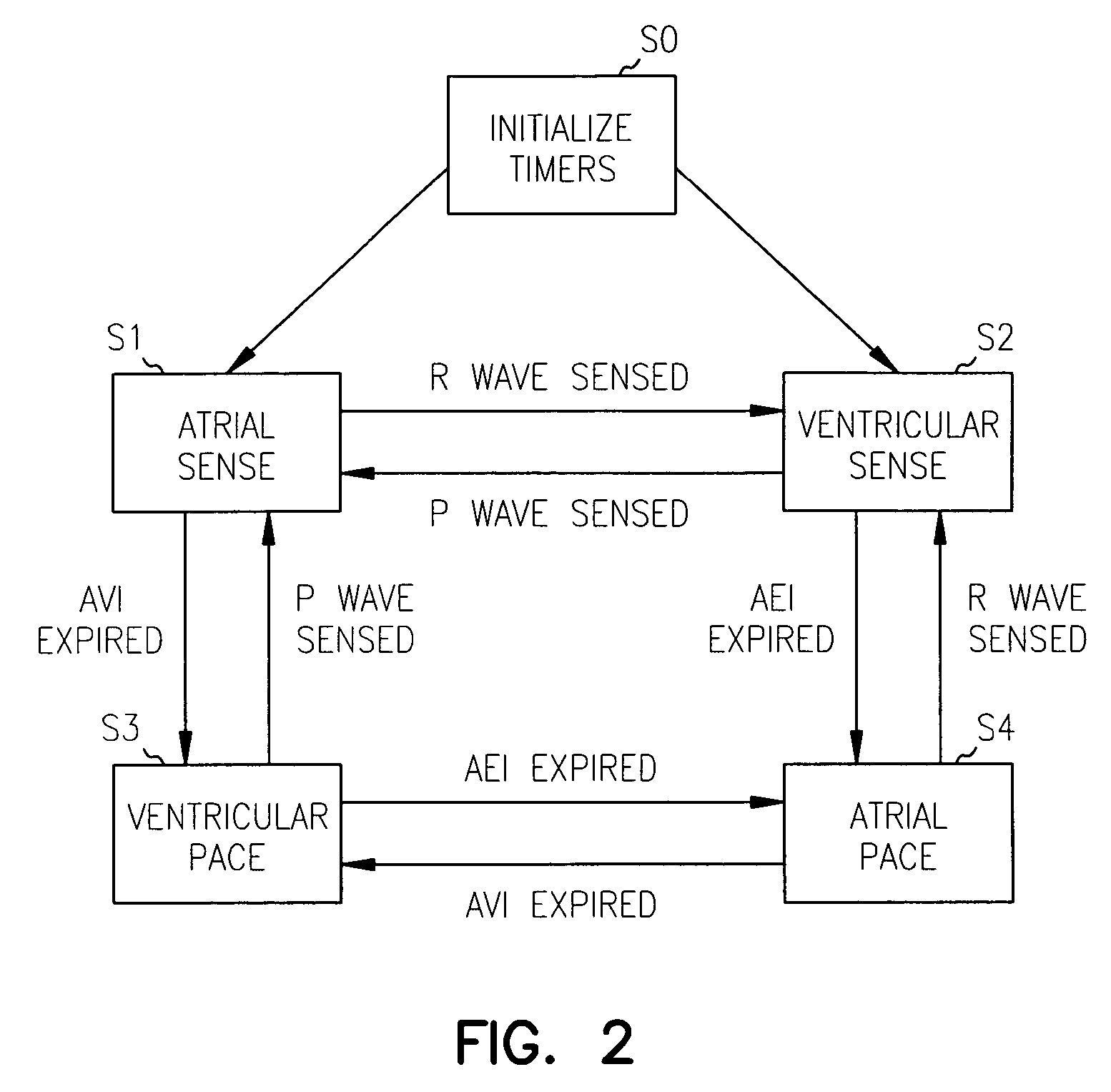

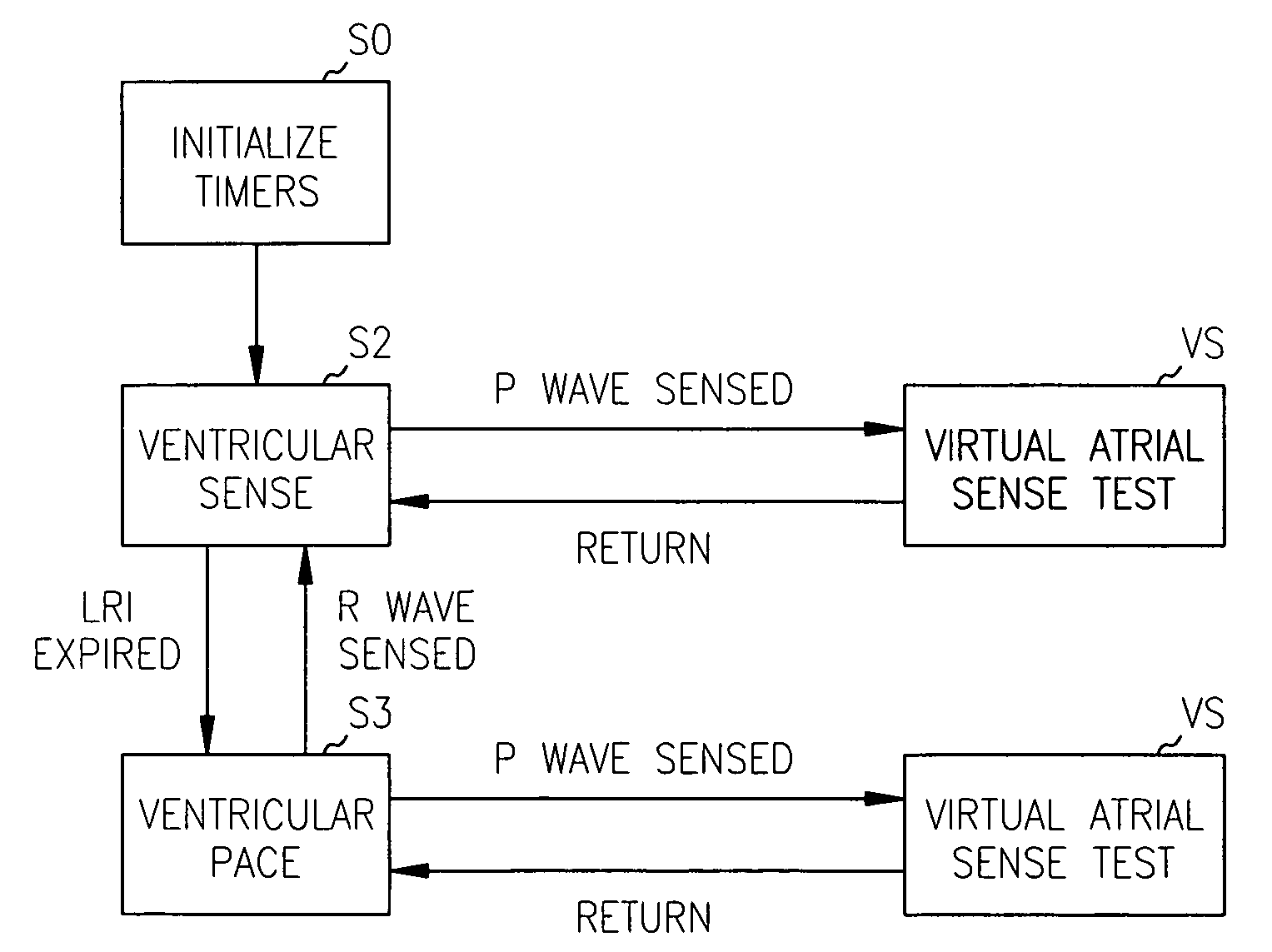

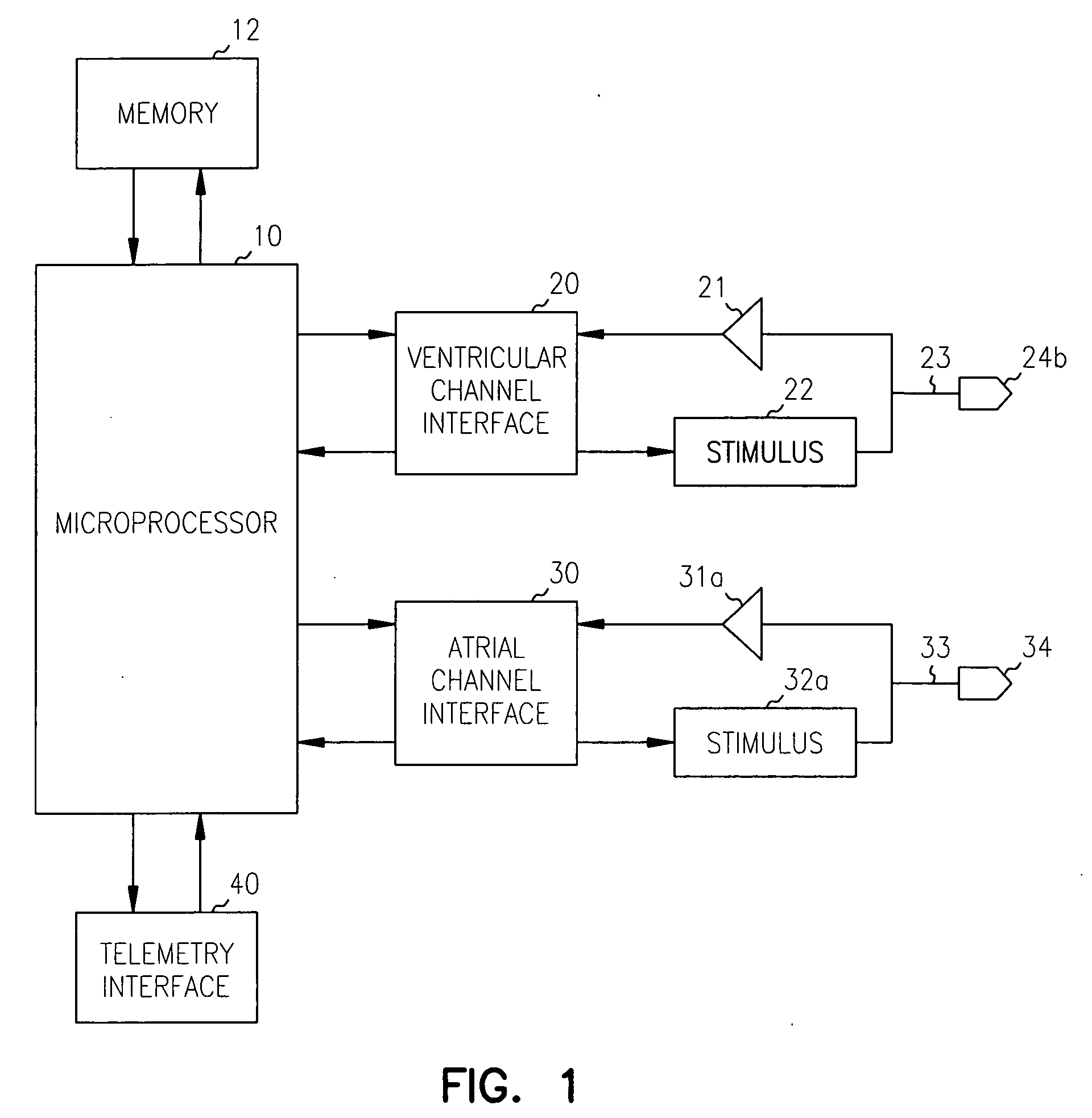

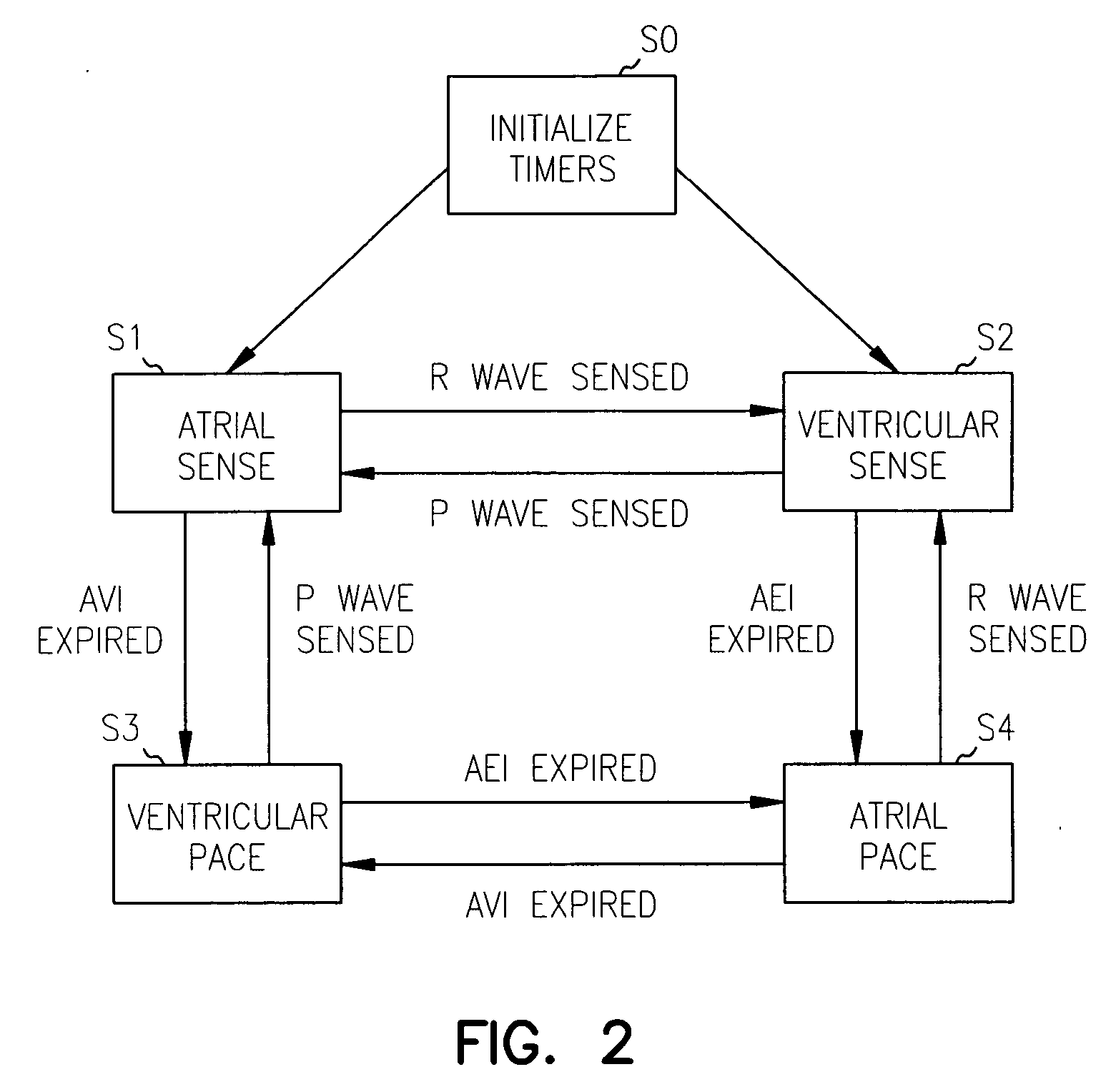

Pacemaker passive measurement testing system and method

A system and method for passively testing a cardiac pacemaker in which sensing signal amplitudes and lead impedance values are measured and stored while the pacemaker is functioning in its programmed mode. The amplitude and impedance data may be gotten and stored periodically at regular intervals to generate a historical record for diagnostic purposes. Sensing signal amplitudes may also be measured and stored from a sensing channel which is currently not programmed to be active as long as the pacemaker is physically configured to support the sensing channel. Such data can be useful in evaluating whether a switch in the pacemaker's operating mode is desirable.

Owner:CARDIAC PACEMAKERS INC

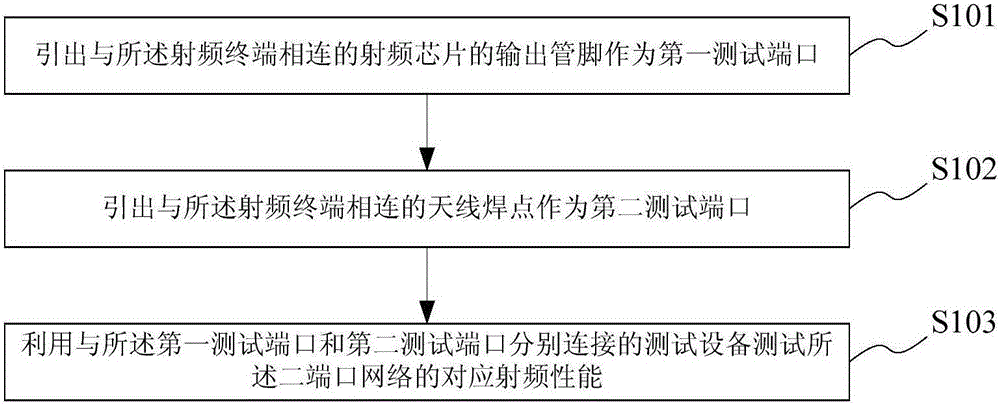

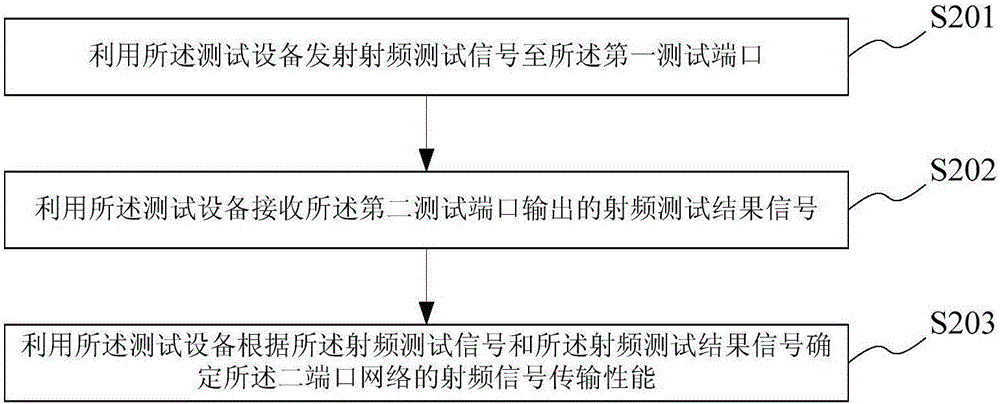

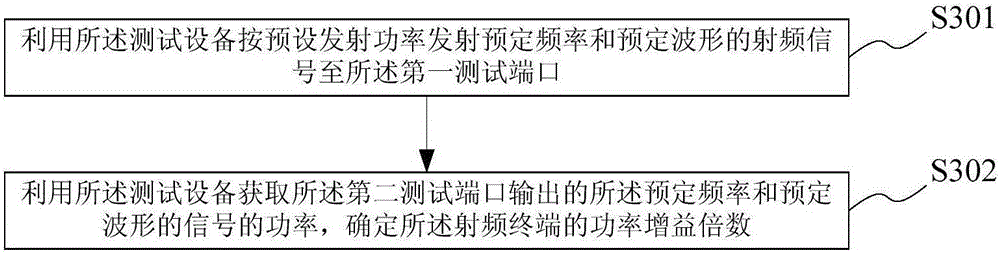

Performance detecting method and system of radio frequency terminal

ActiveCN105162714AImprove performanceSolving RF Matching ProblemsTransmitters monitoringReceivers monitoringPassive testingComputer terminal

The invention provides a performance detecting method and system of a radio frequency terminal. The performance detecting method of the radio frequency terminal comprises steps of: using the output pin, connected with the radio frequency terminal, of a radio frequency chip as a first testing port; using an antenna solder joint connected with the radio frequency terminal as a second testing port, wherein the first testing port, the radio frequency chip, the radio frequency terminal, and the antenna solder joint form a two-port network; and testing the corresponding radio frequency performance of the two-port network by using a testing device connected with the first testing port and the second testing port. The method may be independent of the radio frequency chip, directly detects and debugs the radio frequency terminal which is viewed as a two-port network, is compatible with more active and passive testing methods, modularly analyzes and solves radio frequency matching problems, and improves radio frequency output overall performance.

