Dead load tensile device for tensile test

A technology of tensile test and tensile device, which is applied in the direction of measuring device, using stable tension/compression to test the strength of materials, instruments, etc., can solve the problems of inconstant loading, bulky volume, expensive price, etc., and achieve simple structure, The effect of high precision and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

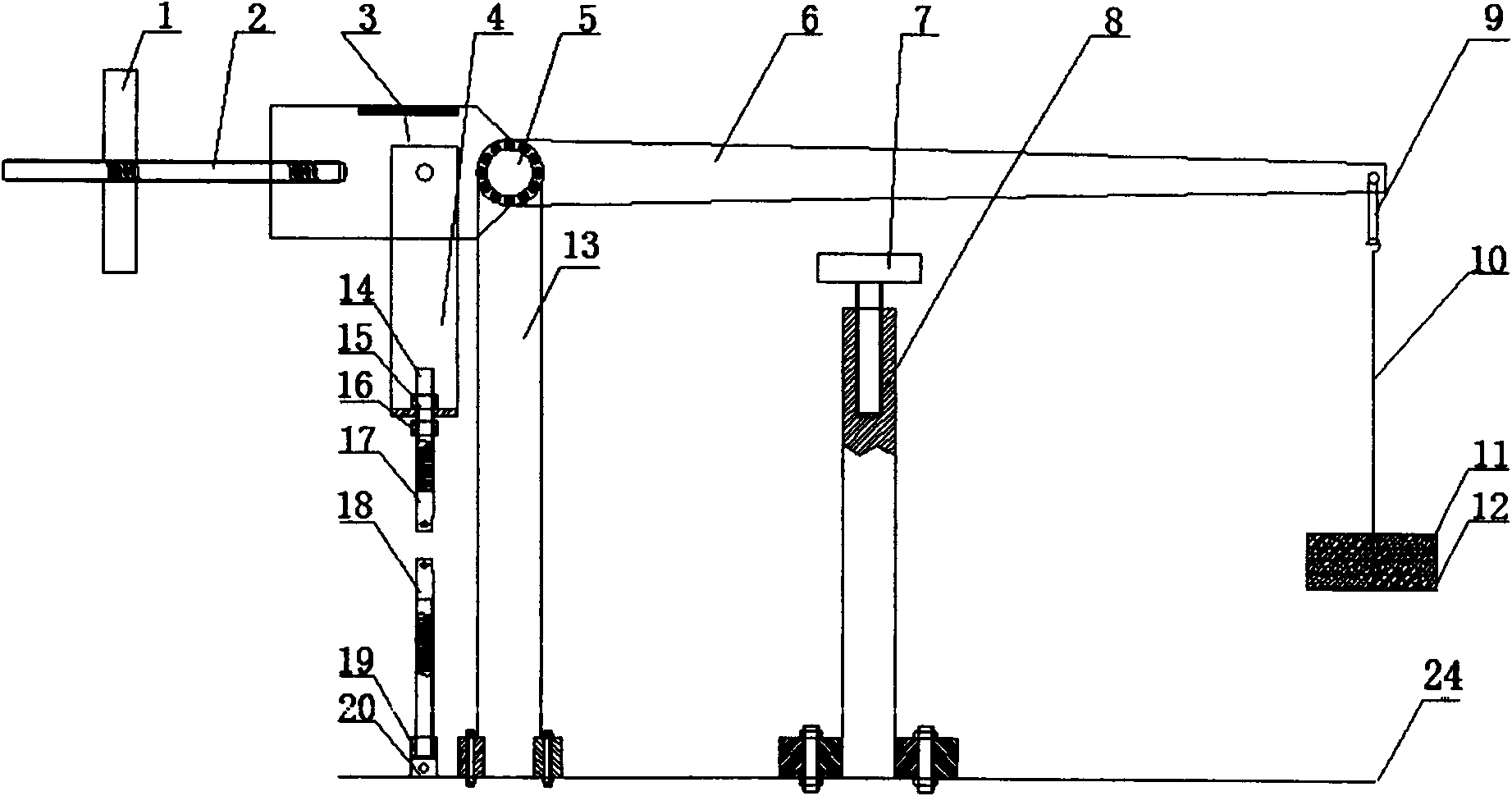

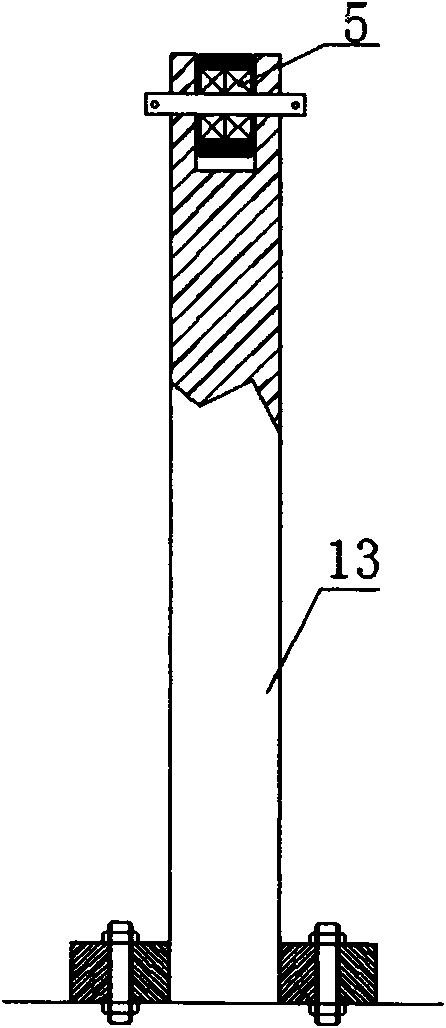

[0016] Implementation case: installation of plate-shaped tensile specimens for constant load tension

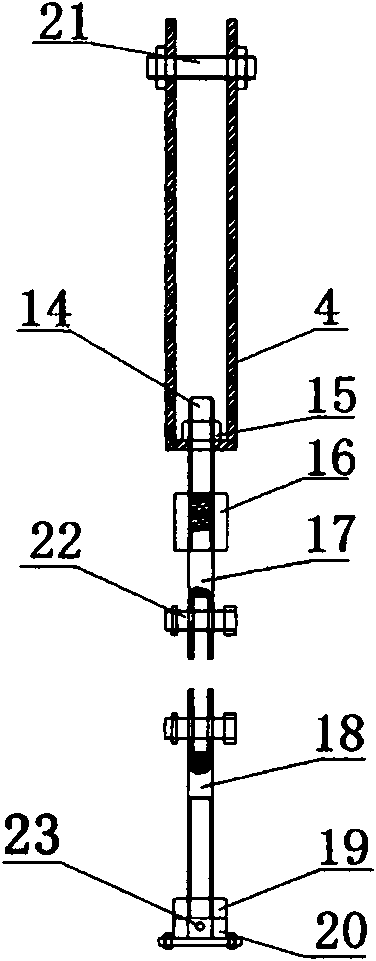

[0017] 1. Select the appropriate upper chuck 17 and lower chuck 18 according to the size of the sample;

[0018] 2. Use figure 2 The upper chuck connecting groove 16 and the lower chuck connecting groove 17 in the upper chuck are respectively fixed in the groove through threads; wherein, the upper chuck connecting groove is connected with the adjusting screw through threads, and the lower chuck connecting groove 19 is passed through The pin is connected with the chuck fixing base 20, so that the chuck can be replaced through the chuck connecting groove;

[0019] 3. Lower the anti-drop support plate 7 in the anti-drop bracket 8 to the lowest point;

[0020] 4. According to the length of the sample, adjust the screw rod 14 so that the total length of the installation part is less than the height of the column, so as to ensure that the tensile stress is applied to the sample,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com