Method for whole-process recycling of multiple biogas slurry components

A whole-process, multi-component technology, applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc. Improve yield and return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

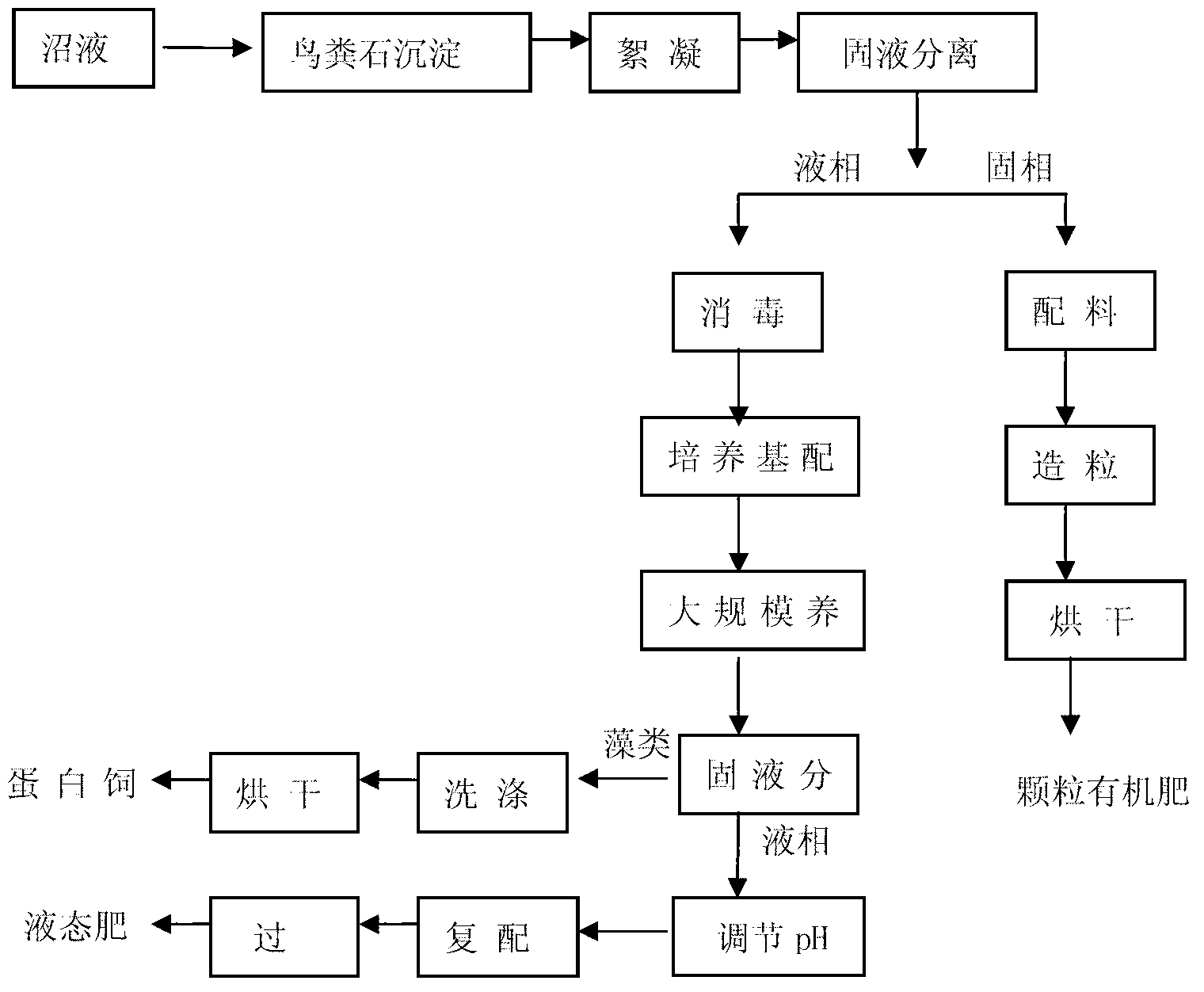

Image

Examples

Embodiment 1

[0017] By detecting and analyzing the concentration of ammonia nitrogen in the biogas slurry, according to the principle of struvite formation, according to the molar ratio of ammonia nitrogen, magnesium ions and phosphate ions at a ratio of 1:1:1, add an appropriate amount of powdered magnesium hydroxide and potassium dihydrogen phosphate After fully stirring and mixing, then stand still for 30 minutes; then add the flocculant PAM to the biogas slurry treated by the struvite precipitation method according to the weight ratio of 0.1%, stir for 10 minutes and mix well, so that the biogas slurry is fully flocculated; The biogas slurry after flocculation is pumped into the plate and frame filter press through the screw pump for solid-liquid separation; the separated biogas residue is fully stirred and mixed by adding peat with high organic matter content and high humic acid content at a weight ratio of 60%. After uniformity, it is granulated by an extrusion granulator and dried by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com