High-temperature flame flow device for dynamically and cyclically testing thermal shock resistance of thermal barrier coating

A technology of thermal barrier coating and thermal shock resistance, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of small flame jet beam spot, large radial temperature gradient of flame flow, and weak heating capacity, etc. The effect of small temperature gradient and constant temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

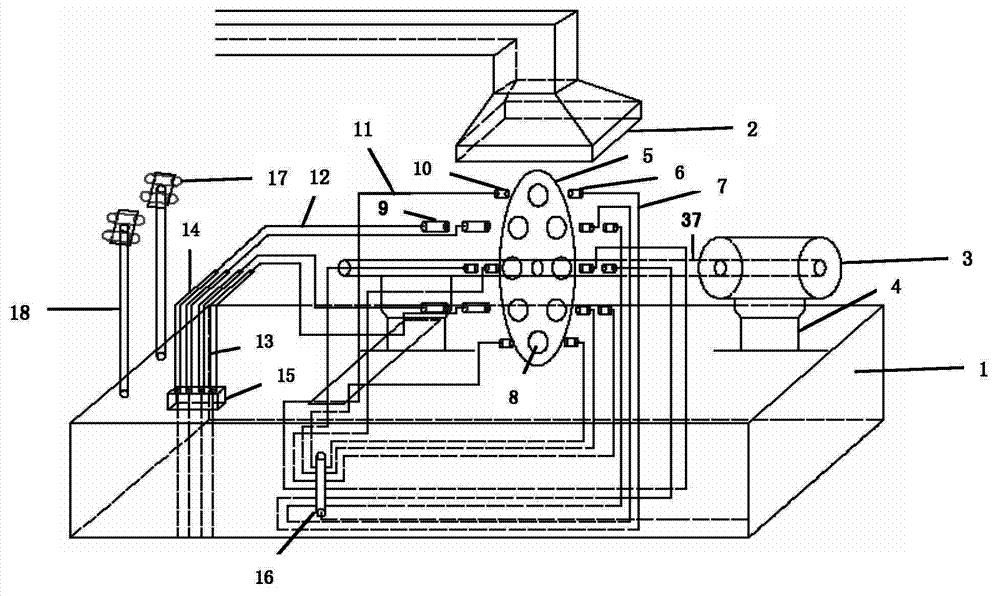

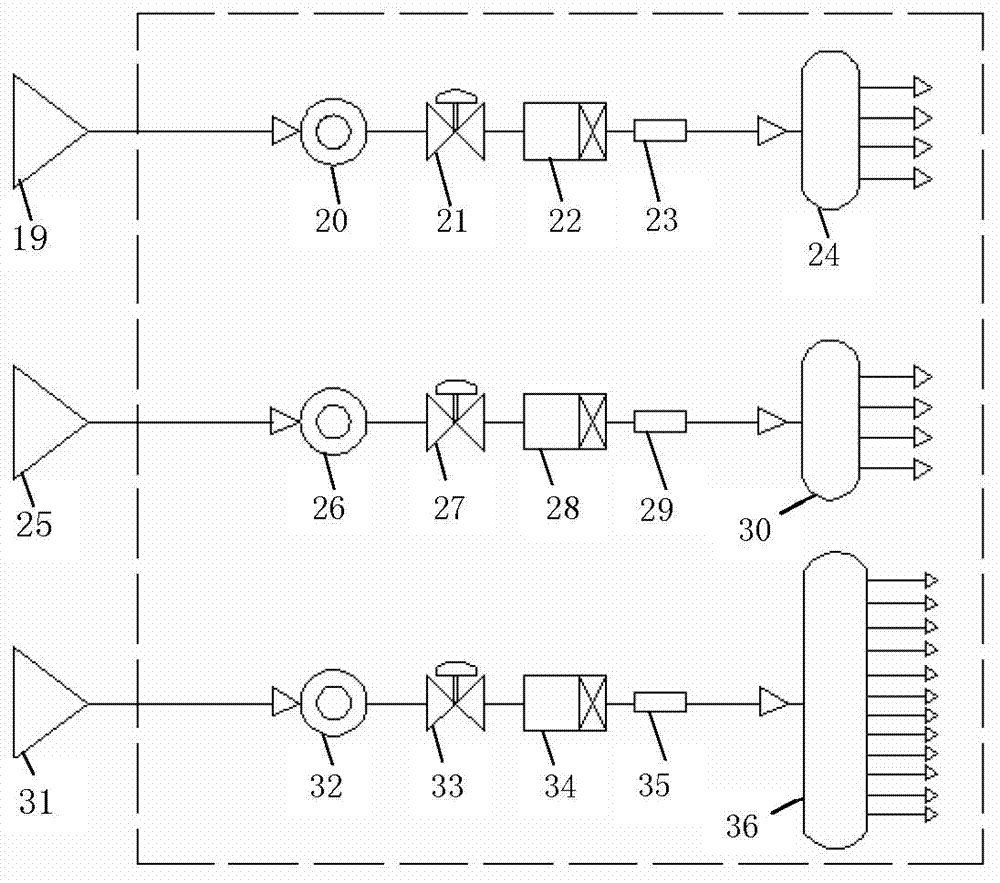

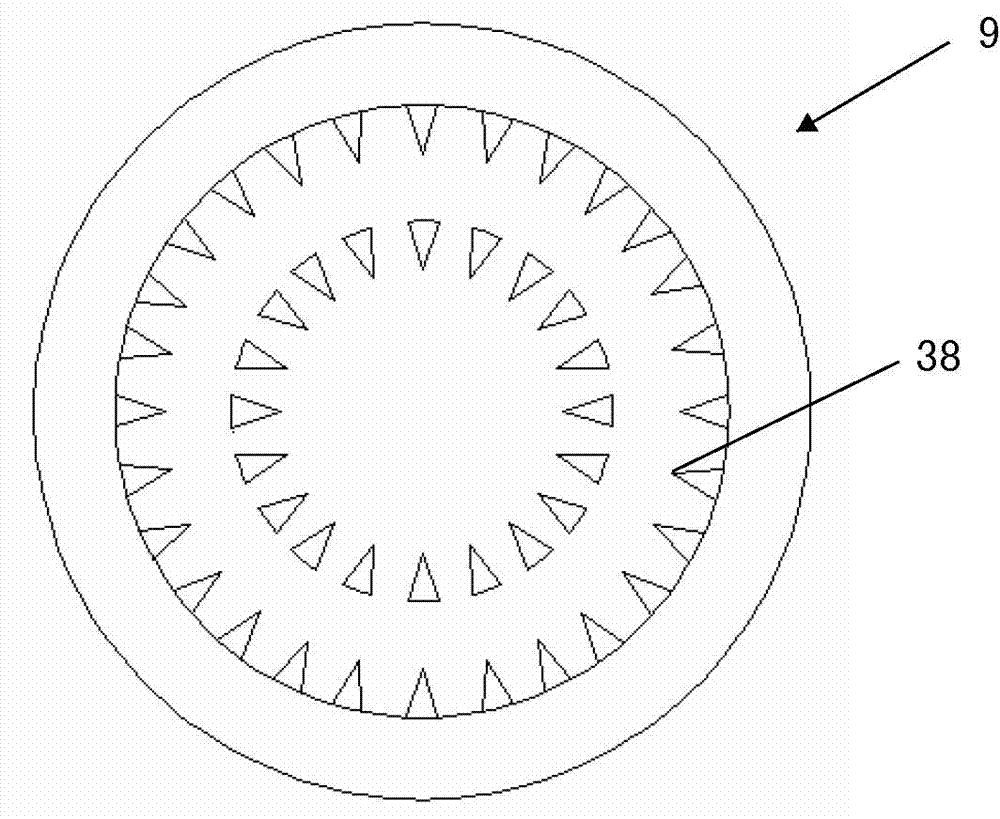

[0037]The high-temperature flame flow device for testing the thermal shock resistance of thermal barrier coatings in a dynamic cycle of the present invention is suitable for testing the thermal shock resistance, which is an important performance index for measuring the service performance of thermal barrier coatings, in the field of aeroengines. figure 1 It is a structural schematic diagram of an embodiment of a high-temperature flame flow device for testing the thermal shock resistance performance of a thermal barrier coating in a dynamic cycle of the present invention. and image 3 It is a schematic cross-sectional view of a flame jet nozzle (hereinafter referred to as a flame nozzle) which is an embodiment of the high-temperature flame device according to the present invention.

[0038] The high-temperature flame flow device for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com