A kind of high flux nanofiltration membrane, its preparation method and application

A nanofiltration membrane, high-throughput technology, applied in the field of materials, can solve the problems of restricting the sustainable development of water treatment and high production costs, improve wettability and uniformity of pore size distribution, reduce production costs, and change the interface position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] As another aspect of the technical solution of the present invention, it also relates to a method for preparing a high-throughput nanofiltration membrane, which includes:

[0031] A cellulose nanofiber layer is arranged on the microfiltration membrane support layer to obtain a cellulose nanofiber / microfiltration membrane composite bottom membrane;

[0032] The surface of the cellulose nanofiber / microfiltration membrane composite bottom membrane is used as the aqueous phase-oil phase interface of the aqueous solution containing polyamine monomers and salts and the organic solution containing polyacyl chlorides, and the polyamine monomers and polyacyl chlorides are The interfacial polymerization reaction is carried out at the interface, thereby forming an ultra-thin separation layer of polyamide on the surface of the cellulose nanofiber / microfiltration membrane composite bottom membrane, and then performing annealing treatment to obtain a high-flux nanofiltration membrane....

Embodiment 1

[0072] Cellulose nanofibers were deposited on a commercially available hydrophilic PTFE film at a deposition density of 20 μg / cm 2 After soaking for 120s in an aqueous solution containing piperazine (2.5mg / ml) and calcium chloride (5mg / ml), the solution on the surface of the composite bottom film was blotted dry, and then the surface of the composite bottom film was soaked in a concentration of 2mg / ml of 1 ,3,5- Trimellitic tricarboxylic hexane solution, reacted for 60s at a temperature of 25°C and a relative humidity of 60%, took it out, cleaned the membrane with n-hexane, and placed the membrane at 60°C for 30min , to obtain high-throughput nanofiltration membranes.

[0073] The high flux nanofiltration membrane prepared above uses 1000ppm Na 2 SO 4 Aqueous solution cross-flow test, the test temperature is 25°C, first reflux at 4bar pressure for 30min, and then test at 2bar pressure, the flux is 49.3Lm -2 h -1 bar -1 , The rejection rate is 96.1%.

