Production test method for communication equipment

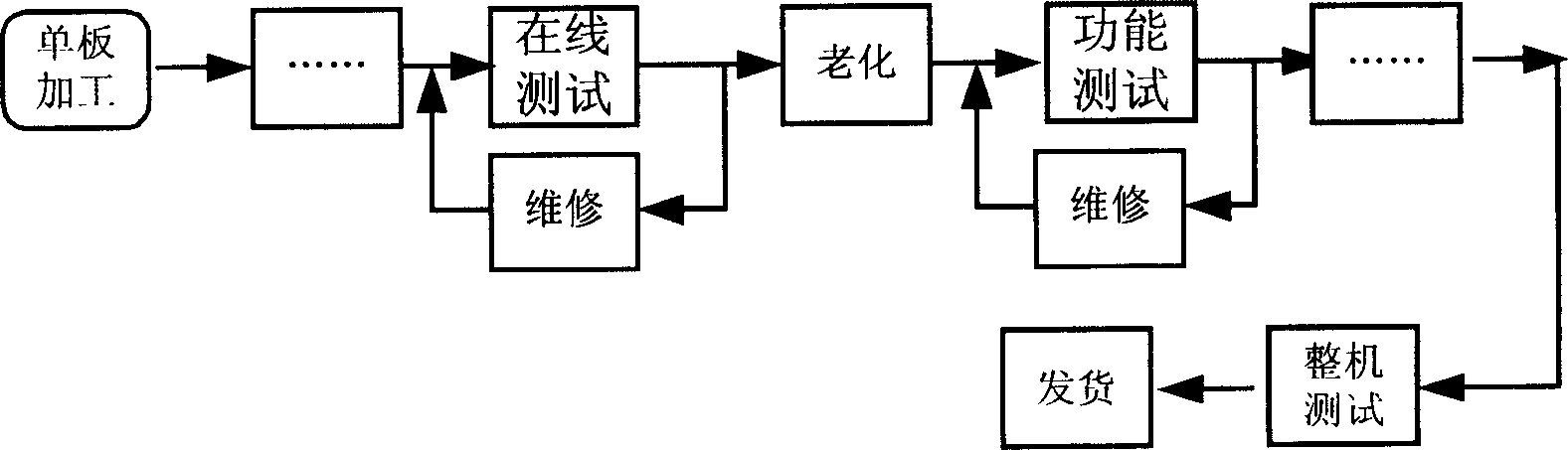

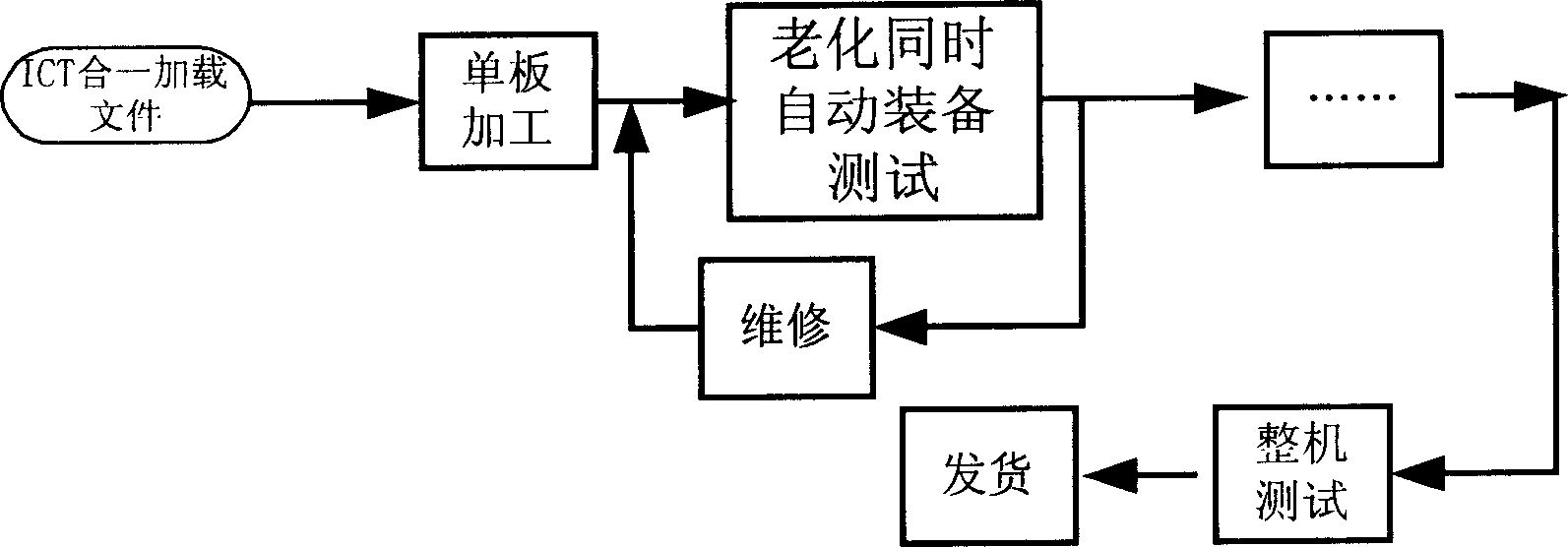

A technology for communication equipment and production testing, applied in the field of communication, can solve the problems of single board unavailability, lower production testing efficiency, and shortened lifespan, so as to improve operability and reliability, improve production testing efficiency, and reduce production testing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

