Preparation method of nitrogen-doped graphene loaded platinum nano-particle catalyst

A nitrogen-doped graphene and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of uneven particle size distribution, Pt nano Particle shedding, reducing electrical activity and other problems, to achieve the effect of improving electron conductivity, accelerating nucleation, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

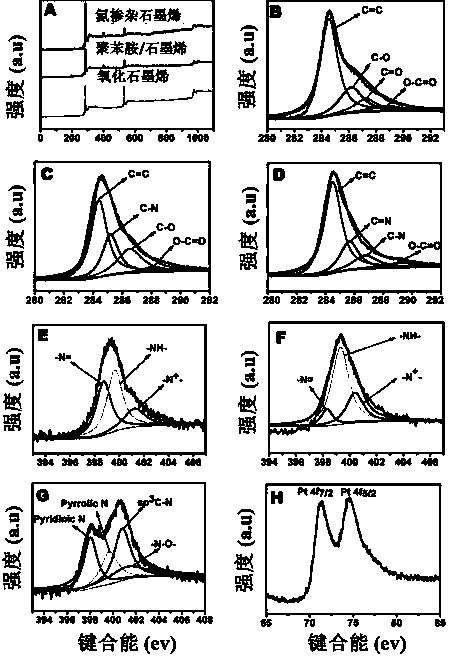

Method used

Image

Examples

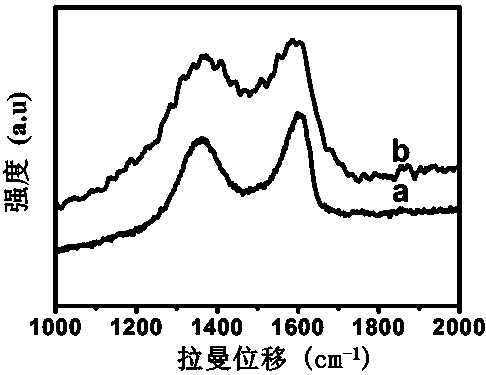

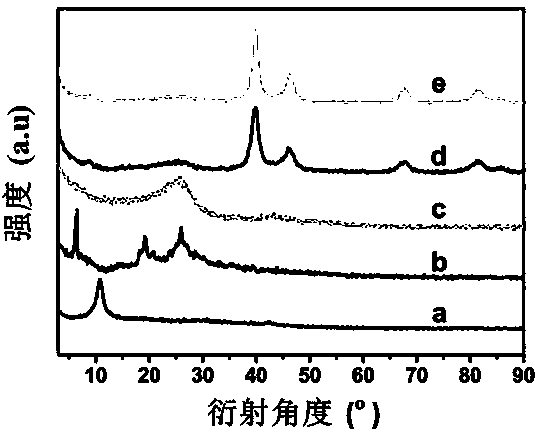

Embodiment 1

[0023] (1) Preparation of graphene oxide (GO): Graphene oxide was prepared by the modified Hummers method (Li, D.; Muller, M. B.; Gilje, S.; Kaner, R. B.; Wallace, G. G. Nat. Nanotechnol. 2008, 3 , 101-105; Hummers, W. S.; Offeman, R. E. J. Am. Chem. Soc. 1958, 80, 1339; Cote, L. J.; Kim, F.; Huang, J. X. J. Am. ). The specific synthesis process is as follows, 1.0 gram (g) graphite and 1.0 g NaNO 3 Add 46 milliliters (mL) of 98% H 2 SO 4 , after 20 minutes of mechanical stirring in an ice bath, slowly add 6.0 g KMnO 4 , transferred to a water bath to control the temperature to be 35 ° C, continue stirring for 60 minutes, take it out from the water bath and add 80 mL of double distilled water at room temperature, after stirring for 30 minutes, add 200 mL of double distilled water, then slowly add 6 The mass ratio (wt%) of mL is 30 wt% H 2 o 2 Solution, react at room temperature for 1 hour, wash with double distilled water after the reaction until the filtrate is neutral, ...

Embodiment 2

[0029] (1) Conduct electrochemical analysis and research on the nanocomposites synthesized in steps (1), (2), (3), and (4) of Example 1, and take 5 μL of 1.0 mg / mL Pt / NGs suspension for drop coating onto the glassy carbon electrode (GCE) surface, and dry at room temperature. Using a three-electrode system, in a nitrogen-saturated concentration of 0.5 M H 2 SO 4 Cyclic voltammetry scanning at a rate of 20 mV / s in solution shows that the electrochemically active area of Pt / NGs catalyst is 73.2 m 2 g -1 ,Such as Figure 6 shown. Using the nanomaterial modified electrode as the working electrode, cyclic voltammetry scanning was performed at a rate of 10 mV / s in an oxygen-saturated KOH solution with a concentration of 0.5 mol / L. The results showed that NGs and Pt / NGs catalysts have good oxygen Electrocatalytic activity, and the electrocatalytic activity of Pt / NGs catalyst for oxygen is higher than that of NGs, such as Figure 7 shown. The modified electrode performs line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com