Method and system for testing infrared remote control

A technology of infrared remote control and test method, applied in signal transmission systems, non-electrical signal transmission systems, instruments, etc., can solve the problems of multi-manual operation, low work efficiency, high labor cost, and achieve lower frequency, lower cost, and lower labor costs. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

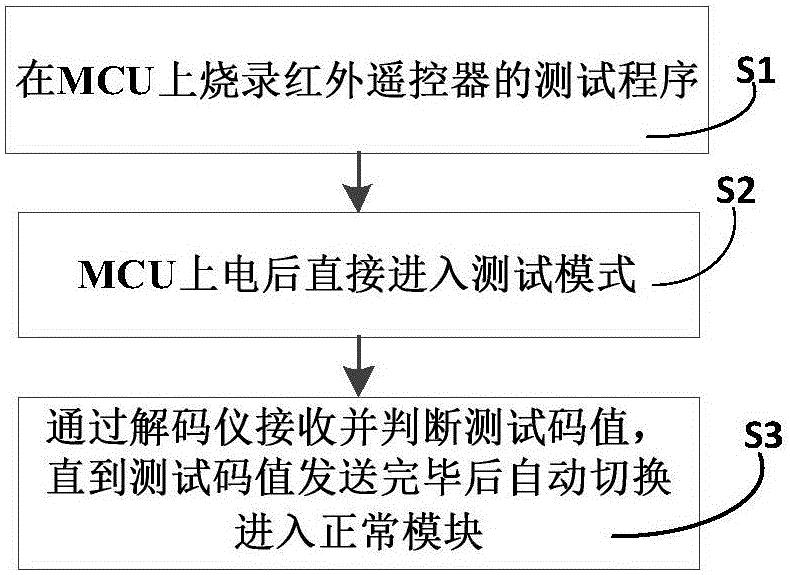

[0022] like figure 1 and figure 2 As shown, this example provides a test method for an infrared remote control, including the following steps:

[0023] Step S1, burning the test program of the infrared remote controller on the MCU;

[0024] Step S2, wait until the MCU is powered on, then directly enter the test mode according to the test program, and the MCU outputs the test code value;

[0025] Step S3, receiving and judging the test code value through the decoder, and entering the normal module through the MCU until the test code value is sent.

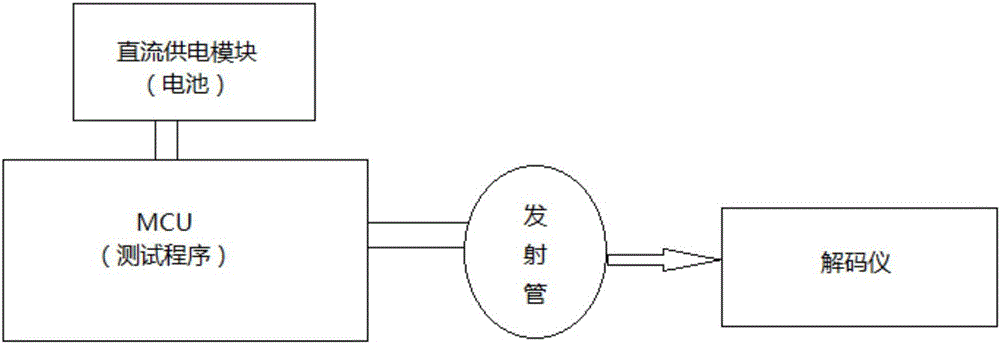

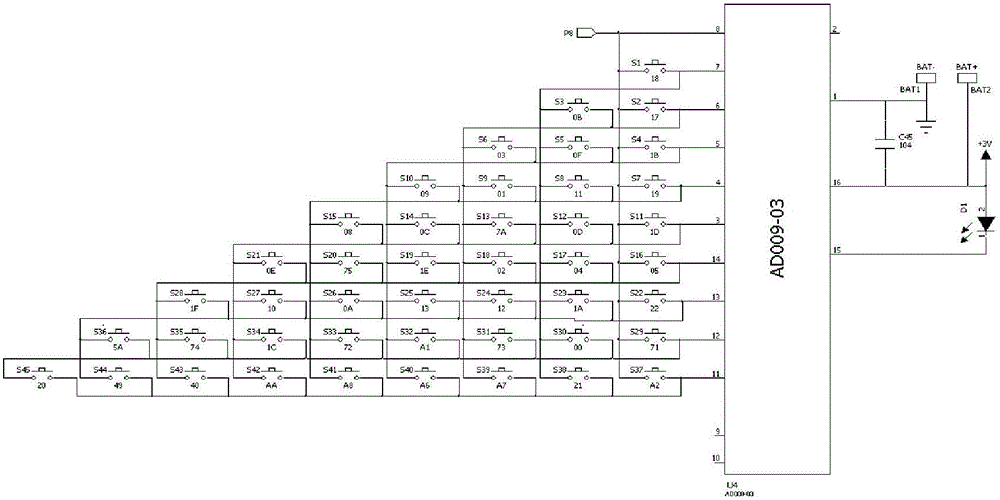

[0026] The step S1 described in this example is used to enable the MCU to automatically send the test code value through the preset test program, and the test code value is image 3 Each button code value shown in the circuit diagram can then be used to detect whether the hardware of the infrared remote controller is normal; in the step S2, after entering the test mode, the IO port of the MCU outputs an infrared test through an ...

Embodiment 2

[0033] This example also provides a testing system for an infrared remote controller, which adopts the testing method for an infrared remote controller as described in Embodiment 1, and includes a DC power supply module connected to the MCU.

[0034] This example also preferably includes a current test fixture, the DC power supply module is arranged on the current test fixture, when the infrared remote controller is placed on the current test fixture, the DC power supply module is connected to realize the MCU. Electricity, and automatically realize the detection of the current value. Therefore, in this example, it is only necessary to place the infrared remote controller on the current test fixture to automatically detect whether the hardware and working current of the infrared remote controller are normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com