Embodiment 2

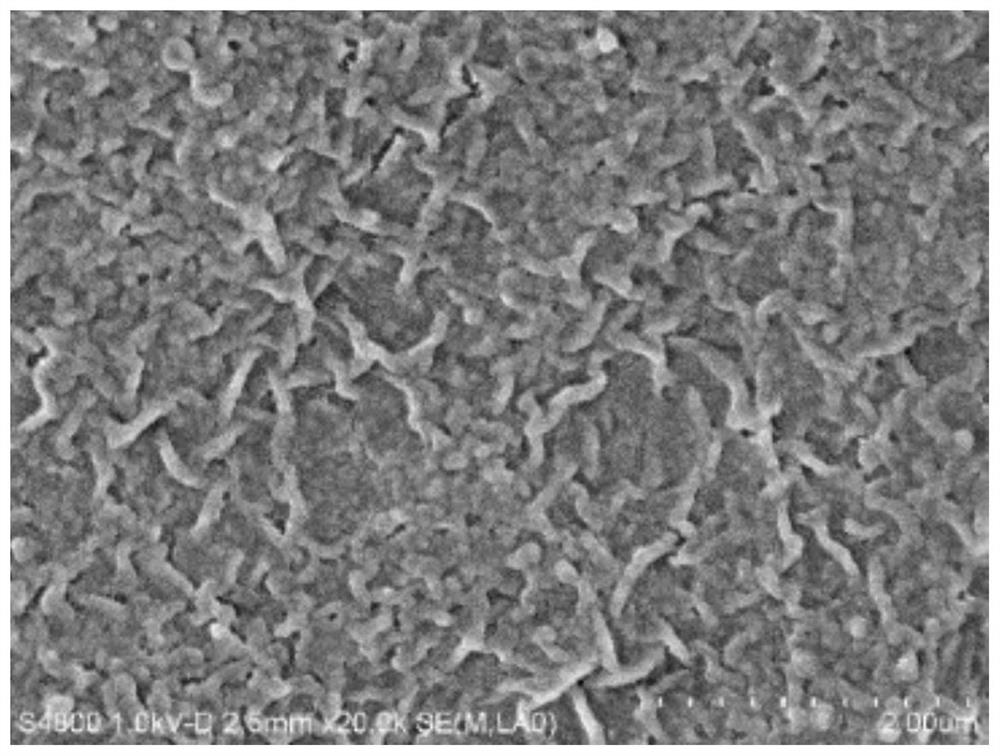

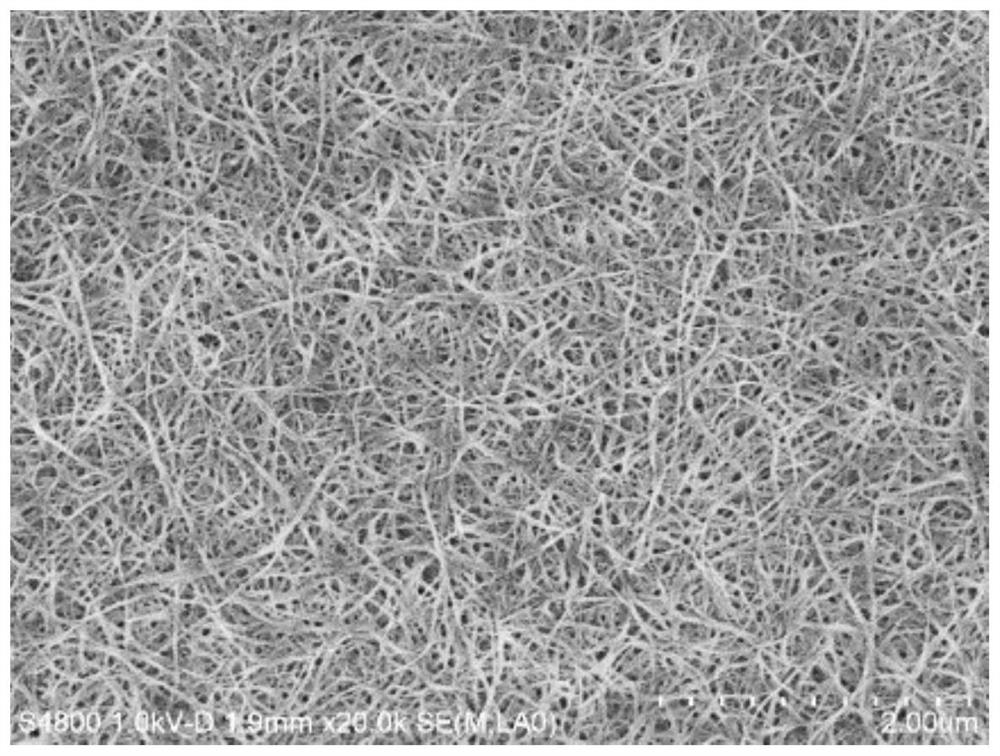

[0075] Cellulose nanofibers were deposited on a commercially available hydrophilic PTFE film at a deposition density of 20 μg / cm 2After soaking for 120s in an aqueous solution containing piperazine (2.5mg / ml) and calcium chloride (10mg / ml), the solution on the surface of the composite bottom film was blotted dry, and then the surface of the composite bottom film was soaked in a concentration of 2mg / ml of 1 ,3,5- Trimellitic tricarboxylic hexane solution, reacted for 60s at a temperature of 25°C and a relative humidity of 60%, took it out, cleaned the membrane with n-hexane, and placed the membrane at 60°C for 30min , to obtain high-throughput nanofiltration membranes. For the SEM image of the surface of the high-throughput nanofiltration membrane obtained after interfacial polymerization in this example, please refer to figure 1 As shown, the SEM image of the surface of the cellulose nanofiber intermediate layer before interfacial polymerization can be found in figure 2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com