Owner:湖州帷幄知识产权运营有限公司

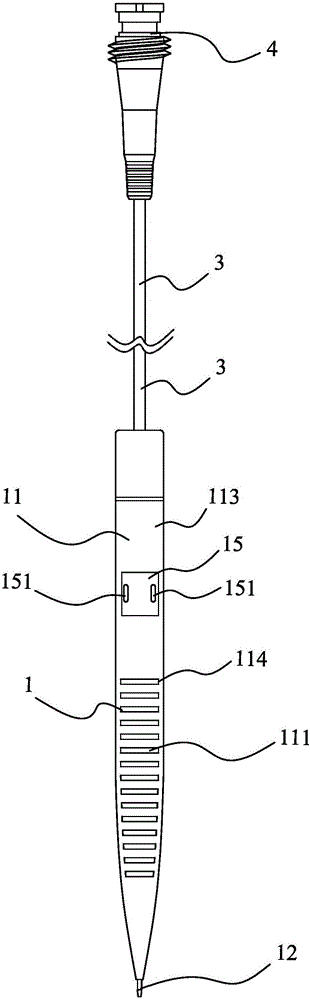

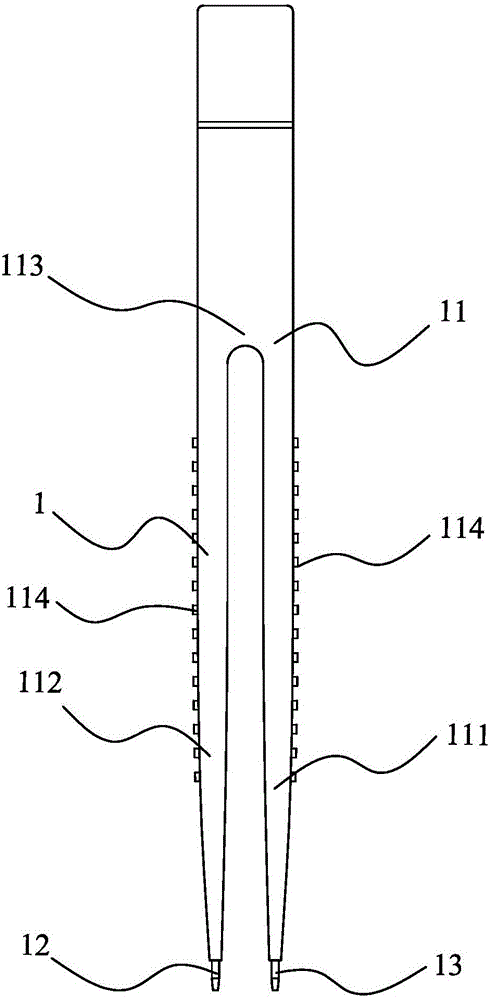

Testing probe and testing method for ripples and noises of power supply

InactiveCN106019169AImprove test efficiencyReduce labor input costsNoise figure or signal-to-noise ratio measurementPower supply testingCapacitanceTest efficiency

The invention provides a testing probe and testing method for ripples and noises of a power supply. The testing probe comprises a testing clamp, a blocking capacitor, and a coaxial line. The testing clamp consists of an insulating housing, a positive electrode, and a ground wire, wherein the positive electrode and the ground wire are fixed in the insulating housing. The insulating housing includes a first clamp leg, a second clamp leg, and a connecting part; at least one of the first clamp leg, the second clamp leg, and the connecting part can deform elastically. One end of the positive electrode extends out of the first clamp leg and forms a positive probe pin and the other end is connected with one end of the coaxial line. One end of the ground wire extends out of the second clamp leg and forms a ground wire probe pin and the other end is connected with one end of the coaxial line; and a connector connected with an oscilloscope is arranged at the other end of the coaxial line. The blocking capacitor is connected in series to the positive electrode. The testing probe with the high testing precision can be operated conveniently and rapidly; and compared with the passive testing probe, the testing efficiency can be improved and the manpower investment cost can be saved effectively.

Owner:UBTECH ROBOTICS CORP LTD

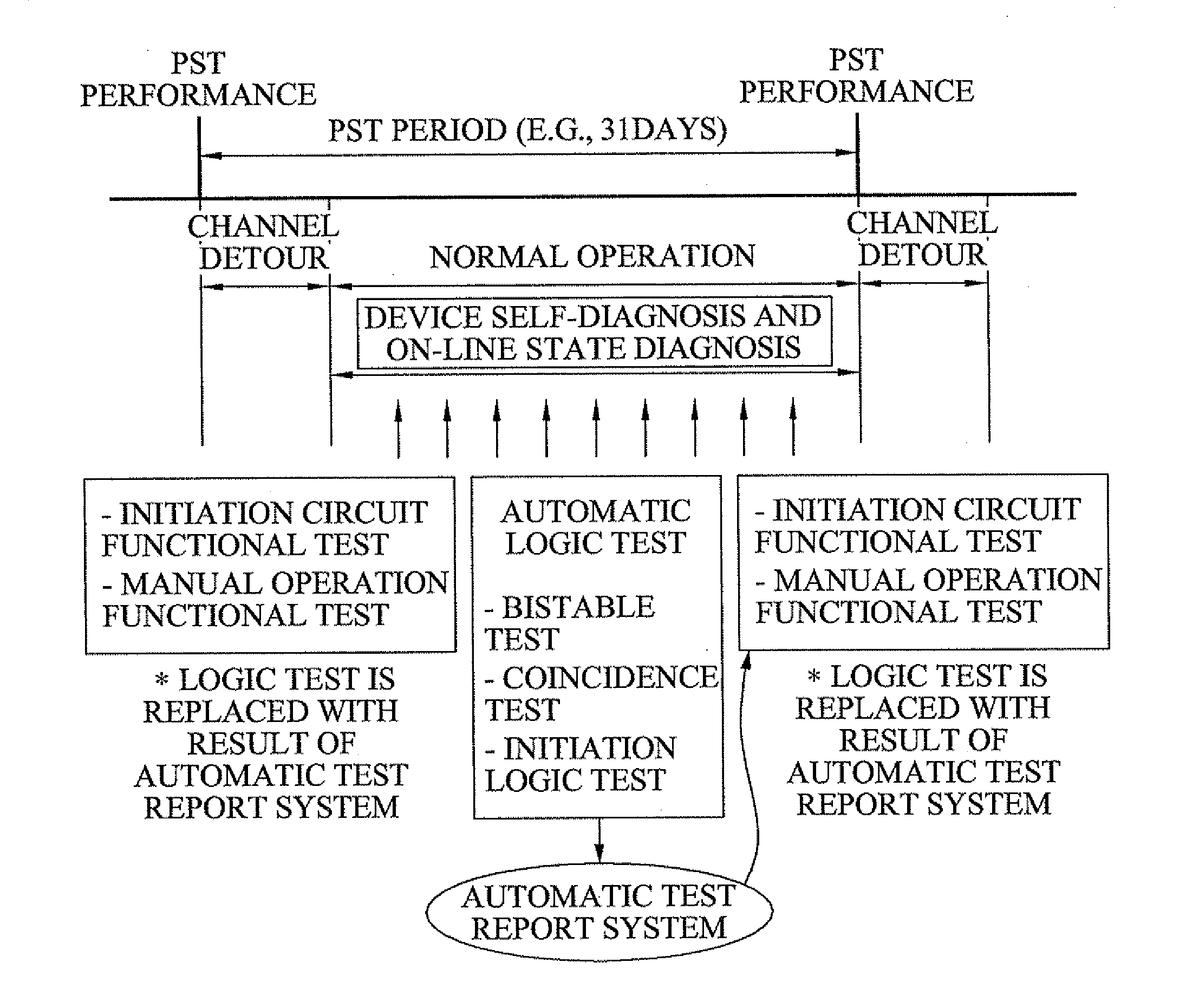

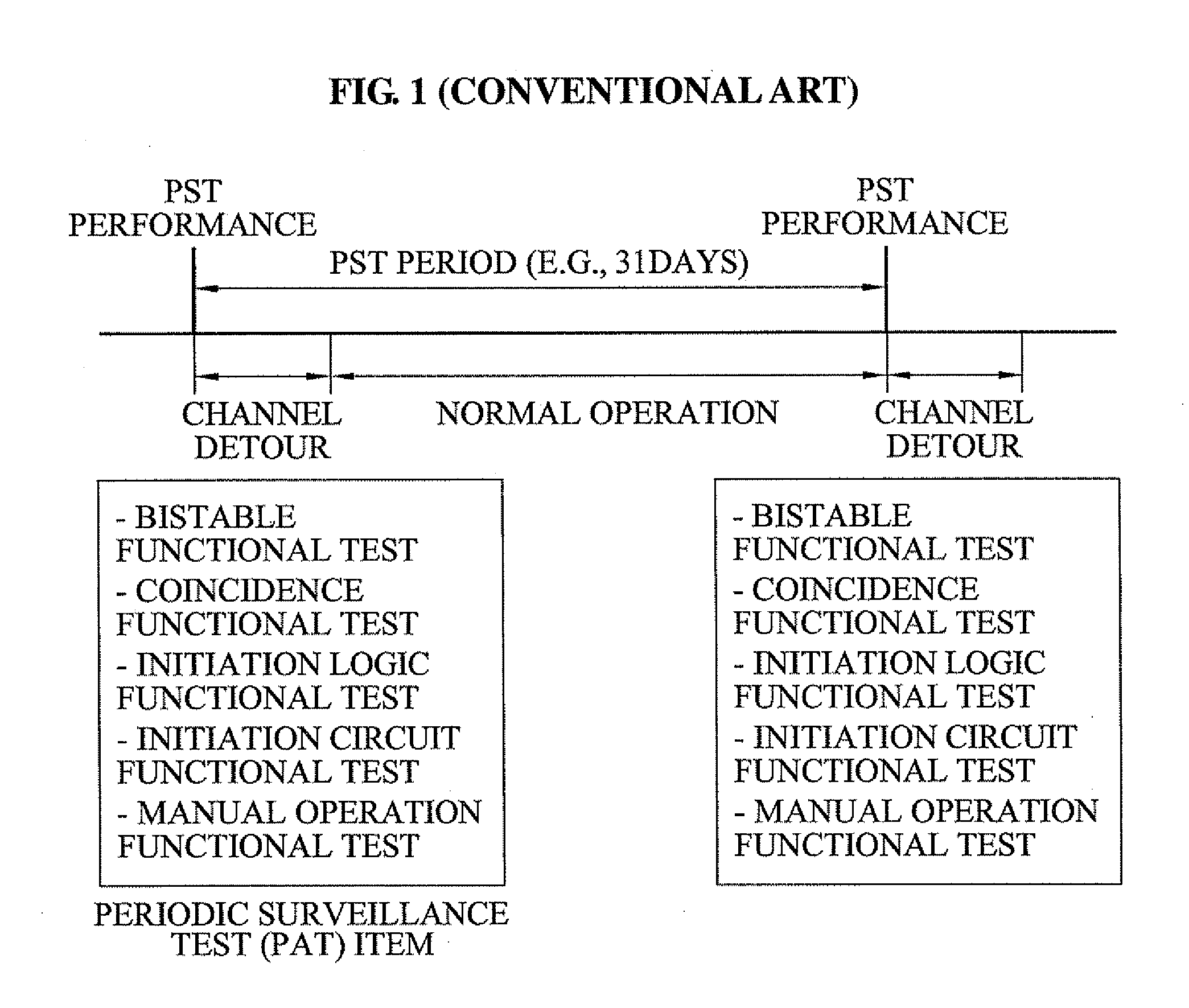

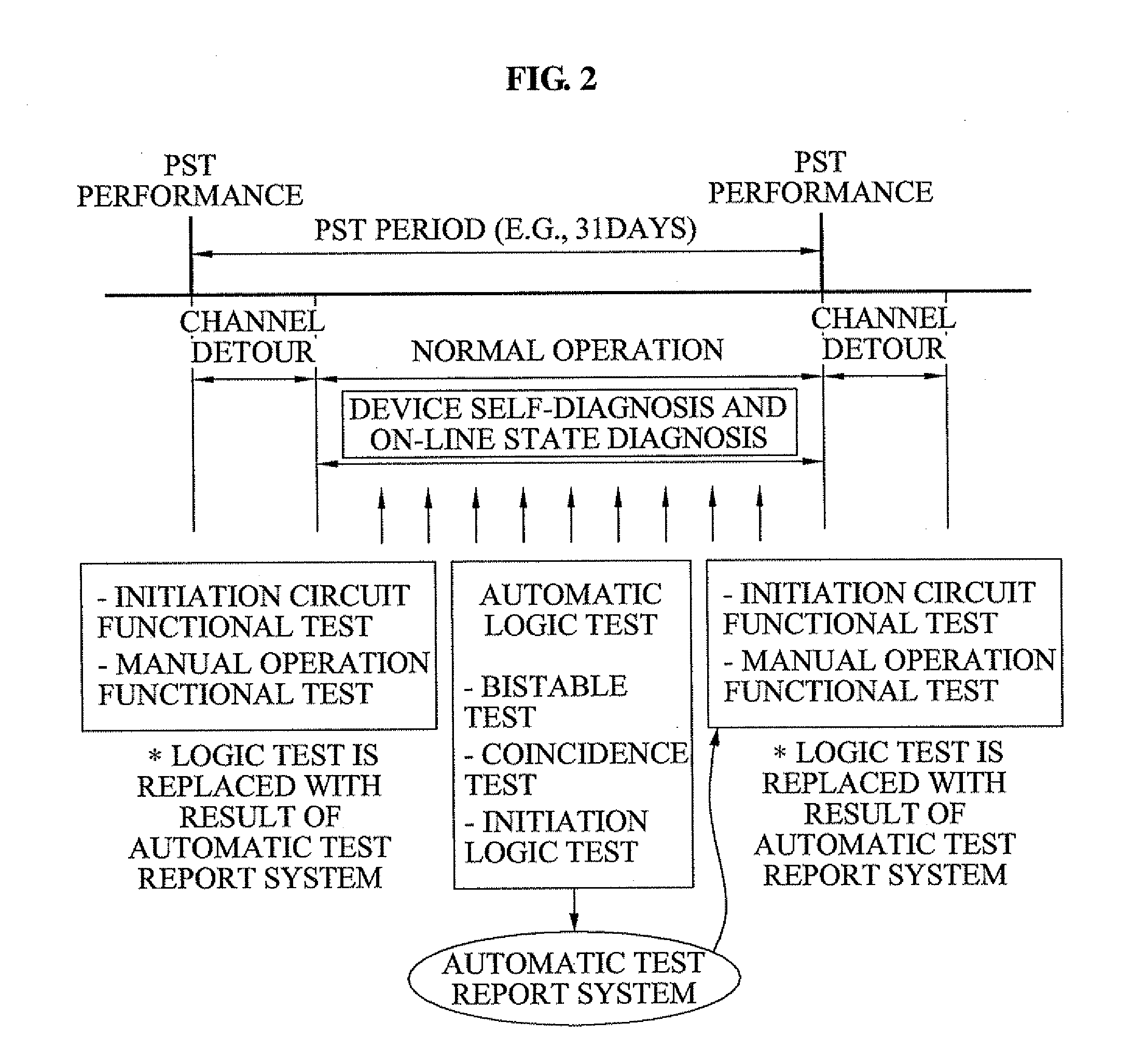

Automated periodic surveillance testing method and apparatus in digital reactor protection system

ActiveUS20110150162A1Minimizing testingReduce operating costsPower plant safety arrangementNuclear energy generationPassive testingEngineering

Provided is an automated periodic surveillance testing method and apparatus in a digital reactor protection system, which unites a passive testing means such as a self-diagnosis or an on-line state comparison with an active testing means such as an automatic logic test and the like in the digital reactor protection system. Accordingly, a device self-diagnosis, an on-line state diagnosis, and an automatic logic test are used as the automated periodic surveillance testing method in the digital reactor protection system. Thus, the time consumed in a periodic surveillance test can be minimized, thereby saving reactor operating costs, and excessive manpower can be avoided, thereby decreasing potential human errors. Also, a channel detour time at which one of multiple channels is detoured can be minimized based on the automated periodic surveillance test in the digital reactor protection system, thereby enhancing stability.

Owner:KOREA ATOMIC ENERGY RES INST +1

Automated monitoring system, virtual oven and method for stress testing logically grouped modules

InactiveUS6766267B2Data processing applicationsResistance/reactance/impedenceComputer hardwareNetwork connection

A virtual oven efficiently conducts stress testing of large numbers of modules. The virtual oven includes a logical grouping of modules, a controller, test instruments and a database which are all connected via a network. The logical groupings of modules of several virtual ovens may be physically accommodated within a single environmental stress screening room. Switching between modules in a logical group permits a single test piece of test equipment to be time-shared among the modules in the logical group. The method of bum-in testing a logical group of modules rotates a test sequence, including passive and active test cycles, between the modules. A test signal is split and supplied to multiple modules. Passive testing may be performed by monitoring parameters of the module while the test signal is supplied to the module. Active testing may be a functional test of the module in which the test signal is supplied to, processed by, and output from the module. Such test signals output from the modules are switched to the test equipment on a time-share basis. In this way, the number or expensive test equipment set-ups may reduced. The controller for each virtual oven also generates displays so that a user can track the test progress of all modules within the virtual oven. The controller also builds a database of the active and passive tests for each module. A graphical user interface may be used to interact with the virtual oven, control the testing, and view the database.

