Testing method of intrinsic noise voltage of microphone and testing device of testing method

A technology of inherent noise and test method, applied in the direction of electrical components, etc., can solve the problems of complex test system, unsuitable for large-scale test occasions of factory lines, etc., and achieve the effect of simple test system, low test requirements, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

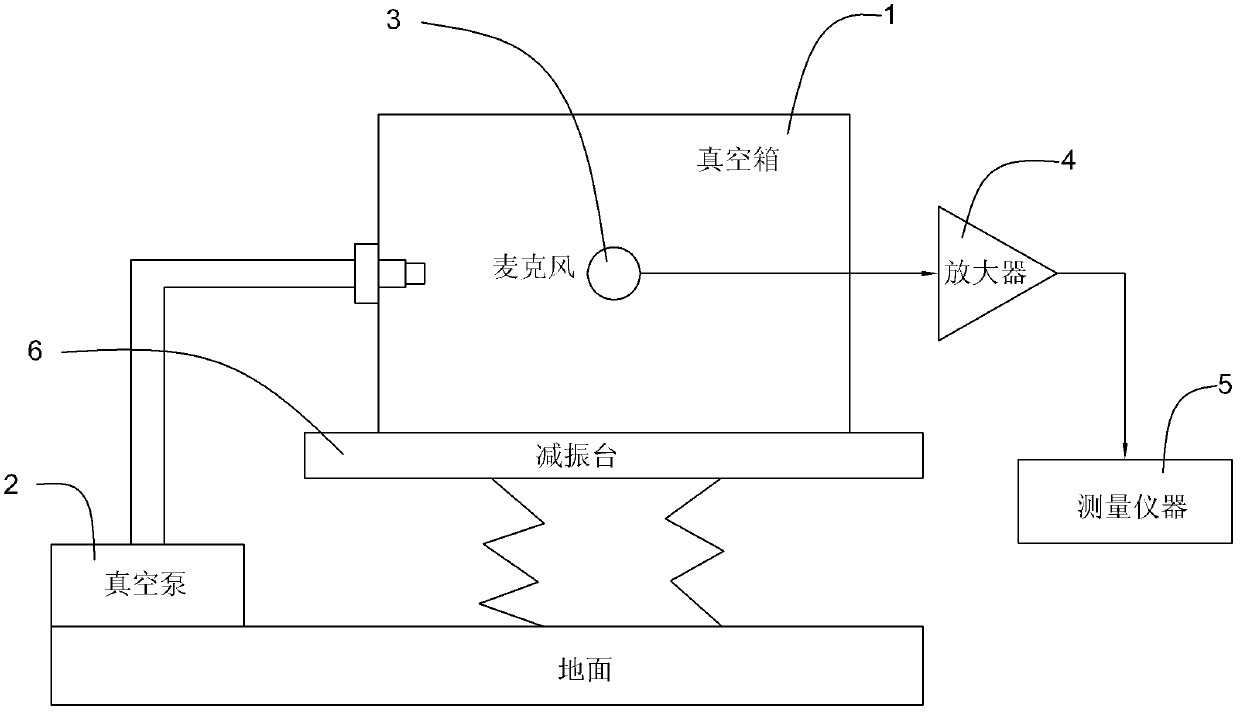

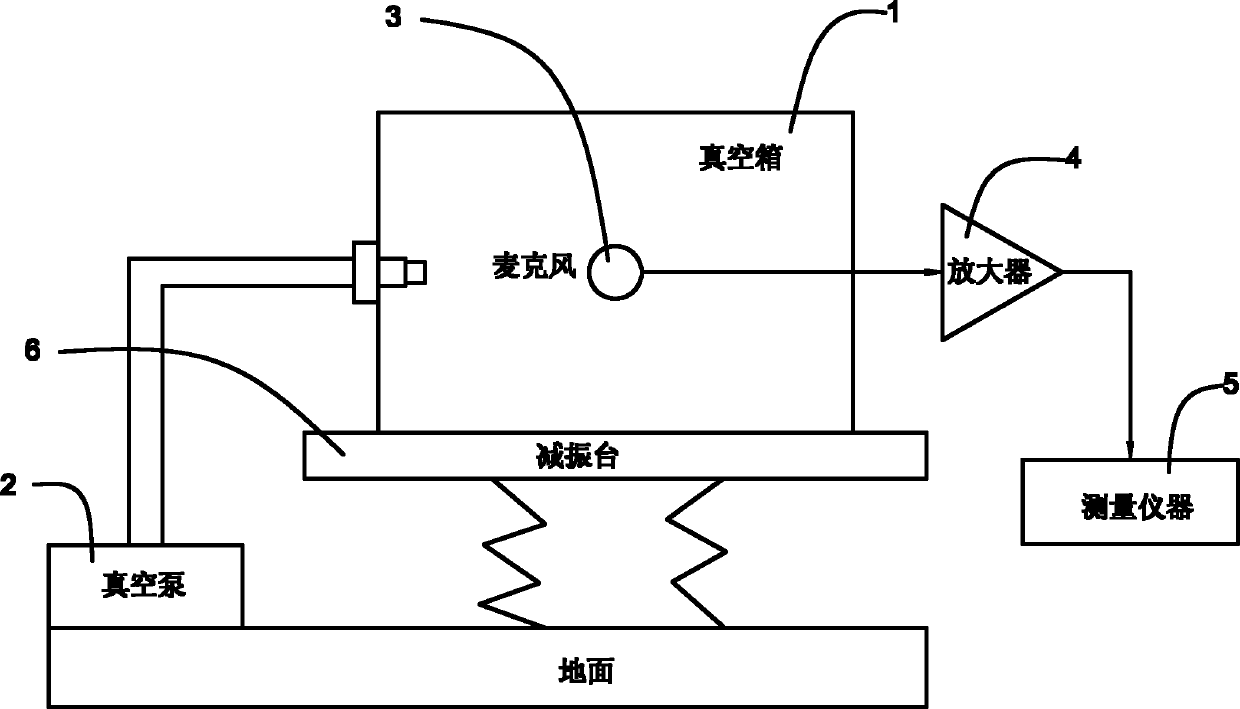

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] The present invention starts from the principle of the inherent noise voltage test of the microphone, which requires that the sound-receiving surface of the microphone is not affected by any sound waves, so we start by cutting off the way for the sound waves to pass into the microphone. Since the sound wave is a mechanical wave, it must rely on the vibration of the elastic medium to propagate, and the air as the elastic medium is pumped out in the vacuum box, and the sound wave cannot propagate, which well isolates the interference of external environmental noise and makes the microphone diaphragm Atmospheric sound pressure is close to zero, which fully meets the theoretical test requirements.

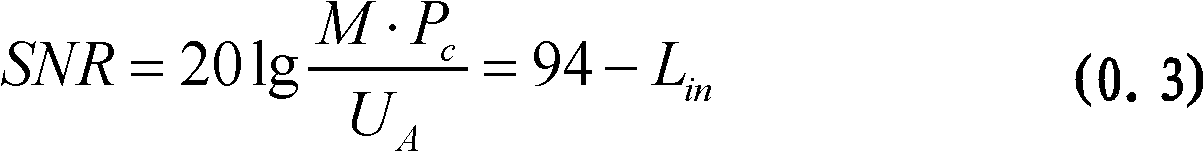

[0015] In fact, when there is no sound wave on the diaphragm of the microphone, there will still be a certain noise voltage output, which is called the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com