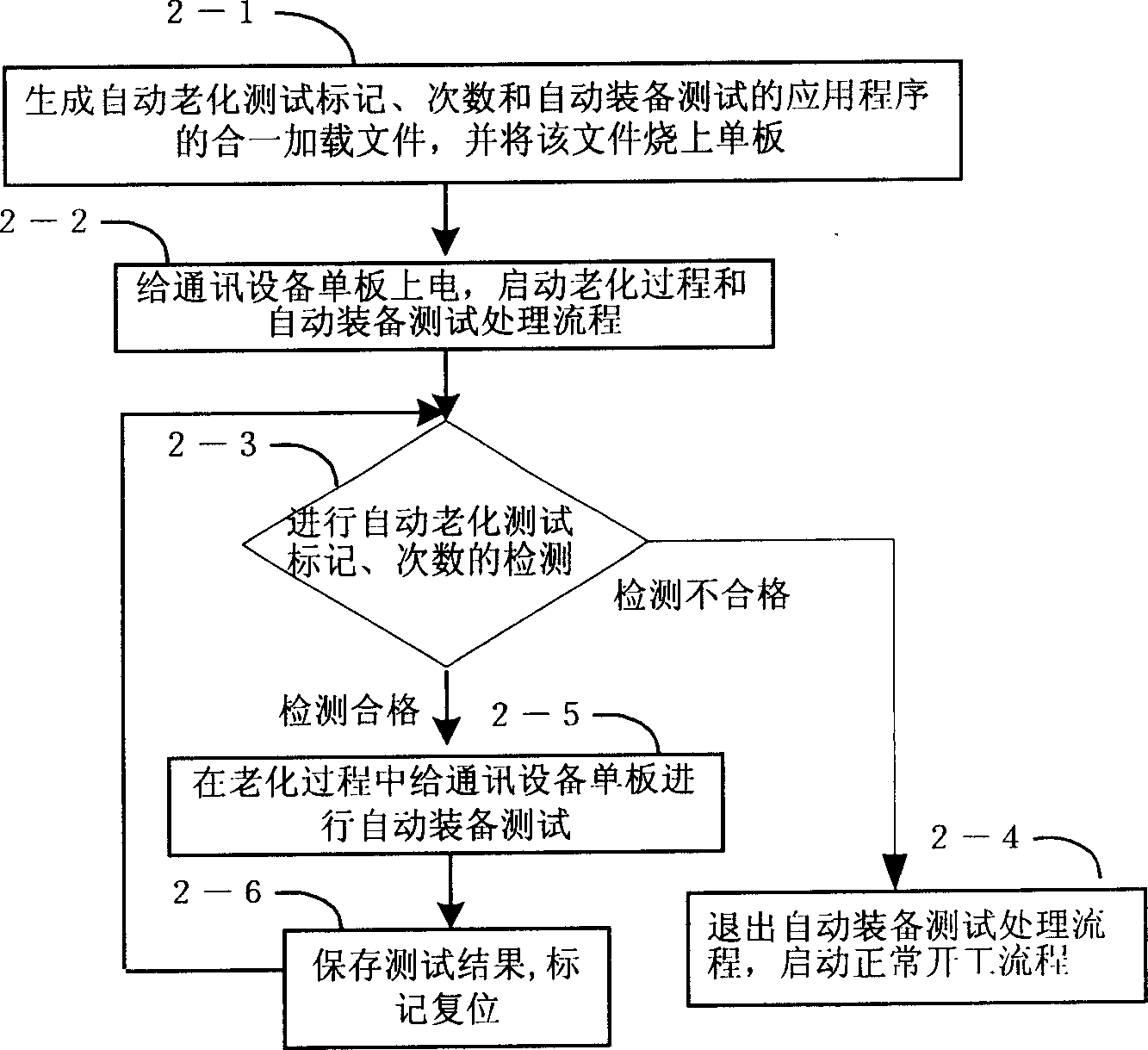

[0049] The present invention provides a method for production testing of communication equipment. The core of the invention is: setting two parameters of automatic aging test mark and automatic aging test times in the single board software, and controlling the automatic equipment test of the communication equipment to be carried out in the aging process according to the parameters.

[0050] The present invention will be described in detail below with reference to the accompanying drawings. The specific processing flow chart of the method of the present invention is as follows: figure 2 shown, including the following steps:

[0051] Step 2-1: Generate an integrated loading file of the automatic burn-in test mark, count and automatic equipment test application, and burn the file on the board.

[0052] The present invention first needs to set the automatic aging test mark and the automatic aging test times on the single-board software. When the automatic burn-in test mark is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com