Owner:CIENA

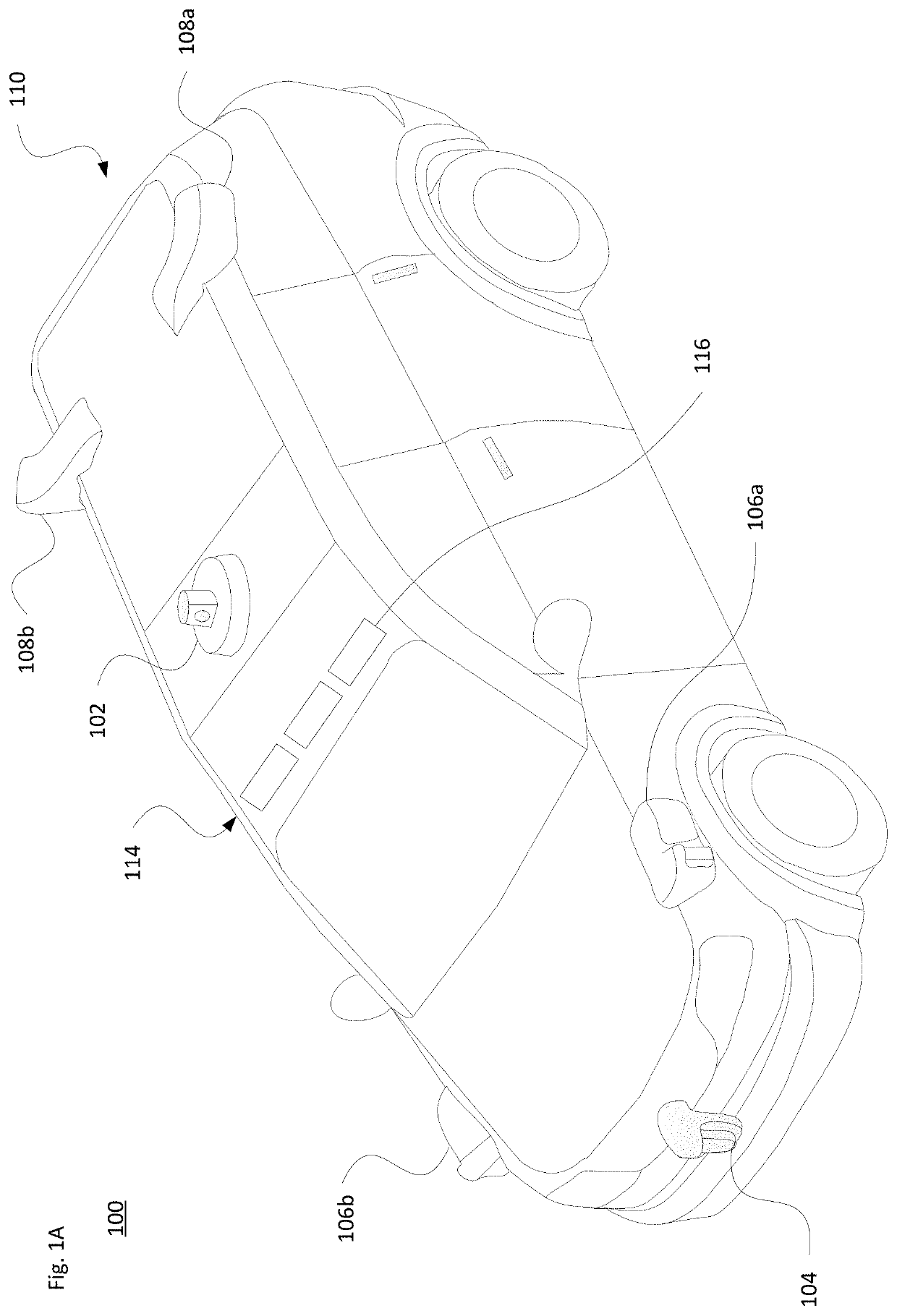

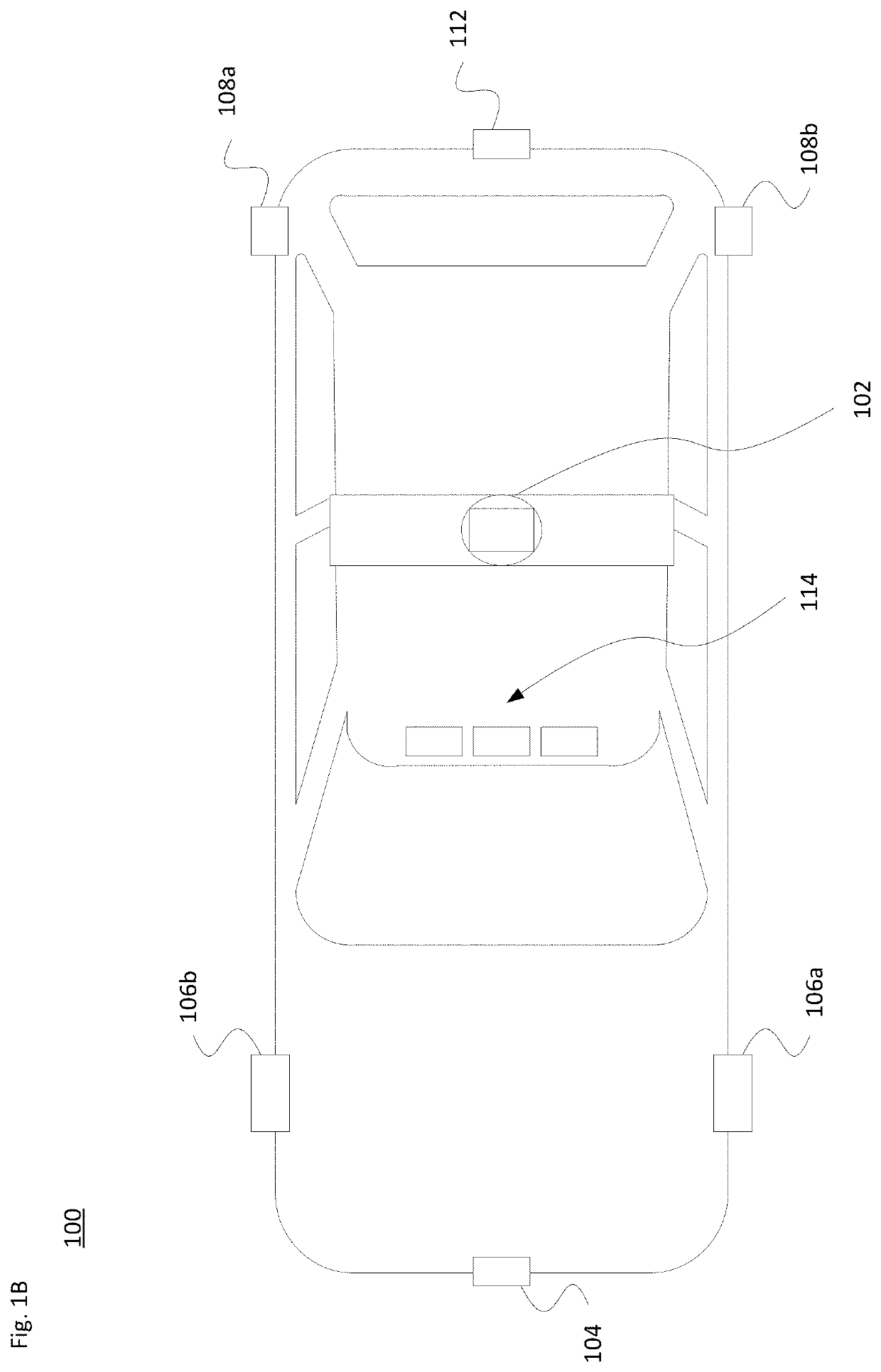

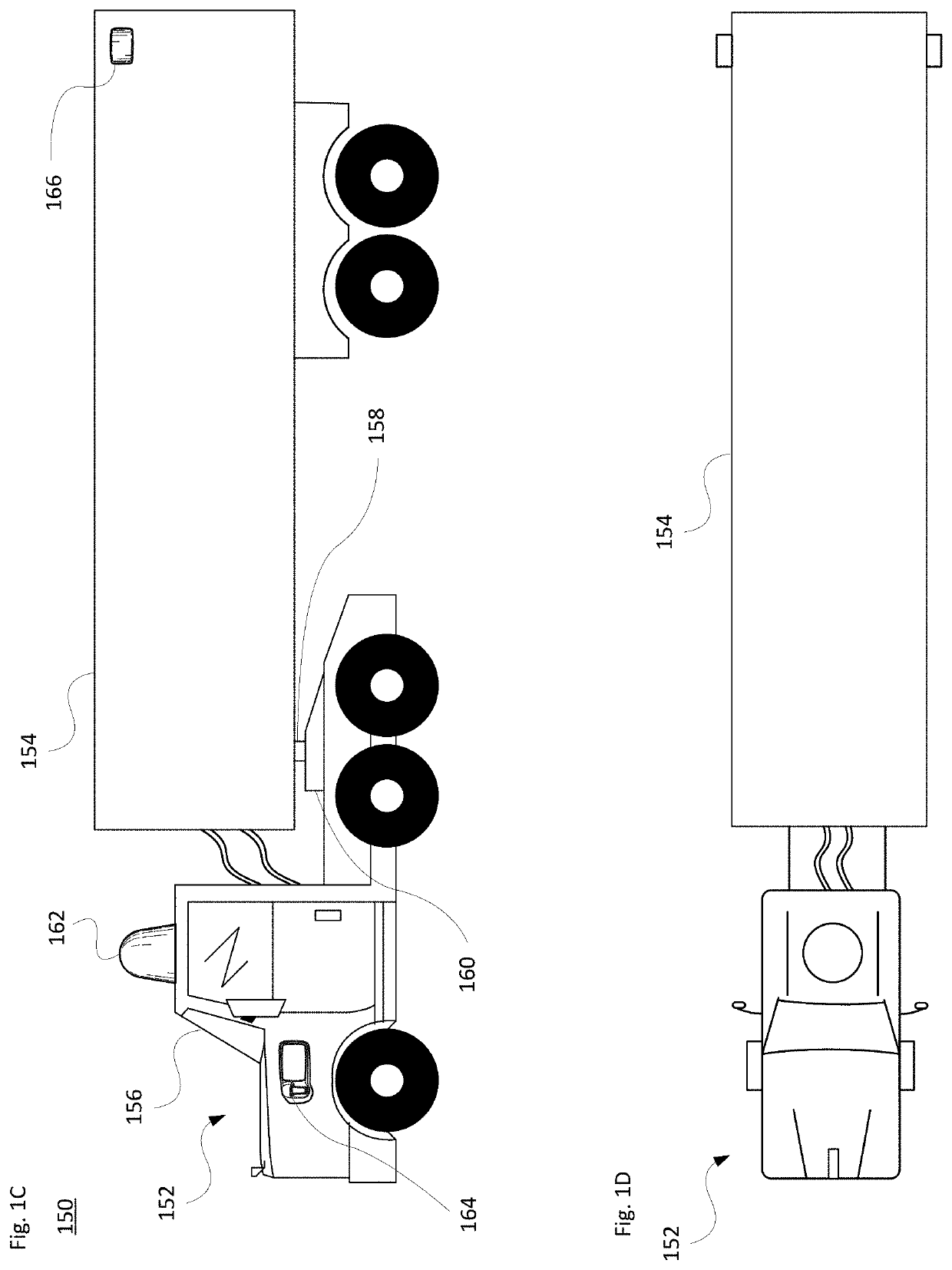

Determining Wheel Slippage on Self Driving Vehicle

ActiveUS20200189567A1Maximum driving speedAutonomous decision making processNavigation instrumentsControl systemIn vehicle

The technology relates to determining the current state of friction that a vehicle's wheels have with the road surface. This may be done via active or passive testing or other monitoring while the vehicles operates in an autonomous mode. In response to detecting the loss of traction, the vehicle's control system is able to use the resultant information to select an appropriate braking level or braking strategy. This may be done for both immediate driving operations and planning future portions of an ongoing trip. For instance, the on-board system is able to evaluate appropriate conditions and situations for active testing or passive evaluation of traction through autonomous braking and / or acceleration operations. The on-board computer system may share slippage and other road condition information with nearby vehicles and with remote assistance, so that it may be employed with broader fleet planning operations.

Owner:WAYMO LLC

Controlling admission of data streams onto a network based on end-to-end measurements

InactiveCN1543157AData switching by path configurationStore-and-forward switching systemsPathPingDiagnostic data

Appropriate determinations in a series of tests, which transition from more passive tests to more active tests, control the admission of data streams onto a network data path. More passive tests can include promiscuous mode and packet-pair tests. When the results of more passive tests indicate a reduce likelihood of a data stream causing a network data path to transition into a congested state, the network data path can be actively probed to make a more precise determination on the likelihood of congestion. A train of diagnostic data packets is transmitted at a diagnostic data transfer rate having a significantly reduced chance of causing congestion. A train of target data packets is transmitted at a requested application transfer data rate. The number of target data packets received within a specified delay threshold is compared to the number of diagnostic data packets receive with the delay threshold. <IMAGE>

Owner:MICROSOFT TECH LICENSING LLC

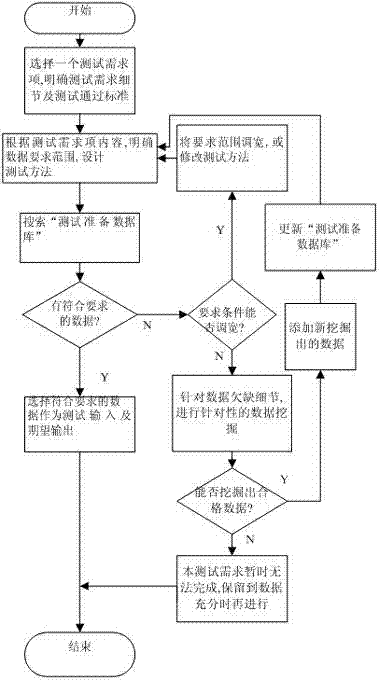

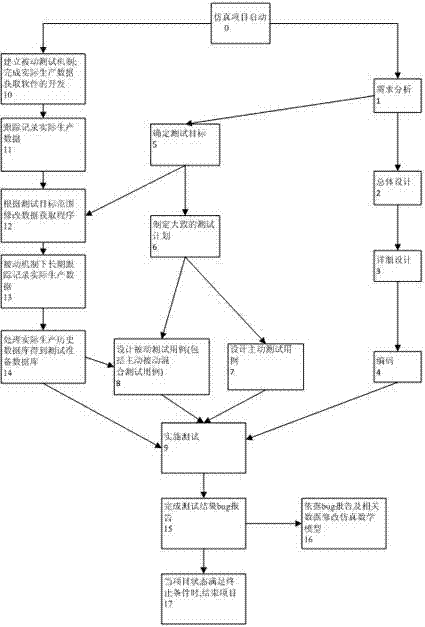

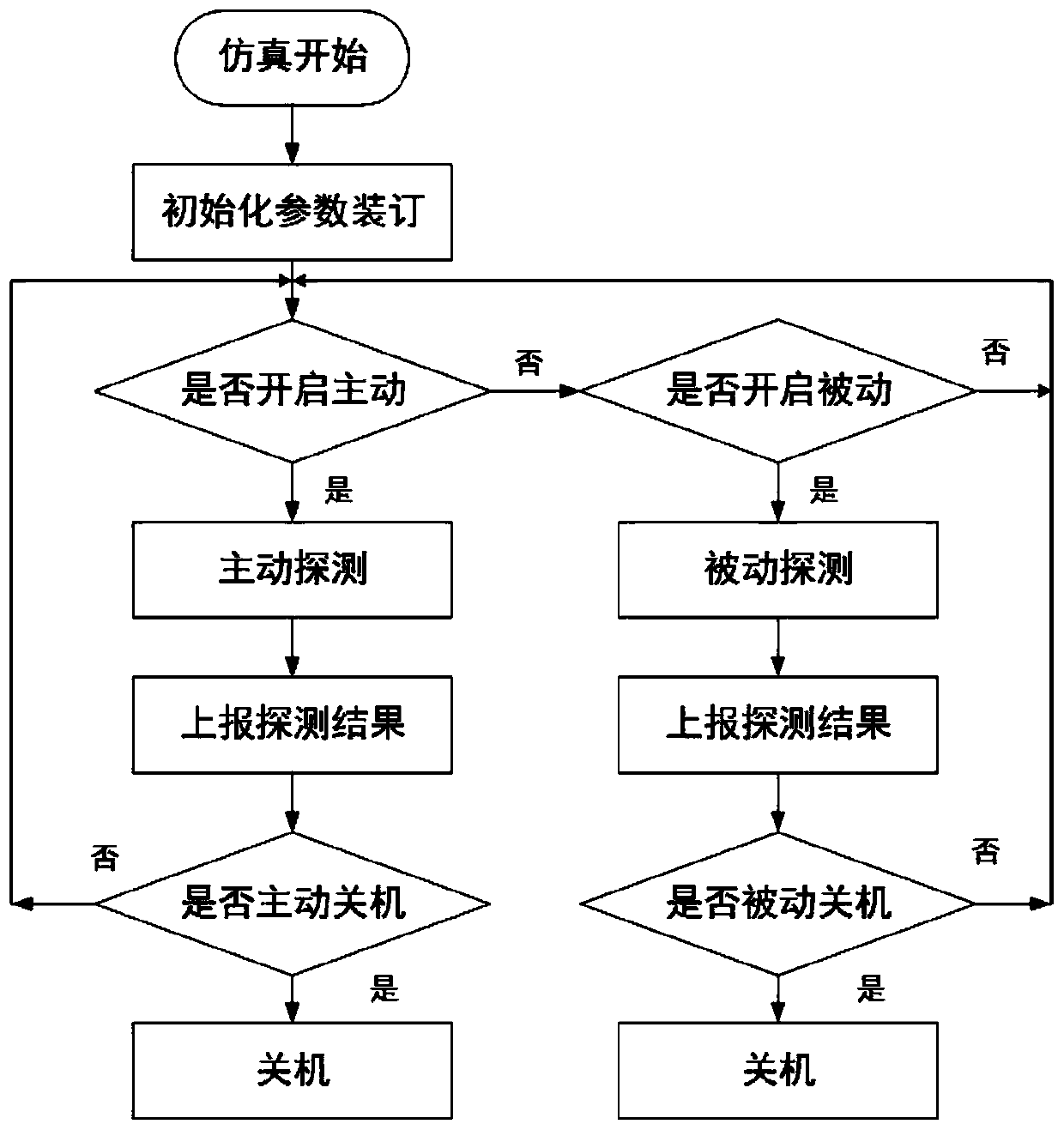

Driving and driven hybrid testing method for simulation system

InactiveCN102955738AImprove sufficiencyImprove practicalitySoftware testing/debuggingPassive testingDesign testing

