Measuring and calculating method of profile line part without datum

A calculation method and profile technology, applied in the field of geometric measurement, to achieve the effect of real measurement results and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

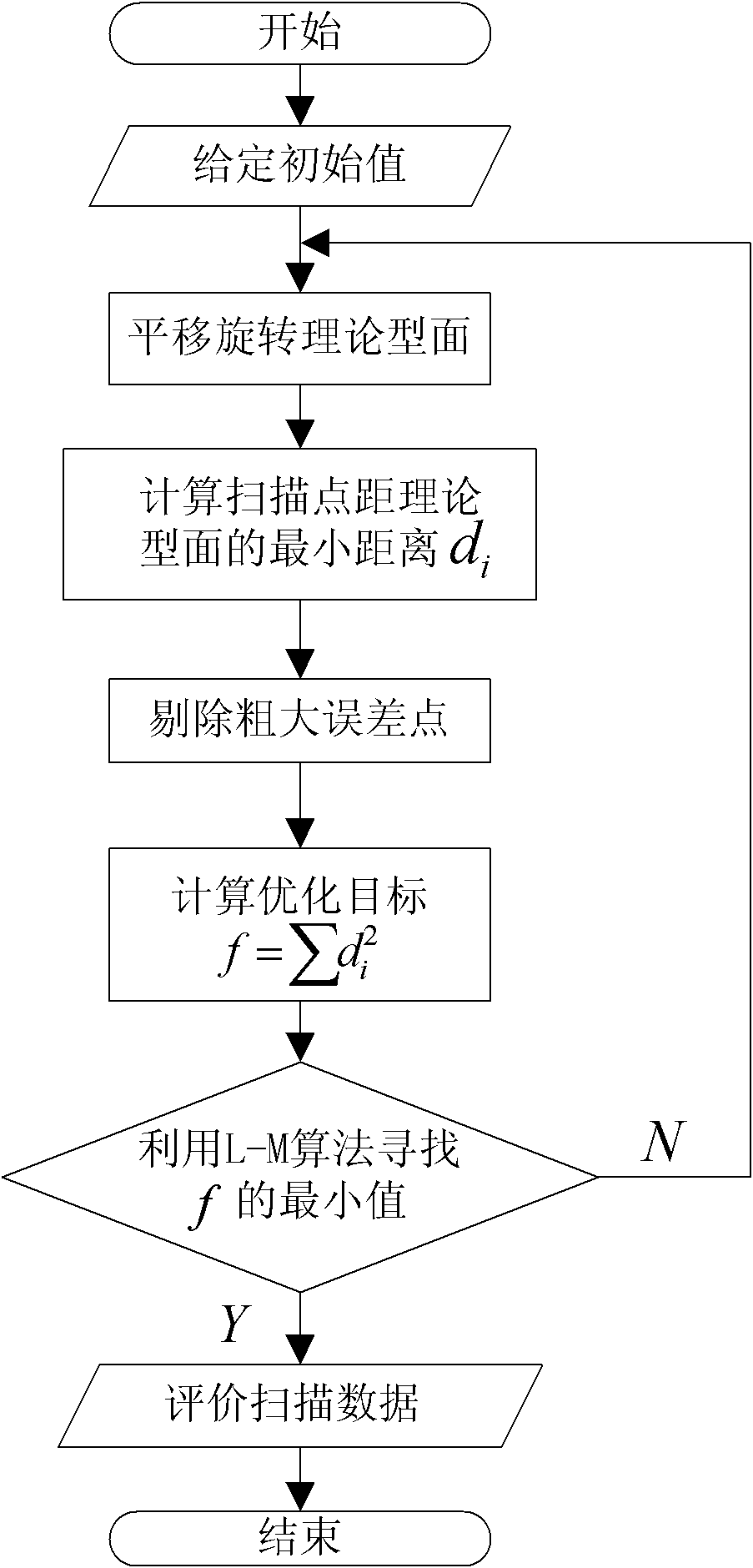

[0060] The present invention provides a method for measuring and calculating parts without reference profile, which is characterized in that: the method for measuring and calculating parts without reference profile is as follows:

