Method and system for automatic terminal detection

An automatic detection and terminal technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of time-consuming and labor-intensive, inability to detect the terminal voltage detection function, unsafe manual operation, etc., to achieve high efficiency, accurate and reliable test results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

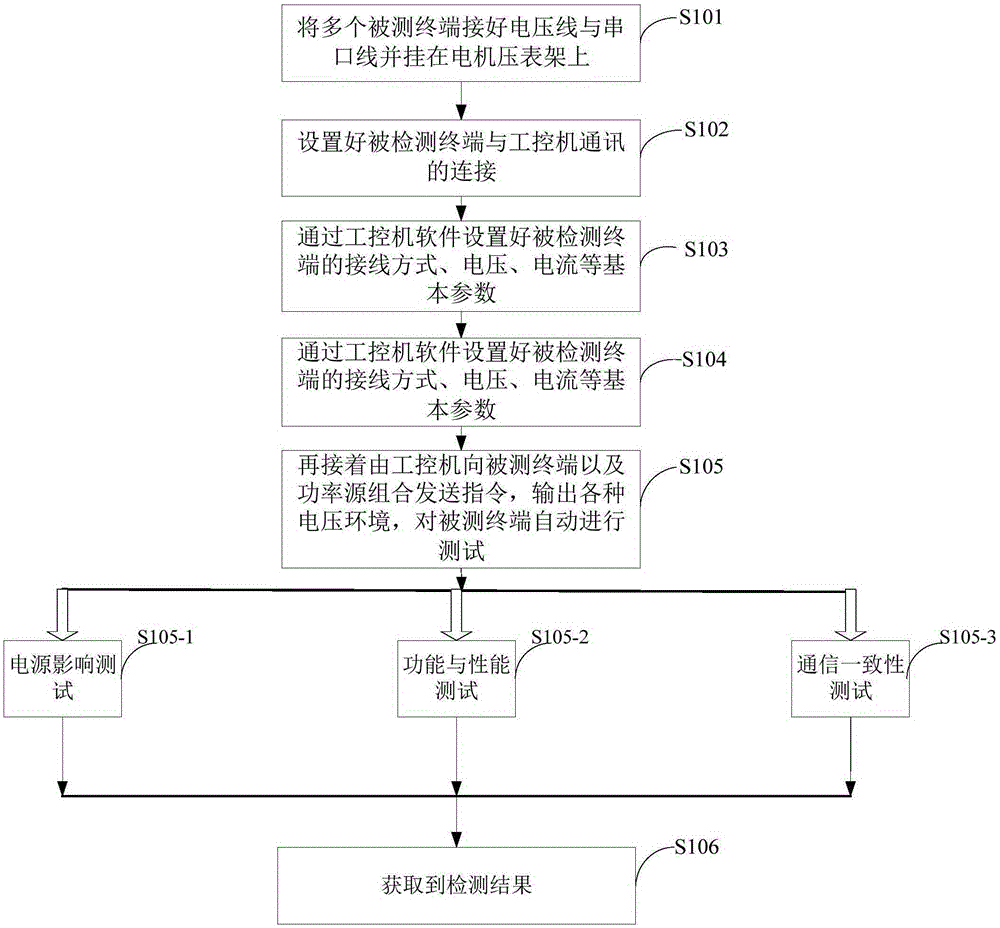

[0033] In order to solve the problem of efficiency and accuracy of the existing terminal voltage detection function detection, the present invention provides a terminal automatic detection method, such as figure 1 shown, including the following steps:

[0034] S101: Connect multiple terminals under test to the voltage line and serial port line and hang them on the motor voltage gauge rack;

[0035] S102: Set up the communication connection between the detected terminal and the industrial computer;

[0036] S103: Set the basic parameters such as the wiring mode, voltage, and current of the detected terminal through the software of the industrial computer;

[0037] S104: Then set or call the pre-saved electric management terminal detection and test scheme through the industrial computer software;

[0038] S105: Then, the industrial computer sends instructions to the terminal under test and the power source combination, outputs various voltage environments, and automatically te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com