The invention discloses a driving and driven hybrid testing method for a simulation system. The driving and driven hybrid testing method comprises the following steps of: (1) selecting a testing requirement item; (2) establishing a'testing preparation database'; (3) designing a case for testing; (4) searching the 'testing preparation database'; (5) acquiring expected output data or a testing pass standard of the case for testing from the data obtained in the step (4); (6) if the 'testing preparation database' does not have data meeting the requirement, adjusting the test method or expanding data conditions, and re-searching the 'testing preparation database'; and (7) after the step (6) is carried out, the 'testing preparation database' has no data meeting the requirement and the searching condition can not be adjusted, carrying out targeted data mining again on deficient data. The driving and driven hybrid testing method disclosed by the invention has the advantages that the sufficiency of test data is improved, the use of repeated data and the like is reduced, the practicability of the test data is effectively increased, and the implementation cost and the implementation time of the driven testing are reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

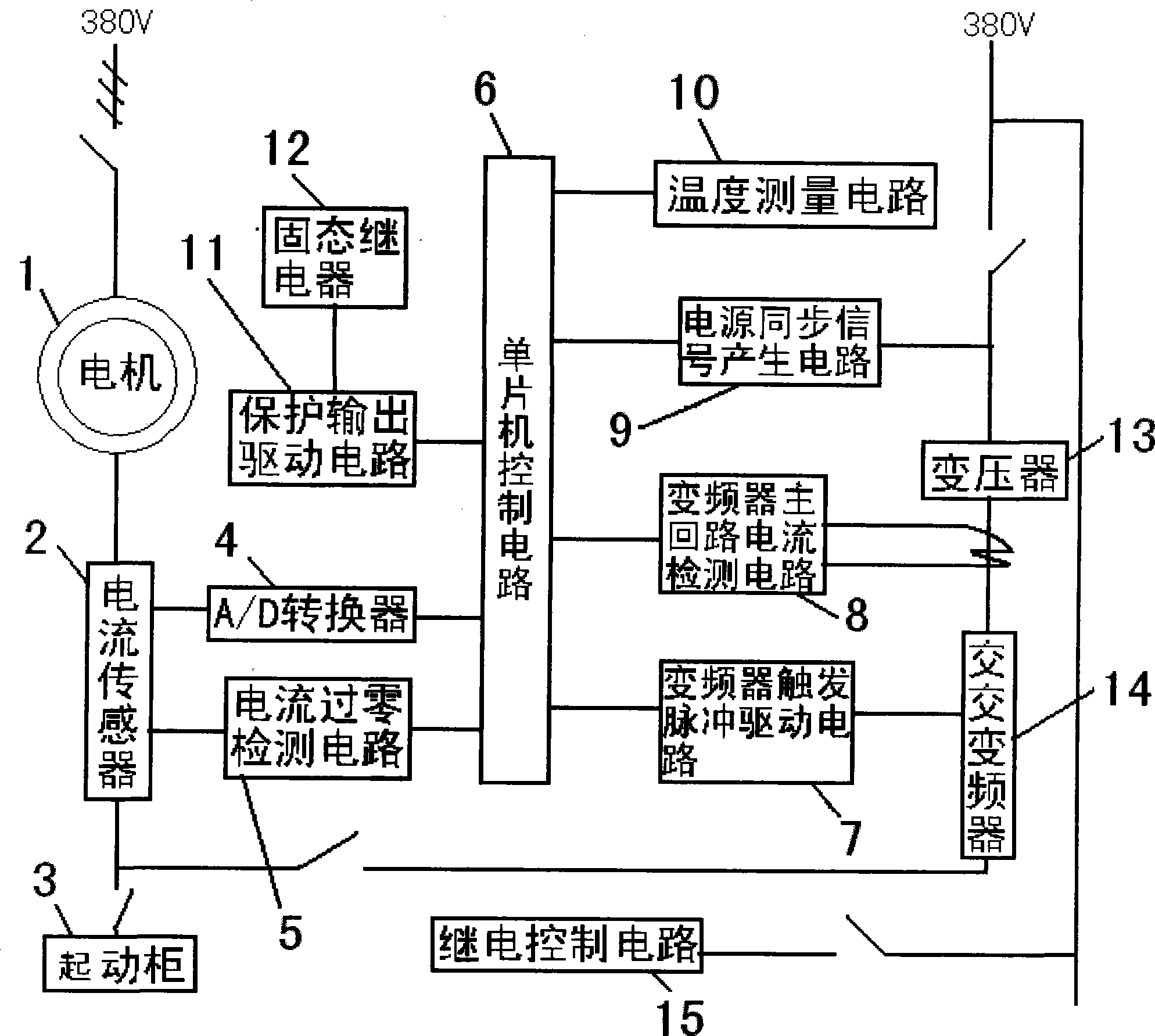

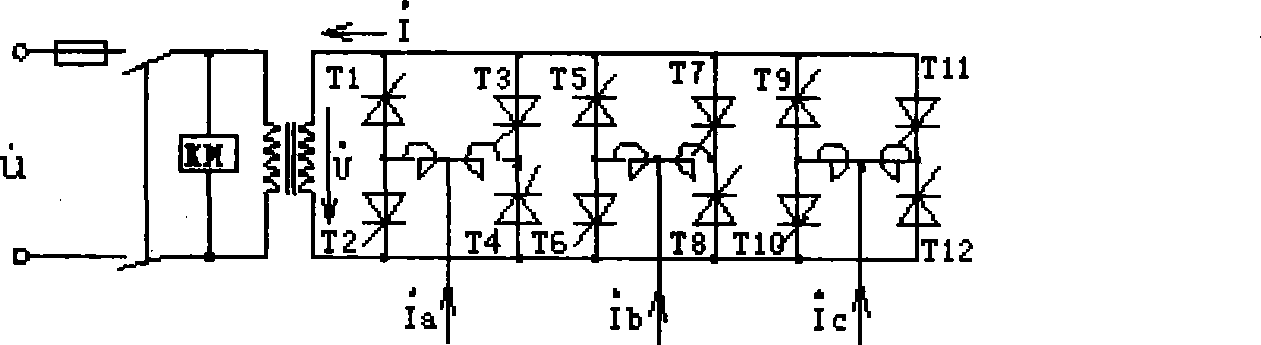

Passive compensating and energy saving apparatus for digital large power winding asynchronous motor

InactiveCN101499770ARealize automatic compensationCommutation is reliableAC motor controlAc-ac conversionFrequency changerMicrocontroller

The invention provides a reactive power compensation and energy-saving device used for a digital large-power winding asynchronous motor, which is characterized in that the rotor current of the motor is detected by a current sensor; furthermore, the detection signal of the current sensor respectively passes by an A / D converter and a current zero-crossing detection circuit and is then input a singlechip control circuit; simultaneously, the synchronous signal of an AC-AC frequency converter power supply is input in the singlechip control circuit; the singlechip carries out data processing according to the mathematic model of the system and the triggering time procedure, outputs the AC-AC frequency converter trigger pulse signal, leads the output voltage frequency of the AC-AC frequency converter to be the same with the rotor current frequency of the asynchronous motor, leads the phase of the AC-AC frequency converter to be lagged by 90 degrees compared with the rotor current; furthermore, the output voltage is changed according to the change of the detection current. The reactive compensation power and energy-saving device has the advantages of realizing the close-ring control of power factor compensation of the winding-typed asynchronous motor, thus achieving the energy-saving object, and adopting the AC-AC frequency conversion current zero-crossing detection circuit with high reliability.

Owner:NANCHANG HANGKONG UNIVERSITY

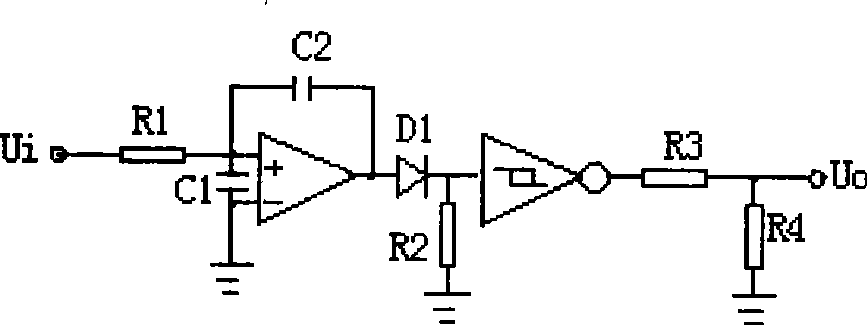

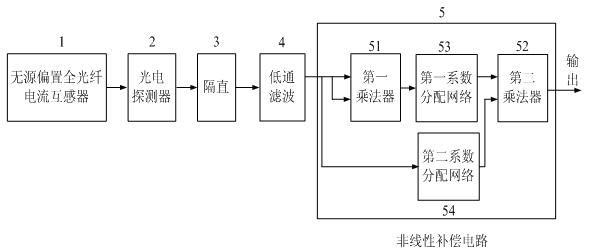

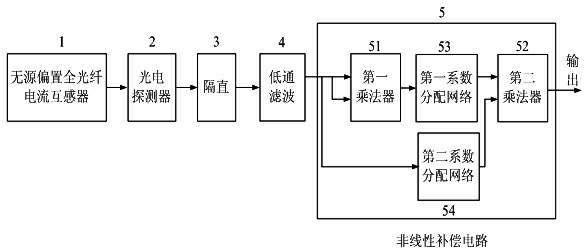

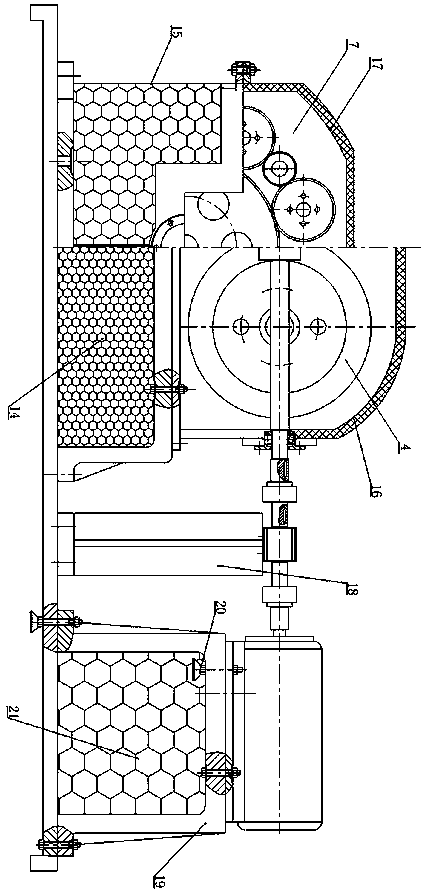

Nonlinear compensating circuit for passive biasing all-fiber current transformer

InactiveCN102628886ALow costSimple signal processing circuitVoltage/current isolationEngineeringAlternating current

The invention discloses a nonlinear compensating circuit for a passive biasing all-fiber current transformer, which belongs to the technical field of testing. The circuit comprises a passive biasing all-fiber current transformer, a photoelectric detector, a blocking circuit, a low-pass filtering circuit and a nonlinear compensating circuit, wherein the output signal of the passive bias all-fiber current transformer enters the photoelectric detector to obtain an electric signal which is relevant to detected current; a direct-current signal is removed from the electric signal through the blocking signal; and the low-pass filtering circuit enters the nonlinear compensating circuit after an alternating-current signal is filtered out through the low-pass filtering circuit, and is used for performing approximate inverse sine calculation and outputting a signal which is relevant to the tested current signal and is corrected nonlinearly. The function of the circuit is completely realized by using simulation circuit elements, so that the nonlinear compensating circuit has a simpler structure and lower cost.

Owner:SHANGHAI UNIV

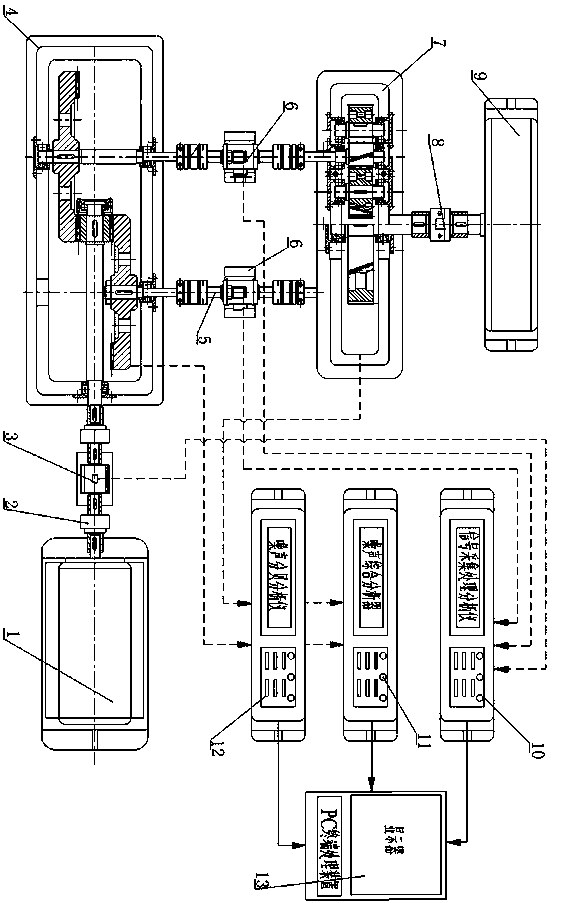

Close noise detection device of face gear reducer for naval vessel

InactiveCN108896302AImplement dynamic load testingReduce the impact of noiseMachine gearing/transmission testingNoise monitoringMeasurement device

The invention relates to a close noise detection device of a face gear reducer for a naval vessel. The objective of the invention is to solve problems of loading and noise monitoring of the gear reducer in the prior art. The detection device comprises a permanent magnet direct current motor which is connected with a face gear two-path flow-dividing active test box through a coupler. An acceleratedspeed sensor is arranged on the coupler. The face gear two-path flow-dividing active test is connected with a cylinder gear four-path power flow-dividing passive test box through two torsion shafts.A rotation speed torque measurement device is arranged on each torsion shaft. The cylinder gear four-path power flow-dividing passive test box is connected with an electric dynamometer. Anti-vibrationisolation layers are arranged at bottoms of the face gear two-path flow-dividing active test box and the cylinder gear four-path power flow-dividing passive test box. Sound isolation covers are arranged on the exteriors. The accelerated speed sensor, the face gear two-path flow-dividing active test box, a high-precision rotation speed torque measurement device, and the cylinder gear four-path power flow-dividing passive test box are connected with a noise monitoring device.

Owner:XIAN TECH UNIV

Pacemaker passive measurement testing system and method

A system and method for passively testing a cardiac pacemaker in which sensing signal amplitudes and lead impedance values are measured and stored while the pacemaker is functioning in its programmed mode. The amplitude and impedance data may be gotten and stored periodically at regular intervals to generate a historical record for diagnostic purposes. Sensing signal amplitudes may also be measured and stored from a sensing channel which is currently not programmed to be active as long as the pacemaker is physically configured to support the sensing channel. Such data can be useful in evaluating whether a switch in the pacemaker's operating mode is desirable.

