Method for producing L-lactic acid

A technology for lactic acid and lactic acid fermentation, applied in microorganism-based methods, biochemical equipment and methods, separation/purification of carboxylic acid compounds, etc. Simple, continuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

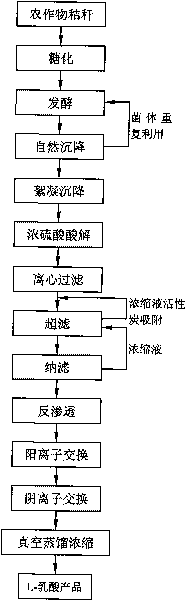

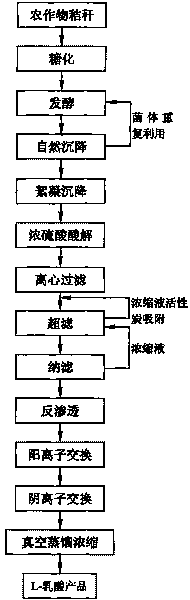

[0029] Attached figure 1 Shown, the operating steps of the present invention are as follows:

[0030] (1) After crushing corn stalks, pass through a 40-mesh sieve, add calcium hydroxide aqueous solution at a ratio of 5L / Kg, heat and stir at 95°C for 25 minutes, add 98% concentrated sulfuric acid to neutralize calcium hydroxide, and separate and remove solids Ingredients and calcium sulfate precipitation, add liquid cellulase with an enzyme activity of 15U / g at a ratio of 1g / L, stir and enzymolyze at 60°C for 60min, and obtain 10L of saccharification solution with a sugar content of 10% by mass;

[0031] (2) The obtained mass percentage is 8-12% saccharification liquid is added in the fermenter, simultaneously adds calcium carbonate 500g, ammonium nitrate 33g, potassium dihydrogen phosphate 4g, sodium dihydrogen phosphate 2.5g, zinc sulfate 3.5g, sulfuric acid Magnesium 3.5g and ferrous sulfate 0.9g, sterilized and cooled to 32°C-34°C, inoculated with spore concentration of 10...

Embodiment 2

[0041] (1) After pulverizing the wheat straw, pass it through a 40-mesh sieve, add calcium hydroxide aqueous solution at a ratio of 5.5L / Kg, heat and stir at 95°C for 20 minutes, add 98% concentrated sulfuric acid to neutralize the calcium hydroxide, and separate the solid Ingredients and calcium sulfate precipitation, add liquid cellulase with an enzyme activity of 15U / g at a ratio of 0.8g / L, stir and enzymolyze at 60°C for 45min, and obtain 10L of saccharification solution with a sugar content of 8% by mass;

[0042] (2) The obtained mass percentage is 8% saccharification liquid and is added in the fermenter, simultaneously adds calcium carbonate 400g, ammonium nitrate 30g, potassium dihydrogen phosphate 3g, sodium dihydrogen phosphate 2g, zinc sulfate 3g, magnesium sulfate 3g and sulfuric acid Ferrous iron 0.8g, sterilized and cooled to 32°C-34°C, inoculated spore concentration of 10 11 500mL of Rhizopus oryzae AS3.819 spore suspension per L, carry out aeration and stirring...

Embodiment 3

[0046] (1) After pulverizing the rice straw, pass it through a 40-mesh sieve, add calcium hydroxide aqueous solution at a ratio of 4.5L / Kg, heat and stir at 95°C for 30 minutes, add 98% concentrated sulfuric acid to neutralize the calcium hydroxide, and separate the solid Ingredients and calcium sulfate precipitation, add liquid cellulase with an enzyme activity of 15U / g at a ratio of 1.2g / L, stir and enzymolyze at 60°C for 70min, and obtain 10L of saccharification solution with a sugar content of 12% by mass;

[0047] (2) Add the 12% saccharified liquid into the fermenter with the obtained mass percentage, and simultaneously add 600 g of calcium carbonate, 35 g of ammonium nitrate, 5 g of potassium dihydrogen phosphate, 3 g of sodium dihydrogen phosphate, 4 g of zinc sulfate, 4 g of magnesium sulfate and sulfuric acid Ferrous iron 1.0g, sterilized and cooled to 32°C-34°C, inoculated spore concentration of 10 11 500mL of rhizopus oryzae AS3.819 spore suspension per L, carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com