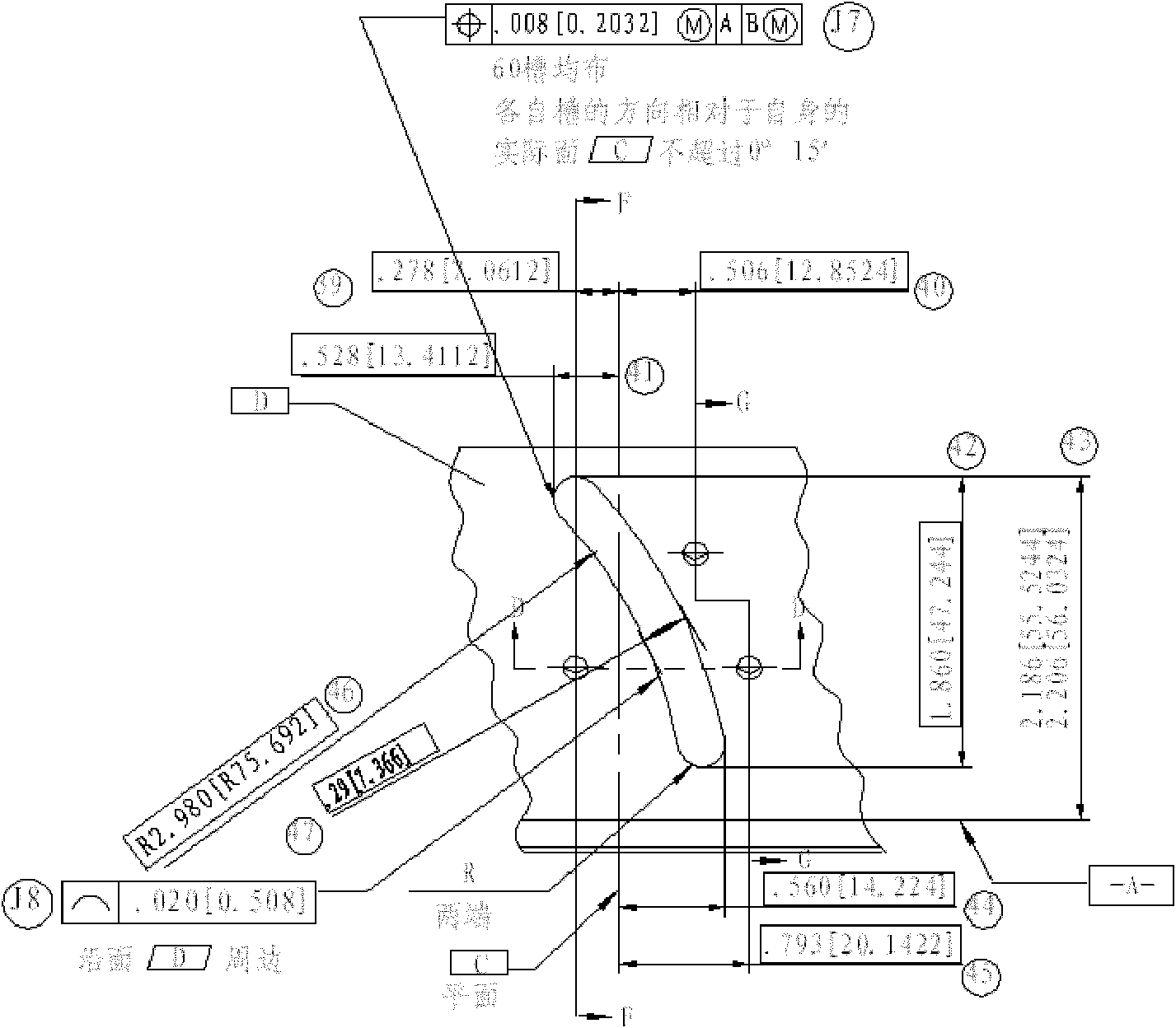

[0061] First, given the initial translation value (Δx, Δy) and rotation angle Δθ of the scanned data point, the default initial value is zero. If the scanned data point deviates greatly from the theoretical profile, the initial value can also be given manually; then, for The scanned data points are translated and rotated, and the minimum distance d between the moved scanned data points and the theoretical surface is calculated one by one i And eliminate gross error points; secondly, use the improved Levenberg-Marquardt algorithm to iteratively solve the least squares fitting value of the theoretical type surface scanning data points; finally, evaluate the scanning data and output the evaluation results.

[0062] Geometry is composed of straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com