Owner:CARDIAC PACEMAKERS INC

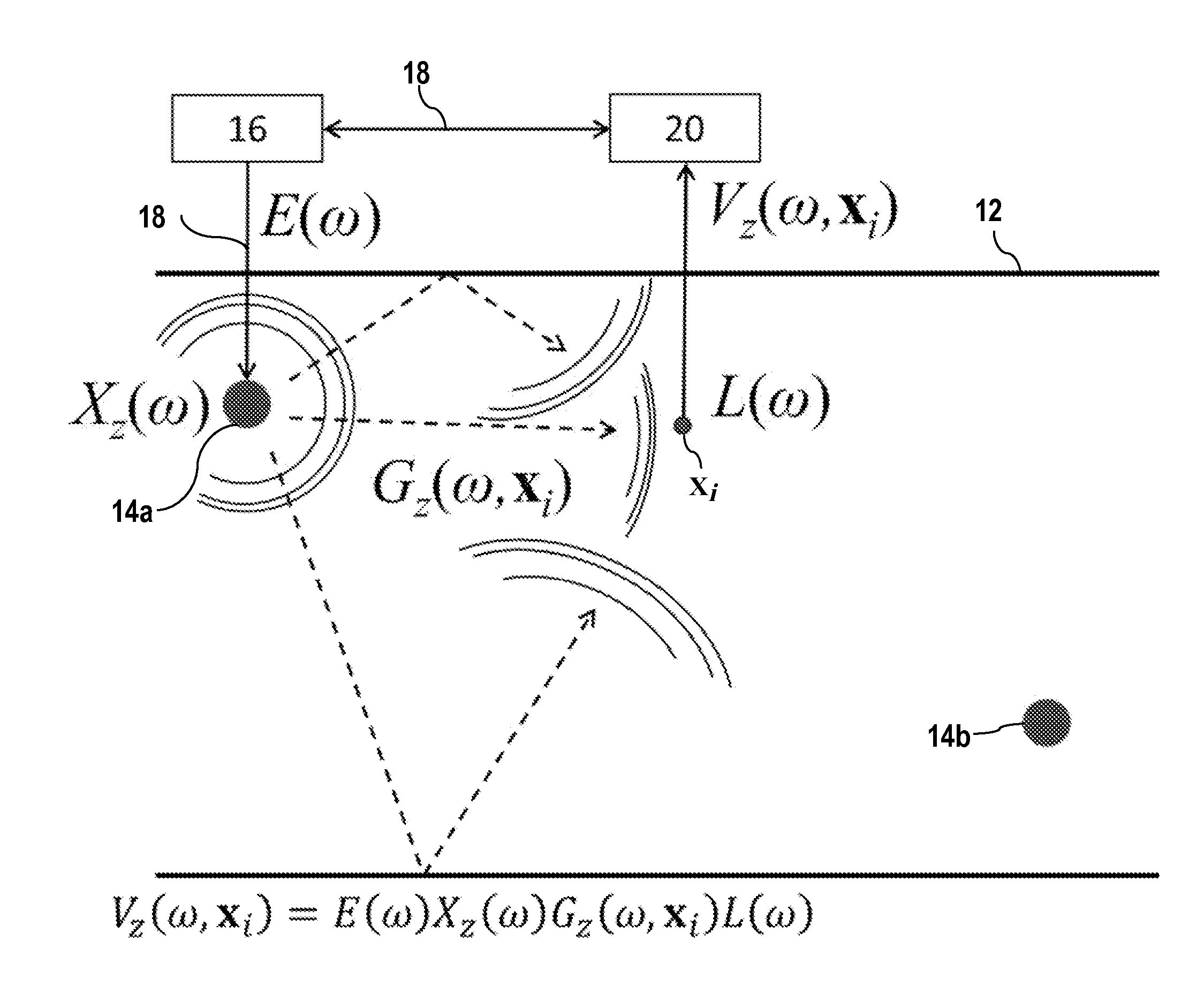

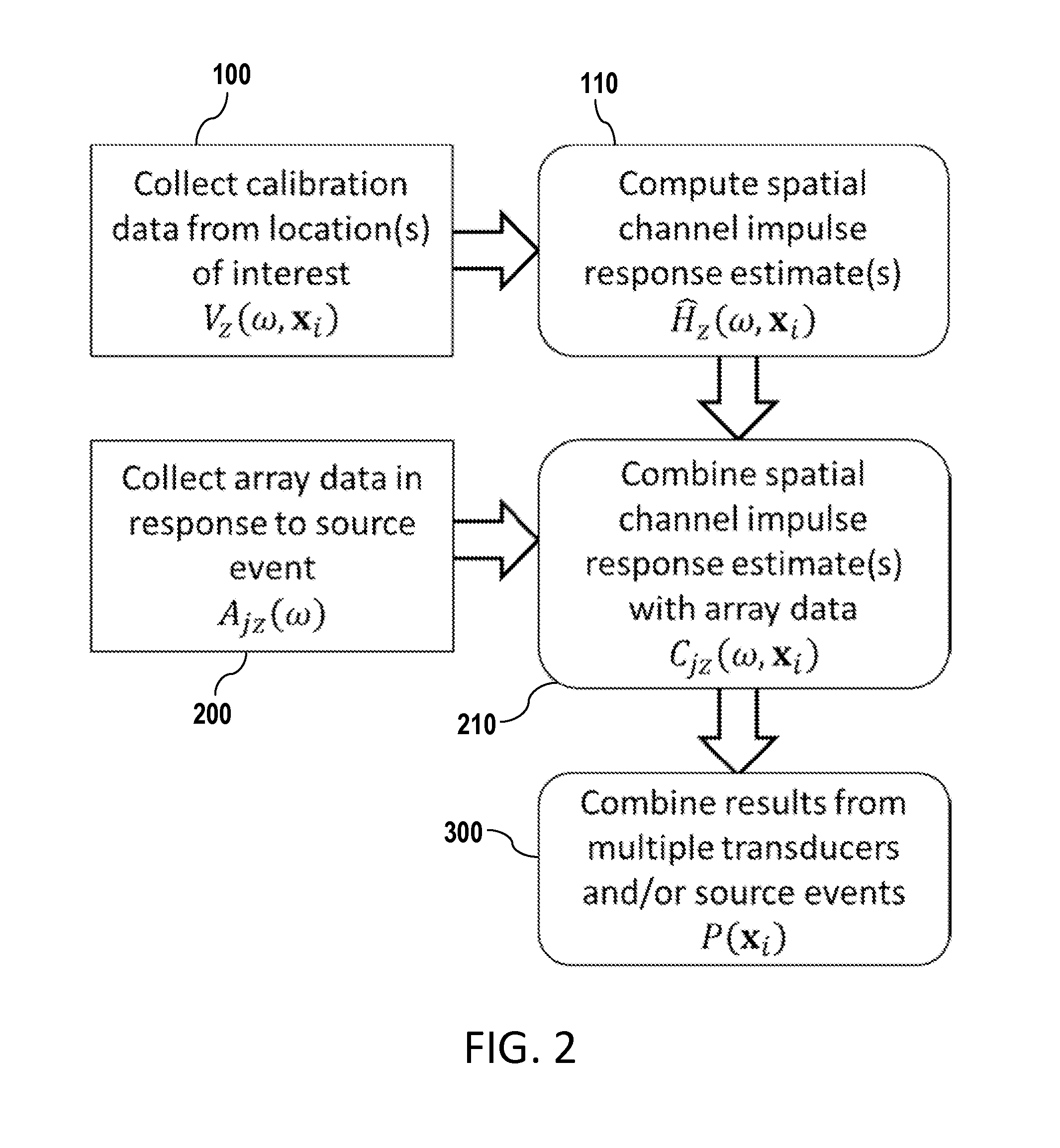

Method and system for passive detection, localization and characterization of mechanical wave sources using ultrasonic guided waves

ActiveUS20150106037A1Power managementAnalysing solids using sonic/ultrasonic/infrasonic wavesChannel impulse responsePassive testing

A method and system for passively detecting, localizing, and / or characterizing a mechanical wave source at one or more spatial points of interest on a structure using ultrasonic guided waves are provided. The method includes estimating the spatial channel impulse response at one or more spatial points of interest using a movable transducer. Collected data recorded in response to transient mechanical waves is then combined with the spatial channel impulse response estimates to detect, localize, and / or characterize the source. A direct path from the mechanical wave source to each transducer is not required. Anisotropies and variations between transducer transfer functions may be accounted for and all propagation paths may be used to perform source localization. The method and system may leverage structural complexity rather than ignore it.

Owner:HIDDEN SOLUTIONS

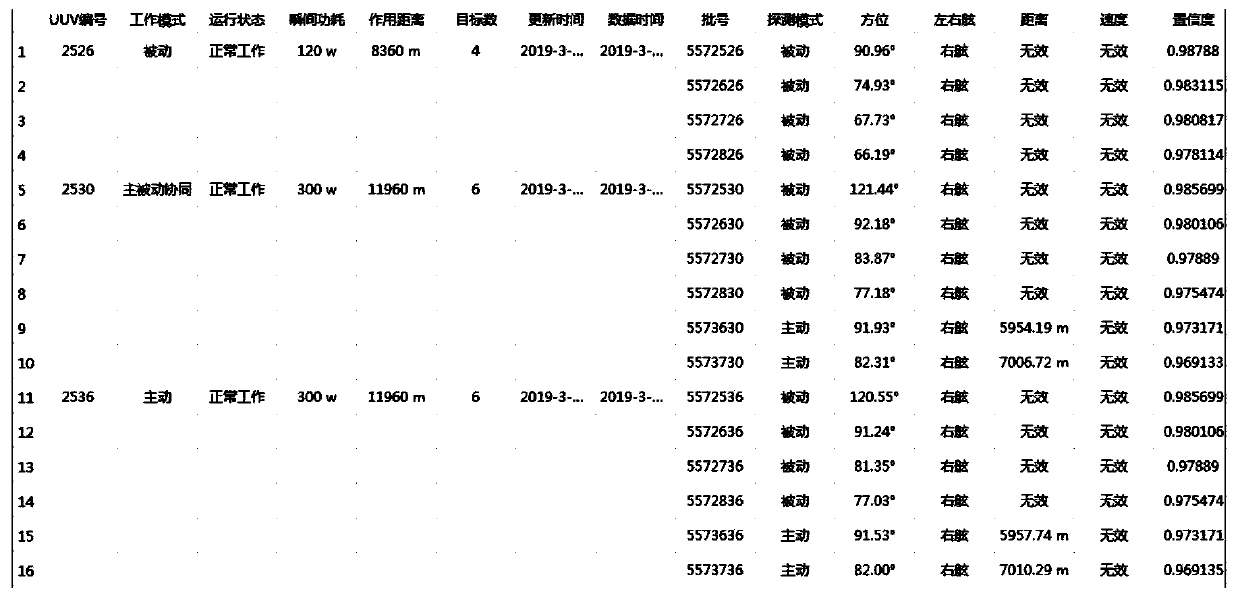

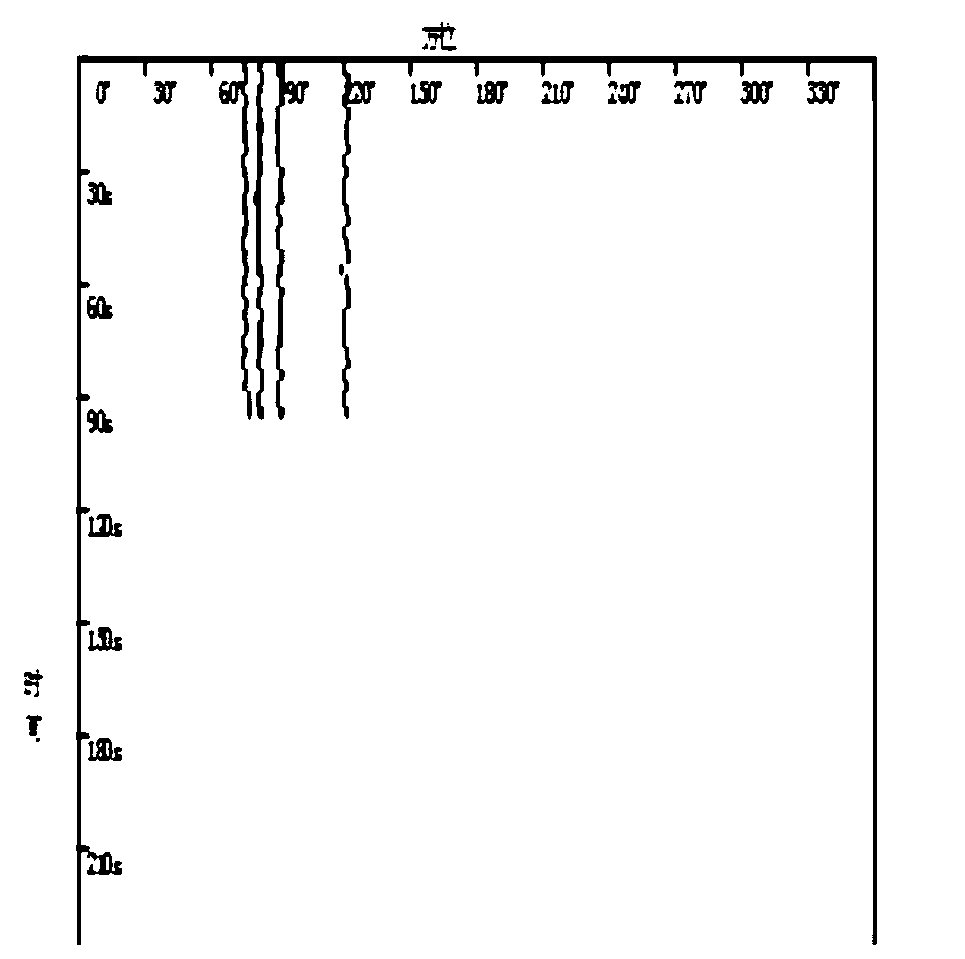

Universal UUV (Unmanned Underwater Vehicle) underwater target detection simulation method and system

The invention discloses a universal UUV (Unmanned Underwater Vehicle) underwater target detection simulation method and system. The method comprises the following steps that: receiving a selected detection mode, wherein the detection mode comprises active detection and passive detection; if the active detection is selected, starting the active detection, and obtaining a target detection result; and otherwise, starting the passive detection to obtain a target detection result. By use of the method and the system, the simulation research service of UUV capacity building can be provided, and through the modeling of typical underwater sound detection equipment and a detection process, a standardized and generalized underwater target detection model is provided.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

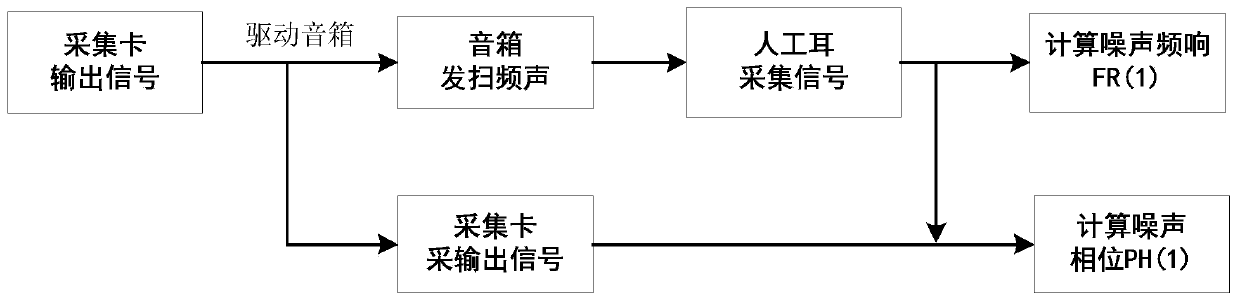

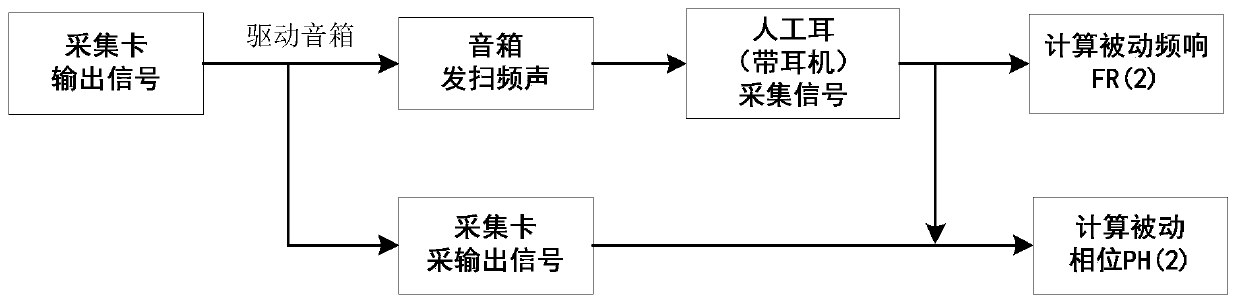

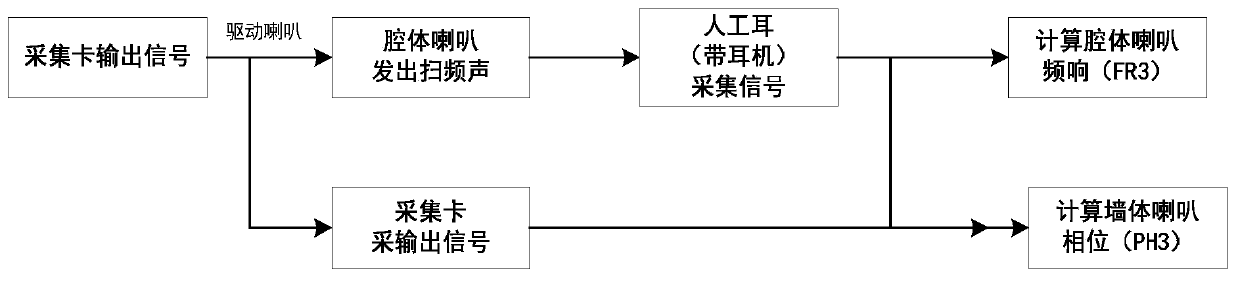

Test method for noise reduction earphone filter calculation

InactiveCN110062320ARealize one-click automatic test calculationThe testing process is simpleElectrical apparatusPassive testingEngineering

The invention discloses a test method for noise reduction earphone filter calculation. The test method comprises the following steps: a noise calibration step; a passive testing step: driving a soundbox to send out a frequency sweeping noise signal through a frequency sweeping signal, collecting a sound signal sent out by the sound box, converting the sound signal into an electric signal, and calculating a frequency response curve of the sound box; meanwhile, collecting the sweep frequency signal, calculating a noise phase curve by combining the collected sound signal emitted by the sound box, and calculating a passive frequency response and a passive phase; a horn parameter testing step: collecting sound signals emitted by the horn and converting the sound signals into electric signals,calculating a cavity horn frequency response curve, and calculating a phase curve of the cavity horn at the same time; a microphone parameter test step; and a calculation step: calculating ideal frequency response data and phase data of the target filter. According to the test method for noise reduction earphone filter calculation, data conversion is automatically carried out, a testing process issimplified, a product development period is shortened, and the product development efficiency is improved.

