Centering device and method used for sheet-shaped material tensile test

A tensile test and centering device technology, applied in measuring devices, analytical materials, instruments, etc., can solve problems such as affecting the accuracy of test results, reducing batch experiment efficiency, and deviation of the centerline of samples, and improving the quality of pasting. , the effect of expanding the scope of application and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A centering device and centering method proposed by the present invention for tensile testing of plate materials will be described in detail below with reference to the accompanying drawings.

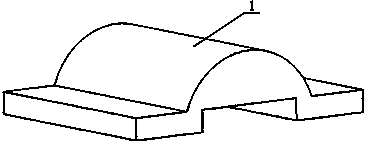

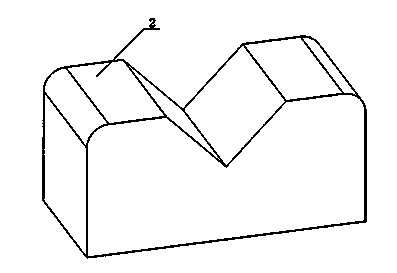

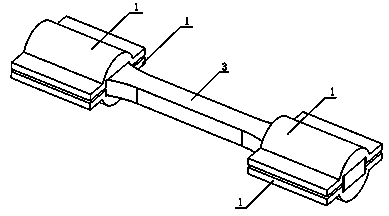

[0030] Such as Figure 5 As shown, a centering device for a tensile test of a plate-shaped material includes a centering reinforcing sheet 1 and a pasting and pressing device. Such as Figure 4 As shown, the sticking and pressing device includes a support frame 6 and a pressing block 2. There is at least one pair of pressing blocks 2, preferably two pairs. Compression blocks 2 are installed in pairs on the support frame 6, and every pair of compression blocks 2 are correspondingly arranged up and down, and at least one compression block 2 in every pair of compression blocks 2 is movably installed on the support frame 6, and can also be two Each compression block 2 is movable. The pressing block 2 that is movably installed on the support frame 6 is installed on the support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com