Multi-channel alloy type hydrogen storage tank activating, performance-testing and packaging integrated equipment and technical flow thereof

An alloy-type, multi-channel technology, applied in mechanical equipment, measuring devices, hydrogen technology, etc., can solve the problems of low degree of automation, single specification of hydrogen storage tank, low versatility, etc., and achieves clear principle and high degree of automation. , Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

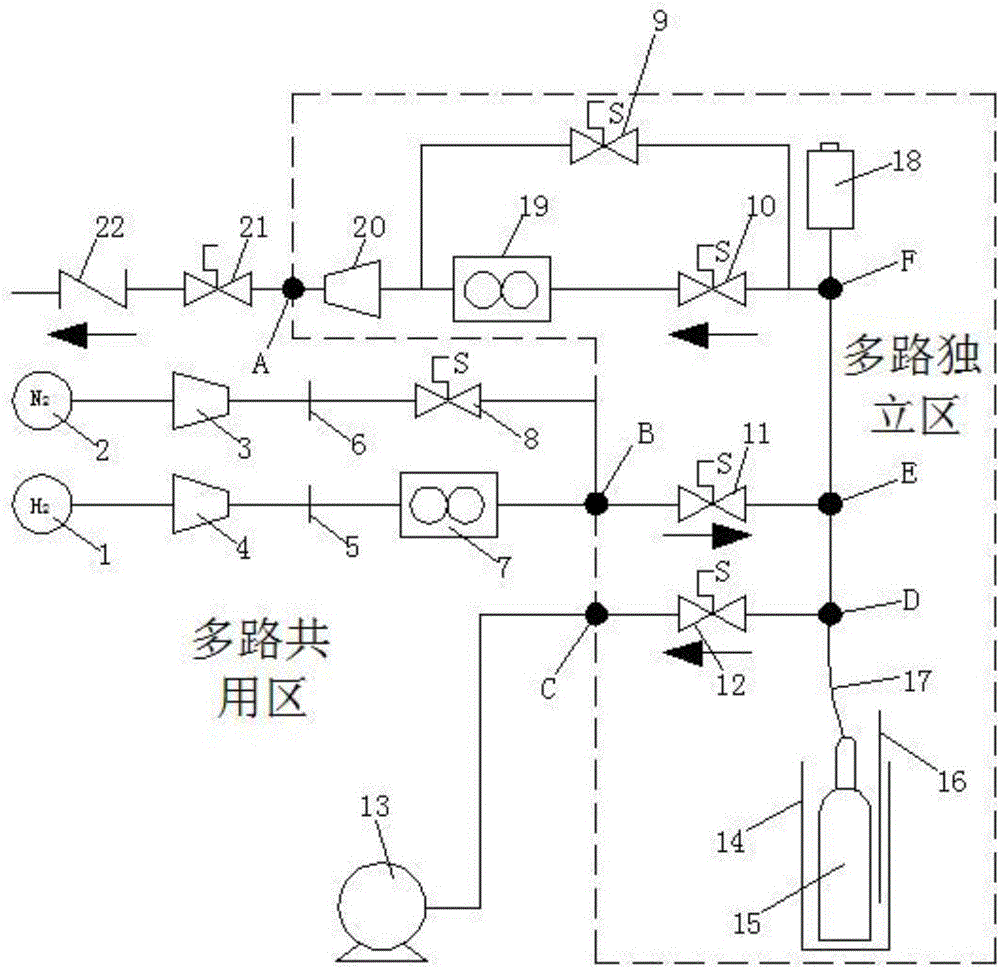

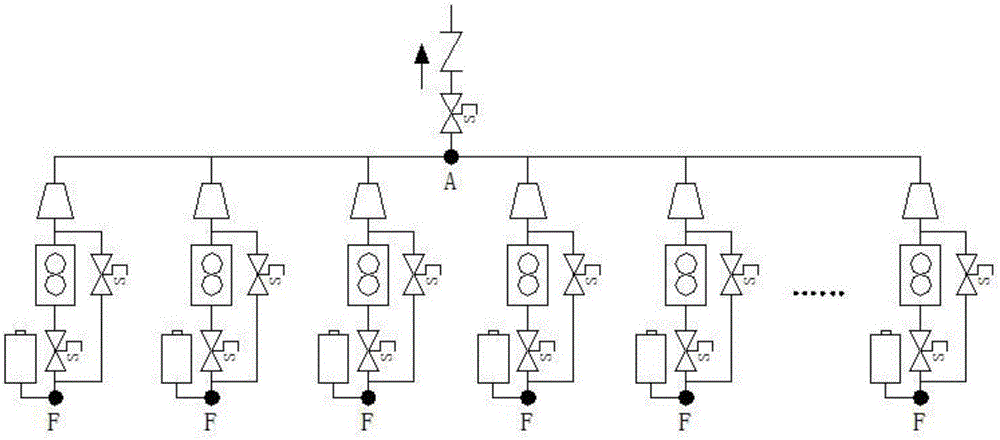

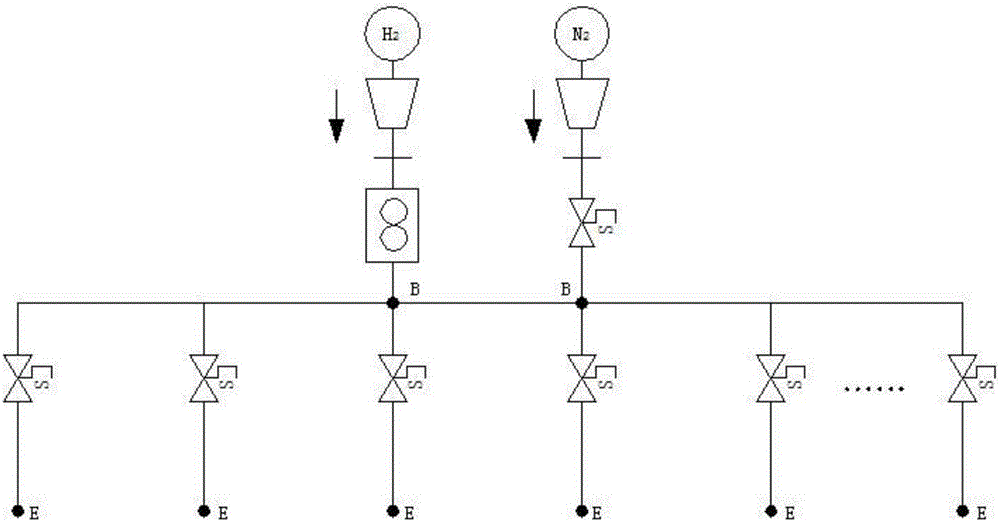

[0040] Such as Figure 1-8 As shown, the multi-channel alloy type hydrogen storage tank activation, performance testing and packaging integrated equipment is composed of the upper gas circuit, the middle gas circuit and the bottom gas circuit;

[0041] The upper gas route is a check valve 22, a sixth 2-way high-pressure solenoid valve 21, a back pressure valve 20, a mass flow controller 19, a third 2-way high-pressure solenoid valve 10, a second 2-way high-pressure solenoid valve 9, a pressure sensor 18 and The first node A is connected; the inlet of the check valve 22 is connected to the outlet of the sixth 2-way high-pressure solenoid valve 21, the inlet of the sixth 2-way high-pressure solenoid valve 21 is connected to the first node A, and the first node A is connected to the back pressure The outlet of the valve 20 is connected, the inlet of the back pressure valve 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com