Owner:SHENZHEN MEGASIG MEASUREMENT & CONTROL TECH CO LTD

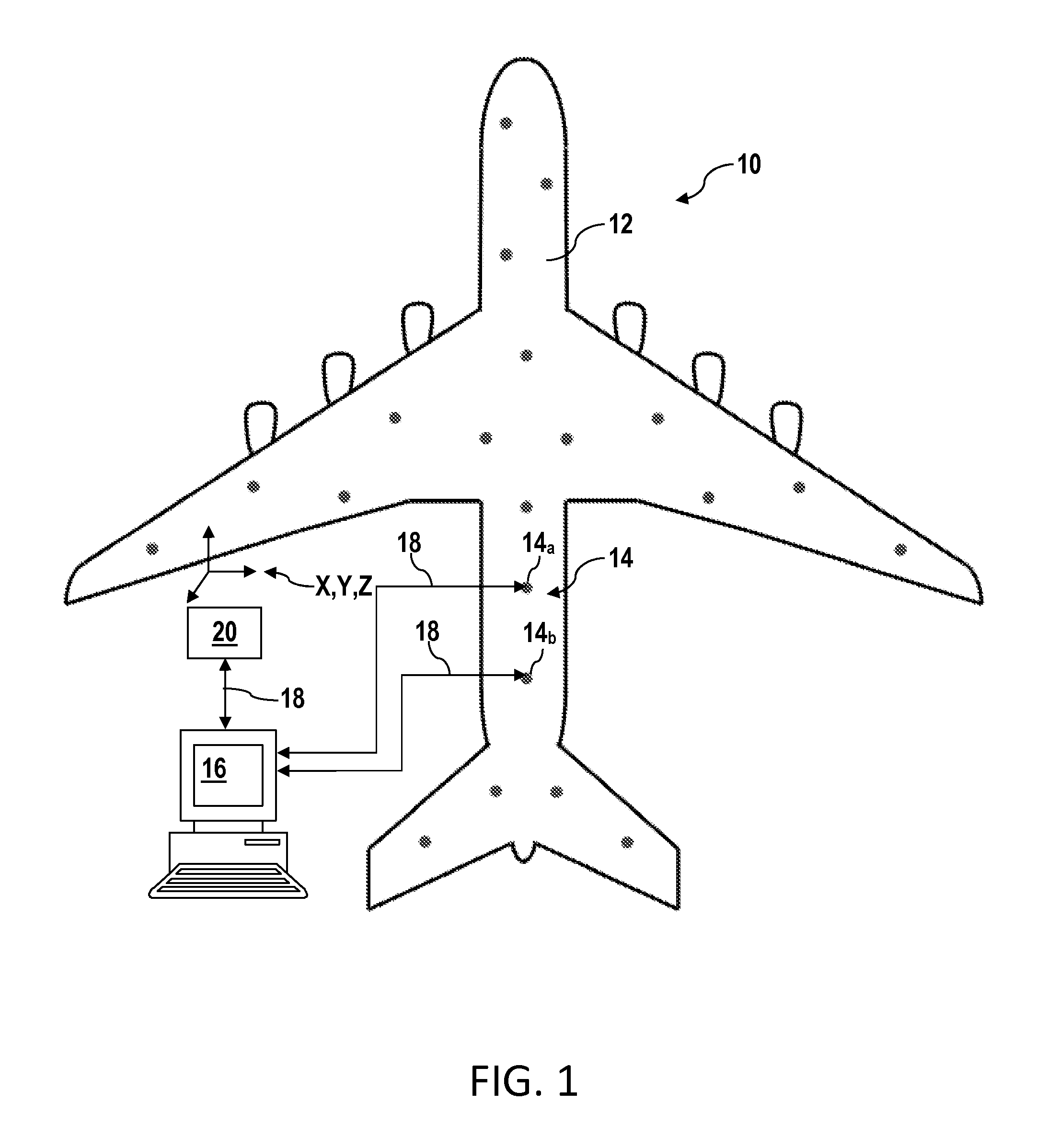

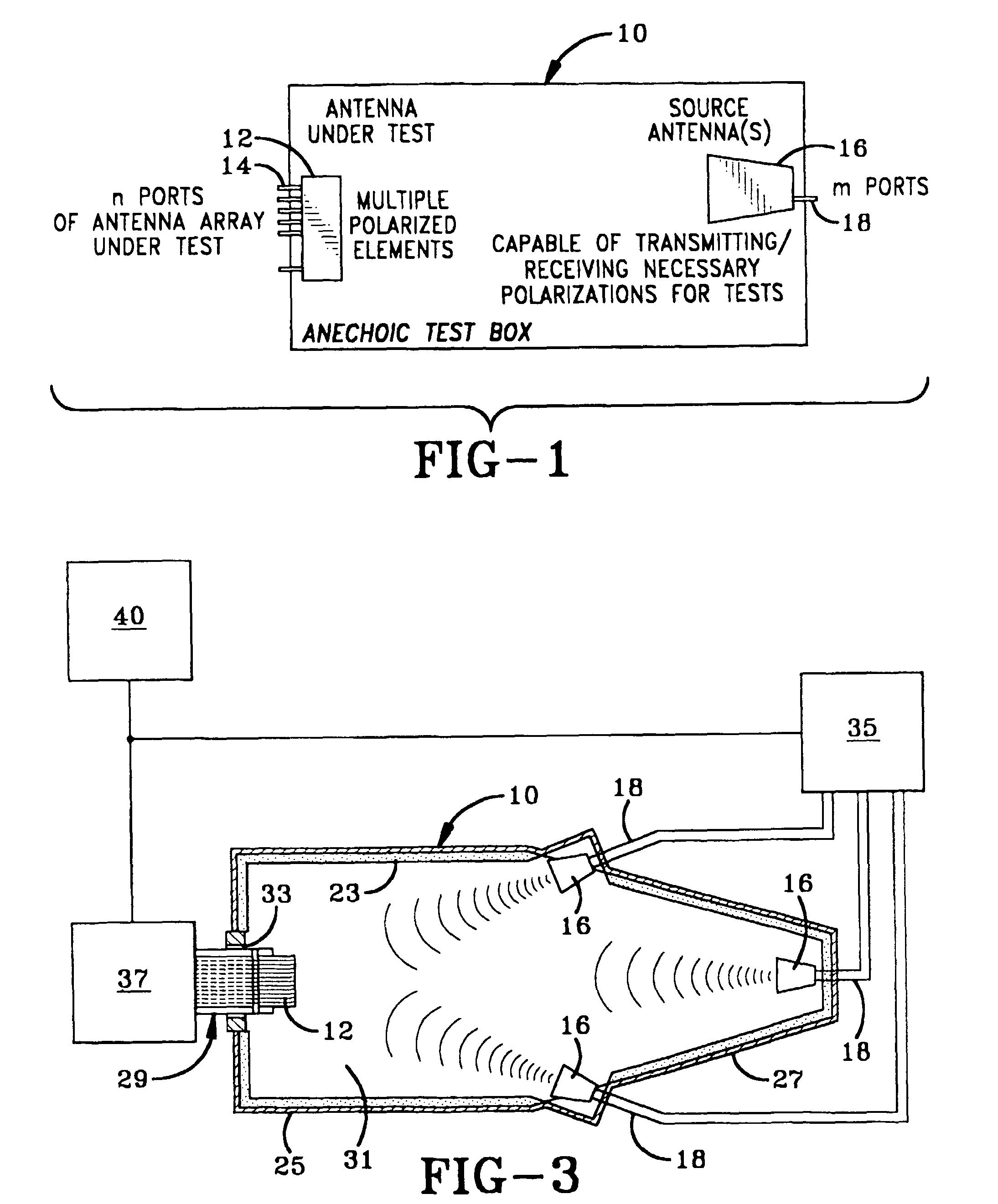

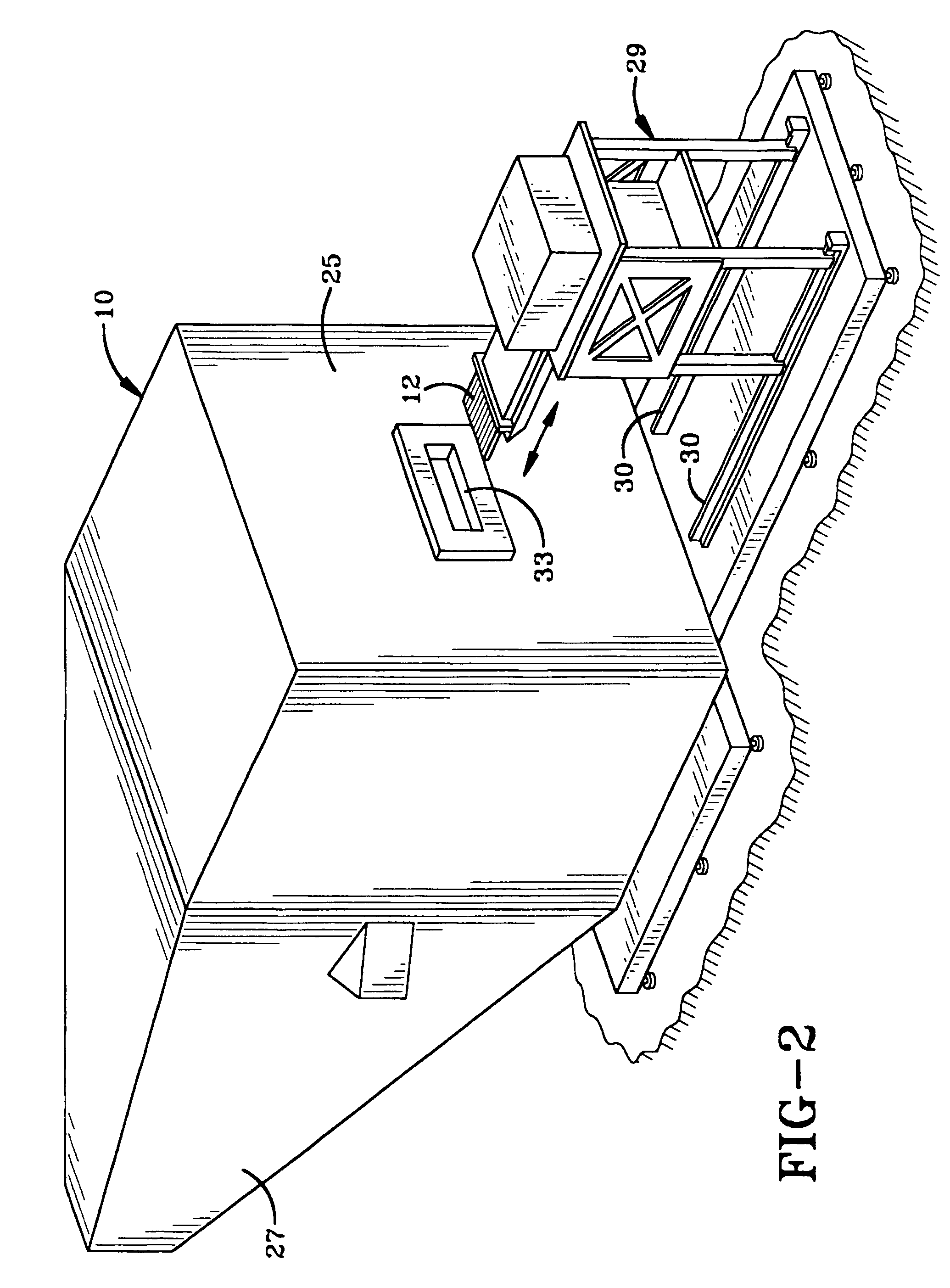

Method and system for determining antenna characterization

InactiveUS7667467B2Avoids and expensive testingResistance/reactance/impedenceRadiating elements structural formsPassive testingPassive networks

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

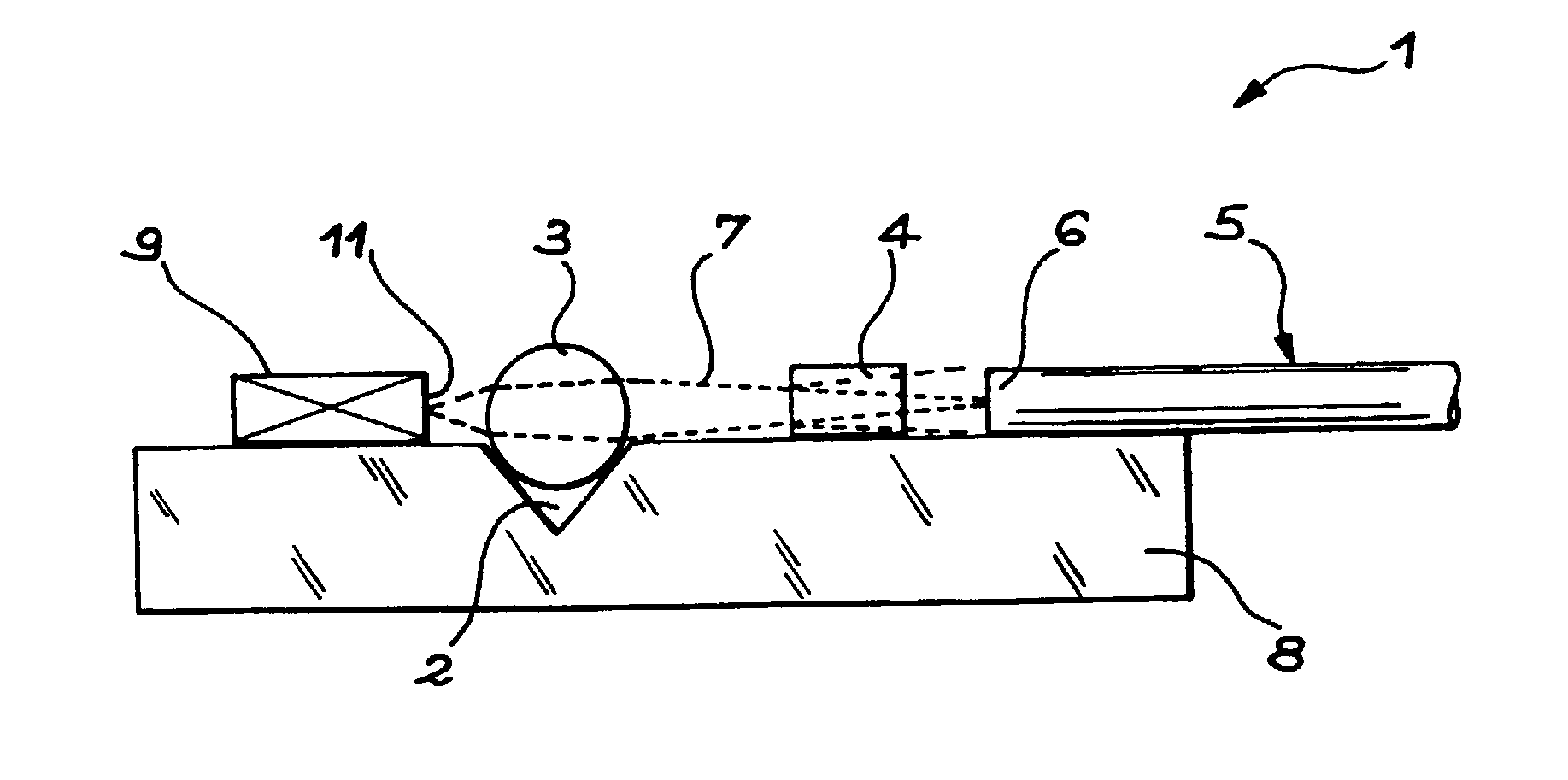

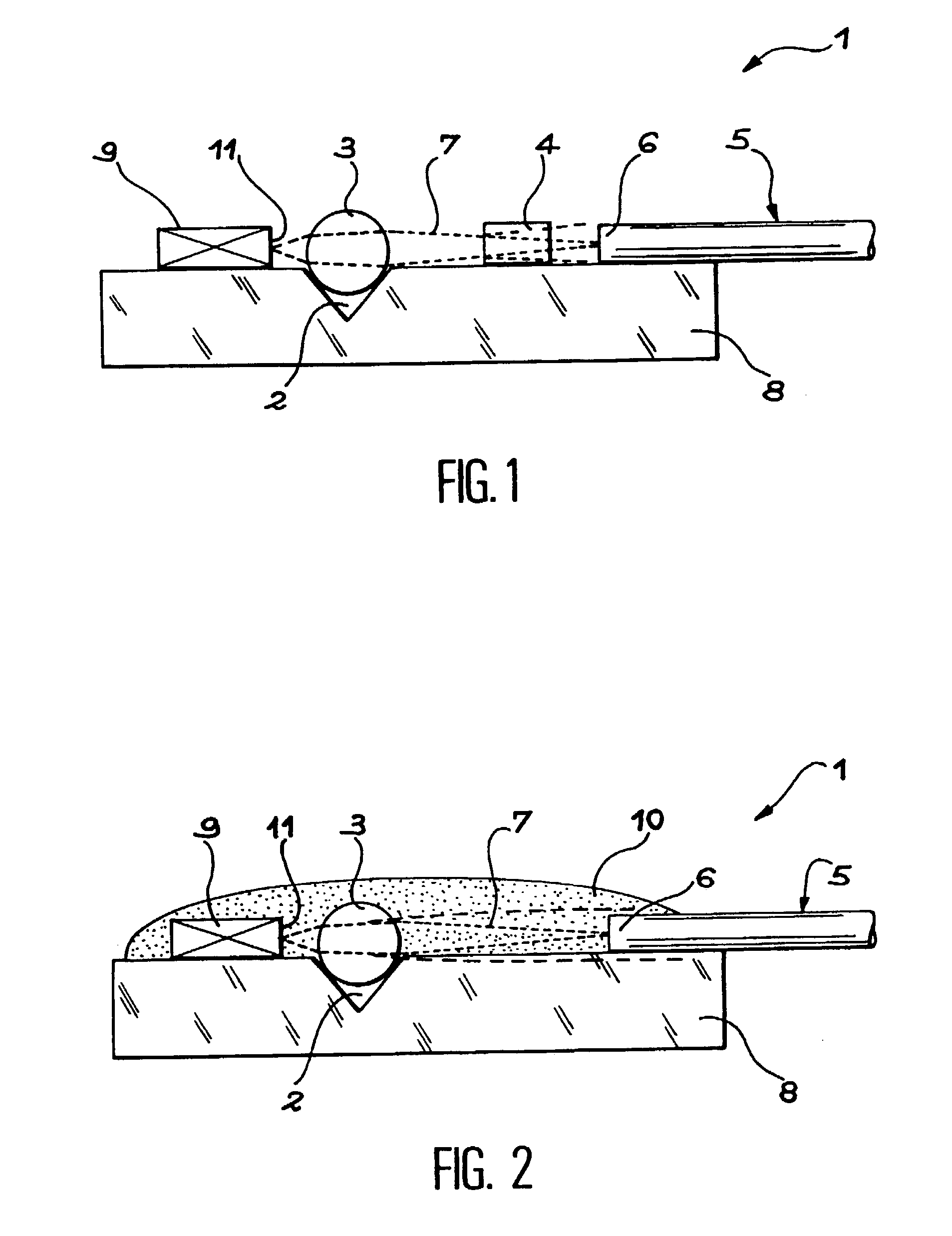

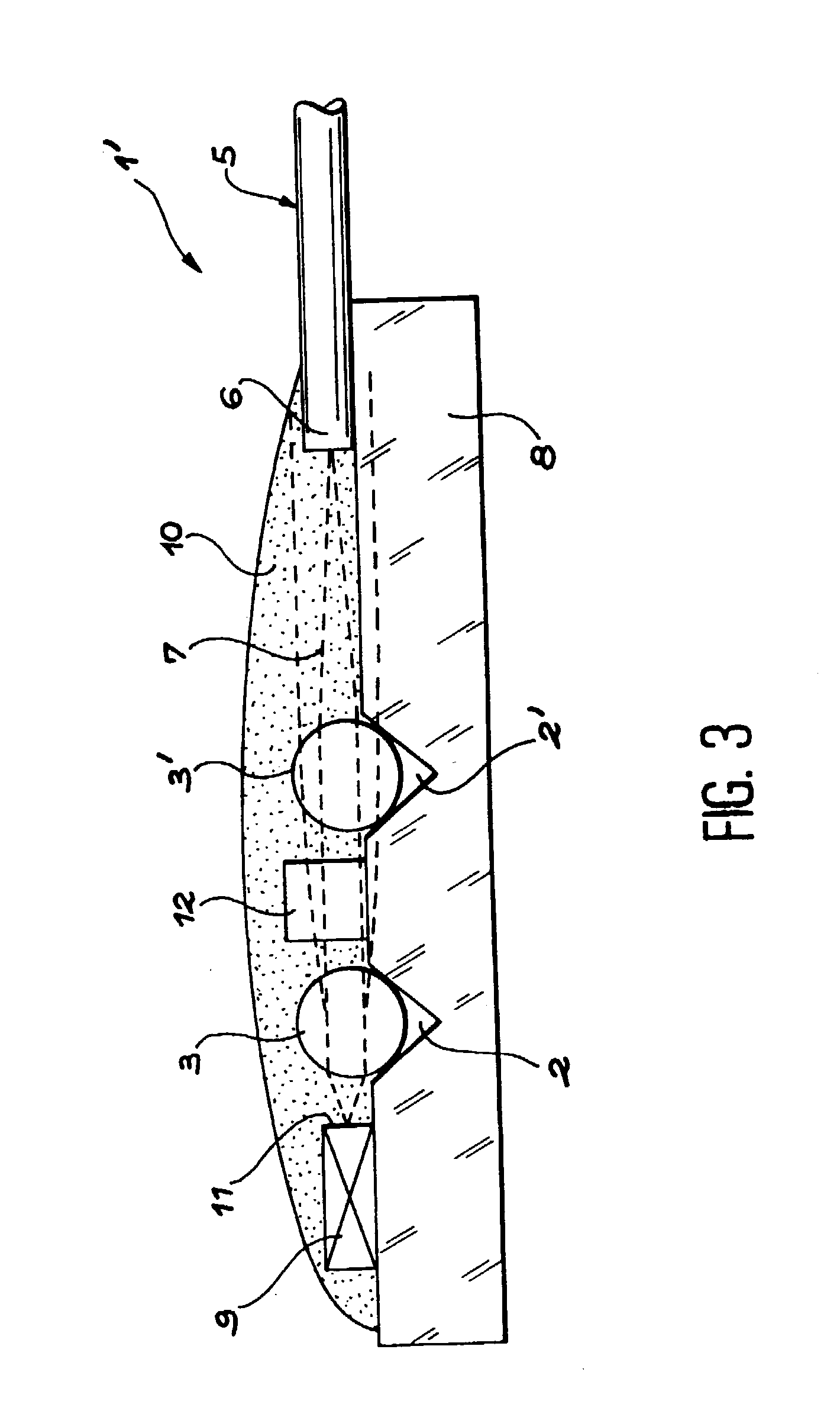

Passive compensating coupling laser device

InactiveUS20030179463A1Constant external efficiencyImprove efficiencyLaser detailsCoupling light guidesFiberTransmitted power

In an optical or optoelectronic module (1) an intermediate medium (4, 10) whose optical index decreases with temperature is introduced into the optical path (7) between a laser diode (9) and an optical fiber (5). This compensates, by passive means, the power losses of the laser emission due to the increase in operating temperature by improving the transmission between the diode (9) and the fiber (5). The intermediate medium (4, 10) is preferably deposited in the form of a capsule (10) enveloping the diode (9) and the end of the fiber (5). This achieves, by passive means, a transmitted power that is independent of the operating temperature.

