Optimum operating voltage test method of avalanche photodiode

An avalanche photoelectric, working voltage technology, applied in the direction of single semiconductor device testing, etc., can solve the problem of not being able to respond to other tasks in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The method for testing the optimum working voltage of the avalanche photodiode of the present invention adopts the mode of time slice rotation, and can quickly and accurately find the optimum working voltage of the APD tube.

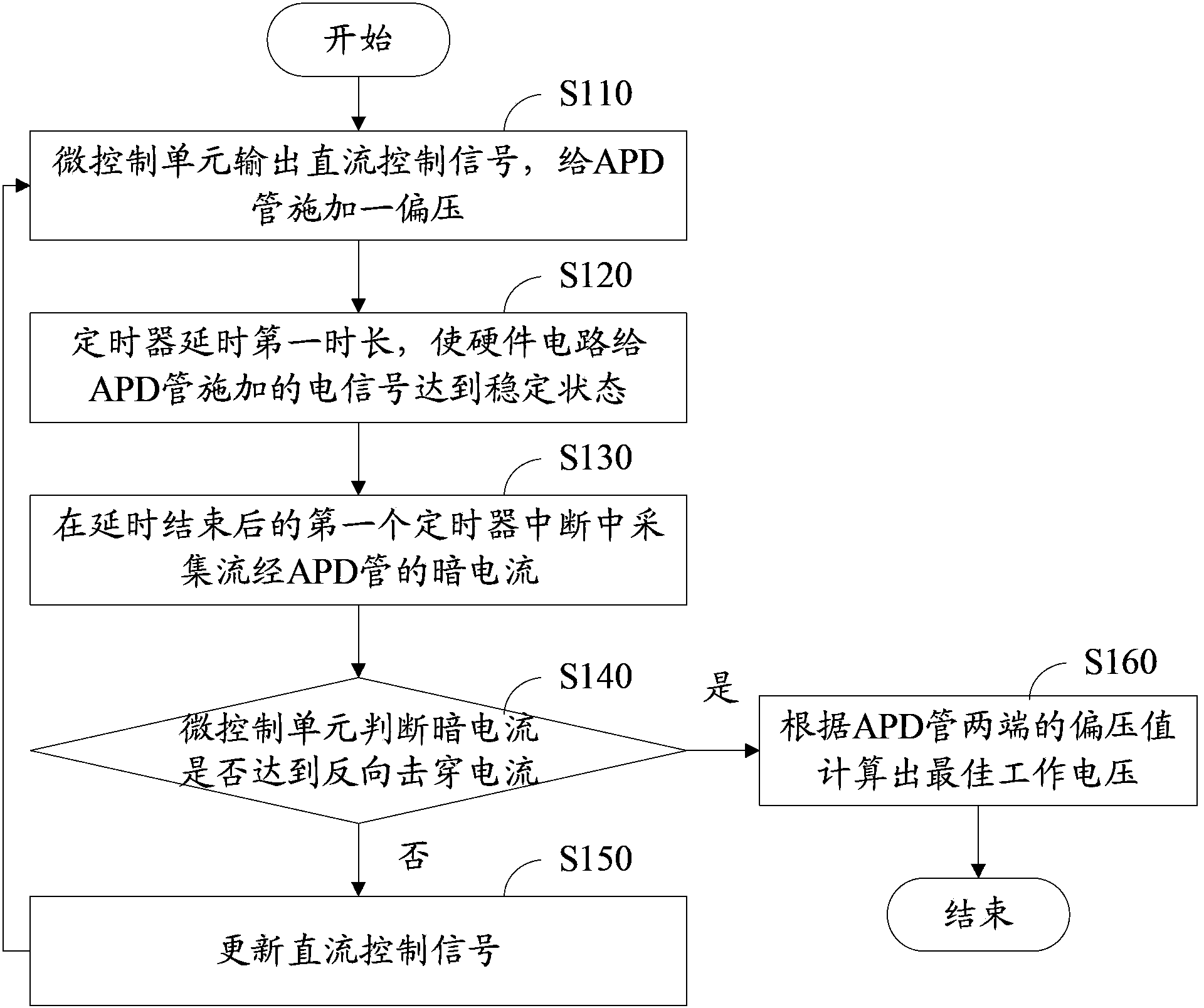

[0015] figure 1 It is a flowchart of a test method for the optimum working voltage of an avalanche photodiode in an embodiment, comprising the following steps:

[0016] S110, the micro control unit outputs a DC control signal, and applies a bias voltage corresponding to the value of the DC control signal to the APD tube.

[0017] The micro control unit outputs an initial DC control signal (DAC signal), and controls the corresponding hardware circuit to apply a bias voltage to the APD tube.

[0018] S120, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com