Cyclic test device for fatigue of aeroengine compressor blade

A technology of aero-engine and test device, which is applied in measurement device, vibration test, mechanical component test and other directions, can solve the problems of low reliability of safe cycle life and hidden dangers in use, and achieves the avoidance of hidden dangers in use and easy operation. , to solve the effect of low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

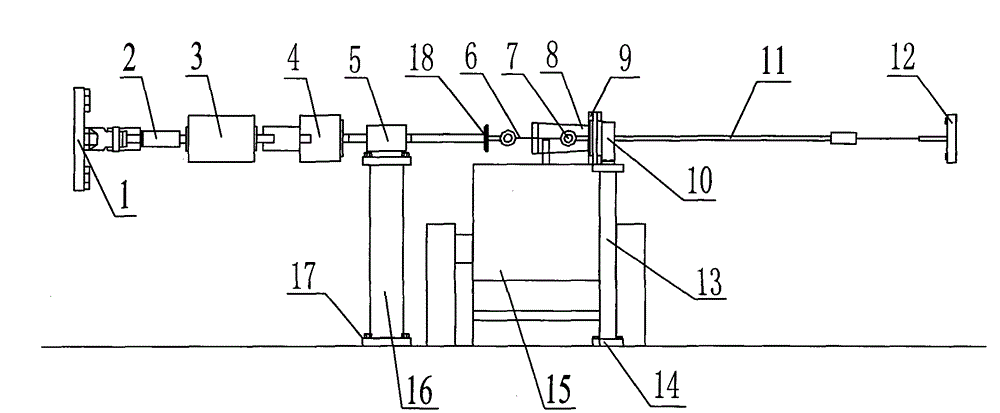

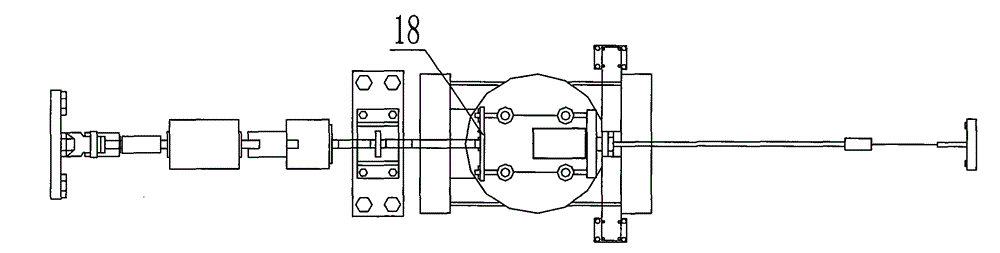

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] The invention provides an aeroengine compressor blade fatigue cycle test device, which includes a centrifugal force loading assembly for simulating the centrifugal force cyclic load borne by the aeroengine compressor blade when it is working. The test device also includes a high frequency vibration loading assembly for use in When simulating the high-frequency load that the aeroengine compressor blades work; the high-frequency vibration loading assembly includes a vibration table 15, a support A13 of a fixed compressor blade test piece 8, and a support B16 of a fixed centrifugal force loading assembly, wherein the vibration The stand 15 is used to apply high-frequency vibration to the compressor blade test piece 8 .

[0017] In order to apply corresponding loads to the compressor blade test piece 8, the compressor blade test piece 8 is fixed on the top of the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com