Owner:OCLARO NORTH AMERICA

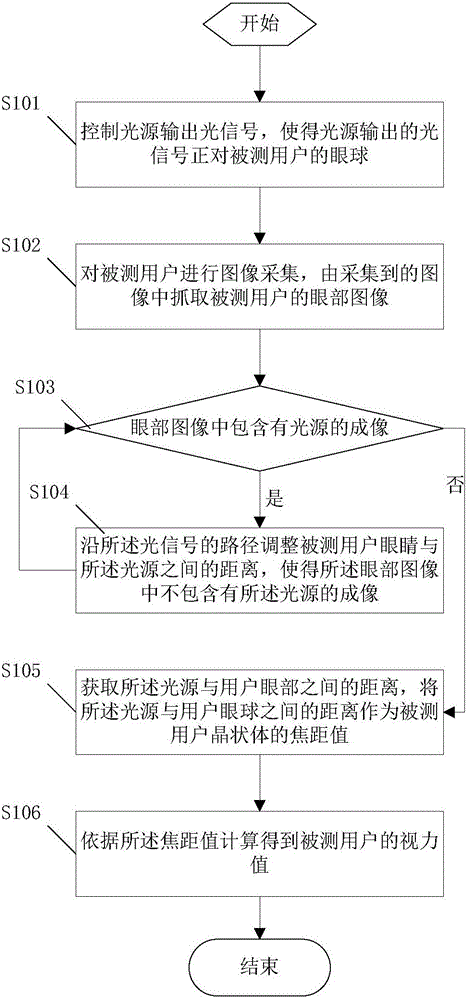

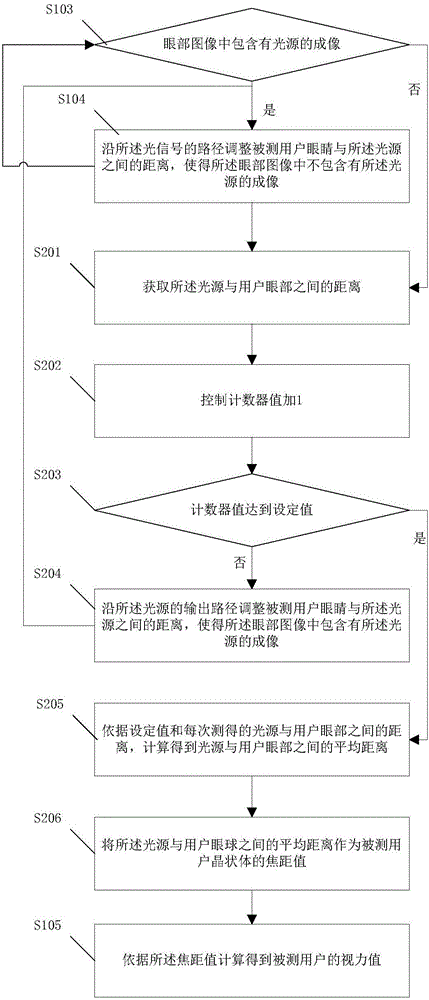

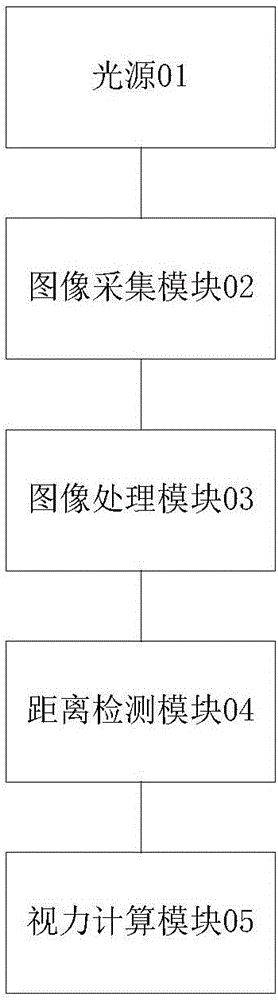

Eyesight detection method and device and eyesight detector

ActiveCN106491075AWill not deformNo deformationRefractometersSkiascopesPassive testingComputer science

The application provides an eyesight detection method and device and an eyesight detector. The method comprises the following steps: controlling a light source to output an optical signal, and enabling light output by the light source to be aligned with an eyeball of a to-be-tested user; acquiring an image of the tested user and capturing an eye image of the to-be-testedtested user from the acquired image; identifying the eye image, judging whether the eye image comprises an image with a light source, if yes, adjusting the distance between an eye of the tested user and the light source along an output path of the light source, otherwise, acquiring the distance between the light source and the eye of the user; taking the distance between the light source and the eyeball of the user as a focal length value of a crystalline lens of the tested user; calculating an eyesight value of the tested user according to the focal length value. In the testing process, the user is in a tested state, and the user does not need to read information actively, therefore, the crystalline lens of the user keeps a normal state all the time in the testing process and does not deform, and an eyesight measurement result is more accurate.

Owner:GREE ELECTRIC APPLIANCES INC

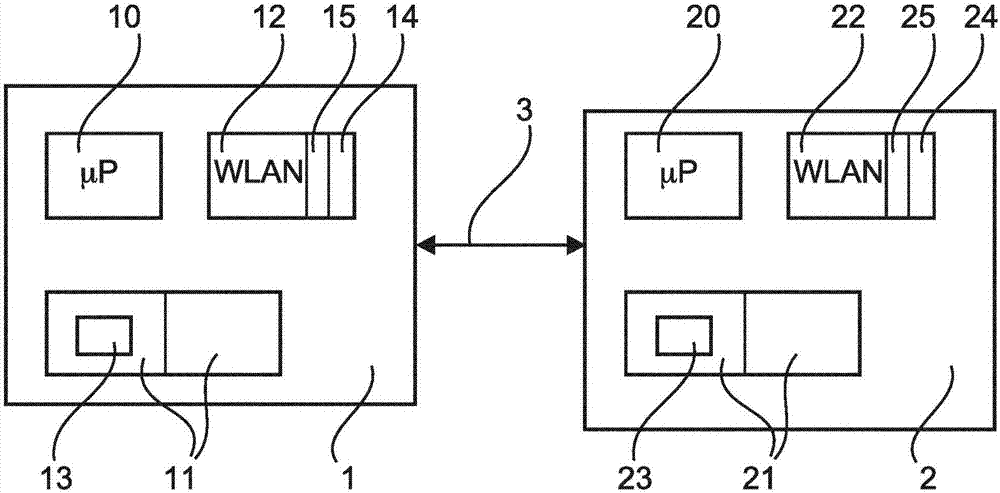

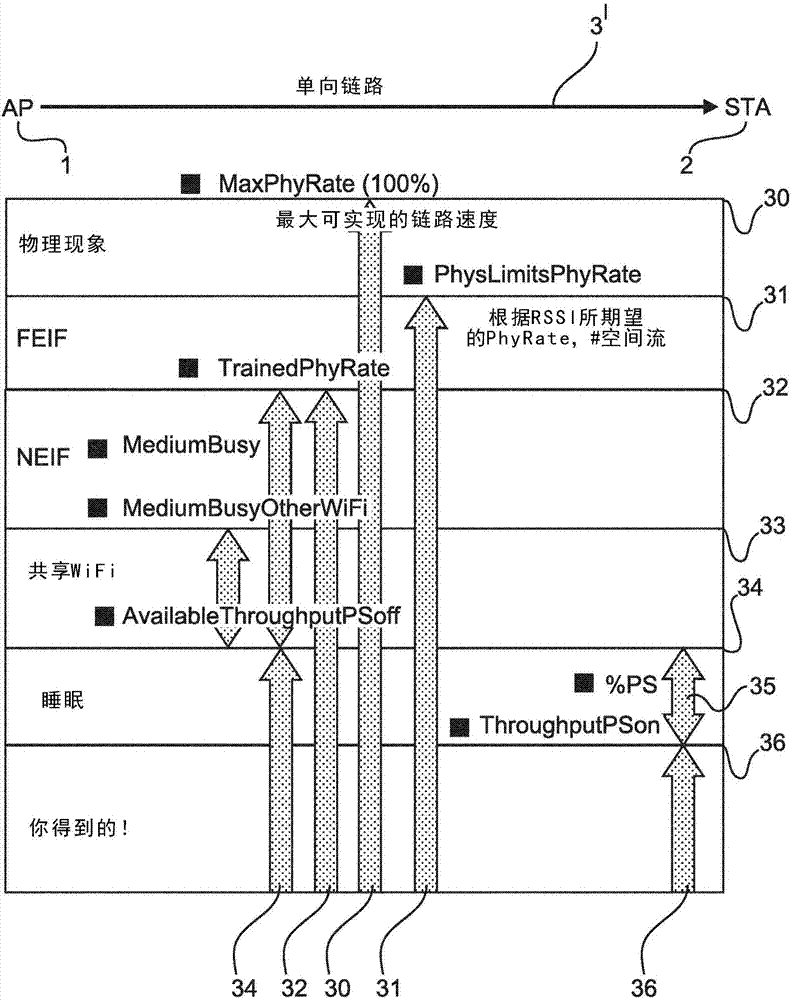

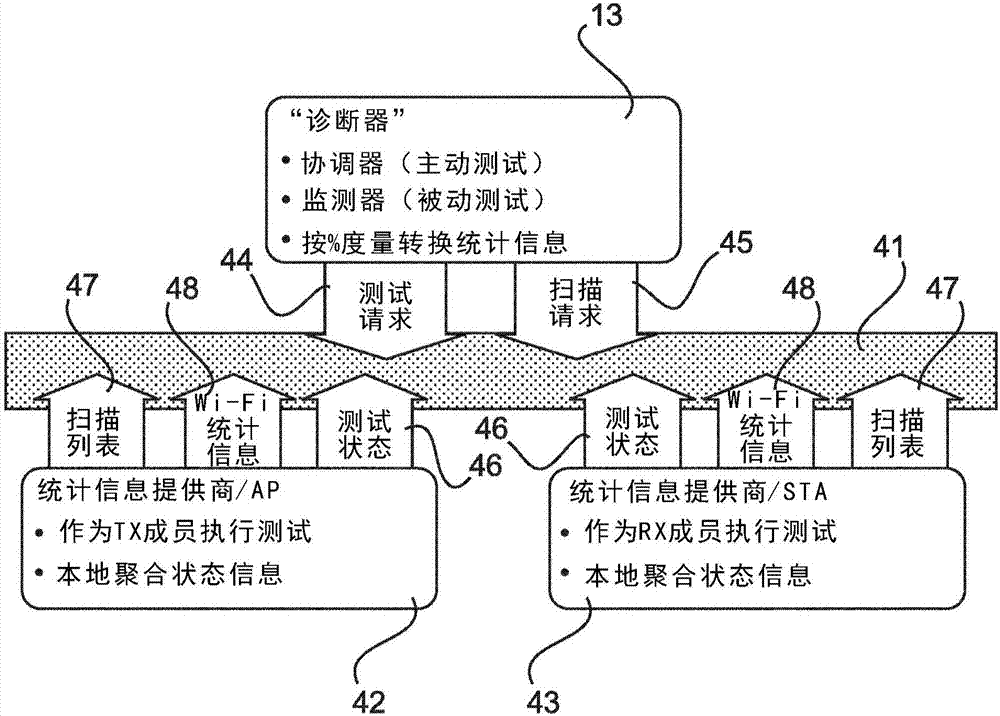

Method for analysing a wireless link of a WI-FI node, respective circuit performing the method, and application

A method for analyzing a wireless link (3) of a wireless node of a customer premises equipment (CPE) device (1) during operation of the CPE device comprises: performing an active test, during which a data transmission is forced through the wireless link, to obtain a first set of parameters, and performing before or after the active test a passive test, which is a monitoring mode during which a data transmission of the CPE device is monitored, to obtain a second set of parameters. In particular, based on the first set of parameters, it is determined whether and to which extent the wireless link is in an uncertainty zone, and based on the second set of parameters, the decision is made to assign an observed decrease in a measured data rate to physics effects or to interference effects.

Owner:AIRTIES BELGIUM SPRL

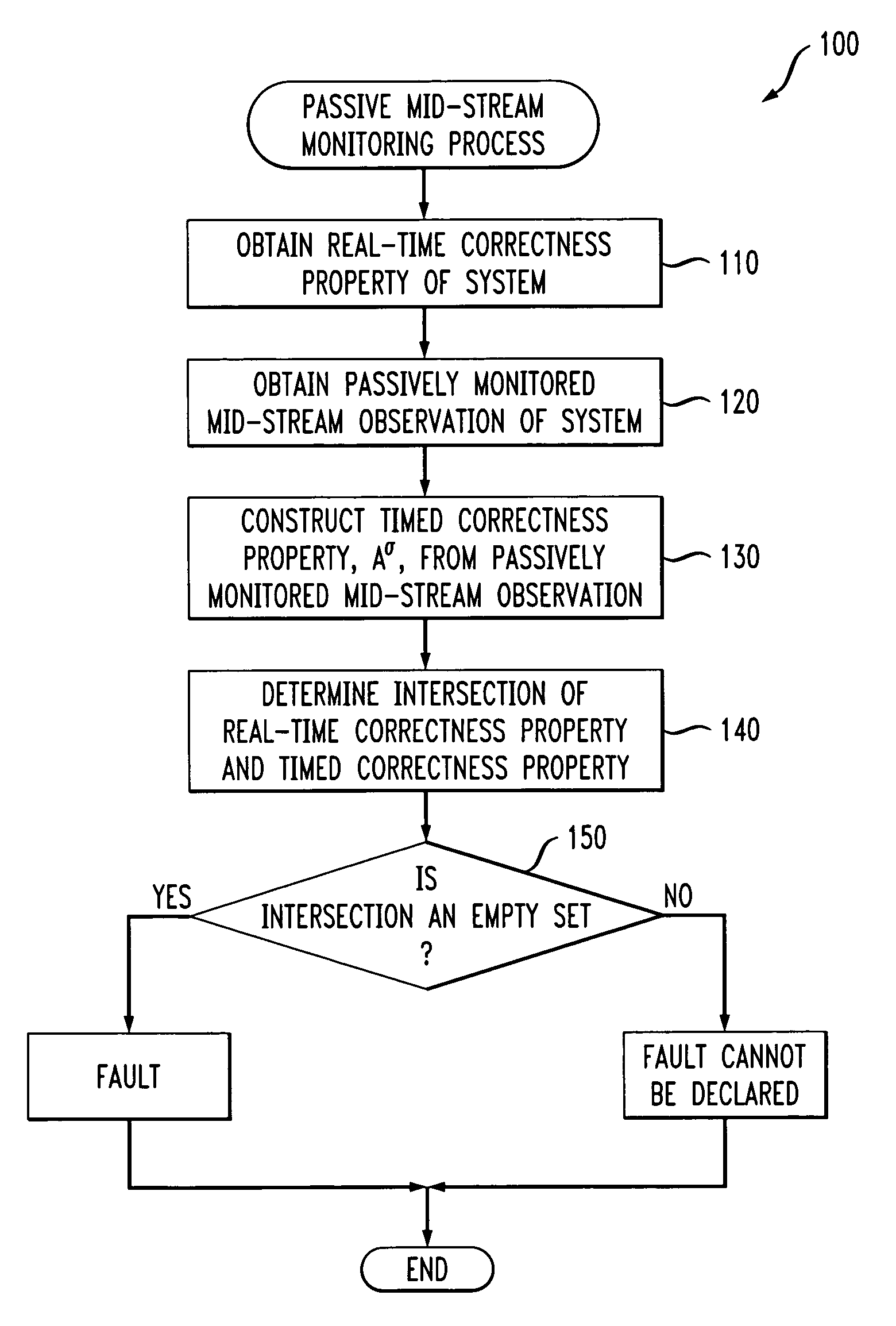

Battery balance management circuit

ActiveUS20190187213A1Stable large current outputImprove product applicabilityCircuit monitoring/indicationCharge equalisation circuitElectricityPassive testing

A battery balance management circuit includes an active and passive testing balance bus, a plurality of battery sets, a primary charging converter, a secondary charging system, an electrical load and a battery management system. An external balance management mechanism is utilized to compensate for current loss of the battery set, effectively enabling the battery sets to provide stable large current output.

