Terminal module used for cable conduction detection

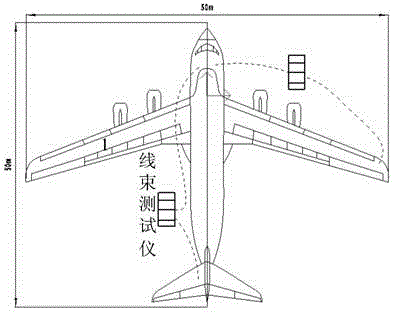

A terminal module and conduction detection technology, which is applied in the direction of fault detection according to conductor type, aircraft component testing, fault location, etc., to achieve the effect of halving the number of test nodes, improving test efficiency, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

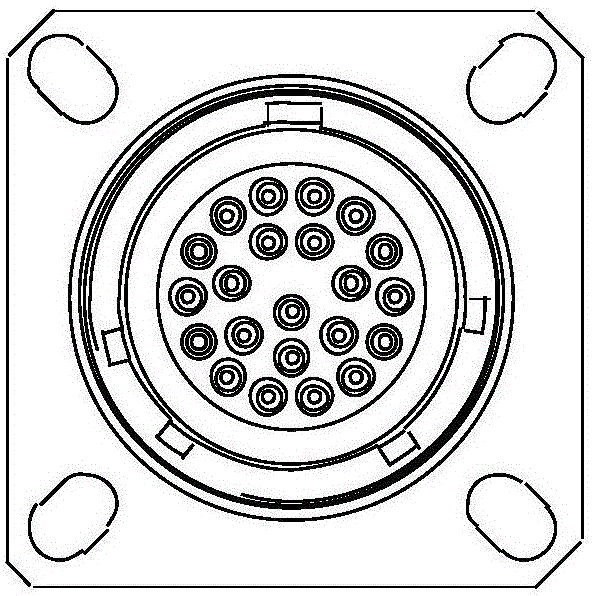

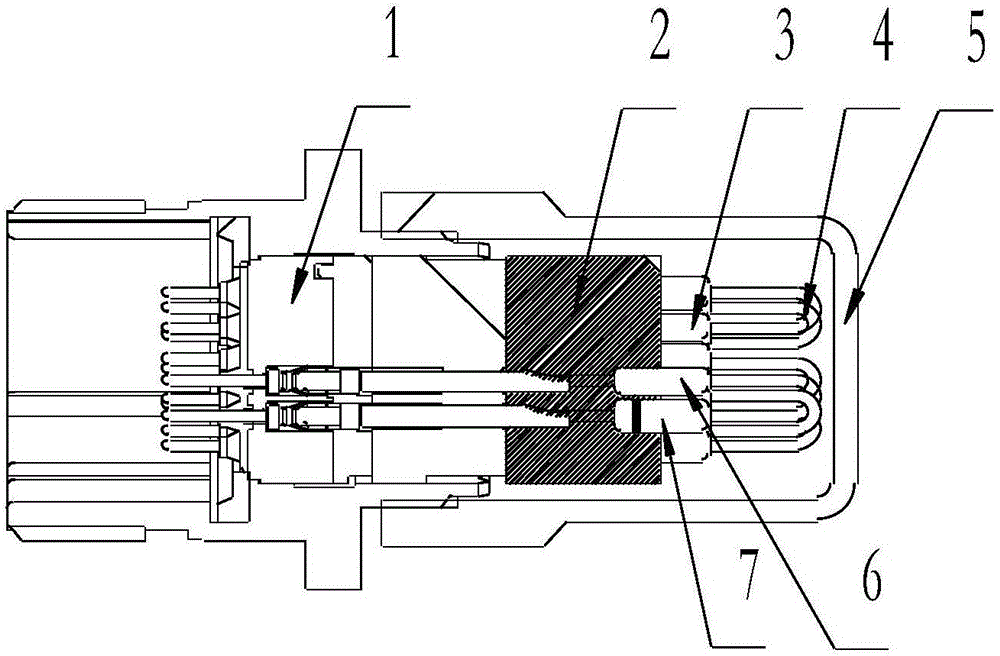

[0021] Determine the type of connector part 1 of the terminal module according to the type of the connector at the other end of the cable under test, and calculate the parameters of the diode 7 and resistor 6 according to the conduction principle requirements of the test instrument.

[0022] According to the number of cores of the tested cable, determine the number of diodes and resistance components. When the number of cores is odd, the connection diagram is as follows: image 3 As shown, when the number of cores is even, the connection diagram is as follows Figure 4 shown.

[0023] In order to ensure the stability of the connection between the electronic components and the contacts, a heat-conducting adhesive layer 2 is poured at the soldering point, which not only ensures the connector, but also meets the heat dissipation requirements of the electronic components. , to ensure insulation performance; a metal shield 5 is added outside the terminal module to protect internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com