Owner:NAT CHUNG SHAN INST SCI & TECH

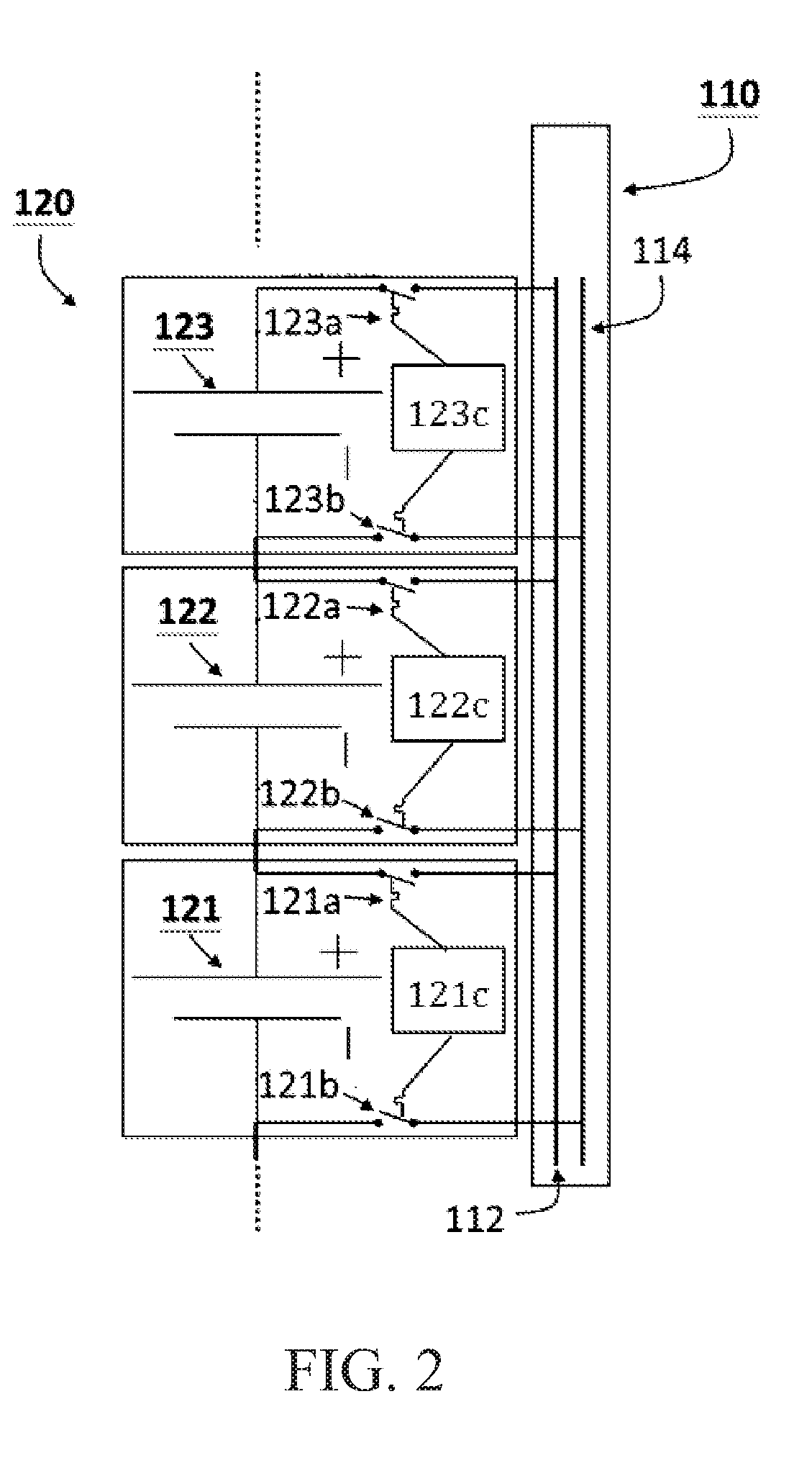

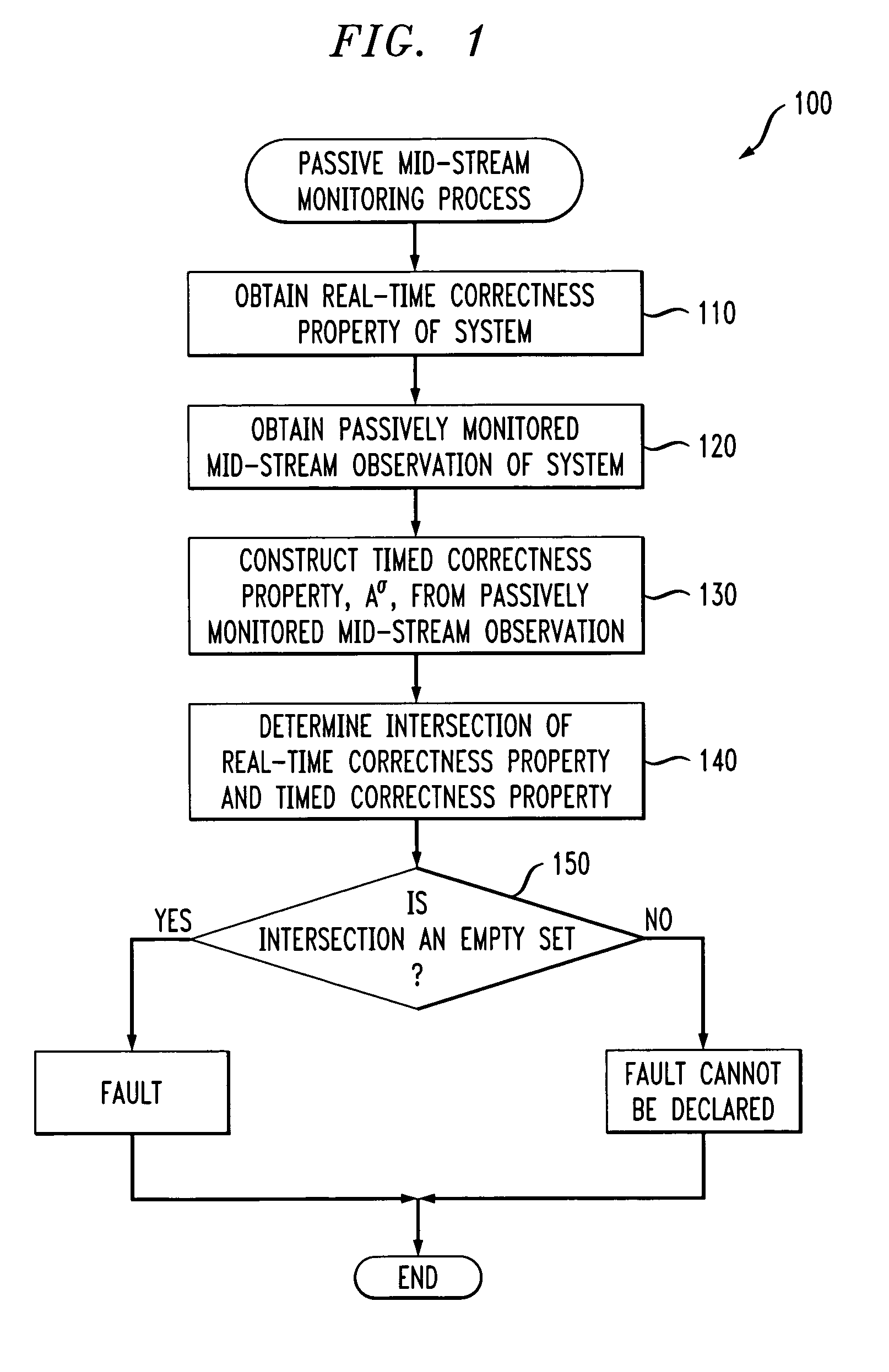

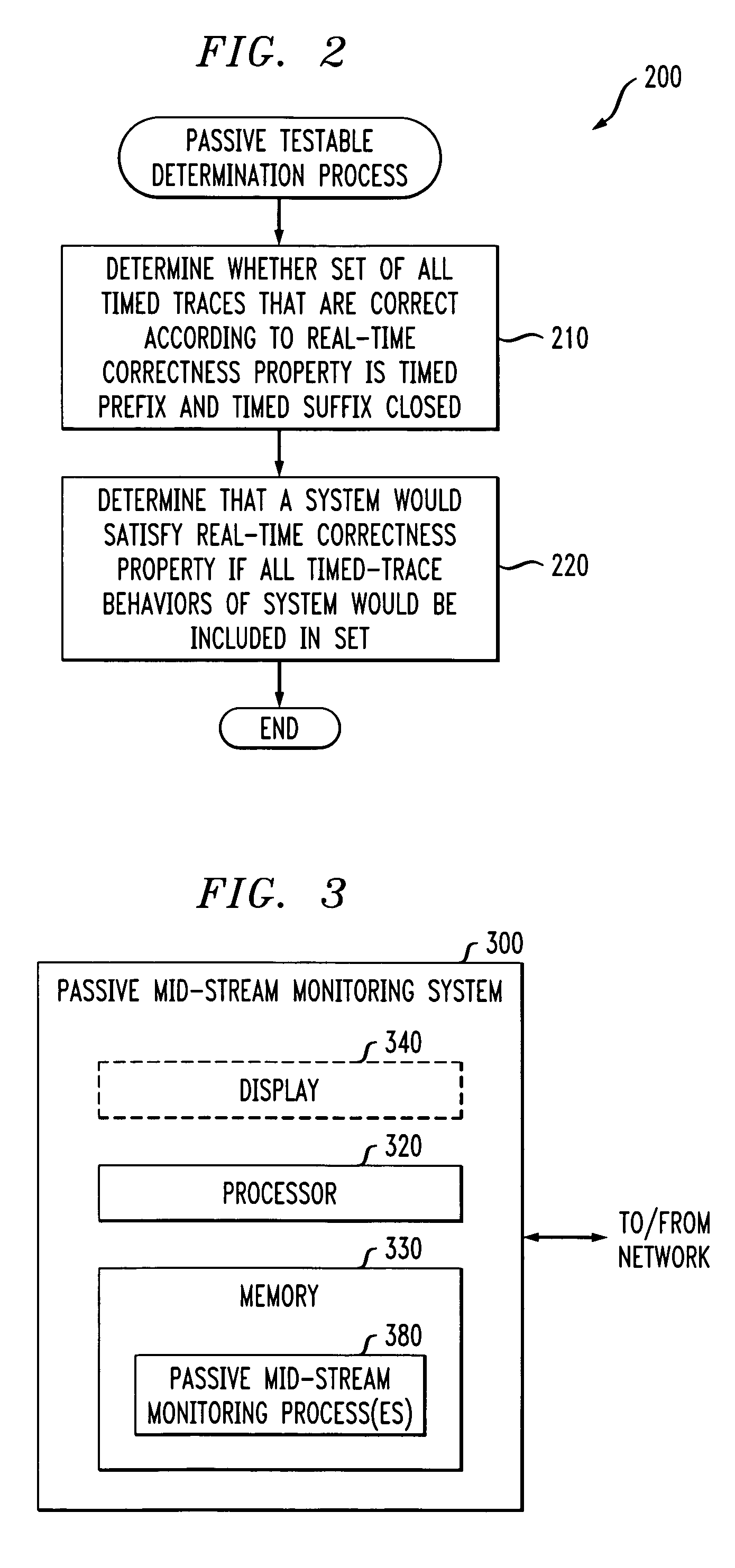

Methods and apparatus for passive mid-stream monitoring of real-time properties

ActiveUS20070124456A1Data processing applicationsDigital computer detailsPassive testingReal-time computing

Methods and apparatus are provided for passive mid-stream monitoring of real-time properties. A passive mid-stream monitoring process is disclosed that determines whether a system is faulty. The passive mid-stream monitoring process obtains a real-time correctness property and a passively monitored mid-stream observation of the system. A timed correctness property, Aσ, is constructed from the passively monitored mid-stream observation. An intersection of the real-time correctness property and the timed correctness property is then determined to determine if the system is faulty. A passively testable determination process is also disclosed that determines whether a real-time correctness property for a system is passively testable. A determination is made as to whether (i) a set of all timed traces that are correct according to the real-time correctness property is timed prefix and timed suffix closed; and (ii) a system would satisfy the real-time correctness property if all timed-trace behaviors of the system would be included in the set.

Owner:WSOU INVESTMENTS LLC

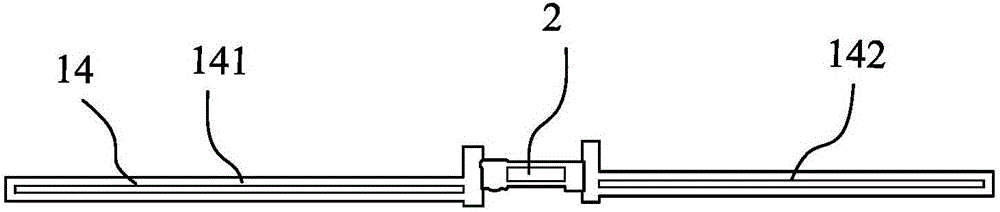

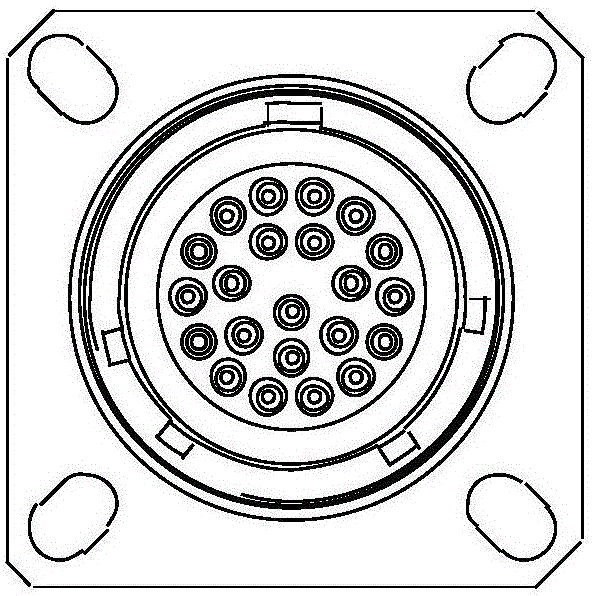

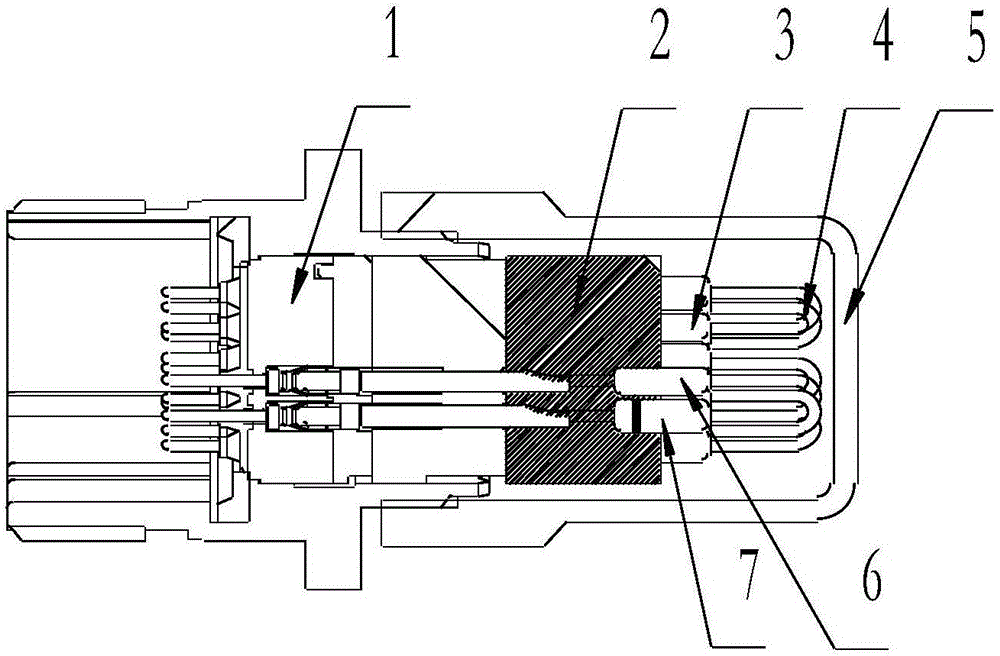

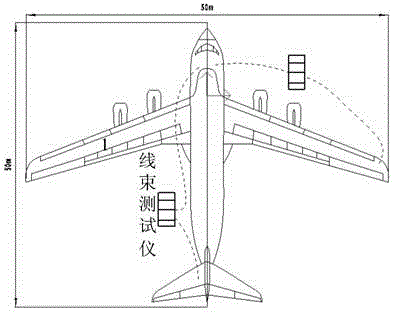

Terminal module used for cable conduction detection

InactiveCN106546876AAvoid clutterImprove the test environmentFault location by conductor typesAircraft components testingElectrical resistance and conductancePassive testing

The invention belongs to the field of passive testing and specifically relates to a terminal module used for cable conduction detection. In a conventional cable test system, a detected cable is connected with a test device after being switched through a test cable, and the two ends of the detected cable need to be switched by use of the test cable; and an adaptor cable is quite clumsy and disordered to use. According to the terminal module, an opening end of a metal protective cover is provided with a connector part, the metal protective cover internally comprises an electronic component, the electronic component comprises multiple unidirectional conduction circuits composed of electronic diodes and resistors, and two end points of each unidirectional conduction circuit are connected with pins corresponding to the connector part; and when a cable is detected, the terminal module is connected with the cable, and by applying test signals to the pins corresponding to the other end of the cable, conduction performance of the cable is determined. A test system is simplified, and at the same time, the performance requirement for a master control unit of the test system is reduced.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Apparatus and method for passive testing of alcohol and drug abuse

InactiveUS8529462B2Digital data processing detailsPerson identificationCompound organicAlcohol and drug

An automated system and method for passive testing of alcohol and drug abuse. The system enters a participant or subject into the system who is to be monitored during a probationary or other program for alcohol or drug abuse offenders. The system provides a drug testing home device or a drug testing kiosk device for use by the participant. The system enrolls the biometrics information of the participant into the computer system (e.g., finger print, voice, image, volatile compound organic gas level, and pH level). When the participant is to be tested in accordance with a testing schedule, the system validates these same biometrics of the participant, conducts the test, and then analyzes the test information for determining if the participant has been using alcohol or other drugs and should be subjected to a confirming urinalysis exam.

Owner:JUSTICE EZ TRAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com